Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ecom B

- Page 1 Operating Instructions...

-

Page 2: Table Of Contents

6.2.1. Gas Fan Burners 6.2.2. Oil Fan Burners 6.3. Diagnosis gas 7. Pressure Tests (option) 8. Adjustment 9. Control 10. Data processing 10.1. Communication 10.2. Data processing with App 11. Maintenance Tips 12. Technical Data 13. FAQ Page 2 ecom-B... - Page 3 ___________________________ Congratulations! With your purchase you have decided on a high-quality product of ecom GmbH. Get to know the product before you start using it while reading care- fully the following instructions of use and the safety indications. Use the product only as described and only for the given areas of applica- tion in order to ascertain its longevity.

-

Page 4: Important Hints

Important Hints The ecom-B meets the requirements of the DIN EN 50379 Part 2. The ecom-B may not be used for continuous emission control! Following minimum times must be kept to get correct measurement results: -1 Minute for fresh air calibration... - Page 5 Fresh air opening Do not lock fresh air opening for fresh air pump! Remove probe tube completely before starting gas analysis! ecom-B Page 5...

-

Page 6: Instrument Design

Cursor control Store Print (confirm (up/down/scroll) selection) Charging IR diode socket (for IR printer) Instrument CAL key ESC key ON/OFF (quit/ Condensate Standby exit menu) Draft connection connection RS232 interface Gas temperature connection temperature Pressure connection connection Page 6 ecom-B... -

Page 7: Switch On Instrument

Fuel oil (B) Type of fuel Natural gas (B) Fuel oil (B) City gas (B) CO2max : 15.4 Coke oven gas (B) A1-fact. : 0.50 Liquid gas (B) Select with ↑↓ Use the cursor keys to select the desired fuel type and confirm with <Enter>. The... -

Page 8: Choose A Storage Location

3. Input or select a data record (Option) Memory number 0 The ecom-B has 300 storage locations (option). In order to call up a data record Data record with data are already stored in the instru- is empty ! ment or to create a new file, choose a data record with the Cursor keys and confirm ↵... -

Page 9: Gas Analysis

The measurement values could be displayed on 4 screen pages (3 x gas analysis; 1 x draught measurement – change with curser keys): 12.5 12.5 12.5 Lambda 1.23 T.Gas °C T.Air °C T.Air °C Losses Lambda 1.23 T.Gas °C 93.0 ecom-B Page 9... - Page 10 93.0 <Enter> / <store> / <Enter>. While check- ing the values the gas pump will be Measurement stored switched off in order to spare the sensors. in temporary memory (back with <ESC>). Page 10 ecom-B...

-

Page 11: Draft Measurement

Draft pressing <store> and added to the other -0.12 values already in the temporary memory. Val.: -0.12 The stored value will appear on the display. Set zero point CAL. ecom-B Page 11... -

Page 12: Record And Print Measurement Result

↵ ↵ ↵ ↵ memory> / Enter> (after successful stor- Continue with: ↑↓ age an “M” will appear right down in the display). Finally a print-out (IR printer re- quired) of the results can be made (key <Print>). Page 12 ecom-B... -

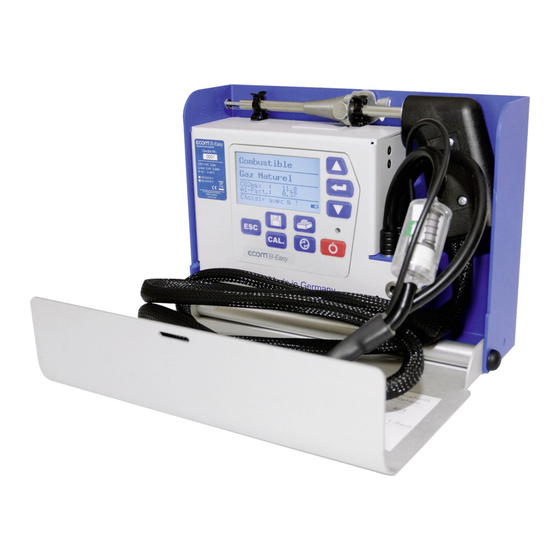

Page 13: After Measurement

2. Slide the probe tube starting at the probe into the space between device and case. Pass the hose here alternately from right to left and from left to right. Probe Probe fixation Storage space for probe tube probe tube ecom-B Page 13... -

Page 14: Mean Value (Option)

After adjustment / control the measurement can be started by <Start> / <Enter>. With the cursor keys <up/down>, it is possible to switch between current and average readings. The measurement can be interrupted by pressing <Standby> (pressing <Standby> again sets the measurement continued). Page 14 ecom-B... -

Page 15: Measurement Routines (Option)

6. Measurement Routines (Option) The ecom-B provides measurement routines that makes standard checking on atmospheric boilers and fan burners easier. 6.1. Atmospheric Boilers Select from the main menu the sub menu „Atmosph. Boilers” and press <Enter>. The table of fuel types will be displayed. Following... - Page 16 Another feature of the ecom-B is to deter- Atmosph. boiler mine the thermal capacity brought to the Gas flow rate boiler. For this the gas meter has to be - - . - m3/h observed. By pressing <Enter> a stop- - - .

- Page 17 CO flue gas For measurement the probe must be posi- tioned in the combustion tube. Apart from Val.: the stored value the maximum CO-value of CO max: 26 ppm the measurement is stored. ecom-B Page 17...

- Page 18 Confirmation could be done by using the key <Enter> (yes / no). ↵ ↵ ↵ ↵ Change: The printout (IR printer required) of all re- sults of the measurement routine could be done by pressing <Print>. Page 18 ecom-B...

-

Page 19: Fan Burners

Select from the main menu the sub menu “Fan burner” and press <Enter>. The table of fuel types will be displayed. Following fuel types can be selected: Type of fuel Natural gas (B) Natural gas (B) Town gas (B) CO2max : 11.8 Coke gas (B) A1-fact. - Page 20 Another feature of the ecom-B is to deter- Burn. w. blower mine the thermal capacity brought to the Gas flow rate boiler. For this the gas meter has to be - - . - m3/h observed. By pressing <Enter> a stop- Perfo.

- Page 21 Burn. w. blower can be determined. Use the probe to check CO ambient the area around the boiler. Besides the stored value (press <store>) the instru- Val.: ment stores the maximum CO-value of the CO max: 9 ppm measurement. ecom-B Page 21...

-

Page 22: Oil Fan Burners

The printout (IR printer required) of all re- sults of the measurement routine could be done by pressing <Print>. 6.2.2. Oil fan burner Using Heating oil (B) as fuel type the rou- Burn. w. blower tine starts by determining the oil flow and Oil rate the thermal capacity brought to the boiler. - Page 23 The printout (IR printer required) of all re- 30 ppm 93.0 % sults of the measurement routine could be T.Gas 166 °C done by pressing <Print>. T.Air 20 °C ↵ ↵ ↵ ↵ Full load Start : ecom-B Page 23...

-

Page 24: Diagnosis Gas

<En- ter>. First the thermal capacity brought to the Diagnosis gas boiler can be determined with the ecom-B. Gas flow rate For this the gas meter has to be observed. - - . - m3/h By pressing <Enter>... - Page 25 Confirmation could be done by using the key <Enter> (yes / no). ↵ ↵ ↵ ↵ Change : The printout (IR printer required) of all re- sults of the measurement routine could be done by pressing <Print>. ecom-B Page 25...

-

Page 26: Pressure Tests (Option)

(delta Connection hose (Gas system – Crospiece) Electrical connection ecom- B/UNO Crospiece Conic test stopple Connection ecom-UNO (+) One-pipe counter cap Connection Squirt High-pressure test or Soot pump stopple ecom-UNO (only for Loading Squirt and Tightness Test) Page 26 ecom-B... - Page 27 Each parameter can be adjusted the same way: 1. Select the parameter with cursor keys <Up/Down>. 2. Press <Enter> to activate. 3. select the digit with the keys <Store> (left), <Print> (right) and adjust with the cursor keys <up/down>. 4. Confirm with <Enter>. ecom-B Page 27...

- Page 28 (IR printer required) by pressing <Print>. 8. If the menu “Pressure Test” is selected again, so the result can be called up with “No” / <Enter> (as long as the ecom-B is on) or a new measurement can be started with “Yes” / <Enter> (switching from “No“...

- Page 29 (IR printer required) by pressing <Print>. 9. If the menu “Loading Test“ is selected again, so the result can be called up with “No” / <Enter> (as long as the ecom-B is on) or a new measurement can be started with “Yes” / <Enter> (switching from “No“...

- Page 30 (IR printer required) by pressing <Print>. 9. If the menu “Tightness Test“ is selected again, so the result can be called up with “No” / <Enter> (as long as the ecom-B is on) or a new measurement can be started with “Yes” / <Enter> (switching from “No“...

- Page 31 Usage property The “Usage property“ acc. to DVGW – TRGI Process form G 624 at conduits is memorised as a measurement routine by the ecom-B. The calculation of the leak rate happens automatically according to the following equation and corresponds herewith to the procedure of...

- Page 32 (IR printer required) by pressing <Print>. 12. If the menu “Usage property“ is selected again, so the result can be called up with “No” / <Enter> (as long as the ecom-B is on) or a new measurement can be started with “Yes” / <Enter> (switch- ing from “No“...

-

Page 33: Adjustment

8. Adjustment In addition to the already described fea- Set clock tures of the ecom-B, various settings could Display contrast be made at the instrument. Select from the Type of fuel main menu the sub-menu <Adjustment> and confirm with <Enter>. A list of the pos-... - Page 34 -No protocol: Data for program „miniDV“ -Remote: only for special applications -DAS: Data for program „DASNT“ (1200 Baud) The programs „miniDV“ und „DASNT“ are available free of charge from the ecom website. Bluetooth (option) (<BLE> no adjustment needed): -Online data = Remote...

- Page 35 5. repeat (2. - 4.) until line 1 is finished 6. deactivate choosing symbols with <Standby> and change with curser <up> to line 2. 7. after finishing the input for all lines leave the menu with <ESC> ecom-B Page 35...

-

Page 36: Control

Further info with ↑↓ -the number of error occurred Last service 26.06.16 103 hrs 10.06.15 073 hrs 31.05.14 035 hrs -Collection of the last maintenance -- . -- . -- -- . -- . -- Further info with ↑↓ Page 36 ecom-B... -

Page 37: Data Processing

The recorded values of the selected data record can be viewed (see chapter 3.). Load data: Possibility of data import e.g. from ecom software (available at „www.ecom.de“ - check the transfer options of your software). Proceed as follows: 1. Connect instrument and PC with a current RS232 cable. -

Page 38: Data Processing With App

10.2. Data processing with App To display and storage of measured values, the "ecom Connect App" for smartphones (iOS or Android) is available. Test results are stored along with customer information in a pdf-file and can be sent f.e. as email attachment. Links to free download of the Apps can be found on the ecom website. -

Page 39: Maintenance Tips

11. Maintenance Tips To secure the accuracy of your measuring instrument we recom- mend the annual check by an authorized ecom partner. In the case of strong demand (e.g. permanent several hours of measurement per day, rough conditions etc.) shorter intervals between checks should be selected - please contact your ecom partner. - Page 40 The hose can be cleaned after all connections on the instrument and the probe itself have been switched off (use warm water and then blow out to dry) Page 40 ecom-B...

-

Page 41: Technical Data

+5 °C to +40 °C; Application limits max. 90 % RH, non-condensing Subject to technical changes V1.6 / 06.2018 ecom GmbH Am Großen Teich 2 D-58640 Iserlohn Phone: +49 (0) 2371 - 945-5 Fax: +49 (0) 2371 - 40305 Internet: http://www.ecom.de eMail: info@ecom.de... -

Page 42: Faq

- T-Air sensor is broken - Thermocouple is broken - Cable is defective Note: The error messages can be ignored at the B by pressing „Enter“. Calculations that depends on these temperatures are not implemented. The instrument shows wrong or... - Page 43 Hint: If you have several instruments of the same type, you can locate an error by exchanging the accessories (probe, hose, temperature sensor etc.). If further questions or problems should arise, please contact the next authorised ser- vice centre. ecom-B Page 43...

Need help?

Do you have a question about the B and is the answer not in the manual?

Questions and answers