Table of Contents

Advertisement

Quick Links

g

GE Multilin

215 Anderson Avenue

L6E 1B3 Markham, ON -CANADA

Tel: (905) 294 6222 Fax: (905) 294 8512

E-mail: gemultilin@ge.com

Internet: www.GEDigitalEnergy.com

GE

Digital Energy

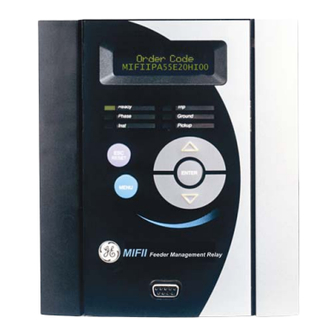

MIFII

Digital Feeder Protection with

Recloser

Instruction manual

GEK-106237P

Copyright © 2009 GE Multilin

GE Multilin

Avda. Pinoa, 10

48170 Zamudio SPAIN

Tel: +34 94 485 88 00 Fax: +34 94 485 88 45

E-mail: gemultilin.euro@ge.com

Advertisement

Table of Contents

Summary of Contents for GE MIFII GEK-106237P

- Page 1 Digital Energy MIFII Digital Feeder Protection with Recloser Instruction manual GEK-106237P Copyright © 2009 GE Multilin GE Multilin GE Multilin Avda. Pinoa, 10 215 Anderson Avenue 48170 Zamudio SPAIN L6E 1B3 Markham, ON -CANADA Tel: +34 94 485 88 00 Fax: +34 94 485 88 45 Tel: (905) 294 6222 Fax: (905) 294 8512 E-mail: gemultilin.euro@ge.com...

-

Page 2: Table Of Contents

METERING FUNCTIONS ................2-26 2.16.3 INPUTS ......................2-26 2.16.4 POWER SUPPLY .................... 2-27 2.16.5 OUTPUTS ......................2-27 2.16.6 COMMUNICATIONS..................2-28 2.16.7 ENVIRONMENTAL ..................2-28 2.16.8 TYPE TESTS AND CERTIFICATIONS............2-28 2.16.9 PRODUCTION TESTS ..................2-30 GEK-106237P MIFII Digital Feeder Relay... -

Page 3: Enervista Mii Setup Software

4.7 VIEW 4.7.1 TRACES ......................4-25 4.7.2 MODBUS MEMORY MAP ................4-26 4.7.3 LANGUAGES ....................4-27 5. SETTINGS 5.1 SETTINGS STRUCTURE 5.2 MAIN SETTINGS 5.2.1 GENERAL SETTINGS..................5-2 5.2.2 PHASE / GROUND TOC SETTINGS (51P / 51G) ( ..........5-3 MIFII Digital Feeder Relay GEK-106237P... - Page 4 9.2 COMMENTS ON THE TEST EQUIPMENT 9.3 WIRING AND NECESSARY EQUIPMENT 9.4 TARGET LEDS 9.5 POWER SUPPLY TEST 9.6 COMMUNICATIONS 9.7 RELAY SETTING 9.8 CONTACT INPUTS 9.9 CONTACT OUTPUTS 9.10 RELAY METERING 9.10.1 CURRENT METERING..................9-10 GEK-106237P MIFII Digital Feeder Relay...

- Page 5 9.16.10 IAC INVERSE LONG CURVE ................9-22 9.16.11 IAC INVERSE SHORT CURVE ................9-22 9.16.12 EPTAR C CURVE.....................9-22 9.16.13 DEFINITE TIME ....................9-23 9.17 THERMAL IMAGE ELEMENT (49) 9.18 TIME SYNCHRONIZATION 9.19 USER SETTINGS 9.19.1 MAIN SETTINGS ....................9-26 9.19.2 ADVANCED SETTINGS ...................9-29 MIFII Digital Feeder Relay GEK-106237P...

- Page 6 B.2 ANSI CURVES B.3 IAC CURVES C. MODBUS C.1 MODBUS FORMAT C.2 READING VALUES C.3 COMMAND EXECUTION C.4 SYNCHRONIZATION C.5 WRITING SETTINGS C.5.1 FRAME STRUCTURE ..................C-8 C.6 ERRORS C.7 MODBUS MAP - SETTINGS C.8 MODBUS MAP- STATUS GEK-106237P MIFII Digital Feeder Relay...

- Page 7 PHYSICAL LAYER ................... E-4 E.3.2 LINK LAYER ..................... E-5 E.3.3 APPLICATION LAYER ..................E-7 F. TIMING ACCURACY FOR 51 F.1 INTRODUCTION ELEMENT F.2 TIME OVERCURRENT ELEMENTS F.3 ANALYSIS OF A PRACTICAL CASE F.4 INTERNATIONAL STANDARD F.5 CONCLUSIONS MIFII Digital Feeder Relay GEK-106237P...

- Page 8 It will take a few seconds for the relay to restart after the completion of the update process. Therefore, before unplugging the relay, please make sure that the relay main screen shows the analog inputs values. GEK-106237P MIFII Digital Feeder Relay...

- Page 9 Figure 1–1: RELAY IDENTIFICATION LABEL (A4454P3) Ensure that the mounting screws have been included with the relay. For product information, instruction manual updates, and the latest software updates, please visit the GE Multilin Home Page (www.GEdigitalenergy.com/multilin). MIFII Digital Feeder Relay...

- Page 10 1 GETTING STARTED 1.1 INSPECTION CHECKLIST Note: If there is any physical damage detected on the relay, or any of the contents listed are missing, please contact GE Multilin immediately at: EUROPE, MIDDLE EAST AND AFRICA: GE MULTILIN Av. Pinoa, 10 48170 Zamudio, Vizcaya (SPAIN) Tel.: +34 94-485 88 54, Fax: +34 94-485 88 38...

-

Page 11: System Requirements

In case of a firmware flashing process, due to the risk of losing communication, GE Multilin will not be responsible in case of a communication failure if the relay and PC are not grounded to the same point. -

Page 12: Installation

After ensuring the minimum requirements for using ENERVISTA MII Setup are met (see previous section), use the following procedure to install the ENERVISTA MII Setup from the enclosed GE ENERVISTA CD. Insert the GE ENERVISTA CD into your CD-ROM drive. - Page 13 When ENERVISTA detects that there is already a version of the program in the Software Library, you can choose whether to install it directly or to check for more versions. Figure 1–5: CHECK FOR UPDATED VERSIONS? MIFII Digital Feeder Relay GEK-106237P...

- Page 14 11. Double-click the installation program once its download is complete, to install the EnerVista MII SETUP software. 12. Select the complete path, including the new directory name, where the EnerVista MII SETUP will be installed. GEK-106237P MIFII Digital Feeder Relay...

- Page 15 16. The default program group where the application will be added to is shown in the Selected Program Folder window. Click Next to begin the installation process, and all the necessary program files will be copied into the chosen directory. MIFII Digital Feeder Relay GEK-106237P...

- Page 16 1 GETTING STARTED 1.2 ENERVISTA MII SETUP SOFTWARE Figure 1–8: PROGRAM FOLDER 17. To finish with the installation process, select the desired language for startup Figure 1–9: LANGUAGE SELECTION GEK-106237P MIFII Digital Feeder Relay...

- Page 17 1.2 ENERVISTA MII SETUP SOFTWARE 1 GETTING STARTED 18. Click Finish to end the installation. The MII device will be added to the list of installed IEDs in the ENERVISTA Launchpad window, as shown below. 1-10 MIFII Digital Feeder Relay GEK-106237P...

-

Page 18: Mii Relay Family Hardware

HARDWARE chapter. To communicate with the relay’s RS485 port from a computer’s RS232 port, a RS232/RS485 converter box is required. GE Multilin offers F485, DAC300 and RS232/485 converters. This converter box is connected to the computer using a “straight through”... -

Page 19: Using The Keypad And Display

To return back to the previous level (from the third to the second level, or from the second to the first one), push the “ESC/ RESET” button. Refer to chapter 8, for more information on the use of the local keypad and display to access information and change settings. 1-12 MIFII Digital Feeder Relay GEK-106237P... -

Page 20: Product Description

• 1 Oscillography record (available only in Option 1 and Option 2 models) • 32 Event recorder (available only in Option 1 and Option 2 models) • Configurable Logic (available only in Option 2 models) GEK-106237P MIFII Digital Feeder Relay... -

Page 21: Introduction

19200 bps. The rear RS485 port can be converted into an RS232 port or into a fiber optic (plastic or glass) serial port by using GE Multilin DAC300, F485 or RS232/485 module, or any other standard converter. The EnerVista MII SETUP communication software is the Windows®... -

Page 22: Access Security Features

Thirty minutes after the last setting change performed, or when the ESC/RESET key is pressed for three seconds or more, the relay returns automatically to the password protected status and will ask for the password again if a new attempt to change settings is made. GEK-106237P MIFII Digital Feeder Relay... -

Page 23: Phase Time Overcurrent Element (51P)Differential Units (87-1 87-2)

IEC curves comply with the criteria specified in the IEC255-4 Standard and British Standard BS142 ANSI curves comply with ANSI C37.90 standards IAC curves simulate the behaviour of GE IAC relays. A time dial can be applied to any of these curves to optimize co-ordination with other devices in the net. Additionally, there is a possibility to define a User’s Curve, which can be used for both three-phase overcurrent and ground elements. - Page 24 (between 0.1 – 2.4 times the rated current in case of 1/5 A ground, or 0.005-0.12 A in case of sensitive ground) and set the current/time operating characteristic (type and time dial). Note: The relay will use either IEC, IAC or ANSI curves, depending on the model. Refer to Appendix B for a deeper explanation of the curves. GEK-106237P MIFII Digital Feeder Relay...

-

Page 25: Overcurrent Elements

The MIFII relay provides 2 Ground Instantaneous Overcurrent Elements, 50G1 (‘1’ for High pickup) and 50G2 (‘2’ for Low pickup). Settings and ranges available for these elements are the same ones described for the Phase Instantaneous Overcurrent Elements, 50P1 and 50P2. MIFII Digital Feeder Relay GEK-106237P... -

Page 26: Thermal Image Element

(settable between 3 and 600 minutes). The cooling time constant 2 can be set between 1 and 6 times the heating time constant 1. Refer to Appendix A for a detailed explanation on the operating principles of this element. GEK-106237P MIFII Digital Feeder Relay... -

Page 27: Recloser Element

Also, settings are available for selecting which protection functions will be enabled after every autorecloser shot. 2.6.2 RECLOSER STATUSES The following diagram describes the different possible statuses for the recloser and the transitions between statuses. Figure 2–2: AUTORECLOSER GENERAL STATUS DIAGRAM MIFII Digital Feeder Relay GEK-106237P... - Page 28 2 PRODUCT DESCRIPTION 2.6 RECLOSER ELEMENT Figure 2–3: AUTORECLOSER DETAILED STATUS DIAGRAM GEK-106237P MIFII Digital Feeder Relay...

- Page 29 RI·LAST SHOT + INCOM.SEQ.TIME ISSUE CLOSE BREAKER LAST SHOT OPERATION INCREASE n WAIT FOR 52 CLOSE RI· 52 CLOSE LAST SHOT BLOCK + RI·LAST SHOT INITIATE RST TIME RESET Figure 2–4: AUTORECLOSER DETAILED STATUS DIAGRAM (2) 2-10 MIFII Digital Feeder Relay GEK-106237P...

- Page 30 The recloser will be latched in the LOCKOUT state until the breaker has been closed and stay closed for the reset lockout time AR RESET LO DELAY. CLOSE After the dead time elapses, the scheme issues the close signal. The close signal is latched until the breaker closes of the scheme goes to LOCKOUT. GEK-106237P MIFII Digital Feeder Relay 2-11...

-

Page 31: Recloser Settings

“reclaim time” which is the minimum time required between successive reclose sequences. used to select which events will initiate the autorecloser scheme. Autoreclose initiation masks: trip masks: used to select which function will be enabled to trip. After 1 2-12 MIFII Digital Feeder Relay GEK-106237P... -

Page 32: Cold Load Pickup (Available Only In Option 2 Models)

The T IN and T OUT timer values, as well as the multiplying constants K50P and K51P, and the function permission are settings associated to the COLD LOAD PICKUP. These settings are included in the ADVANCED SETTINGS group. They will be described in detail in the SETTINGS section. GEK-106237P MIFII Digital Feeder Relay 2-13... -

Page 33: Breaker Failure To Open

4% of it. The settings associated to BREAKER FAILURE TO OPEN are the function permission and the timer value. They are included in the ADVANCED SETTINGS group. They will be described in the SETTINGS section. 2-14 MIFII Digital Feeder Relay GEK-106237P... -

Page 34: I2 Counter (Available Only In Option 2 Models)

0.000 to 999.000, and for the “Number of Openings” counter it is from 0 to 999. From the keypad and display it is only possible to set both fields to zero. GEK-106237P MIFII Digital Feeder Relay 2-15... -

Page 35: Events (Available In Option 1 And Option 2 Models)

Digital output 4 active/non active Digital input 1 active/non active Digital input 2 active/non active Settings change disabled by digital input active/non active Trip operation by digital input Trip operation by command Auxiliary digital output latch reset 2-16 MIFII Digital Feeder Relay GEK-106237P... - Page 36 52A open/closed 52 open/closed Group 2 selection by digital input Oscillography triggered by digital input Oscillography triggered by command Breaker failure Alarm Settings change EEPROM failure User settings/Factory settings OPTION 1: MIFII***E1**00; OPTION 2: MIFII***E2**00 GEK-106237P MIFII Digital Feeder Relay 2-17...

-

Page 37: Oscillography (Available In Option 1 And Option 2 Models)

Oscillography trigger by digital input Protection functions: 50P1, 50P2, 50G1, 50G2, 51P, 51G, 49, general Protection functions: 50P1, 50P2, 50G1, 50G2, 51P, 51G, 49, general Protection functions: 50P1, 50P2, 50G1, 50G2, 51P, 51G, 49, general 2-18 MIFII Digital Feeder Relay GEK-106237P... - Page 38 MIFII relay with option C stores 4 oscillography records, with a resolution of 16 samples per cycle with a total length of 150 cycles (including prefault cycles) each register. In General Settings there is a setting for prefault cycles. It is adjustable from 10 to 140 cycles. GEK-106237P MIFII Digital Feeder Relay 2-19...

-

Page 39: Multiple Setting Groups

Settings are divided in two different categories: Main Settings and Advanced Settings. This makes setting the relay extremely simple for those users who want to use just the Main functions of the MIFII relay. Users who require the full functionality of the relay can use the Advanced Settings. 2-20 MIFII Digital Feeder Relay GEK-106237P... -

Page 40: Measurement And Self-Test

Self-monitoring tests are carried out both when the unit is started up and during normal operation. Any internal problem detected by the self-monitoring function will issue an alarm and the READY output contact will be released, indicating an out of service condition. GEK-106237P MIFII Digital Feeder Relay 2-21... -

Page 41: User Interface

3 seconds (RESET) providing that the trip condition has disappeared. The LED associated to function pickup is self-reset type, and stays on while the pickup condition (current above setting) exists. 2-22 MIFII Digital Feeder Relay GEK-106237P... -

Page 42: Keypad And Display

MIFII units are supplied together with EnerVista MII SETUP software, a Windows based software that allows communication with the relay for data viewing and retrieval, as well as oscillography, I/O configuration and logical configuration (in models where these features are available). GEK-106237P MIFII Digital Feeder Relay 2-23... -

Page 43: Ordering Codes

2.OPTION 2: Includes all OPTION 1 features, plus cold load pickup, breaker failure to open protection, breaker monitoring, breaker maintenance and configurable logic. ACCESSORIES A depth-reducing collar can be ordered separately. This collar reduces the mounting depth in 63 mm (2.48 inches). 2-24 MIFII Digital Feeder Relay GEK-106237P... -

Page 44: Technical Specifications

Between 20 and 30 ms for I> 2 x Actual Pickup Operate Time: ± 5% or 50ms(whichever is greater) of settled time for I > 2 times the Actual Timing Accuracy: Pickup Type/measure time: DFT of 1 cycle GEK-106237P MIFII Digital Feeder Relay 2-25... -

Page 45: Metering Functions

4 x In continuously. Current Withstand: 100 x In for 1 sec. 2.16.3.2 DIGITAL INPUTS Voltage Level: 300 Vdc maximum for HI power supply 75 Vdc maximum for LO power supply Recognition Time: < 4 ms 2-26 MIFII Digital Feeder Relay GEK-106237P... -

Page 46: Power Supply

Contact Carry Continuous: 10 A at 250 Vac. general purpose ¾ HP, 124 Vac 1-1/2 HP, 250 Vac 10A, 250 Vac, 0.4 PF, B300 pilot duty Make and Carry: 30 A Breaking: 4000 VA GEK-106237P MIFII Digital Feeder Relay 2-27... -

Page 47: Communications

Electrostatic Discharge Immunity Test Level 4 CM (8 kV). Level 3 AM (8 kV) IEC 60255-22-3 / EN 61000-6-2 (2001) / Radiated RF Fields Immunity Test Level 3 (10 V/m), 80-1000 MHz. ENV 50204 (1995) 2-28 MIFII Digital Feeder Relay GEK-106237P... - Page 48 4 of the correspond report. IEC 60255-5 (1977) Dielectric Test In the paragraph relating to dielectric test for 2 kV, 50 Hz applications for all the groups defined in paragraph 4 of the correspond report. GEK-106237P MIFII Digital Feeder Relay 2-29...

-

Page 49: Production Tests

EN 60255-21-3 (1996) Seismic Test 2.16.9 PRODUCTION TESTS Insulation Test: IEC255-5 (Tested on CTs, Power Supply terminals, Contact Inputs and Contact Outputs) 2.16.10 APPROVALS Manufactured under an ISO9001 Registered system Conforms to CE Marking UL listed 2-30 MIFII Digital Feeder Relay GEK-106237P... -

Page 50: Hardware

The modular design of the relay simplifies repair or replacement of its components, without the need to manipulate the wiring. These types of operations must be performed exclusively by qualified personnel and only after removing auxiliary voltage from the unit. GEK-106237P MIFII Digital Feeder Relay... -

Page 51: Mounting

This allows the user access to the front keypad, display and communication port. The wiring is at the rear of the unit. The drilling dimensions are shown on the drilling dimension diagram. Note: Dimensions are shown in inches (mm). Figure 3–2: MOUNTING AND DIMENSIONS DRAWING FOR MIFII MODELS WITH DEPTH REDUCING COLLAR MIFII Digital Feeder Relay GEK-106237P... -

Page 52: Rear Description

DIN connectors of the module. A slow and careful insertion must be made until the module is correctly aligned, and then a more firm insertion can be applied, never forcing the module. GEK-106237P MIFII Digital Feeder Relay... -

Page 53: Typical Wiring Diagram

3.1 DESCRIPTION 3 HARDWARE 3.1.4 TYPICAL WIRING DIAGRAM Recommended cable section: 12/16 AWG. Copper conductor only. Tightening torque: 1.2 Nm. Figure 3–4: TYPICAL WIRING DIAGRAM FOR MIFII RELAY WITHOUT RECLOSER MIFII Digital Feeder Relay GEK-106237P... - Page 54 3 HARDWARE 3.1 DESCRIPTION Figure 3–5: TYPICAL WIRING DIAGRAM FOR MIFII RELAY WITH RECLOSER GEK-106237P MIFII Digital Feeder Relay...

-

Page 55: Control Power

CAUTION: CONTROL POWER SUPPLIED TO THE RELAY MUST MATCH THE RATED VOLTAGE OF THE RELAY. IF THE VOLTAGE IS APPLIED TO THE WRONG TERMINALS, DAMAGE MAY OCCUR. RANGE RATED VOLTAGE OPERATION RANGE 24/48 Vdc 19.2~57.6 Vdc 110/250 Vdc 88~300 Vdc 110/230 Vac 88~264 Vac MIFII Digital Feeder Relay GEK-106237P... -

Page 56: Ac Current Transformer Inputs

The exact placement of a zero sequence CT, so that ground fault current will be detected, is shown below. Twisted pair cabling on the zero sequence CT is recommended. Figure 3–6: ZERO SEQUENCE CORE BALANCE CT INSTALLATION GEK-106237P MIFII Digital Feeder Relay... -

Page 57: Contact Inputs / Outputs

If it is not possible to ensure the previous conditions, the connection shown below can be used, where lines are wired only to inputs (A8 and A9), and the common (A10) is connected to the unit ground terminal. Figure 3–8: CONTACT INPUTS CONNECTIONS (AC ACTIVATION) MIFII Digital Feeder Relay GEK-106237P... -

Page 58: Output Contacts Configuration

Next figure shows the PCB of a MIFII relay, and the location of the jumpers used to select the configuration of each output contact (NO or NC). Figure 3–9: PCB SCHEME SHOWING THE JUMPERS TO CONFIGURE THE OUTPUT CONTACTS (NC / NO) GEK-106237P MIFII Digital Feeder Relay... -

Page 59: Outputs Isolation

The Jx jumper is a tin-solder jumper easy to remove using a de-soldering tool. The standard factory default output contact configuration consists of one group of four outputs, with the same common. The figure below shows the configuration: 3-10 MIFII Digital Feeder Relay GEK-106237P... - Page 60 OUT1 and OUT2 must operate together to operate like a single output. The configuration of OUT1 and OUT2 must be the same so both outputs close simultaneously and operate successfully. Figure 3–11: OUT1 AND OUT2 CONFIGURATION TO ACT AS A NORMALLY OPEN CONTACT GEK-106237P MIFII Digital Feeder Relay 3-11...

- Page 61 OUT2 as NOT ASSIGNED, so it never change its state and remains closed, and OUT1 as required by the application (output configuration is only available in models option 1 and 2). 3-12 MIFII Digital Feeder Relay GEK-106237P...

-

Page 62: Rs232 Front Communications Port

RELAY FRONT RS232 PORT, IT IS COMPULSORY TO CONNECT THE RELAY GROUND TO THE SAME GROUND AS THE PC. OTHERWISE, USE AN UNGROUNDED COMPUTER. FOR THIS PURPOSE, PLEASE FOLLOW THE SAFETY INSTRUCTIONS IN CHAPTER 1 GEK-106237P MIFII Digital Feeder Relay 3-13... -

Page 63: Rs485 Communications Port

“A” and “B”, although many devices use terminals named “+” and “-“. As a general rule, terminals “A” should be connected to terminals “-“, and terminals “B” to “+”. There are exceptions to this rule, such as the GE ALPS and DDS family of relays. -

Page 64: Communications

The EnerVista MII SETUP software package uses only ModBus protocols, and is designed to communicate with a single relay at a time. GE Multilin offers different communication software packages, such as GE-POWER and ENERVISTA, which can be used to communicate simultaneously with several relays. -

Page 65: Starting Communication

The main screen of EnerVista MII SETUP software includes the following components: • Title • Main menu bar • Main icon bar • Working area • Status bar Figure 4–1: ENERVISTA MII SETUP MAIN SCREEN MIFII Digital Feeder Relay GEK-106237P... -

Page 66: File

Communication, View and Help menus for configuration. 4.2.2 OPEN Option that allows to open previously created setting files for their modification. Once the relay model is selected, the program will enable Setpoint, Actual, Communication, View and Help sub-menus. GEK-106237P MIFII Digital Feeder Relay... -

Page 67: Settings File Converter

Finally, the settings will be charged on the Enervista MII Setup on offline mode, so it must be saved in order to get the new .ajs file. 4.2.4 PROPERTIES From the File – Properties option, the program will show a screen including the relay model information, firmware version, etc., as shown on Figure 4–4: Figure 4–4: MODEL/VERSION MIFII Digital Feeder Relay GEK-106237P... -

Page 68: Get Info From Relay

Double clicking on the document with the left mouse button will enlarge the document view, and double clicking with the right button will reduce the size. GEK-106237P MIFII Digital Feeder Relay... -

Page 69: Print

The File – Print option prints the relay settings using Windows default (active) printer. 4.2.10 CLOSE The File – Close option exits the program. It does not prompt for confirmation or save the open file. MIFII Digital Feeder Relay GEK-106237P... -

Page 70: Setpoint

File->Save option in order to preserve them) with the Store button. If the OK button is pressed without having pressed Store (a window asking confirmation will appear), the settings of this group will be discarded. Figure 4–8: FUNCTION MENU GEK-106237P MIFII Digital Feeder Relay... -

Page 71: Main Settings

4.3.3.2 OTHER ADVANCED SETTINGS Besides the Flex Curve values, the user may configure the mask of events that will generate an event report and the events that will generate an oscillography. MIFII Digital Feeder Relay GEK-106237P... -

Page 72: Relay Configuration

These functions are distributed in groups, and only functions in the same group can be chosen for the same OR gate. • OR: activates the OR button for the I/O configuration column (see previous point). The window that appears when the OR button is pressed can be seen in Figure 4–13: GEK-106237P MIFII Digital Feeder Relay... - Page 73 MEMORY (only for outputs and LEDs): when MEMORY checkbox is enabled, the respective element will be latched. If the cause that generated the activation of the output or LED does no longer exist, the element will remain active until a RESET command is performed. 4-10 MIFII Digital Feeder Relay GEK-106237P...

-

Page 74: Logic Configuration

1. If result of the OR gate drops to 0, output will be 1 for 15s and after that time output will be 0. See Chapter 7 for more details on logic configuration. GEK-106237P MIFII Digital Feeder Relay... -

Page 75: Date /Time

Figure 4–15: CHANGE DATE/TIME Once the new date and time have been sent, the user can check in the status graph, or even in the relay itself, that the new date/time has been correctly entered. 4-12 MIFII Digital Feeder Relay GEK-106237P... -

Page 76: Actual Values

Protection function status (pickup / trip for each function). • Active settings group number. • Contact inputs and outputs status, and LEDs status. • Information from the self-test functions of the device. Figure 4–16: STATUS WINDOW GEK-106237P MIFII Digital Feeder Relay 4-13... -

Page 77: Event Recorder

CSV (Comma Separated Values) format. This is a standard text table format that can be opened with most commercially available database or spreadsheet programs such as MS Access or Excel. 4-14 MIFII Digital Feeder Relay GEK-106237P... -

Page 78: Waveform Capture

The program will request the path and filename where the file is to be stored, by means of the following form: Figure 4–18: OSCILLOGRAPHY RECORD This file can be viewed using GE_OSC software (the use of this software is described in manual GEK-105596). GEK-106237P MIFII Digital Feeder Relay 4-15... -

Page 79: Operations

4.5 OPERATIONS 4 COMMUNICATIONS 4.5OPERATIONS From Operations menu the user can perform all possible operation commands. Figure 4–19: OPERATIONS MENU 4-16 MIFII Digital Feeder Relay GEK-106237P... -

Page 80: Communication

After making any change, pressing Store button saves the changes without exiting the window. Pressing OK saves and exits and pressing Cancel exits without saving changes. 4.6.1 COMPUTER In COMPUTER dialog the user can configure the necessary adjustments to communicate with the relay from a PC. Figure 4–20: COMMUNICATIONS DIALOG GEK-106237P MIFII Digital Feeder Relay 4-17... - Page 81 The following window will appear: Figure 4–22: COMMUNICATION CONTROL – COMMUNICATING i. i.e., the first time a writing operation is performed against the relay during the current communication 4-18 MIFII Digital Feeder Relay GEK-106237P...

- Page 82 Then a new window appears allowing to view the captured screen, to save the captured file in BMP or JPG format, or to print it (the print dialog window will appear so as the user can select which printer to use and enter the appropriate printer settings). Figure 4–24: PRINT SCREEN GEK-106237P MIFII Digital Feeder Relay 4-19...

-

Page 83: Troubleshooting

SEND button. Figure 4–25: TROUBLESHOOTING Refer to preceding section to learn about Print Screen button. i.To check how to read memory map addresses from the relay refer to the corresponding section further in this chapter 4-20 MIFII Digital Feeder Relay GEK-106237P... -

Page 84: Upgrade Firmware Version

After selecting the file that will be used to update the FLASH memory, the following screen will be displayed: Figure 4–27: RELAY IDENTIFICATION After introducing the Slave Address and Relay password (1 and 1 by default), the following screen will be displayed, showing details of the old model and the new model: GEK-106237P MIFII Digital Feeder Relay 4-21... - Page 85 If the update is to a model option with higher functionality (see OPTION 1, OPTION 2 and OPTION R in the model list), the program will request a password. This password can be obtained placing an order with GE Multilin. The following three parameters must be clearly indicated in the order: •...

- Page 86 After completing the previous screen, and during the loading process, the following screen will be displayed, showing the update process status: Figure 4–30: UPDATE PROCESS During the update, the display and LEDs will blink until the total completion of the process. Then the following screen will appear: Figure 4–31: UPDATE COMPLETED GEK-106237P MIFII Digital Feeder Relay 4-23...

- Page 87 If the user wants to keep the same settings after the memory update, a copy of the settings should be stored in a file before starting the update process. 4-24 MIFII Digital Feeder Relay GEK-106237P...

-

Page 88: View 4.7.1 Traces

Communication > Computer menu. When TRACES are active, the ModBus communication traces will be displayed in the lower part of the screen, as shown in Figure 4–32: Figure 4–32: MODBUS TRACES GEK-106237P MIFII Digital Feeder Relay 4-25... -

Page 89: Modbus Memory Map

CSV format (to be later opened with any database or spreadsheet program as MS Excel). It is recommended to use this feature as memory map changes with relay model and firmware version so this is the safest way of obtaining the appropriate memory map for every single relay. Figure 4–33: MODBUS MEMORY MAP 4-26 MIFII Digital Feeder Relay GEK-106237P... -

Page 90: Languages

LANGUAGES option is only active when there is no active communication with the relay. If the PC is communicating with the relay, to activate this option the user must switch communication off in Communication – Computer menu. Figure 4–34: LANGUAGES GEK-106237P MIFII Digital Feeder Relay 4-27... - Page 91 4.7 VIEW 4 COMMUNICATIONS 4-28 MIFII Digital Feeder Relay GEK-106237P...

-

Page 92: Settings Structure

Check that the relay number and password in the MIFII display match the numbers entered in the dialog window of the EnerVista MII SETUP, after clicking on Relay Connection. CT ratio settings allow the user to view the current measures in primary values. GEK-106237P MIFII Digital Feeder Relay... -

Page 93: Main Settings

0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2 Communication 2 Baud COM2 Baud rate 0.3,0.6,1.2,2.4,4.8,9. rate* 6,19.2 Prefault cycles* Prefault Cycles Prefault Cycles 10-140 *Only available for option C models. For further information please see APPENDIX E MIFII Digital Feeder Relay GEK-106237P... -

Page 94: Phase / Ground Toc Settings (51P / 51G)

Ground IOC 50G1 50G1 Permission to Trip 50G1 Trip Trip Enable 50G1 Yes/No 50G1 Tap / Pickup (for 1/5 A 50G1 Pickup Pickup 50G1 1 In (Ground) 0.1 – 30 In (Gnd) 0.1 In (G) ground) GEK-106237P MIFII Digital Feeder Relay... -

Page 95: Thermal Image Settings (49)

49 Alarm Level Alarm Level 49 80 % 70% – 100% ITH Heating Time Constant τ1 Heat Time 49 3 – 600 min. 1 min Cooling Time Constant τ2 1 – 6 times τ1 Cool Time 49 MIFII Digital Feeder Relay GEK-106237P... -

Page 96: Autorecloser Settings (79)

AR 51G Shot 1 AR 51G Shot 1 Yes / No trip after Shot 1 Permission Permission for 49 function to trip AR 49 Shot 1 AR 49 Shot 1 Yes / No after Shot 1 Permission GEK-106237P MIFII Digital Feeder Relay... - Page 97 AR 51G Shot 4 AR 51G Shot 4 Yes / No trip after Shot 4 Permission Permission for 49 function to trip AR 49 Shot 4 AR 49 Shot 4 Yes / No after Shot 4 Permission MIFII Digital Feeder Relay GEK-106237P...

- Page 98 GEK-106237P MIFII Digital Feeder Relay...

-

Page 99: Phase / Ground Toc Settings (51P/ 51G) (Group 2)

0.1 – 30 In (Gnd) 0.1 In (G) 50G2 Pickup Value (sensitive Pickup 50G2 Pickup 50G2 0.005 A 0.005-0.12 A 0.001 A ground) 50G2 Time Delay Delay 50G2 Delay 50G2 0 s. 0.00 –600.00s. 0.01 s. MIFII Digital Feeder Relay GEK-106237P... -

Page 100: Thermal Image Settings (49) (Group 2)

A Parameter A Parameter 0.0500 0.0000-125.0000 0.0001 B Parameter B Parameter 0.0000 0.0000-3.0000 0.0001 P Parameter P Parameter 0.0400 0.0000-3.0000 0.0001 Q Parameter Q Parameter 1.0000 0.0000-2.0000 0.0001 K Parameter K Parameter 0.000 0.000-1.999 0.001 GEK-106237P MIFII Digital Feeder Relay... -

Page 101: Events And Oscillography Masks (Only Enervista Mii Setup)

Oscillo trigg by DI Oscillo trigger by command Oscillo trigg by comm Breaker failure to open BF to open Alarm Alarm Settings change Settings change EEPROM failure EEPROM failure User settings/Factory settings User settings 5-10 MIFII Digital Feeder Relay GEK-106237P... -

Page 102: Oscillography Masks

Time Dial Selected); if the curve type selected is DEFINITE TIME, then the Time Dial setting is ignored and the time delay used is the one specified in DEFINITE TIME setting. GEK-106237P MIFII Digital Feeder Relay... -

Page 103: Time Synchronization

MIFII includes an internal clock to time tag events. This clock can be either synchronized with the computer clock or set manually using the EnerVista MII SETUP software program (see Setpoints – Clock). It can also be set to a given Date and Time using the faceplate keypad (DATE & TIME menu entry). 5-12 MIFII Digital Feeder Relay GEK-106237P... -

Page 104: Input Configuration (For Options 1 And 2)

In order to configure an input with more than one element from the same group, we must first activate the OR button, click on the I/O CONFIGURATION option and select the desired group, then select the desired elements. For inverting an element, select the NOT button. Finally, click the OK button. GEK-106237P MIFII Digital Feeder Relay... - Page 105 Finally, to validate the selected configuration, the user must click on the OK button both in the "OR ASSIGNMENT" and the "I/O CONFIGURATION" screens. Figure 6–2: INPUT CONFIGURATION WITH MORE THAN ONE FUNCTION (OR) MIFII Digital Feeder Relay GEK-106237P...

- Page 106 In the example above, Input 2 has been programmed as 52a, inverted. In case the user wants to program more than one function for each input, then an OR must be selected, as in the example regarding input configuration with more than one element (OR). GEK-106237P MIFII Digital Feeder Relay...

-

Page 107: Input Elements

It is only possible to switch to Group 2 through digital input Group change Reset (PULSE) This element resets latched LEDs and outputs Oscillo trigger (PULSE) Triggers oscillography element General input Generic element that may be used in logic configuration. MIFII Digital Feeder Relay GEK-106237P... -

Page 108: Outputs And Leds Configuration (For Options 1 And 2)

MODELS WITH RECLOSER RECLOSER Phase trip Close breaker Ground trip Phase trip 50 trip Ground trip 49 Alarm 50 trip The default LED configuration is as follows: CONFIGURATION MEMORY Phase trip Ground trip 50 Trip Pickup GEK-106237P MIFII Digital Feeder Relay... - Page 109 (see logic configuration further on in this chapter and in Chapter 4. COMMUNICATIONS) and then choose the logic diagrams as the elements that will activate the output/LED MIFII Digital Feeder Relay GEK-106237P...

-

Page 110: Output And Led Elements

50G1 element pickup 50P2 pickup 50P2 element pickup 50G2 pickup 50G2 element pickup 51P pickup 51P element pickup 51G pickup 51G element pickup 49 Alarm 49 element pickup Pickup Pickup of any of the above mentioned elements GEK-106237P MIFII Digital Feeder Relay... - Page 111 This signal can be used to activate LEDs or auxiliary outputs. If the user wants the protection unit to trip, then the trip enable setting must be activated. In this case, the relay will activate the trip contact. MIFII Digital Feeder Relay GEK-106237P...

-

Page 112: Logic Configuration

Signals must be used in order, starting with L1 IN1. If we want to use more than one signal in the same AND gate, use L1 IN2 first and then L1 IN3. If we want to use another AND gate, use AND 2 first, and then AND3. GEK-106237P MIFII Digital Feeder Relay... - Page 113 For this purpose, please refer to the "I/O Configuration" section in this manual. Logics can be assigned both to LEDs or outputs, so that each user can create the desired configuration for a specific application The "Application Notes" section in this manual describes several real application examples. MIFII Digital Feeder Relay GEK-106237P...

- Page 114 7.1 LOGIC DESCRIPTION Time diagram for the logic configuration: Pickup Dropout Timer Timer Logic input Logic output Pickup Dropout Timer Timer Logic input Logic output Pickup Dropout Dropout Timer Timer Timer Pickup timer Logic input Logic output GEK-106237P MIFII Digital Feeder Relay...

-

Page 115: Logic Elements

50G1 element pickup 50P2 pickup 50P2 element pickup 50G2 pickup 50G2 element pickup 51P pickup 51P element pickup 51G pickup 51G element pickup 49 Alarm 49 element pickup Pickup Pickup of any of the above mentioned elements MIFII Digital Feeder Relay GEK-106237P... - Page 116 E2PROM failure Active when a failure is detected in EEPROM management User settings This element is green when the default settings are active and red when the user’s settings are active GEK-106237P MIFII Digital Feeder Relay...

- Page 117 A 52a or 52b input must be configured. If there are two inputs configured as 52a and 52b, the relay will not take into account the input configured as 52a and will act according only to the status of the input configured as 52b. MIFII Digital Feeder Relay GEK-106237P...

-

Page 118: Keypad And Display

These types of messages are located within a menu structure that groups the information into categories. This chapter describes the way to navigate this menu structure and shows the complete structure so that the user can reach certain screens quickly. GEK-106237P MIFII Digital Feeder Relay... -

Page 119: Faceplate Keypad

From the main screen, the Menu key enters the menu structure. From that point on, the user can navigate through the menu structure using Up and Down arrows to move horizontally, Enter to enter submenus and Escape to exit to the upper level. MIFII Digital Feeder Relay GEK-106237P... -

Page 120: Alphanumeric Display And Leds

See Chapter 4 for more information on how to configure LEDs.The color of the four LEDs in rows 2 and 3 can be changed between red and green in any relay model. The way to do this is to press simultaneously up and down arrow keys for more than 2 seconds. Then a new menu appears: GEK-106237P MIFII Digital Feeder Relay... - Page 121 8.3 ALPHANUMERIC DISPLAY AND LEDS 8 KEYPAD AND DISPLAY MIFII Digital Feeder Relay GEK-106237P...

-

Page 122: Operations

1 51P A 2.19 Enter 28-02 05:41:30 2 50P1 A 1.21 Enter 01-01 00:00:00 3 ---- - ---- Enter 01-01 00:00:00 4 ---- - ---- Enter 01-01 00:00:00 5 ---- - ---- GEK-106237P MIFII Digital Feeder Relay... -

Page 123: Hmi Password

Once it has been entered, the relay asks for the new password. Here is an example of how to change from HMI password value 1 to 2: If you don’t know the programmed password please contact GE Multilin Technical Service and have the encoded password value shown in Main Settings > Product Setup > HMI handy. -

Page 124: Menu Tree

8 KEYPAD AND DISPLAY 8.5 MENU TREE 8.5MENU TREE GEK-106237P MIFII Digital Feeder Relay... - Page 125 8.5 MENU TREE 8 KEYPAD AND DISPLAY MIFII Digital Feeder Relay GEK-106237P...

- Page 126 8 KEYPAD AND DISPLAY 8.5 MENU TREE GEK-106237P MIFII Digital Feeder Relay...

- Page 127 8.5 MENU TREE 8 KEYPAD AND DISPLAY 8-10 MIFII Digital Feeder Relay GEK-106237P...

- Page 128 8 KEYPAD AND DISPLAY 8.5 MENU TREE GEK-106237P MIFII Digital Feeder Relay 8-11...

- Page 129 8.5 MENU TREE 8 KEYPAD AND DISPLAY 8-12 MIFII Digital Feeder Relay GEK-106237P...

- Page 130 8 KEYPAD AND DISPLAY 8.5 MENU TREE GEK-106237P MIFII Digital Feeder Relay 8-13...

- Page 131 8.5 MENU TREE 8 KEYPAD AND DISPLAY 8-14 MIFII Digital Feeder Relay GEK-106237P...

-

Page 132: Relay Commissioning

Unpack the relay and verify that no parts are broken and that the relay has not suffered any damage during transit. Verify that the model number indicated on the faceplate corresponds to the model ordered. GEK-106237P MIFII Digital Feeder Relay... -

Page 133: Comments On The Test Equipment

In case of using AC voltage for the activation of digital inputs, and having connected the inputs common (A10) with the ground terminal, it is necessary to remove this connection before testing insulation on group 3. MIFII Digital Feeder Relay GEK-106237P... -

Page 134: Wiring And Necessary Equipment

Optionally, it is advisable to have a PC available, with the EnerVista MII SETUP software installed. • Relay wiring diagram. Connect the relay as shown in For safety reasons, the external protection earth terminal should be securely grounded. Energize the relay through terminals. Figure 9–1: TEST CONNECTIONS FOR MIFII (RELAY GEK-106237P MIFII Digital Feeder Relay... -

Page 135: Target Leds

9.4 TARGET LEDS 9 RELAY COMMISSIONING 9.4TARGET LEDS Check that pressing the “ESC/RESET” button for more than 3 seconds, all the front target LEDs light up and reset. MIFII Digital Feeder Relay GEK-106237P... -

Page 136: Power Supply Test

Shown values are only illustrative, as due to the nature of the internal power supply (switched power supply), the consumption currents are high frequency currents, and the meters used measure these values with a poor accuracy. GEK-106237P MIFII Digital Feeder Relay... -

Page 137: Communications

PC and the relay (refer to figure 3-10). If the front port is used, a straight through cable is needed. If the rear RS485 port is used, an RS485/RS232 converter is needed. GE Multilin offers DAC300, F485 or RS232/485 converters. -

Page 138: Relay Setting

These tests are only valid for the default factory configuration. Different configurations involving modifications in certain elements, such as different contact configuration, will require a subsequent modification of the test procedure. GEK-106237P MIFII Digital Feeder Relay... -

Page 139: Contact Inputs

INFORMATION menu on the faceplate or a PC and the ACTUAL VALUES menu in the EnerVista MII SETUP program (Actual> Actual Values) to easily check which input gets active for each test. Repeat this test at minimum and maximum permissible voltages. MIFII Digital Feeder Relay GEK-106237P... -

Page 140: Contact Outputs

Remove the Power Supply from the relay and check that the Alarm Output Contact (terminals B5-B6) is closed. Set the power supply back to the relay terminals and check that the Alarm Output Contact is open. GEK-106237P MIFII Digital Feeder Relay... -

Page 141: Relay Metering

Set the relay to 50Hz and apply the following current: In (Amps) 0.1 x In (ground) 4 x In (ground) Check that the relay measures the current with accuracy better than 3%. Set the relay at 60Hz and repeat the test. 9-10 MIFII Digital Feeder Relay GEK-106237P... - Page 142 With 1.1 times the pickup current the relay should trip in between 10 to 50 ms. With 4 times the pickup current the relay should trip in between 10 to 40 ms. The test should be carried out for phases A, B and C. GEK-106237P MIFII Digital Feeder Relay 9-11...

- Page 143 With 1.1 times the pickup current the relay should trip in between 10 to 50 ms. With 4 times the pickup current the relay should trip in between 10 to 40 ms. The test should be carried out for phases A, B and C. 9-12 MIFII Digital Feeder Relay GEK-106237P...

-

Page 144: Model E: Ground Ioc High Setting Element (50G1)

With 0.9 times the pickup current the relay should not trip. With 1.1 times the pickup current the relay should trip in between 10 to 50 ms. With 4 times the pickup current the relay should trip in between 10 to 40 ms. GEK-106237P MIFII Digital Feeder Relay 9-13... -

Page 145: Ground Ioc Low Setting Element (50G2)

With 0.9 times the pickup current the relay should not trip. With 1.1 times the pickup current the relay should trip in between 10 to 50 ms. With 4 times the pickup current the relay should trip in between 10 to 40 ms. 9-14 MIFII Digital Feeder Relay GEK-106237P... -

Page 146: Phase Toc Element (51P)

Apply 0.9 times the pickup current into phase C and the relay should not trip. Apply 1.5 times the pickup current and the relay should trip between 27 and 39 sec. Apply 5 times the pickup current and the relay should trip between 1.5 and 1.8 sec. GEK-106237P MIFII Digital Feeder Relay 9-15... -

Page 147: Ansi Inverse Curve

Apply 0.9 times the pickup current at the ground terminals and the relay should not trip. Apply 1.5 times the pickup current and the relay should trip between 10.86 and 12.25 sec. Apply 5 times the pickup current and the relay should trip between 3.69 and 4.16 sec. 9-16 MIFII Digital Feeder Relay GEK-106237P... -

Page 148: Iac Very Inverse Curve

Apply 0.9 times the pickup current at the ground terminals and the relay should not trip. Apply 1.5 times the pickup current and the relay should trip between 1.38 and 1.56 sec. Apply 5 times the pickup current and the relay should trip between 0.53 and 0.60 sec. GEK-106237P MIFII Digital Feeder Relay 9-17... -

Page 149: Definite Time

Apply 1.1 times the pickup current and the relay should trip in 1.0 sec. Acceptable time range is between 1.00 and 1.06 sec. Apply 4 times the pickup current and the relay should trip in 1.0 sec. Acceptable time range is between 1.00 and 1.06 sec. 9-18 MIFII Digital Feeder Relay GEK-106237P... -

Page 150: Ground Toc Element (51G)

Apply 0.9 times the pickup current at the ground terminals and the relay should not trip. Apply 1.5 times the pickup current and the relay should trip between 23.4 and 31.8 sec. Apply 5 times the pickup current and the relay should trip between 3.1 and 3.6 sec. GEK-106237P MIFII Digital Feeder Relay 9-19... -

Page 151: Iec Extremely Inverse Curve

Apply 0.9 times the pickup current at the ground terminals and the relay should not trip. Apply 1.5 times the pickup current and the relay should trip between 36.2 and 51.3 sec. Apply 5 times the pickup current and the relay should trip between 3.88 and 4.27 sec. 9-20 MIFII Digital Feeder Relay GEK-106237P... -

Page 152: Ansi Very Inverse Curve

Apply 0.9 times the pickup current at the ground terminals and the relay should not trip. Apply 1.5 times the pickup current and the relay should trip between 27.27 and 30.75 sec. Apply 5 times the pickup current and the relay should trip between 2.50 and 2.82 sec. GEK-106237P MIFII Digital Feeder Relay 9-21... -

Page 153: Iac Extremely Inverse Curve

Apply 0.9 times the pickup current at phase C and the relay should not trip. Apply 2 times the pickup current and the relay should trip between 43.3 and 47.8 sec. Apply 5 times the pickup current and the relay should trip between 23.4 and 25.9 sec. 9-22 MIFII Digital Feeder Relay GEK-106237P... -

Page 154: Definite Time

Apply 1.1 times the pickup current and the relay should trip in 1.0 sec. Acceptable time range is between 1.00 and 1.06 sec. Apply 4 times the pickup current and the relay should trip in 1.0 sec. Acceptable time range is between 1.00 and 1.06 sec. MODEL E: DIRECTIONAL UNITS ( GEK-106237P MIFII Digital Feeder Relay 9-23... -

Page 155: Thermal Image Element

OPERATING TIME (SEC.) (AMPS) (AMPS) RELAY 960 - 1072 141 - 156 35.4 - 39 Note: You must reset the Thermal Image Element after each test, to start the following one from the same cold status. 9-24 MIFII Digital Feeder Relay GEK-106237P... -

Page 156: Time Synchronization

Synchronize the relay date and time with the PC, using the EnerVista MII SETUP communications program (SETPOINT – CLOCK). Check using the keypad and display that the relay is actually in synchronism with the computer. GEK-106237P MIFII Digital Feeder Relay... -

Page 157: User Settings

50G1 Function Ground IOC 50G1 50G1 Permission to Trip 50G1 Trip Trip Enable 50G1 Yes/No 50G1 Tap / Pickup (for 1/5 50G1 Pickup Pickup 50G1 0.1 – 30 In (Gnd) 0.1 In (G) A ground) 9-26 MIFII Digital Feeder Relay GEK-106237P... - Page 158 Autorecloser Permission for 49 to Init AR 49 Permission Init AR 49 Init Yes / No Autorecloser Permission for a DI to Init AR External Permission AR EXTERN Init Yes / No Autorecloser Init GEK-106237P MIFII Digital Feeder Relay 9-27...

- Page 159 AR 51G Shot 4 Yes / No function to trip after Shot 4 Permission Permission for 49 function AR 49 Shot 4 Permission AR 49 Shot 4 Yes / No to trip after Shot 4 9-28 MIFII Digital Feeder Relay GEK-106237P...

-

Page 160: Advanced Settings

Delay 50P2 Delay 50P2 0.00 –600.00s. 0.01 s. Gnd IOC High Set GROUND IOC 50G1 Ground IOC 50G1 group 2 (group 2) 50G1 Permission to Trip Enable 50 G1 Trip Enable 50 G1 Yes/No Trip GEK-106237P MIFII Digital Feeder Relay 9-29... - Page 161 0.001 s Drop out time T OUT On Load Time 0.000-60.000 s 0.001 s Constant. 50P pickup K 50P Phase IOC Mult 1.00-5.00 0.01 Constant 51P pickup K 51P Phase TOC Mult 1.00-5.00 0.01 9-30 MIFII Digital Feeder Relay GEK-106237P...

- Page 162 BF to open Alarm Alarm Settings change Settings change EEPROM failure EEPROM failure User settings/Factory settings User settings counter, breaker failure to open and cold load pickup functions, available only in MIFII models with OPTION 2 GEK-106237P MIFII Digital Feeder Relay 9-31...

- Page 163 Oscillo by comm. Yes / No Oscillo by digital input Oscillo by digital input Yes / No Oscillo by trip Oscillo by trip Yes / No Oscillo by pickup Oscillo by pickup Yes / No 9-32 MIFII Digital Feeder Relay GEK-106237P...

- Page 164 10 INSTALLATION AND MAINTENANCE 10.1 INSTALLATION 10 INSTALLATION AND MAINTENANCE 10.1 INSTALLATION The relay should be installed in a clean, dry and dust-free place, with no vibrations. It should also be well lit to facilitate inspection and testing. Operational conditions as defined in section 3 must not be exceeded in any case. The relay should be mounted on a vertical surface.

- Page 165 10.2 GROUND CONNECTION AND DISTURBANCES SUPPRESSION 10 INSTALLATION AND MAINTENANCE 10.2GROUND CONNECTION AND DISTURBANCES SUPPRESSION Threaded plug labelled as GND (refer to 1.3) should be correctly grounded, so that the disturbance suppression circuits in the system work correctly. This connection should be as short as possible (preferably 25 cm or less) to guarantee maximum protection.

- Page 166 10 INSTALLATION AND MAINTENANCE 10.3 MAINTENANCE 10.3MAINTENANCE Given the important role that the protection relays play in the operation of any installation, a periodical program of tests is highly recommended. The unit incorporates built-in diagnostic functions that permit immediate identification with only the aid of the keypad and display, the detection of some of the most likely circuit failures.

- Page 167 10.4 CLEANING INSTRUCTIONS 10 INSTALLATION AND MAINTENANCE 10.4CLEANING INSTRUCTIONS In case of detecting accumulated pollution, the unit can be cleaned with a clean cloth, either dry or slightly dampened with a cleaner containing alcohol. Abrasive cleaners must be avoided, as these can damage the metallic surface or the electrical connection elements. 10-4 MIFII Digital Feeder Relay GEK-106237O...

- Page 168 Using the HMI it is possible to see an encrypted numerical value corresponding to the current HMI password. This value can be viewed in the MAIN SETTINGS – PRODUCT SETUP – HMI Password menu. Please contact GE Multilin Technical Support to decrypt this value and obtain the HMI password.

- Page 169 Anyway, it is recommended to check the converter’s documentation to confirm the manufacturer’s criterion. For the concrete case of GE PM’s F485 converter, connections are SDA with “-“and SDB with “+”. Q8 After the previous steps, I cannot communicate through the rear RS485 port.

- Page 170 ASCII format ("Microsoft Excel“), as well as specific applications for viewing oscillography records, as GE Multilin’s GE OSC software. Q13 My MIFII unit has the display off but the Ready LED is ON; does that mean the relay needs to be repaired? A13 No, it doesn’t.

- Page 171 11.1 MIFII FAQ 11 MII FAMILY FAQ (FREQUENTLY ASKED QUESTIONS) 11-4 MIFII Digital Feeder Relay GEK-106237P...

- Page 172 RS-485 ports can use different criteria for defining port polarities. In order to avoid misuse of the MIFII rear communication port, please verify connections in accordance with information provided in the MIFII instruction book. GEK-106237P MIFII Digital Feeder Relay 12-1...

- Page 173 Do not use both the 52/a and 52/b inputs to monitor the status of a circuit breaker. MIFII monitors breaker status by means of a single contact that can be selected as either a 52/a or a 52/b contact, using both will result in wrong breaker status evaluation. 12-2 MIFII Digital Feeder Relay GEK-106237P...

- Page 174 The relay does not - Relay or PC not grounded - Ensure ground connection communicate via the - Incorrect polarity - Invert polarity RS485 port - Incorrect baud rate, address, etc. - Test other baud rate, etc. GEK-106237P MIFII Digital Feeder Relay 13-1...

- Page 175 13.1 MIFII TROUBLESHOOTING GUIDE 13 TROUBLESHOOTING GUIDE 13-2 MIFII Digital Feeder Relay GEK-106237P...

- Page 176 The Thermal Image protection is especially applicable to this situations, due to its operating principle. In general, it is a standard backup protection for many protection schemes, for almost any device, motors, generators, cables, etc. GEK-106237P MIFII Digital Feeder Relay...

- Page 177 In this sense, it can be said that Thermal Image relays have memory, as they remember the previous status of the machine, and start computing temperature based on that status. After an overload condition, the protection simulates the cooling process of the machine using a separate time constant. MIFII Digital Feeder Relay GEK-106237P...

- Page 178 / (a * S), according to the defined parameters. It indicates the heating speed of the element (it is the amount of time it takes to reach the 63% of the final temperature.) α: Parameter which a value equal to: a * S / R GEK-106237P MIFII Digital Feeder Relay...

- Page 179 Equation [10], represents the basic tripping algorithm for a thermal image relay, that for a given τ and I , can be drawn, in ∞ general using a logarithm plane, using “v” as the parameter, as shown in Figure A–1: and Figure A–2: MIFII Digital Feeder Relay GEK-106237P...

- Page 180 For some applications, the use of separate time constants can be useful. For motors, it can be useful to use a time constant for normal conditions, and a different one, much lower, for locked rotor conditions (as the heat transmission capability gets reduced when the machine is not spinning). GEK-106237P MIFII Digital Feeder Relay...

- Page 181 Where: θ Temperature increase at a given time θ Rated temperature (temperature reached if I = IN) Protected element rated current Current flowing through the protected element Time τ Time constant MIFII Digital Feeder Relay GEK-106237P...

- Page 182 1 to 6 times the heating time constant τ1. If the current is greater than 15% In, the element will be considered to be connected (spinning), and then, the cooling time constant will be τ1. GEK-106237P MIFII Digital Feeder Relay...

- Page 183 A.6 MIFII THERMAL CURVES APPENDIX A Figure A–1: THERMAL CURVE FOR Τ1 = 3 MINUTES. MIFII Digital Feeder Relay GEK-106237P...

- Page 184 APPENDIX A A.6 MIFII THERMAL CURVES Figure A–2: THERMAL CURVES FOR Τ1 = 3 MIN. GEK-106237P MIFII Digital Feeder Relay...

- Page 185 A.6 MIFII THERMAL CURVES APPENDIX A A-10 MIFII Digital Feeder Relay GEK-106237P...

- Page 186 V <20.00 trip time will be: ≥ For V 20.00, trip time will be the same as for 20 times the setting: Where: Table B–1: GE IEC/BS142 INVERSE TIME CURVE CONSTANTS CURVE NAME Extremely inverse IEC Curve C Very inverse IEC Curve B 13.5...

- Page 187 8.00 0.05 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.20 1.40 1.60 1.80 2.00 9.00 10.00 0.04 0.08 0.16 0.24 0.32 0.40 0.48 0.57 0.65 0.73 0.81 0.97 1.13 1.29 1.45 1.62 MIFII Digital Feeder Relay GEK-106237P...

- Page 188 APPENDIX B B.1 IEC/BS142 CURVES Figure B–1: IEC/BS142 INVERSE CURVES GEK-106237P MIFII Digital Feeder Relay...

- Page 189 B.1 IEC/BS142 CURVES APPENDIX B Figure B–2: IEC/BS142 VERY INVERSE CURVES MIFII Digital Feeder Relay GEK-106237P...

- Page 190 APPENDIX B B.1 IEC/BS142 CURVES Figure B–3: IEC/BS142 EXTREMELY INVERSE CURVES GEK-106237P MIFII Digital Feeder Relay...

- Page 191 For 1.05 V < 20.00, trip time will be ≥ For V 20.00, trip time will be the same as for 20 times the setting Where: Table B–3: GE ANSI INVERSE TIME CURVE CONSTANTS CURVE NAME Extremely inverse 0.0399 0.2294 0.5000 3.0094...

- Page 192 8.00 0.05 0.11 0.22 0.33 0.44 0.55 0.66 0.77 0.88 0.99 1.10 1.32 1.54 1.76 1.97 2.19 9.00 0.05 0.10 0.20 0.29 0.39 0.49 0.59 0.69 0.79 0.88 0.98 1.18 1.38 1.57 1.77 1.96 10.00 GEK-106237P MIFII Digital Feeder Relay...

- Page 193 B.2 ANSI CURVES APPENDIX B Figure B–4: ANSI INVERSE MIFII Digital Feeder Relay GEK-106237P...

- Page 194 APPENDIX B B.2 ANSI CURVES Figure B–5: ANSI VERY INVERSE GEK-106237P MIFII Digital Feeder Relay...

- Page 195 B.2 ANSI CURVES APPENDIX B Figure B–6: ANSI EXTREMELY INVERSE B-10 MIFII Digital Feeder Relay GEK-106237P...

- Page 196 For 1<I/Ipickup<1.05 the unit will show a pickup signal and generate no trip For 1.05<=I/Ipickup<30 trip time will be: For I/Ipickup >= 30 Where: Table B–5: GE IAC INVERSE TIME CURVE CONSTANTS IAC CURVE SHAPE IAC Extremely Inverse Extr Inverse 0.0040...

- Page 197 0.204 0.201 0.198 0.882 0.579 0.415 0.363 0.338 0.323 0.313 0.306 0.301 0.297 1.176 0.773 0.553 0.484 0.450 0.430 0.417 0.408 0.401 0.396 10.0 1.470 0.966 0.692 0.605 0.563 0.538 0.522 0.510 0.502 0.495 B-12 MIFII Digital Feeder Relay GEK-106237P...

- Page 198 APPENDIX B B.3 IAC CURVES Figure B–7: IAC INVERSE GES-7001 GEK-106237P MIFII Digital Feeder Relay B-13...

- Page 199 B.3 IAC CURVES APPENDIX B Figure B–8: IAC VERY INVERSE GES-7002 B-14 MIFII Digital Feeder Relay GEK-106237P...

- Page 200 APPENDIX B B.3 IAC CURVES Figure B–9: IAC EXTREMELY INVERSE GES-7005 GEK-106237P MIFII Digital Feeder Relay B-15...

- Page 201 B.3 IAC CURVES APPENDIX B Figure B–10: IAC INVERSE LONG GES-7004 B-16 MIFII Digital Feeder Relay GEK-106237P...

- Page 202 APPENDIX B B.3 IAC CURVES Figure B–11: IAC INVERSE LONG GES-7003 GEK-106237P MIFII Digital Feeder Relay B-17...

- Page 203 B.3 IAC CURVES APPENDIX B B-18 MIFII Digital Feeder Relay GEK-106237P...

- Page 204 Differences between selecting the Intel or Motorola setting are explained in the following table: INTEL MOTOROLA ModBus Map Addressing One byte at a time One word at a time Data presentation High Byte – Low Byte Low Byte – High Byte Operations Selection + Confirmation Confirmation GEK-106237P MIFII Digital Feeder Relay...

- Page 205 FUNCTION BEGINNING #REGS 04FEH 004BH 653DH Intel Reply ADDRESS FUNCTION BYTES DATA0 DATA74 500DH 0200H 84D5H Motorola Request: ADDRESS FUNCTION BEGINNING #REGS 027FH 004BH 359DH Motorola Reply: ADDRESS FUNCTION BYTES DATA0 DATA74 0D50H 0002H 2783H MIFII Digital Feeder Relay GEK-106237P...

- Page 206 Intel Reply: FIELD LENGTH Relay address 1 byte Function 1 byte (10H) Beginning address 1 word (000H) (High byte – low byte) Nº of registers 1 word (0003H) (High byte – low byte) 1 word GEK-106237P MIFII Digital Feeder Relay...

- Page 207 1 word (000H) (High byte – low byte) Number of registers 1 word (0001H) (High byte – low byte) Number of bytes 1 byte (02) Value of the registers Register1=>Command code (Low byte – High byte). 1 word MIFII Digital Feeder Relay GEK-106237P...

- Page 208 01 00H 00 00H E5ECH Intel Reply: ADDRESS FUNCTION BEGINNING #REGS 0000H 0003H 8008H Motorola Request: ADDRESS FUNCTION BEGINNING #REGS BYTES DATA0 0000H 0001H 10 00H AB90H Motorola Reply: ADDRESS FUNCTION BEGINNING #REGS 0000H 0001H 01C9H GEK-106237P MIFII Digital Feeder Relay...

- Page 209 FUNCTION BEGINNING #REGS #BYTES DATA0 DATA1 DATA2 DATA3 0000H 0004H FE 00H C8CAH 7476H 4500H B950H Motorola Synchronization: ADDRESS FUNCTION BEGINNING #REGS #BYTES DATA0 DATA1 DATA2 DATA3 0000H 0004H FE 00H 0045H 7674H CAC8H 3919H MIFII Digital Feeder Relay GEK-106237P...

- Page 210 Change the setting Execute a confirmation command using the corresponding code (See command execution) For Motorola format, only the last two steps are necessary To modify a setting, use function 10H (PRESET MULTIPLE REGISTERS in MODBUS) GEK-106237P MIFII Digital Feeder Relay...

- Page 211 01C9H SETTING CHANGE Intel Request: ADDRESS FUNCTION BEGINNING #REGS #BYTES 0128H 0008H DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7 5052H 5545H 4241H 2020H 2020H 2020H 2020H 2020H A0A2H Data0 => 5152H (PR)Data4 => 2020H MIFII Digital Feeder Relay GEK-106237P...

- Page 212 0003H 0200H 0100H 0000H E69EH Intel Reply: ADDRESS FUNCTION BEGINNING #REGS 0000H 0003H 8008H Motorola Request: ADDRESS FUNCTION BEGINNING #REGS BYTES #DATA0 0000H 0001H 0200H A730H Motorola Reply: ADDRESS FUNCTION BEGINNING #REGS 0000H 0001H 01CFH GEK-106237P MIFII Digital Feeder Relay...

- Page 213 FUNCTION + 80 H COD. ERROR 0DC2H We can receive the following values in the error code field: ILLEGAL FUNCTION ILLEGAL DATA ADDRESS ILLEGAL DATA VALUE SLAVE DEVICE FAILURE ACK. SLAVE BUSY NEGATIVE ACKNOWLEDGE MEMORY PARITY ERROR C-10 MIFII Digital Feeder Relay GEK-106237P...

- Page 214 Trip Enable 51P 01CA 00E5 Trip Enable 51G Trip Enable 51G 01CA 00E5 Trip Enable 50P1 Trip Enable 50P1 01CA 00E5 Trip Enable 50P2 Trip Enable 50P2 01CA 00E5 Trip Enable 50G1 Trip Enable 50G1 GEK-106237P MIFII Digital Feeder Relay C-11...

- Page 215 011E A50PH IE50PH 023C 011E A 50NH IE50NH 023C 011E A51P I E51P 023C 011E A51N I E51N 023C 011E A 50PL IE50PL 023C 011E A 50NL IE50NL 023C 011E A 49 I E49 C-12 MIFII Digital Feeder Relay GEK-106237P...

- Page 216 AR 50G2 Init AR 50P2 Shot 1 0244 0122 AR 49 Init AR 50G2 Shot 1 0244 0122 AR EXTERN Init AR 49 Shot 1 0246 0123 AR 50P1 Shot 1 AR 50P1 Shot 2 GEK-106237P MIFII Digital Feeder Relay C-13...

- Page 217 AR 49 Shot 4 IDEN 024E 0127 Outage Time Trip Min Time FLOAT32 0252 0129 On Load Time Delay FLOAT32 0256 012B Phase IOC Mult Settings Group FLOAT32 025A 012D Phase TOC Mult Relay Operation FLOAT32 C-14 MIFII Digital Feeder Relay GEK-106237P...

- Page 218 50NL 052E 0297 dd49 dd49 052E 0297 052E 0297 052E 0297 Output 1 Output 1 052E 0297 Output 2 Output 2 052E 0297 Output 3 Output 3 052E 0297 Output 4 Output 4 GEK-106237P MIFII Digital Feeder Relay C-15...

- Page 219 TH Capacity Used TH Capacity Used FLOAT32 0552 02A9 I^2 Value I^2 Value FLOAT32 0556 02AB Breaker Trips Breaker Trips FLOAT32 055A 02AD UINT16 055E 02AF UINT16 0592 02C9 SUCt SUCt 1024 BUFFER 09C2|1442 04E1|0A21 2688|18 BUFFER 1454 0A2A C-16 MIFII Digital Feeder Relay GEK-106237P...

- Page 220 An alarm can be issued when the circuit is open. The figure below shows the typical wiring diagram that will provide trip circuit monitoring while the circuit breaker is closed. +Vdc TRIP TRIP INP#1 INP#2 Breaker Auxiliary Contact (52a) TRIP COIL GEK-106237P MIFII Digital Feeder Relay...

- Page 221 52a contact, as shown below: +Vdc TRIP TRIP INP#1 INP#2 Breaker Auxiliary Contact (52a) TRIP COIL VALUE OF RESISTOR R Supply Ohms Watts 48 Vdc 10 K 125 Vdc 25 K 250 Vdc 50 K MIFII Digital Feeder Relay GEK-106237P...

- Page 222 D.1.1 SETTINGS AND CONFIGURATION Settings and configuration related to this function are described below: Under I/O CONFIGURATION, Input#1 must be configured as 'General Input'. It will be used to monitor the permanent presence of voltage. GEK-106237P MIFII Digital Feeder Relay...

- Page 223 D.1 TRIP CIRCUIT SUPERVISION FOR MII-FAMILY RELAYS APPENDIX D Under LOGIC CONFIGURATION, LOGIC#1, Invert Input#1 and set the timer to the time delay to produce the Trip Circuit Supervision Alarm, for example 15 seconds MIFII Digital Feeder Relay GEK-106237P...

- Page 224 Under I/O Configuration, configure LEDs and outputs as required. In this example, LED#1 and configurable output#1 are configured to operate when a Trip Circuit failure is detected. They are also configured to have memory, so they will remain active even if the Trip Circuit failure disappears. GEK-106237P MIFII Digital Feeder Relay...

- Page 225 D.1 TRIP CIRCUIT SUPERVISION FOR MII-FAMILY RELAYS APPENDIX D MIFII Digital Feeder Relay GEK-106237P...

- Page 226 Communication Baud rate --- Comm Baud Rate 0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2 Communication 2 Baud COM2 Baud rate 0.3, 0.6, 1.2, 2.4, 4.8, rate 9.6, 19.2 Prefault cycles Prefault Cycles Prefault Cycles 10-140 GEK-106237P MIFII Digital Feeder Relay...

- Page 227 If a setting or switchgear change by the rear port is required, we could not be doing it by the keyboard or the front port. MIFII Digital Feeder Relay GEK-106237P...

- Page 228 The application layer of this companion standards does not use explicit APPLICATION PROTOCOL CONTROL INFORMATION (APCI). This is implicit in the contents of the ASDU DATA UNIT IDENTIFIER and in the type of link service used. GEK-106237P MIFII Digital Feeder Relay...

- Page 229 (DTE). Glass fibre Plastic fibre F-SMA type connector BFOC/2,5 type connector E.3.1.3 TRANSMISION CONTROL SPECIFICATIONS The standard transmission speed are 9.6 kbits/s or 19.2 kbits/s (adjustable). 9600 bit/s 19200 bit/s MIFII Digital Feeder Relay GEK-106237P...

- Page 230 F-Code 14:= link service not functioning Primary messages that cannot be passed on due to a malfunction are answered with an F-Code 14. The FCB bit is processed alternately. PRM = 0 F-Code 15:= link service not functioning GEK-106237P MIFII Digital Feeder Relay...

- Page 231 Such messages are answered by the protection equipment by means of a short message with function code 1 and are not processed. This leads to a loss of information. The exception to this is the broadcast command. MIFII Digital Feeder Relay GEK-106237P...

- Page 232 SYSTEM FUNCTIONS IN MONITOR DIRECTION. SEMANTICS <0> End of general interrogation <0> Time Synchronization <2> Reset FCB <3> Reset CU <4> Start/restart <5> Power on b) STATUS INDICATIONS IN MONITOR DIRECTION SEMANTICS <16> Auto-recloser active GEK-106237P MIFII Digital Feeder Relay...

- Page 233 <65> Start/pick-up L <66> Start/pick-up L <67> Start/pick-up N <68> General trip <69> Trip L <70> Trip L <71> Trip L <72> Trip I>> (back-up operation) <73> Fault location X in ohms <74> Fault forward/line MIFII Digital Feeder Relay GEK-106237P...

- Page 234 Read values or attributes of all entries of one group <243> Read directory of a single entry <244> Read value or attribute of a single entry <245> End of general interrogation of generic data <249> Write entry with confirmation GEK-106237P MIFII Digital Feeder Relay...

- Page 235 Other basic application functions that may involve the utilization of polling procedures are then described without repeating details about this procedure. Test mode Blocking of monitor direction Disturbance data E-10 MIFII Digital Feeder Relay GEK-106237P...

- Page 236 Ready for transmission of tags <29> Transmission of tags <30> Transmission of disturbance values <31> End of transmission b) SELECTION OF STANDARD ADSUS IN CONTROL DIRECTION ADSU MEANING <6> Time synchronization <7> General interrogation <10> Generic data GEK-106237P MIFII Digital Feeder Relay E-11...

- Page 237 Acknowledgement for disturbance data transmission c) SUMMARY OF PRIVATE DATA IN MIFII DESCRIPTION ASDU <160> <140> Reading of AR shot counts (Autoreclosure indication) <4> <1> <160> <160> Measurement of I2t breaker arcing counter <4> <2> (Measurement) E-12 MIFII Digital Feeder Relay GEK-106237P...

- Page 238 APPENDIX F F.1 INTRODUCTION APPENDIX F TIMING ACCURACY FOR 51 ELEMENTF.1INTRODUCTION The aim of this appendix is to explain the behavior of GE MII Family relay regarding the dependent time overcurrent protection. GEK-106237P MIFII Digital Feeder Relay...

- Page 239 Since IEC Standard does not fix time error limits for current ratios below 2 (see F.4 of this appendix for more information), GE MII Family Relays fixes a maximum error of 5% maximum permitted in all range for I / Ipu > 2. Care must be taken to use (in the formula) the current measured by the relay.

- Page 240 Please, take into account that the ±5% error is in the Current Axis (X). Once the formula is used, the error in the Time Axis (Y) will be a function of the Current and the Curve, which, in this case, has a great slope: GEK-106237P MIFII Digital Feeder Relay...

- Page 241 The current error is below 3%, as stated in the specifications, and the timing error will depend on it, according to the general formula. Though the example is for a 3 phase relay, the same is applicable to single phase ones. MIFII Digital Feeder Relay GEK-106237P...

- Page 242 The two criteria that may apply for the trip, according to the IEC Standard, are: 1)Gs ≤ Gt ≤ 1.3*Gs Therefore, there is a 30% tolerance. In GE MIFII Relays, this is the followed criterion, with a 5% tolerance. 2)Gt = Gs Not really recommended, in order to avoid undesired trips.

- Page 243 Value of characteristic quantity as multiple of setting value (G Limiting error as multiple of assigned error c)In other cases, the manufacturer shall state the reference. MIFII Digital Feeder Relay GEK-106237P...

- Page 244 F.5 CONCLUSIONS F.5CONCLUSIONS The GE MIFII Relay works according to its specifications and to the IEC Standard as well. In the real case used for this report, the specification would be the following range: Lower time limit ≤ Time to trip ≤ Upper time limit 30.375 ≤...

- Page 245 F.5 CONCLUSIONS APPENDIX F MIFII Digital Feeder Relay GEK-106237P...