Oki OF5900 Maintenance Manual

Maintenance manual

Hide thumbs

Also See for OF5900:

- User handbook manual (109 pages) ,

- Manual do usuário (109 pages) ,

- User manual (50 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Chapters

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Oki OF5900

-

Page 1: Oki Data Corporation

OKIFAX 5700/5900 Maintenance Manual Second Edition Note: Throughout this manual there are many references to the G4/ISDN option. This option is not available in the U.S. or CANADA. October, 1999 Oki Data Corporation... -

Page 2: Table Of Contents

Contents CHAPTER 1 GENERAL INFORMATION GENERAL INFORMATION ..............1.1 General Performance ................1.2 General User’s Functions ................ 1.3 General Maintenance Functions .............. 1.4 General Appearance ................1.5 Basic Performance Specifications ............1-11 1.6 Reports and Lists ..................1-21 CHAPTER 2 INSTALLATION PROCEDURE Setup Information .................. - Page 3 2.9.5.3.2 TX Mode Default ....................2-74 2.9.5.4 Dial Options: ......................2-80 2.9.5.4.1 Redial Tries ......................2-83 2.9.5.4.2 Redial Interval ...................... 2-84 2.9.5.4.3 Dial Prefix ......................2-85 2.9.5.5 Incoming Options: ....................2-89 2.9.5.5.1 CNG COUNT ....................... 2-91 2.9.5.5.2 Distinctive Ring ....................2-92 2.9.5.6 Report Options: ....................

- Page 4 4.3.20 Disassembling the Printer Unit ................4-23 4.3.21 LED Head ......................4-24 4.3.22 Toner Lookout Board .................... 4-25 4.3.23 Stacker Cover ...................... 4-26 4.3.24 Fusing Unit ......................4-26 4.3.25 Manual Feed Assembly ..................4-26 4.3.26 Back-up Roller, Transfer Roller ................4-27 4.3.27 Resist Roller, Hopping Roller, Sensor Plates ............

- Page 5 7.18 No Document Feeding ................7-22 7.19 Multiple Document Feeding ..............7-23 7.20 Document Skew ..................7-24 7.21 Document Jam ..................7-26 7.22 Printer Unit ....................7-27 7.22.1 Precautions ......................7-27 7.22.2 Troubleshooting Flow Charts of Printer Unit............7-28 Appendix A PC Board Decriptions and Operation A1.1 Unit Configuration and Block Diagram ..............

-

Page 6: General Information

CHAPTER 1 GENERAL INFORMATION... -

Page 7: General Performance

• 128 mm to 356 mm Length setting: Long documents (1500 mm) are also available. (7) Automatic document feeder (ADF) • 50 sheets (NA Letter/A4-size: 20-lb/75gm Oki Data recommended paper) • 30 sheets (NA Letter/A4-size: 16 to 28-lb/60 to 105gm) (8) Recording paper •... - Page 8 (12) Scanning resolution a) Horizontal: • 300 dot per inch Note: 600 dpi x 15.4 mm; copy is available. b) Vertical: • 300 dot per inch, 15.4, 7.7, and 3.85 lines per mm Note: 300 dpi x 300 dpi; Transmission is available. (13) Scanning method •...

- Page 9 (21) Protocol • ITU-T Rec. T.30 • ITU-T Rec. G4 Class 1 (option) • OKI special protocols: High speed protocol (G3) (22) Error correction scheme • ITU-T ECM (23) Image memory • Basic model: 2.5 M-byte (OKIFAX 5700) 4.5 M-byte (OKIFAX 5900) •...

-

Page 10: General User's Functions

General User’s Functions Transmission (1) Transmit mode • Automatic transmit mode • Manual transmit mode (2) Instant Dialling (3) Delayed feeder transmission (4) Memory transmission • 40 sessions (5) Delayed memory transmission (within 3 days) • 20 specified times for OKIFAX 5700 •... - Page 11 Reception (1) Receive mode • Automatic receive mode • Manual receive mode • TEL/FAX receive mode • TAD mode • Memory receive mode • PC receive mode • Forwarding mode (2) Memory only reception (3) No toner/No paper reception (memory) (4) Confidential message reception •...

- Page 12 (14) Smoothing printing In case of 8 dot/mm x 3.85 lines/mm 300 dot/inch x 784 lines/inch (15) Auto dialing • Speed dialing: OKIFAX 5700; 1 to 140 (1 to 40 are assigned to one-touch keys.) OKIFAX 5900; 1 to 230 (1 to 80 are assigned to one-touch keys.) •...

-

Page 13: General Maintenance Functions

(4) Group directory (5) Activity report (6) Active memory files (7) Broadcast MCF (Message Confirmation) (8) Protocol dump (G3 and G4) (9) NIC configuration (10) Log. report (11) G4 Log. report (12) Self diagnosis report Report options (1) MCF. (Single-Loc.) (2) MCF. - Page 14 (8) Tone (TEL/FAX) test (When NCU board is installed.) (9) Loop back 1 (When ISDN option board is installed.) (10) Loop back 2 (When ISDN option board is installed.) (11) INFO0 sending (When ISDN option board is installed.) (12) INFO1 sending (When ISDN option board is installed.) (13) INFO2 sending (When ISDN option board is installed.) (14) INFO3 sending (When ISDN option board is installed.) (15) Pulse (1kHz) send (When ISDN option board is installed.)

-

Page 15: General Appearance

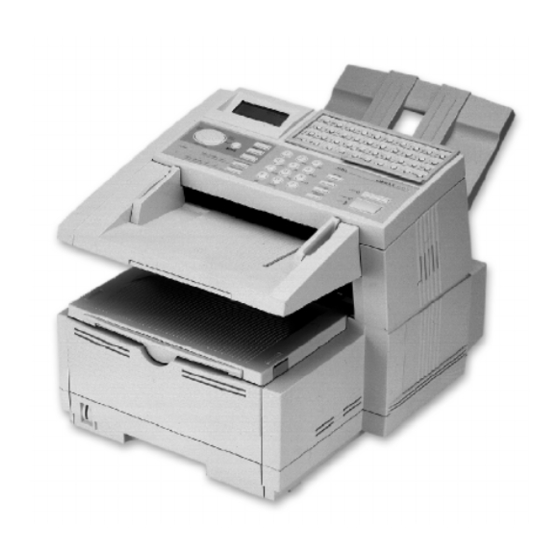

General Appearance Figure 1.4.1 shows the general appearance of the OKIFAX 5700/5900. Stacker-Document Operation Panel Tray-Document Tray-Paper Figure 1.4.1 General Appearance of OKIFAX 5700/5900 OKIFAX 5700/5900 1 - 9... - Page 16 Figure 1.4.2 Control Panel of OKIFAX 5700/5900 OKIFAX 5700/5900 1 - 10...

-

Page 17: Basic Performance Specifications

Basic Performance Specifications Table 1.5.1 shows basic performance specifications: Table 1.5.1 Basic Performance Specifications Item Specifications Applicable line 1) PSTN (Public switched telephone network) 2) PBX (Private branch exchange ) 3) ISDN (Integrated services digital network): Option 4) LAN (Local area network): Option Line interface 600 ohm balanced 1) Impedance... - Page 18 3) Weight, thickness and condition: Same as above Note: One single sheet should be loaded on the manual paper feeder for one occation. For best results use Oki Data recommended papers 1) Xerox 4200 (20-lb/75gm base weight paper) OKIFAX 5700/5900...

- Page 19 Item Specifications Recording paper cassette Up to 250 sheets/cassette First cassette (Oki Data recommended paper) Second cassette (option) Up to 500 sheets/cassette (Oki Data recommended paper) Effective recording paper Printing area Recording paper feeding direction 1) Printable area Printable area...

- Page 20 Item Specifications 2) Guaranteed printing area Guaranteed printing area 14 inch 13 inch Letter Size A4 Size Legal Size Legal Size inch inch inch inch 279.4 11.7 355.6 13 330.2 8.27 210 10.5 266.7 11.2 284.3 13.5 342.9 12.5 317.5 203.2 7.77 197.3 203.2...

- Page 21 “MSG. IN MEMORY”, and the Alarm LED turn on. Minimum scan line time for 0 ms, when receiving in ECM mode of from an Oki Data receiving facsimile. 5 ms at 15.4 line/mm or 7.7 line/mm and 10 ms at 3.85 line/ mm when receiving from a non-Oki Data facsimile or non- ECM mode.

- Page 22 The modem automatically selects transmission speed according to the line condition. Protocol 1) ITU-T Rec. T.30 2) Oki special protocol (speed protocol) The T.30 handshaking procedure will be conducted at message transmission speed instead of 300 baud, during transmission multi-page.

- Page 23 Item Specifications Image transmission time 2.5 seconds at 33.6 kbps with JBIG for OKIFAX 5900 and 3.0 seconds at 33.6 kbps for OKIFAX 5700 per sheet of ITU-T No.1 evaluation test chart. Note: This speed denotes the time interval correspond- ing to Phase C (message transmission phase) as referred to in ITU-T T.30.

- Page 24 Item Specifications Memory capacity (Image Basic model Optional memory memory) OKIFAX 5700 2.5 M-byte 2/4 M-byte OKIFAX 5900 4.5 M-byte 2/4 M-byte OKIFAX 5900 Memory OKIFAX 5700 condition [pages] Print Priority=OFF Print Priority=ON Standard (without option) With option 2 M-byte board 4 M-byte Note1: ITU-T No.1 sample document is used to count the...

- Page 25 Item Specifications ISDN G4 (option) The follwing four modes are supported. 1) G4 function 2) ISDN G4 communication 3) ISDN G3 communication 4) ISDN Report and List Note: For details, see appendix “ISDN G4 option sys- tem specifications”. Power supply unit and Power Power consumption of the machine (Typical power with- consumption of the machine out optional board)

- Page 26 Item Specifications Ambient condition Temperature and Humidity In operation Unit Power off mode During Storage Temperature 32 - 110 14 - 110 50 - 90 (0 - 43) (-10 - 43) ( C) (10 - 32) Humidity 10 - 90 10 -90 20 - 80 Maximum wet bulb...

-

Page 27: Reports And Lists

Reports and Lists Table 1.6.1 shows Report and Lists Specifications. Table 1.6.1 Report and Lists Specifications Item Specifications Active memory files This report will be manually or automatically printed out for information of transmission/reception data stored in the memory. When there is no stored image data in the memory at all, the Active memory files is not printed out. - Page 28 Item Specifications Power outage report If received communications are lost due to power failure, this report is printed out automatically at power recovery. The information printed on the Power outage report is not printed out on the Activity report. See Fig. 1-6-8 Confidential reception report This report will be informed operator about a stored confidential messages in the memory and automatically...

- Page 29 DATE TIME DISTANT STATION ID MODE PAGES 1 2 / 2 4 1 3 : 0 0 OKI DATA SYS-1 CALLING 1 2 / 2 4 1 2 : 0 3 OKI DATA SYS-2 CALLING 1 2 / 2 4...

- Page 30 ACTIVE MEMORY FILES P2 1 2 / 2 4 / 1 9 9 8 1 9 : 1 0 ID=ODS PERSONAL BOX BOX NO. MODE ENTRIES PAGES CONF CONF CONF CONF POLL POLL POLL POLL POLL POLL POLL POLL POLL POLL POLL POLL...

-

Page 31: Active Memory Files

DATE TIME DISTANT STATION ID MODE PAGES 1 2 / 2 4 1 3 : 0 0 OKI DATA SYS-1 CALLING 1 2 / 2 4 1 5 : 3 0 OKI DATA SYS-9 CALLING 1 2 / 2 4... -

Page 32: Activity Report

0 1 ’ 1 0 ” ODS FUKUSHIMA POLL=01 0000*7 1 2 / 2 4 1 3 : 0 0 0 1 ’ 0 0 ” OKI DATA SYS POLLED 0000 Confidential reception *2: Manual TX *3: Memory reception *4: Broadcast TX... -

Page 33: Message Confirmation

MESSAGE CONFIRMATION 12/24/1998 17:05 ID=OKI DATE S,R-TIME DISTANT STATION ID M OD E PAGES RESULT 1 2 / 2 4 0 ' 2 0 " 123456789012345678901234 CALLING 0000 IMAGE Fig. 1-6-3-1 Message Confirmation (When the transmission is normal end.) OKIFAX 5700/5900... - Page 34 MESSAGE CONFIRMATION Printed only when Error page 12/24/1998 17:05 ID=OKI DATE S.R-TIME DISTANT STATION ID MODE PAGES RESULT 1 2 / 2 4 0 ' 2 0 " 123456789012345678901234 CALLING 0000 POSSIBLE ERROR PAGE:*001*002 IMAGE Fig. 1-6-3-2 Message Confirmation (Error report)

- Page 35 (1) Title of the report (2) Date and time when the report was printed. (3) Sender ID (4) Total TX and total RX time (5) Date of transmission or reception (6) Time when the communication started (7) Length of time for which the OKIFAX 5700/5900 was connected to the line (8) Identification of the remote station •...

- Page 36 BROADCAST ENTRY REPORT P1 12/24/1998 17:04 ID=OKI TAKASAKI LOCATION ID LOCATION ID 1=1234567890123456789012345678901234567890 2=1234567890123456789012345678901234567890 3=OKI-SHIBAURA 4=OKI-SHIBAURA 5=FX-050 6=FX-175 7=FX-175VP-ENHANC 8=FX-056 9=OKIFAX450 10=OKIFAX460M 11=M125INTL 12=M125-US 13=OKIFAX5600 14=OKIFAX1050 15=OKIFAX1000 16=OKIFAX2200 17=OF-3GX 18=115AD 19=2275 20=OF-8 21=OF-18 22=OF-58H 23=M4200 24=5400 25=OF-2B 26=OF-1 27=OF-21 28=2127...

- Page 37 BROADCAST ENTRY REPORT P2 12/24/1998 17:04 ID=OKI TAKASAKI LOCATION ID KEYPAD 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 Fig. 1-6-4-2 Broadcast Entry Report for OKIFAX 5700 (2/2) OKIFAX 5700/5900 1 - 31...

- Page 38 BROADCAST ENTRY REPORT P1 12/24/1998 17:04 ID=OKI TAKASAKI LOCATION ID LOCATION ID 1=1234567890123456789012345678901234567890 2=1234567890123456789012345678901234567890 3=OKI-SHIBAURA 4=OKI-SHIBAURA 5=FX-050 6=FX-175 7=FX-175VP-ENHANC 8=FX-056 9=OKIFAX450 10=OKIFAX460M 11=M125INTL 12=M125-US 13=OKIFAX5600 14=OKIFAX1050 15=OKIFAX1000 16=OKIFAX2200 17=OF-3GX 18=115AD 19=2275 20=OF-8 21=OF-18 22=OF-58H 23=M4200 24=5400 25=OF-2B 26=OF-1 27=OF-21 28=2127...

- Page 39 159=KAI-SISYA-NOR 160=KAI-SISYA-SWE 161=KAI-SISYA-DEN 162=KAI-SISYA-GER 163=KAI-SISYA-TCH 164=KAI-SISYA-POL 165=KAI-SISYA-AUT 166=KAI-SISYA-BEL 167=KAI-SISYA-FRE 168=KAI-SISYA-ESP 169=KAI-SISYA-GRE 170=KAI-SISYA-AUS 171=KAI-SISYA-SIN 172=KAI-SISYA-HNG 173=OKI DATA USA 174=OKI DATA INTL 175=OKI DATA BGR 176=OKI DATA IRL 177=OKI DATA NOR 178=OKI DATA SWE 221=ABCDEFGHIJ12345 222=ABCDEFGHIJ23456 223=ABCDEFGHIJ34567 224=ABCDEFGHIJ45678 225=ABCDEFGHIJ56789 226=ABCDEFGHIJ67890 227=ABCDEFGHIJ78901 228=ABCDEFGHIJ89012...

-

Page 40: Broadcast Entry Report

BROADCAST ENTRY REPORT 12/24/1998 17:04 ID=OKI TAKASAKI LOCATION ID LOCATION ID 1=1234567890123456789012345678901234567890 50=1234567890123456789012345678901234567890 100=OKI-SHIBAURA KEYPAD 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 1234567890123456789012345678901234567890 Fig. 1-6-4-5 Broadcast Entry Report (When the destination of Broadcast TX is specified by Speed Dial No.1, No.50, and No.100) - Page 41 START TIME = 12/24 17:22 TOTAL TIME = 1:22'22" LOCATION ID PAGES RESULT LOCATION ID PAGES RESULT 1=OKIDATA SYS1 2=OKI DATA SYS2 3=OKIDATA SYS3 4=OKI DATA SYS4 5=OKIDATA SYS5 6=OKI DATA SYS6 7=OKIDATA SYS7 8=OKI DATA SYS8 9=OKIDATA SYS9 10=OKI DATA SYS10...

- Page 42 BROADCAST CONFIRMATION REPORT P2 12/24/1998 19:22 ID=OKI LOCATION ID PAGES RESULT KEYPAD 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 Fig. 1-6-5-2 Broadcast Confirmation Report P2 for OKIFAX 5700 OKIFAX 5700/5900 1 - 36...

- Page 43 START TIME = 12/24 17:22 TOTAL TIME = 1:22'22" LOCATION ID PAGES RESULT LOCATION ID PAGES RESULT 1=OKIDATA SYS1 2=OKI DATA SYS2 3=OKIDATA SYS3 4=OKI DATA SYS4 5=OKIDATA SYS5 6=OKI DATA SYS6 7=OKIDATA SYS7 8=OKI DATA SYS8 9=OKIDATA SYS9 10=OKI DATA SYS10...

- Page 44 12/24/1998 19:22 ID=OKI LOCATION ID PAGES RESULT LOCATION ID PAGES RESULT 141=OKIDATA SYS141 142=OKI DATA SYS142 143=OKIDATA SYS143 144=OKI DATA SYS144 145=OKIDATA SYS145 146=OKI DATA SYS146 147=OKIDATA SYS147 148=OKI DATA SYS148 149=OKIDATA SYS149 150=OKI DATA SYS150 151=OKIDATA SYS151 152=OKI DATA SYS152...

-

Page 45: Broadcast Confirmation Report

19:22 ID=OKI PAGES = 001 START TIME = 12/24 17:22 TOTAL TIME = 1:22'22" LOCATION ID PAGES RESULT LOCATION ID PAGES RESULT 1=12345678901234567890 50=OKI DATA SYS2 100=OKIDATA SYS3 KEYPAD 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 123456789012345678901234 Fig. 1-6-5-5 Broadcast Confirmation Report (When the destination of Broadcast TX is specified by Speed Dial No.1, No.50, and No.100) - Page 46 CONFIGURATION P1 12/24/1998 22:00 ID=ODC TAKASAKI USER FUNCTION SETUP MACHINE SETTINGS < 10 > AUTO ANSWER MODE < 11 > MONITOR VOLUME HIGH-MID. < 12 > BUZZER VOLUME L O W < 13 > USER LANGUAGE ENGLISH < 14 > REMOTE DIAGNOSIS <...

- Page 47 CONFIGURATION P2 12/24/1998 22:00 ID=ODC TAKASAKI USER FUNCTION SETUP REPORT OPTIONS < 70 > MCF. (SINGLE-LOC.) < 71 > MCF. (MULTI-LOC.) < 72 > MESSAGE IN MCF. < 73 > ERR. REPORT (MCF.) LAN OPTIONS < 80 > AUTO TRAY SW <...

-

Page 48: Technical Functions: Setup

CONFIGURATION P3 12/24/1998 22:00 ID=ODC TAKASAKI TECHNICAL FUNCTION SETUP < 01 > SERVICE BIT < 02 > MONITOR CONT. < 03 > COUNTRY CODE < 04 > TIME/DATE PRINT < 05 > TSI PRINT < 06 > TAD MODE TYPE2 <... - Page 49 CONFIGURATION P1 12/24/1998 22:00 ID=ODC TAKASAKI USER FUNCTION SETUP MACHINE SETTINGS < 10 > AUTO ANSWER MODE < 11 > MONITOR VOLUME HIGH-MID. < 12 > BUZZER VOLUME L O W < 13 > USER LANGUAGE ENGLISH < 14 > REMOTE DIAGNOSIS <...

- Page 50 CONFIGURATION P2 12/24/1998 22:00 ID=ODC TAKASAKI USER FUNCTION SETUP REPORT OPTIONS < 70 > MCF. (SINGLE-LOC.) < 71 > MCF. (MULTI-LOC.) < 72 > MESSAGE IN MCF. < 73 > ERR. REPORT (MCF.) TEL NO. FORWARDING NO. FORWARD ON P-ERR. = 6992 RELAY REPORT NO.

- Page 51 Note: *1: Printed only when Service Bit = ON. *2: When Service Bit = OFF, printed or not depending on the xpare bit. USER FUNCTION SETUP > MACHINE SETTINGS > No.26: POWER SAVE MODE is skipped at the time of COUNTRY CODE=USA of DEFAULT TYPE=1(ODA) regardless of the xpara bit. *3: Printed when the MFP option is specified in Mfpunlock setup.

- Page 52 TELEPHONE DIRECTORY P1 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE / MODE 1 OKI DATA SYS1 LOC# 1234567890123456789012345678901234567890 33.6K ALT# 0101 2 OKI DATA SYS2 LOC# 0002 33.6K ALT# 0102 3 OKI DATA SYS3 LOC# 0003 33.6K...

- Page 53 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 31 OKI DATA SYS31 LOC# 1234567890123456789012345678901234567890 [ 1 2 : 1 2 ] 33.6K ALT# 0010 32 OKI DATA SYS32 LOC# 0010 [ 1 2 : 1 2 ] 33.6K...

- Page 54 TELEPHONE DIRECTORY P3 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 61 OKI DATA SYS61 LOC# 1234567890123456789012345678901234567890 33.6K 62 OKI DATA SYS62 LOC# 0002 33.6K 63 OKI DATA SYS63 LOC# 0003 33.6K 64 OKI DATA SYS64 LOC# 0004 33.6K...

- Page 55 TELEPHONE DIRECTORY P4 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 91 OKI DATA SYS91 LOC# 1234567890123456789012345678901234567890 33.6K 92 OKI DATA SYS92 LOC# 0002 33.6K 93 OKI DATA SYS93 LOC# 0003 33.6K 94 OKI DATA SYS94 LOC# 0004 33.6K...

- Page 56 TELEPHONE DIRECTORY P5 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 121 OKI DATA SYS121 LOC# 1234567890123456789012345678901234567890 33.6K 122 OKI DATA SYS122 LOC# 0002 33.6K 123 OKI DATA SYS123 LOC# 0003 33.6K 124 OKI DATA SYS124 LOC# 0004 33.6K...

- Page 57 TELEPHONE DIRECTORY P1 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE / MODE 1 OKI DATA SYS1 LOC# 1234567890123456789012345678901234567890 33.6K ALT# 0101 2 OKI DATA SYS2 LOC# 0002 33.6K ALT# 0102 3 OKI DATA SYS3 LOC# 0003 33.6K...

- Page 58 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 31 OKI DATA SYS31 LOC# 1234567890123456789012345678901234567890 [ 1 2 : 1 2 ] 33.6K ALT# 0010 32 OKI DATA SYS32 LOC# 0010 [ 1 2 : 1 2 ] 33.6K...

- Page 59 TELEPHONE DIRECTORY P3 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 61 OKI DATA SYS61 LOC# 1234567890123456789012345678901234567890 33.6K ALT# 0010 62 OKI DATA SYS62 LOC# 0002 33.6K ALT# 0010 63 OKI DATA SYS63 LOC# 0003 33.6K ALT# 0010...

- Page 60 TELEPHONE DIRECTORY P4 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 91 OKI DATA SYS91 LOC# 1234567890123456789012345678901234567890 33.6K 92 OKI DATA SYS92 LOC# 0002 33.6K 93 OKI DATA SYS93 LOC# 0003 33.6K 94 OKI DATA SYS94 LOC# 0004 33.6K...

- Page 61 TELEPHONE DIRECTORY P5 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 121 OKI DATA SYS121 LOC# 1234567890123456789012345678901234567890 33.6K 122 OKI DATA SYS122 LOC# 0002 33.6K 123 OKI DATA SYS123 LOC# 0003 33.6K 124 OKI DATA SYS124 LOC# 0004 33.6K...

- Page 62 TELEPHONE DIRECTORY P6 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 151 OKI DATA SYS151 LOC# 1234567890123456789012345678901234567890 33.6K 152 OKI DATA SYS152 LOC# 0002 33.6K 153 OKI DATA SYS153 LOC# 0003 33.6K 154 OKI DATA SYS154 LOC# 0004 33.6K...

- Page 63 TELEPHONE DIRECTORY P7 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 181 OKI DATA SYS181 LOC# 1234567890123456789012345678901234567890 33.6K 182 OKI DATA SYS182 LOC# 0002 33.6K 183 OKI DATA SYS183 LOC# 0003 33.6K 184 OKI DATA SYS184 LOC# 0004 33.6K...

- Page 64 TELEPHONE DIRECTORY P8 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 211 OKI DATA SYS211 LOC# 1234567890123456789012345678901234567890 33.6K 212 OKI DATA SYS212 LOC# 0002 33.6K 213 OKI DATA SYS213 LOC# 0003 33.6K 214 OKI DATA SYS214 LOC# 0004 33.6K...

-

Page 65: Telephone Directory

TELEPHONE DIRECTORY 12/24/1998 17:05 ID=OKI LOCATION ID TEL NO G3-ECHO / G3-RATE MODE 1 OKI DATA SYS1 LOC# 1234567890123456789012345678901234567890 33.6K ALT# 0101 50 OKI DATA SYS50 LOC# 0002 33.6K 100 OKI DATA SYS100 LOC# 0003 33.6K Fig. 1-6-7-14 Telephone Directory (When the destination is registered by Speed Dial No.1, No.50, and No.100 only.) -

Page 66: Power Outage Report

1 0 : 3 0 ODS TAKASAKI LOST 1 2 / 2 4 1 2 : 0 5 0 1 ' 2 0 " OKI FAX CONF=01 LOST 0000 1 2 / 2 4 1 3 : 0 0 0 0 ' 2 0 "... -

Page 67: Confidential Rx Report

CONFIDENTIAL RX REPORT 12/24/1998 17:05 ID=OKI DATE S,R-TIME DISTANT STATION ID M O D E PAGES RESULT 1 2 / 2 4 0 1 ' 3 0 " 123456789012345678901234 CONF=01 0000 Fig. 1-6-9 Confidential RX Report (1) Title of the report (2) Date and time when the report was printed. - Page 68 PROTOCOL DUMP P1 12/24/1998 19:00 ID=OKI TAKASAKI DATE TIME S.R-TIME DISTANT STATION ID M O D E PAGES RESULT 1 2 / 2 4 1 8 : 5 6 0 0 ' 3 3 " 123456789012345678901234 CALLING 0000 PPS_MPS PPS_PRI_EOP...

- Page 69 PROTOCOL DUMP P2 12/24/1998 19:00 ID=OKI TAKASAKI RECEIVED FRAME CSI/CIG/TSI SEP/SUB Fig. 1-6-10-2 Protocol Dump P2 (G3) (1) Title of the report (2) Date and time when the report was printed (3) Sender ID (4) Date of communication (5) Time of communication...

-

Page 70: Self Diagnosis Report

SELF DIAGNOSIS REPORT 12/24/1998 12:00 ID=0dc Takasaki MAIN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM1 VERSION aaaa HASH hhhh PROGRAM2 VERSION aaaa HASH hhhh LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh DEFAULT TYPE M O D E M VERSION hhhh RAM1... - Page 71 SELF DIAGNOSIS REPORT 12/24/1998 12:00 ID=0dc Takasaki MAIN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM1 VERSION aaaa HASH hhhh PROGRAM2 VERSION aaaa HASH hhhh LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh DEFAULT TYPE M O D E M VERSION hhhh RAM1...

- Page 72 Note: *1: a indicates an alphanumeric character; n indicates a numeric character (0 to 9); h indicates a hexadecimal number; and b indicates 0 or 1. *2: Printed when the option memory board is mounted and if not, entry lines following this line are not omitted.

- Page 73 12/24/1998 18:15 DATA/TIME 12/24/1998 13:32 EXEC TSK PROMIS TSKNO : NGNO 0004 FLASH COUNT : 00000067 MSGDATA TSKDATA 01 00 01 01 02 03 04 05 01 01 01 01 01 01 01 01 01 01 01 10 01 00 01 01 02 03 04 05 01 01 01 01 01 01 01 01 01 01 01 10 01 00 01 01 02 03 04 05 01 01 01 01 01 01 01 01 01 01 01 10...

- Page 74 FUNCTION LIST P1 12/24/1998 22:00 ID=0dc Takasaki TO ACCESS PROGRAM MENU ITEMS: -PRESS THE MENU KEY -TO LOCATE A MENU ITEM. USE THE UP-DOWN ARROW KEY -SELECT THE MENU ITEM USING EITHER THE ENTER OR RIGHT ARROW KEYS TO QUICKLY ACCESS A SPECIFIC "SETUP" ITEM: -PRESS THE MENU KEY -ENTER THE TWO-DIGIT NUMBER OF THE SETUP ITEM ON THE TEN KEY PAD MENU...

- Page 75 FUNCTION LIST P2 12/24/1998 22:00 ID=0dc Takasaki MENU SETUP MACHINE SETTINGS < 10 > AUTO ANSWER MODE FAX/TEL/TF/TAD/MEM/PC/FWD * 1 1 < 11 > MONITOR VOLUME SELECT FROM 5 SOUND LEVEL < 12 > BUZZER VOLUME SELECT FROM 4 SOUND LEVEL <...

- Page 76 FUNCTION LIST P3 12/24/1998 22:00 ID=0dc Takasaki MENU SETUP REPORT OPTIONS < 70 > MCF. (SINGLE-LOC.) ON/OFF < 71 > MCF. (MULTI-LOC.) ON/OFF < 72 > MESSAGE IN MCF. ON/OFF < 73 > ERR. REPORT (MCF.) ON/OFF LAN OPTIONS < 80 > AUTO TRAY SW ON/OFF <...

- Page 77 FUNCTION LIST P1 12/24/1998 22:00 ID=0dc Takasaki STEP ACCESSING TO THE WANTED ITEM: -PRESS THE MENU KEY -CHOOSE THE ITEM WITH THE UP-DOWN KEY -DECIDE THE CHOSEN ITEM WITH THE ENTER or RIGHT KEY SPEED ACCESSING TO THE WANTED ITEM: =PRESS THE MENU KEY -ENTER THE NUMBER OF THE ITEM MENU...

- Page 78 FUNCTION LIST P2 12/24/1998 22:00 ID=0dc Takasaki MENU SETUP MACHINE SETTINGS < 10 > AUTO ANSWER MODE FAX/TEL/MEM/PC/FWD * 1 1 < 11 > MONITOR VOLUME SELECT FROM 5 SOUND LEVEL < 12 > BUZZER VOLUME SELECT FROM 3 SOUND LEVEL <...

- Page 79 FUNCTION LIST P3 12/24/1998 22:00 ID=0dc Takasaki MENU SETUP REPORT OPTIONS < 70 > MCF. (SINGLE-LOC.) ON/OFF < 71 > MCF. (MULTI-LOC.) ON/OFF < 72 > MESSAGE IN MCF. ON/OFF < 73 > ERR. REPORT (MCF.) ON/OFF COUNTER DRUM COUNT PRINT COUNT SCAN COUNT PRINTER CLEANING...

- Page 80 Note: *1: Printed only when Service Bit = ON. *2: When Service Bit = OFF, printed or not depending on the xpare bit. USER FUNCTION SETUP > MACHINE SETTINGS > No.26: POWER SAVE MODE is skipped at the time of COUNTRY CODE=USA of DEFAULT TYPE=1(ODA) regardless of *the xpara bit. •3: Printed when the MFP option is specified in Mfpunlock setup.

-

Page 81: Group Directory

GROUP DIRECTORY 12/24/1998 17:04 ID=OKI TAKASAKI GROUP NO. #1=OKI DATA SYS1 LOCATION ID LOCATION ID 1 = 1234567890123456789012345678901234567890 2 = 1234567890123456789012345678901234567890 3 = OKI-SHIBAURA 4 = OKI-SHIBAURA 5 = FX-050 6 = FX-175 7 = FX-0175VP-ENHANC 8 = FX-056 9 = OKIFAX450... - Page 82 GROUP DIRECTORY P1 12/24/1998 17:04 ID=OKI TAKASAKI GROUP NO. #1=OKI DATA SYS1 LOCATION ID LOCATION ID 1 = 1234567890123456789012345678901234567890 2 = 1234567890123456789012345678901234567890 3 = OKI-SHIBAURA 4 = OKI-SHIBAURA 5 = FX-050 6 = FX-175 7 = FX-0175VP-ENHANC 8 = FX-056...

- Page 83 GROUP DIRECTORY P2 12/24/1998 17:04 ID=OKI TAKASAKI GROUP NO. #1=OKI DATA SYS1 LOCATION ID LOCATION ID 141 = KAI-EIGYOU-INTL 142 = KAI-EIGYOU-GBR 143 = KAI-EIGYOU-NOR 144 = KAI-EIGYOU-SWE 145 = KAI-EIGYOU-DEN 146 = KAI-EIGYOU-GER 147 = KAI-EIGYOU-TCH 148 = KAI-EIGYOU-POL...

- Page 84 GROUP DIRECTORY 12/24/1998 17:04 ID=OKI TAKASAKI GROUP NO. #1=OKI DATA SYS1 LOCATION ID LOCATION ID 1 = 1234567890123456789012345678901234567890 50 = 1234567890123456789012345678901234567890 100 = OKI-SHIBAURA Fig. 1-6-14-4 Group Directory (When the destination of Speed Dial No.1, No.50, and No.100 is selected by the group destination.)

- Page 85 PROTOCOL DUMP P1 12/24/1998 19:00 ID=OKI TAKASAKI DATE TIME S,R-TIME DISTANT STATION ID M O D E PAGES RESULT 1 2 / 2 4 1 8 : 5 6 0 0 ' 3 3 " OKI SHIBAURA CALLING-G4 0000 DCH.

- Page 86 PROTOCOL DUMP P2 12/24/1998 19:00 ID=OKI TAKASAKI CR/CN 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00...

-

Page 87: (18) Setup

(1) Title of the report (2) Date and time when the report was printed (3) Sender ID (4) Date of communication (5) Time of communication (6) One message transmission/reception time (7) Identification of remote station • CSI and/or telephone number (8) Mode of transmission/reception according to ITU-T designation (9) Total number of pages in communication (10) Identification of the result of the communication... -

Page 88: Nic Configuration

NIC CONFIGURATION 24/12/1998 19:00 ID=OKI Takasaki MLETB07 Version 1.0.1 TCP/IP status IP address : 192.168.1.21 Subnet Mask : 255.255.255.0 Gateway addr: 192.168.1.254 NetWare status NWPrint mode: Failed EtherTalk status Zone Name Type Name : LaserWriter Object Name : ML1E4048 MAC Address : 00:80:92:1E:40:48 Fig. - Page 89 * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *User name: SUPERVISOR(2) Queue:...

- Page 90 CHAPTER 2 INSTALLATION PROCEDURE...

-

Page 91: General

Setup Information General The following flowchart outlines the installation procedure. Site selection (See 2.2) Unpacking (See 2.3) Contents identification (See 2.4) Installation of attachments (See 2.5) AC cord connection (See 2.6) Telephone and line connection (See 2.7) Packing for shipment (See 2.8) General procedure key operation (See 2.9.1) - Page 92 Clock adjustment (See 2.9.5.1) ID/Password programming (See 2.9.5.2) Machine settings (See 2.9.5.3) Dialing options (See 2.9.5.4) Incoming options (See 2.9.5.5) Report options (See 2.9.5.6) LAN options (See 2.9.5.7) Table: User Default setting (See 2.9.6) Table: Technical default setting (See 2.9.7) Table: Dial parameter default setting (See 2.9.8) Off-line tests...

- Page 93 Site Selection INSTALLATION Precautions for Installation (1) Fluctuation in line voltage • 120VAC (102V to 127V) • 230VAC (198V to 264V) (2) Room temperature • 50 to 90°F (10 to 32°C) (3) Humidity • 20 to 80% RH (4) Operating environment •...

- Page 94 Document exit Document Paper exit (face down) Paper exit (face up) Recording paper cassette Paper 11.81" 19.69" (300mm) (500mm) Note: *1: This space necessary for having the telephone set. *2: This space is necessary for removing the recording paper cassette. *3: This space is necessary for installing the document stacker and allow space for the fan exhaust.

- Page 95 Unpacking Procedure (1) Remove the on the top of the carton box and open its cover. External carton box Packing tape Packing tape Carton label Figure 2.3.1 Unpacking Procedure (1) (2) Take out the accessory box from the carton box. (See figure 2.3.2) (3) Take out the machine with plastic wrapper from the box.

- Page 96 Box-Accessories Connecting Codes Toner Cartrige Stacker Document OKIFAX 5700/5900 Pad-Assy (L) 40932401 Pat-Assy (R) 40932402 Box-Individual Bar Code Figure 2.3.2 Unpacking Procedure (2) OKIFAX 5700/5900 2 - 6...

- Page 97 Contents Identification After having taken out the machine and accompainied accessaries from the carton box, check the contents according to the following list. Table 2.4.1 Contents List Item No. Name Q’ty Remarks OKIFAX 5700/5900 facsimile AC power cord I/D unit Already installed.

- Page 98 Installation of Attachments (1) Items • Image Drum (ID) Unit (already installed) • Toner cartridge • Recording paper • Document stacker (2) Procedure 1) Toner cartridge • Peel off the fixed tape attached to the tray-paper. • Open the tray-document and tray-paper. Figure 2.5.1 Toner Cartridge Installation (1) •...

- Page 99 • Take out the toner cartridge from the damp proof bag, shake it five or six times as shown in the illustration to eliminate the toner deflection, and peel off the seal genitly. Seal Toner cartridge Figure 2.5.3 Toner Cartridge Installation (3) •...

- Page 100 • Press the gray lever forward until it stops. Figure 2.5.5 Toner Cartridge Installation (5) • Clean the toner scattered in the vicinity of the toner cartridge using a cloth moistened with cold water. Do not use hot water since it makes the toner stick there. •...

- Page 101 2)Recording paper Note: About 250 sheets of the new paper can be set in the recording paper cassette. • Remove the paper cassette from the facsimile by pulling the cassette tab. • Sheets must not exceed the paper full marker of the new paper limit indication. If excessive sheets are set, it will cause paper jams.

- Page 102 3) Document stacker • Hang the document stacker onto hanging position. OKIFAX 5700/5900 2 - 12...

- Page 103 AC Cord Connection The power supply is provided as follows: Normal input voltage 120VAC (Voltage range 102 to 127VAC) Normal input voltage 230VAC (Voltage range 198 to 250VAC) Check whether the AC voltage of your input is within the above-mentioned voltage range and if so, check that the power switch is turned OFF.

- Page 104 Telephone and Line Connection (1) Procedure • Connect the lines. Exchange line External telephone cable Packing for Shipment Caution: When packing the OKIFAX 5700/5900 for shipment, REMOVE THE IMAGE DRUM AND TONER FROM THE UNIT AND SHIP SEPARATELY! Failure to do this will result in damage to the machine. OKIFAX 5700/5900 2 - 14...

-

Page 105: B. Programming And Initial Settings

Programming and Initial Settings Initial Settings 2.9.1 General Procedure of Key Operation Note: The fonts displayed on the LCD operation panel may differ from the fonts written this manual. Accessing to desired functions: • There are two methods for accessing a desired function: Step access and Speed access (direct access). - Page 106 User functions MENU Delayed TX Note: Delayed Batch TX Options preceded by a number in permit speed access. Priority TX Other options do not permit speed access. Confidential TX Relayinitiate TX Polling TX/RX Polling TX Bulletin Poll (BOX) Memory Poll Memory Poll (BULL) Feeder Poll Polling RX...

- Page 107 Machine Settings Auto Answer Mode Monitor Volume Buzzer Volume User Language Remote Diagnosis Tx Mode Default No Toner Mem. Rx Mem. Full Save Instant Dial Restrict Access ECM Function Closed Network Tone Save Sender ID 1'st Paper Size 2'nd Paper Size Power Save Mode ISDN Dial Mode Speech Receive...

- Page 108 Report Options MCF (Single-Loc.) MCF (Multi-Loc.) Image in MCF. Err. Report (MCF.) LAN Options AUTO TRAY SW. PAPER SIZE CHECK LAN PRINT T.O. IP ADDRESS SUBNET MASK DEFAULT GATEWAY Counter ( Service bit = ON), (Service bit = OFF & Toner Counter Clear = ON), ( Service bit = OFF &...

- Page 109 MENU RESOLUTION key x 2 Local Test Self Diagnosis Sens. Calibration LED Test Tone Send Test Modem Send Test Modem Rec. Test MF(Tone) Test Tone(T/F) Test LOOP BACK 1 LOOP BACK 2 INFO0 SENDING INFO1 SENDING INFO3 SENDING PULSE (1KHZ) SEND PULSE (2KHZ) SEND PULSE (N2KHZ) SEND Setup...

- Page 110 System Reset All Data CLR Location Data CLR Config. Data CLR Default Type Set PC Loading G4 PC Loading OKIFAX 5700/5900 2 - 20...

- Page 111 2.9.2 Technical Functions: Setup 1. This section explains items generally conducted by service personnel, not by users. (1) Step access 1) The machine is standby state with no document. 2) Press the MENU/EXIT key once. 3) Press the RESOLUTION key twice. The display will be shown the “TECHNICAL PRG.”.

- Page 112 2.9.2.1 Technical Functions Operation 1 Select Menu is shown as below: 1. Local Test 2. Technical Setup: Go to Section 2.9.2.2 3. System Reset 4. Default Type Set 5. PC Loading 6. G4 PC Loading M E N U 6 P O L L I N G T X / R X 7 >...

- Page 113 2.9.2.2 Technical Functions Operation 2 Setup 01: Service Bit (OFF/ON) 02: Monitor Cont. (OFF/ON) 03: Country Code (selecting the country code) 04: Time/Date Print (OFF/ONCE/ALL) 05: TSI Print (OFF/ON) 06: TAD Mode (OFF/TYPE1/TYPE2/TYPE3) 07: Real Time Dial (OFF/TYPE1/TYPE2) 08: TEL/FAX Switch (OFF/ON) 09: MDY/DMY (Month/Day/Year or Day/Month/Year)

- Page 114 T E C H N I C A L P R G . T E C H N I C A L P R G . X X <Speed Access> 1 L O C A L T E S T 1 >...

- Page 115 <Speed Access> ENTER/ S E T U P 0 8 T E L / F A X S W I T C H "08" 0 7 R E A L T I M E D I A L > O F F 0 8 >...

- Page 116 <Speed Access> ENTER/ "15" S E T U P 2.9.2.2.2 T1(RX) TIMER VALUE 1 4 T 1 ( T X ) T I M E R V A L U E 1 5 > T 1 ( R X ) T I M E R V A L U E 1 6 T 2 T I M E R * 1 0 0 M S ENTER/ "16"...

- Page 117 <Speed Access> ENTER/ "22" S E T U P 2.9.2.2.6 T/F TONE ATT. 2 1 A T T E N U A T O R 2 2 > T / F T O N E A T T . 2 3 M F A T T . ENTER/ S E T U P "23"...

- Page 118 <Speed Access> ENTER/ "29" S E T U P 2 9 V 3 4 T X R E T R Y 2 8 T R L A T C H C U R R E N T > O F F 2 9 >...

- Page 119 <Speed Access> ENTER/ S E T U P 3 6 J B I G F A C I L I T Y "36" 3 5 P R I N T P R I O R I T Y > O F F 3 6 >...

-

Page 120: T1 (Tx) Timer Value

2.9.2.2.1 T1 (TX) Timer Value Set the T1 timer (call connection wait time: XTTO) for transmission. S E T U P T E C H N I C A L P R G . 1 4 1 3 H / M O D E M R A T E 1 >... -

Page 121: T1 (Rx) Timer Value

2.9.2.2.2 T1 (RX) Timer Value Set the T1 timer for reception. The time from issue of the first DIS to issue of a signal is checked. If a time-out occurs, the line is disconnected. S E T U P T E C H N I C A L P R G . 1 5 1 4 T 1 ( T X ) T I M E R V A L U E 1 >... - Page 122 2.9.2.2.3 T2 Timer *100ms Registers the time duration (in seconds) for which the fax detects the EOL interval during reception of phase C. The fax disconnects the line when EOL cannot detect within T2 Timer. S E T U P T E C H N I C A L P R G .

- Page 123 2.9.2.2.4 Error Criterion Registers the threshould value whether to transmit RTN or MCF signal when the error occurs in received data. S E T U P T E C H N I C A L P R G . 1 8 1 7 D I S B I T 3 2 1 >...

- Page 124 2.9.2.2.6 T/F Tone Att. Adjusts the attenuation (dB) for the quasi-ring back tone send signal of TEL/FAX switching. Adjusting value is 0 to 15dB in one dB steps. S E T U P T E C H N I C A L P R G . 2 2 2 1 A T T E N U A T O R 1 >...

- Page 125 2.9.2.2.8 Ring Dura. *10ms Selects the minimum ring detection time to meet country's requirements. Adjusting time is 100MS to 990MS in 10MS steps. S E T U P T E C H N I C A L P R G . 2 4 2 3 M F A T T .

-

Page 126: Led Headstrobe

2.9.2.2.10 LED Headstrobe Setting of LED print head strobe signals (00000 - 11111). Selection of strobe sidth in LED head. "00000" is lightest and "11111" is darkest. S E T U P T E C H N I C A L P R G . 2 6 2 5 C M L T I M I N G * 1 0 0 M S 1 >... - Page 127 2.9.2.3 Technical Functions (Setup) • Table 2.9.2.3 shows the initial setting items and their purpose. (The default setting is different by the individual countries.) • Each item can be accessed by entering it on Technical Setup. • The detailed procedures of the initial setting items will be explained on the following tables.

- Page 128 Table 2.9.2.3 Technical Functions: Setup (2/11) Item Specifications Time and date print Determine whether the date and time set on the local machine are to be printed at the beginning of the re- ceived image. 1) Setting values OFF/ONCE/ALL selectable. OFF: Not printed ONCE: Printed on page 1 only...

- Page 129 Table 2.9.2.3 Technical Functions: Setup (3/11) Item Specifications TAD mode (For external tele- Switches between TAD modes. phone answering device.) This setting is required to determine whether TAD is to be selected in the AUTO ANSWER mode and set the fax operation to be performed after completion of TAD-side operation (response).

- Page 130 Table 2.9.2.3 Technical Functions: Setup (4/11) Item Specifications TEL/FAX switching Determine whether the TEL/FAX mode can be selected in the AUTO ANSWER mode. 1) Setting values Selective OFF: Not selective * When OFF is selected in the TEL/FAX mode, the FAX mode will be selected automatically.

- Page 131 Table 2.9.2.3 Technical Functions: Setup (5/11) Item Specifications MH only Determine whether only MH coding is to be handled forcibly. Switches the function of limiting the image compression to MH codes only. This setting is required when the line noise affects the received image.

- Page 132 Table 2.9.2.3 Technical Functions: Setup (6/11) Item Specifications DIS bit32 Determine whether the thirty-second bit (expansion bit) of DIS is to be sent out. 1) Setting values ON: Transmits a bit32 and a successing bit 32. OFF: Not transmit * When OFF is selected, machines of other compa- nies cannot receive documents in the EX.FINE, SEP/SUB mode or JBIG.

- Page 133 Table 2.9.2.3 Technical Functions: Setup (7/11) Item Specifications Attenuator Set the FAX signal attenuator (level). • Since the maximum send signal power level (dB) of the fax is at 0dB, you can select 0dB to -15dB in one dB steps for the send signal power level. 1) Setting values 0-15 dB se;ectable (in 1 dB steps): except FRE FRE: 7-15dB...

- Page 134 Table 2.9.2.3 Technical Functions: Setup (8/11) Item Specifications LED head strobe Set the LED head strobe time. The larger the value, the darker the image. 1) Setting values 00000 to 11111 (5 bits) Note1: When the rank marking of the new replaced LED print head (new part) is same as that of the old used LED print head (old part), you do not always have to set the LED print head strobe signal.

- Page 135 Relay initiate transmission operation cannot be performed. * If REMOTE DIAGNOSIS is set to ON although NSF Switch (this setting) is set to OFF, an NSF is sent and sent immediately if Oki’s original function is ON (confidential, etc.). OKIFAX 5700/5900 2 - 45...

- Page 136 Table 2.9.2.3 Technical Functions: Setup (10/11) Item Specifications ID/TSI priority Determines whether the personal ID or TSI is given priority during LCD display and printing. 1) Setting values Personal ID is given priority TSI: TSI is given priority ID/TSI PRIORITY=ID ID/TSI PRIORITY=TSI LCD display during LCD display during...

- Page 137 Table 2.9.2.3 Technical Functions: Setup (11/11) Item Specifications Print priority Determine whether the memory is mainly used for printing. This setting is required to rescue the image data that cannot be stored in the page memory if ACC compres- sion is carried out during PC/LAN printing. 1) Setting values Relationships between settings and page memory capacities are as follows:...

- Page 138 2.9.2.4 TEL/FAX automatic switching This function is used for the purpose of TEL/FAX automatic switching as follows. 1) If the machine detects a call with a CNG signal indicating an auto send facsimile call, it starts an automatic document receiving operation. 2) If machine detects a call without a CNG signal, machine generates the buzzer sounds as a telephone call.

- Page 139 (20/35 sec) LIFT HANDSET PRESS STOP TO CANCEL Load document NSF, CSI, DIS Press START Button AUTO REC. START Manual OKI TOKYO Transmission PAGE 001 RECEIVING G3/33.6K CML"OFF" 1 sec 1 sec 3.2 sec To detect CNG signal Notes *1: Ring Back Tone — 1 sec. ON, 3.2 sec. OFF *2: When you want to talk by phone, pick up handset.

- Page 140 2.9.2.5 TAD mode • TAD: Telephone Answering Device • TAD can be connected to extenal telephone terminal to record your messages. • TAD records your speech and switches an automatic voice message response to the calling station. Note1: A choice of TAD mode is available by technical Function (Setup No.06). Note2: The predetermined time is selectable between 20 or 30 sec.

- Page 141 • TAD mode flow chart 1) In case of TYPE2: If the fax does not CNG signal during working of TAD, the fax will go to standby state. 2) In case of TYPE 3: The fax does not detect CNG signal during 15 seconds from TAD operation starting. The fax starts CNG signal detection after 15 seconds from TAD operation.

- Page 142 2.9.2.6 Outline of Parallel Pick Up Parallel pick up is a function that controls a fax (to make a fax in receive mode) from a telephone set connected parallel to a fax. The two possible parallel connections of telephone sets A and B are shown in the figure. Remote control FAX (OKIFAX 5700/5900 etc.) To Modem...

- Page 143 (1/2) TEL1 S1.1~2 OFF-HOOK TEL2 Detector (2/2) I SW S1 - 3~6 Ring Detector " Impedance C31 R590 matching CN15 ~ Loop CN45 Current Detection MUTE LINE , AR arresters to Modem MF 2-digit Receiving special code CML: ON sensitivity MUTE circuit...

- Page 144 2.9.3 User’s Functions This section explains the items usually set up by general users. • Select Menu is shown as below: 1. Delayed TX 2. Delayed Batch TX 3. Priotity TX 4. Confidential TX 5. Relayinitiate TX 6. Polling TX/RX 7.

- Page 145 Menu selection 1 2 : 0 0 F A X 1 0 / 0 1 / 1 9 9 8 1 2 : 0 0 T E L Document on hopper S E L E C T L O C A T I O N ( S ) M E M O R Y F R E E 1 0 0 % O R P R E S S C O P Y MENU Key...

- Page 146 2.9.4 Location Program 1) The machine is standby state with no document. 2) Press the MENUEXIT key once. 3) Press the SHIFT DOWN ( ) key two times. 4) The menu option “9 LOCATION PROGRAM” indicated by the blinking cursor is se- lected, and press the ENTER/SHIFT RIGHT ( ) key.

-

Page 147: Location Program

Location Program M E M U 8 R E P O R T P R I N T 9 > L O C A T I O N P R O G R A M 1 0 S E T U P ENTER/ L O C A T I O N P R O G R A M ENTER/... - Page 148 Table 2.9.4.1 Location Program (1/2) Item Specifications Speed Dial Register speed dial number. (LOC#/NAME/ALT#/Communication parameters) * Only LOC# may be registered. (If NAME is omitted, location search will not be made.) 1) Number of speed dials OKIFAX 5700: 1-140 (1-40 are assigned to ONE TOUCH keys.) OKIFAX 5900: 1-230 (1-80 are assigned to ONE TOUCH keys.)

- Page 149 Table 2.9.4.1 Location Program (2/2) Item Specifications Batch TX time Set a batch transmission time (24-hour system). When a time is specified, locations can be specified during batch transmission operation. 1) Number of batch TX times that can be registered OKIFAX 5700/5900: 10 (Speed dial numbers 31-40 are assigned.) * Registration is enabled if the specified speed dial...

- Page 150 2.9.5 Setup 1) The machine is standby state with no document. 2) Press the MENU key once. 3) Press the SHIFT DOWN ( ) key three times. 4) The menu option “10 SETUP” indicated by the blinking cursor is selected, and press the ENTER/SHIFT RIGHT ( ) key.

- Page 151 M E N U 9 L O C A T I O N P R O G R A M 1 0 > S E T U P 1 1 C O U N T E R ENTER/ S E T U P ENTER/ 1 >...

-

Page 152: Clock Adjustment

2.9.5.1 Clock Adjustment <Speed Access> S E T U P M E N U 1 > C L O C K A D J U S T M E N T 6 P O L L I N G T X / R X 2 I D / P A S S W O R D P R G . -

Page 153: Id/Passward Programming:

2.9.5.2 ID/Passward Programming: 01. TSI/CSI 02. Sender ID 03. Personal Box 04. Mem. Password 05. Restrict ID 06. ISDN TID (Country Code/ISDN No./ISDN ID) 07. ISDN Sub No. <Speed Access> S E T U P M E N U 1 C L O C K A D J U S T M E N T 6 P O L L I N G T X / R X 2 >... -

Page 154: Tsi/Csi

2.9.5.2.1 TSI/CSI This function is used to register TSI/CSI. <Speed Access> I D / P A S S W O R D P R G . M E N U 0 1 0 1 > T S I / C S I 6 P O L L I N G T X / / R X 0 2 S E N D E R I D 7 >... -

Page 155: Sender Id

2.9.5.2.2 Sender ID This function is used to register a sender ID. <Speed Access> I D / P A S S W O R D P R G . M E N U 0 2 0 1 T S I / C S I 6 P O L L I N G T X / / R X 0 2 >... - Page 156 2) Confidential A box used only for confidential reception. Either sub frame or Oki mode (NSF) can be selected. When a confidential box is opened, a password must be registered so that other persons cannot print data.

- Page 157 Table 2.9.5.2 ID/Password Prg. (2/3) Item Specifications Mem. Password Set the password for using the Auto Answer Mode (MEM.: Memory only reception mode). Persons who do not know the password cannot make changes or print memory data in the Auto Answer Mode (MEM. mode). This setting is disabled when Auto Answer Mode is set to MEM.

- Page 158 Table 2.9.5.2 ID/Password Prg. (3/3) Item Specifications ISDN TID Set a terminal ID. 1) Setting values This setting consists of the following: - Country code 3 characters (digits only) - ISDN No. (subscriber number) 20 characters (digits only) - ISDN ID (subscriber code) 10 characters (alphabetic characters, lowercase characters) * The setting data must be transferred to the G4...

-

Page 159: Machine Settings:

2.9.5.3 Machine Settings: 10: Auto Answer Mode (FAX, TEL, T/F, TAD, MEM, PC, and FWD) 11: Monitor Volume (OFF/LOW/MID./HIGH-MID./HIGH) 12: Buzzer Volume (LOW/MIDDLE/HIGH) 13: User Language (ENGLISH/OTHER: Second language) 14: Remote Diagnosis (OFF/ON) 15: TX Mode Default (STANDARD/FINE/EXTRA FINE/PHOTO) (LIGHT/NORMAL/DARK) 16: No Toner Mem. - Page 160 <Speed Access> S E T U P M E N U X X 2 I D / P A S S W O R D P R G . 6 P O L L I N G T X / R X 3 >...

- Page 161 <Speed Access> 1 6 T X M O D E D E F A U L T M A C H I N E S E T T I N G S ENTER/ "16" > O F F 1 5 T X M O D E D E F A U L T 1 6 >...

- Page 162 <Speed Access> ENTER/ M A C H I N E S E T T I N G S 2 3 S E N D E R I D "23" 2 2 T O N E R S A V E >...

-

Page 163: Auto Answer Mode

2.9.5.3.1 Auto Answer Mode This function is used to set up the auto answer mode. M A C H I N E S E T T I N G S M E N U 1 0 > A U T O A N S W E R M O D E 6 P O L L I N G T X / R X 1 1 M O N I T O R V O L U M E 7 >... -

Page 164: Tx Mode Default

2.9.5.3.2 TX Mode Default This function is used to set default values for the transmission mode selected with a docu- ment set in the feeder. M A C H I N E S E T T I N G S M E N U 1 4 R E M O T E D I A G N O S I S 6 P O L L I N G T X / R X... - Page 165 Table 2.9.5.3 Machine Settings (1/5) Item Specifications Auto answer mode Set up the auto answer mode (FAX/TEL/T/F/TAD/MEM/ PC/FWD) The following restrictions are placed on individual mode settings according to the machine status and setting: 1) T/F (TEL/FAX AUTO SW.) mode This mode can be selected only when TEL/FAX Switch is set to ON.

- Page 166 Table 2.9.5.3 Machine Settings (2/5) Item Specifications User language Select the language used for LCD display or report printing. 1) Setting values English/Other Other (second language): GER (German), FRE (French), etc. * English/Other is selected according to country code. Remote diagnosis Determine whether remote maintenance is to be enabled from the remote center.

- Page 167 Table 2.9.5.3 Machine Settings (3/5) Item Specifications Memory full save When the memory becomes full during read, the operator must determine whether the read pages are to be saved or canceled. Determine whether the read pages are to be saved or canceled automatically if the operator forget to save/cancel them and therefore an operation T.O.

- Page 168 Table 2.9.5.3 Machine Settings (4/5) Item Specifications ECM function Determine whether ECM transmission is to be performed. 1) Setting values ON (ECM transmission performed)/OFF (ECM trans- mission not performed) Closed network Set up closed network. The TSI/CSI of the remote machine is compared with the low-order 4 digits of the speed dial of the local machine.

- Page 169 Table 2.9.5.3 Machine Settings (5/5) Item Specifications 2’nd paper size Set the size of recording paper in the second tray. EXEC./JIS-B5/A5 can be set only when LAN is mounted. 1) Setting values A4/LETTER/LEGAL 13/LEGAL 14/EXEC./JIS-B5/A5 * The setting data must be transferred to the G4 board.

-

Page 170: Dial Options:

2.9.5.4 Dial Options: 40: Redial Tries (0 to 10 •FRE, 0 to 5=FRE) 41: Redial Interval (1 to 6 •FRE, 1 to 12 =FRE) 42: Auto Start (OFF/ON) 43: Dial Tone Detect (OFF/ON) 44: Busy Tone Detect (OFF/ON) 45: MF/DP (DP/MF) 46: Pulse Dial Rate (10/16/20 pps) - Page 171 <Speed Access> S E T U P M E N U X X 3 M A C H I N E S E T T I N G S 6 P O L L I N G T X / R X 4 >...

- Page 172 <Speed Access> "47" ENTER/ D I A L O P T I O N S 4 7 P U L S E M A K E R A T I O 4 6 P U L S E D I A L R A T E 3 3 % 4 7 >...

-

Page 173: Redial Tries

2.9.5.4.1 Redial Tries This function is used to set the number of redial tries. D I A L O P T I O N S M E N U 4 0 > R E D I A L T R I E S 6 P O L L I N G T X / R X 4 1 R E D I A L I N T E R V A L 7 >... -

Page 174: Redial Interval

2.9.5.4.2 Redial Interval This function is used to set an auto redial interval. D I A L I N G O P T I O N S M E N U 4 0 > R E D I A L T R I E S 6 P O L L I N G T X / R X 4 1 R E D I A L I N T E R V A L 7 >... -

Page 175: Dial Prefix

2.9.5.4.3 Dial Prefix This function is used to set the access digits for connecting a PBX line to the public line. D I A L O P T I O N S M E N U 5 2 5 0 P B X L I N E 4 P O L L I N G T X / R X 5 1 F L S / E A R T H / N O R M A L 5 >... - Page 176 Table 2.9.5.4 Dial Options (1/3) Item Specifications Redial tries Sets on the redial tries to meet the regulations of the installed country. 1) Setting values Country code = Other than FRE: 0-10 (in one-try steps) FRE: 1-5 (in one-tray steps) Redial Interval Set an automatic redialing interval to meet the regula- tions of installed country.

- Page 177 Table 2.9.5.4 Dial Options (2/3) Item Specifications Pulse Dial Rate Determine a DP pulse rate used at call origination. 1) Setting values 10pps/16pps/20pps selectable * Selection is skipped over when the ISDN board is mounted. (selection allowed if SERVICE BIT=ON) Pulse Make Ratio Set a DP make ratio at used at call origination.

- Page 178 Table 2.9.5.4 Dial Options (3/3) Item Specifications Flash/Earth/Normal Set the method of switching between flash and earth modes for PBX line. 1) Setting values NORMAL/FLASH/EARTH selectable (PBX line origi- nation types) * Selection is skipped over when the ISDN board is mounted.

-

Page 179: Incoming Options:

2.9.5.5 Incoming Options: 60: Incoming Ring (OFF/ON/DRC) 61: Remote Receive (OFF/00/11/22/33/44/55/66/77/88/99/**/##) 62: T/F Timer Programming (20/35SEC) 63: Continuous Tone (OFF/ON) 64: PC/FAX Switch (OFF/ON) 65: CNG Count (1 to 5) 65: Ring Response (1RING/5SEC/10SEC/15SEC/20SEC) 66: Distinctive Ring (OFF/ON/SET) <Speed Access> S E T U P M E N U X X 4 D I A L O P T I O N S... - Page 180 <Speed Access> ENTER/ "66" I N C O M I N G O P T I O N S 6 6 R I N G R E S P O N S E 6 5 C N G C O U N T >...

-

Page 181: Cng Count

2.9.5.5.1 CNG COUNT I N C O M I N G O P T I O N S M E N U 6 4 P C / F A X S W I T C H 6 P O L L I N G T X / R X 6 5 >... -

Page 182: Distinctive Ring

2.9.5.5.2 Distinctive Ring This function is used to make settings for distinctive ring learning (remembrance) and detec- tion. I N C O M I N G O P T I O N S M E N U 6 5 C N G C O U N T 6 P O L L I N G T X / R X 6 6 R I N G R E S P O N C E 7 >... - Page 183 Table 2.9.5.5 Incoming Options (1/3) Item Specifications Incoming Ring Set up the soft ringer. Instead of ringer circuit, software can control built-in speakerto ring sound. 1) Setting values ON (Sounded)/OFF (Not sounded)/DRC (Sounded during DRC detection) * Selection is skipped over when the ISDN board is mounted.

- Page 184 Table 2.9.5.5 Incoming Options (2/3) Item Specifications T/F Timer Programming Set the time till start of automatic reception when the operator has performed no operation for the call termi- nated in the TEL/FAX mode. 1) Setting values 20SEC/35SEC selectable * Selection is skipped over when the ISDN board is mounted.

- Page 185 Table 2.9.5.5 Incoming Options (3/3) Item Specifications Distinctive Ring Determine whether a distinctive is to be remembered and detected. Only in GER, SUI, and AUT modes, OFF is set as the default. When ON is selected, reception operation starts only when a remembered ring pattern is detected.

-

Page 186: Report Options:

2.9.5.6 Report Options: 70: MCF. (Single-Loc.) (OFF/ON) 71: MCF. (Multi-Loc.) (OFF/ON) 72: Image in MCF. (OFF/ON) 73: Error Report (MCF.) (OFF/ON) <Speed Access> S E T U P M E N U X X 5 I N C O M I N G O P T I O N S 6 P O L L I N G T X / R X 6 >... - Page 187 Table 2.9.5.6 Report Options Item Specifications Message Confirmation Report Determine whether a single location transmission result (Single lacation) report is to be output automatically. 1) Setting values Report is output automatically. OFF: Report is not output automatically. Message Confirmation Report Determine whether a multi-location transmission result (Multiple locations) report is to be output automatically.

-

Page 188: Lan Options:

2.9.5.7 LAN Options: 80: Auto Tray Switch (OFF/ON) 81: Paper Size Check (OFF/ON) 82: LAN Print Timeout (5SEC/30SEC/5MIN) 83: IP Address See Section 2.9.5.7.1 84: Subnet Mask See Section 2.9.5.7.2 85: Default Gateway See Section 2.9.5.7.3 <Speed Access> S E T U P M E N U X X 5 I N C O M I N G O P T I O N S 6 P O L L I N G T X / R X... -

Page 189: Ip Address

2.9.5.7.1 IP Address This function is used to display the IP address from the NIC, confirm the data from the terminal, and change settings. L A N O P T I O N S M E N U 8 2 L A N P R I N T T . O . 6 P O L L I N G T X / R X 8 3 >... - Page 190 Entering an IP address value 1) Setting data is received from NIC. When HSP error has occured during the data recep- tion, the machine returns to the "LAN OPTIONS" menu screen after "FUNC. NOT AVAIL" is displayed during 3 seconds. 2) When three digits of the network ID or host ID have been entered, the blinking cursor automatically moves to the position following the dot.

-

Page 191: Subnet Mask

2.9.5.7.2 Subnet Mask This function is used to display the sub net address from NIC, confirm the data from the terminal, and change settings. L A N O P T I O N S M E N U 8 3 I P A D D R E S S 6 P O L L I N G T X / R X 8 4 >... -

Page 192: Default Gateway

2.9.5.7.3 Default Gateway This function is used to display the gateway address from NIC, confirm the data from the terminal, and change settings (NIC option setting). L A N O P T I O N S M E N U 8 3 I P A D D R E S S 6 P O L L I N G T X / R X 8 4 S U B N E T M A S K... - Page 193 Table 2.9.5.7 LAN Options (1/2) Item Specifications Auto Tray Switch Determine whether the current tray is automatically switched to another tray when the current tray runs out of paper in the LAN print mode. This setting can be made only when the second tray is installed.

- Page 194 Table 2.9.5.7 LAN Options (2/2) Item Specifications Subnet Mask Display the subnet address from the NIC, check the data from the terminal, and change the setting. 1) Setting values 32 bits are divided into four 8-bit decimal values for setting. The decimal values are separated by dots as shown below.

-

Page 195: User Default Setting

2.9.6 User Default Setting OKIFAX 5700/5900 2 - 105... -

Page 196: Technical Default Setting

2.9.7 Technical Default Setting OKIFAX 5700/5900 2 - 106... -

Page 197: Default Setting Of Dial Parameters

2.9.8 Default Setting of Dial Parameters OKIFAX 5700/5900 2 - 107... -

Page 198: Off-Line Tests

2.9.9 Off-line Tests (1) Purpose Activate self-diagnosis which includes: 1) Main board • CPU ROM version printing • CPU RAM check • PROG version printing • LANGUAGE version printing • DEFAULT version printing • MODEM version printing • RAM check •... -

Page 199: Self Diagnosis Flow

2.9.9.1 Self Diagnosis Flow To check ROMs, RAMs and printing function. Test report will be automatically printed out. L O C A L T E S T 1 > S E L F D I A G N O S I S 2 S E N S . - Page 200 SELF DIAGNOSIS REPORT 12/24/1998 12:00 ID=0dc Takasaki MAIN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM1 VERSION aaaa HASH hhhh PROGRAM2 VERSION aaaa HASH hhhh LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh DEFAULT TYPE M O D E M VERSION hhhh RAM1...

- Page 201 SELF DIAGNOSIS REPORT 12/24/1998 12:00 ID=0dc Takasaki MAIN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM1 VERSION aaaa HASH hhhh PROGRAM2 VERSION aaaa HASH hhhh LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh DEFAULT TYPE M O D E M VERSION hhhh RAM1...

- Page 202 Note: *1: a indicates an alphanumeric character; n indicates a numeric character (0 to 9); h indicates a hexadecimal number; and b indicates 0 or 1. *2: Printed when the option board is mounted and if not, entry lines following this line are not omitted.

-

Page 203: On-Line Tests

2.9.10 On-line Tests 1. Transmission (1) Load documents (2) Make sure that • The loaded documents are fed in automatically. • The STD and NORMAL lamps light. • The display shows SELECT LOCATION(S) OR PRESS COPY. (3) Dial the telephone number of the remote machine by the ten-key pad. (4) Make sure that the telephone number of the remote machine is shown on the dis- play. - Page 204 Typical Transmission flow OKIFAX 5700/5900 2 - 114...

- Page 205 Typical Reception flow OKIFAX 5700/5900 2 - 115...

-

Page 206: Installation Of Optional Units

2.10 Installation of optional units 2.10.1 Optional units (1) Items • Memory EXP. Board-RA1-/-2 • Board-G4A • Board-LAN • 2nd tray unit (2) Procedure • Turn the facsimile power switch OFF and remove the AC power cord. Note: Unplug the AC power cord from the wall outlet first and then from the facsimile. •... -

Page 207: Memory Board Installation Instruction

2.10.2 Memory Board Installation Instruction 1. Remove Cover-Rear, Plate-Rear Plate-Rear Cover-Rear 2. Connect Memory Board Memory Board 3. Attach Plate-Rear and Cover-Rear. OKIFAX 5700/5900 2 - 117... -

Page 208: Network Card Installation Instruction

2.10.3 Network Card Installation Instruction 1. Remove Cover-Rear, Plate-Rear and 2 piece of Plate-dummy. Plate-dummy Plate-Rear 2. Connect Network card with Adapter board, then, mount it into the room. Before installation, check #1 of Dip- Cover-Rear switch should be "ON" and #2 - #4 be "OFF". -

Page 209: G4 Board Installation Instruction

2.10.4 G4 Board Installation Instruction 1. Remove Cover-Rear, Plate-Rear and Plate-dummy. Caution: Remove only lower Plate-dummy. Plate-dummy Plate-Rear Cover-Rear 2. Mount G4 Board. G4 board 3. Attach Plate-Rear, and fix G4 (G4 board) board with 2 screws, then fix Plate- Rear. - Page 210 CHAPTER 3 BRIEF TECHNICAL DESCRIPTION...

- Page 211 Paper eject roller Paper eject Image data (Face down) board LED head Charger Exposure Paper Toner Doctor board eject cartridge blade board roller Charging Paper path Cleaning Developing Toner Cleaning Paper selector Developing roller roller supply roller eject (Face up) Inlet sensor Fusing Outlet sensor...

- Page 212 Fundamentals of the Electro-Photographic Process The electro-photographic process involves six sub-processes: (1) Charging (2) Exposure (3) Development (4) Transfer (5) Fusing (6) Cleaning Outline of each process is explained below. Process Illustration Description The surface of the electro- photographic Image drum is uniformly charged with negative charges by applying a negative Power...

- Page 213 Process Illustration Description The recording paper is placed over the Image drum surface and a EP drum positive charge, opposite in polarity to the toner, is applied to the reverse side of the paper from the transfer roller. The toner is attracted by the positive charge and is transferred to the paper.

-

Page 214: Actual Electo-Photographic Process

Actual Electo-photographic Process The electro-photographic process consists of six essential processes. The following Figure 3.2.1 provides a general description. 2 LED head Electro-photographic drum 1 Charge roller Toner 6 Cleaning roller 5 Heater roller 3 Developing roller Recording paper Back-up roller 4 Transfer roller * Process: 1 : Charging... -

Page 215: Boards And Units

Boards and Units The following boards and units constitute the facsimile transceiver machine. Standard • MCNT (Main control board) R76- (OKIFAX 5900) R76-2 (OKIFAX 5700) • V.34 Modem C34/H34- • NCU (Network Control Unit) UNC- (USA/Canada) WN5- (INT'L) DN5- (GER) FN5- (UK/France) •... -

Page 216: Overall Dimension And Mechanical Structure Of Okifax 5700/5900

Overall Dimension and Mechanical Structure of OKIFAX 5700/5900 Separation rubber Feed roller ADF roller Pinch roller Scan roller Sub roller Feed roller Document exit Document Paper exit (face down) Image sensor Paper exit (face up) EP drum Paper Hopping roller Heater roller Resist roller Backup roller... - Page 217 HIGH-VOLTAGE POWER SUPPLY MCNT LOW-VOLTAGE G4 or ADAPTER POWER SUPPLY MODEM INLET MEMORY AC SWITCH BATTERY Fig. 3.4.1-1 Overall Dimension and Mechanical Structure 2/2 OKIFAX 5700/5900 3 - 7...

- Page 218 CHAPTER 4 MECHANICAL DISASSEMBLY REASSEMBLY...

-

Page 219: Precautions For Parts Replacement

General The section explains the procedures for replacement of parts, assemblies, and units in the field. Only the disassembly procedures are explained here. For reassembly, reverse the disassembly procedure. Precautions for Parts Replacement DANGER Do Not You may be subjected to high-voltage electric shock by touching the following parts without an insulating material: Touch ! a. - Page 220 (2) Do not disassembly the printer as long as it is operating normally. (3) Do not remove parts which do not have to be touched; try to keep the disassembly to a minimum. (4) Use specified service tools. (5) When disassembling, follow the laid out sequences. Parts may be damaged if these se- quences are not followed.

-

Page 221: Tools

Tools Table 4.1 shows the tools required for the replacement of parts such as circuit boards and mechanical units. Q'ty Remarks Service tools Philips screw driver (L) Philips screw driver (M) Flat screw drivers (S) Philips screw driver (S) Radio pliers Nippers Multimeter 1 Short-ciucuit test... - Page 222 Start LED Print Doc. table Head Rear Cover NCU Cover Plate guard NCU Board Side Cover (R) Side cover (L) Speaker Control Separation Panel unit Rubber Control panel Assy OPE-Board Frame Feed Roller scanner Sensor Roller (U) Assy Scan Motor Exit Roller Frame Sub-roller...

- Page 223 Appearance of the OKIFAX 5700/5900 OKIFAX 5700/5900 4 - 5...

-

Page 224: Document Table Cover

4.3.1 Document Table Cover Screw 1. Open the operation panel. 2. Remove the cover by unscrewing four screws. 4.3.2 Rear Cover and NCU Cover 1. Unscrew two screws (1). 2. Slide the rear cover up slightly and pull it forward for removal. 3. -

Page 225: Main Cover

4.3.3 Main Cover 1. After removing the document cover, rear Scanner unit cover, and NCU cover, open the scanner unit and stacker cover. Caution: Secure the scanner unit by engaging its hooks with the stacker cover. Stacker cover Two screws 2. - Page 226 4. First, disengage the two hooks at the back. Next, remove the main cover with it lifted. Two hooks Main cover OKIFAX 5700/5900 4 - 8...

-

Page 227: Operation Unit

Operation unit 4.3.4 Operation Unit 1. Disconnect the connector. Connector 2. Open the operation unit and slide it leftward for removal. Caution: Pull out the connector cable from the frame. Operation unit Connector cable Frame OKIFAX 5700/5900 4 - 9... -

Page 228: Ncu Board

4.3.5 NCU Board Remove the NCU board by unscrewing two screws. Caution: Earth cable position is different from each machine version. NCU board Earth cable Earth cable Two screws 4.3.6 MODEM Board 1. Remove the plate by unscrewing two screws (1). 2. -

Page 229: Plate Package

4.3.7 Plate Package 1. Unscrew two screws (1) and pull out the rear plate. Rear plate Two screws 1 2. Unscrew four screws (2) and take out Screw 2 the package plate. Caution: Before removing the package plate, disconnect Battery connector. -

Page 230: Scanner Unit (Cis)

4.3.8 Scanner Unit (CIS) 1. Disconnect six connectors (CN8, 9, 13, 14, 15 and SP) Connectors/cores 2. Remove four cores. 3. Remove the torque limiter by unscrewing two screws. Torque limiter Two screws 4. Pull out the connector cable from the Scanner unit stacker frame and remove the scanner unit. -

Page 231: Stacker Frame

4.3.9 Stacker Frame Remove the AC inlet and unscrew three screws to remove the stacker frame. Stacker frame AC inlet 4.3.10 Printer Unit 1. Disconnect three flat cables and two Screw Two connector cables connector cables 2. Remove the shield by unscrewing one Three flat cables screw. - Page 232 3. Remove the printer unit by unscrewing Six screws six screws. Caution: The number of pins of the CN2 connector is the same as that of the CN3 connector; how- ever, colors of these connec- tors are different (CN2 is yellow and CN3 is white).

-

Page 233: Main Board

4.3.12 Main Board 1. Remove the shield plate by unscrewing Shield plate six screws. 2. Unscrew four screws and disconnect two connector cables, then slide the main board for removal. 4.3.13 Contact Assembly and High-/ Low-voltage Power Supply Boards 1. Remove the high-/low-voltage power Low-voltage power supply board supply boards by unscrewing seven screws. -

Page 234: Disassembling The Operation Unit

4.3.14 Disassembling the Operation Unit 1. Remove the paper guide (U) assembly by unscrewing two screws. Two screws Paper guide (U) 2. Unscrew 22 screws and disengage six hooks to remove the P76/P77 board P77 board assembly. 3. Remove the numeric key pad. P76 board OKIFAX 5700/5900 4 - 16... - Page 235 One touch key Numeric key pad 4. Disconnect the white connector to separate the P76 board from the P77 P77 board board. Spring connector Caution: The white connector is a spring P76 board connector. Be careful not to damage the connector when disconnecting it.

-

Page 236: Disassembling The Scanner Unit (L)

Paper guide (U) Assembly Separation Rubber Separation Rubber The Separation Rubber can be removed from the Paper Guide (U) Assembly. Feed Roller 1. Remove the ground cable by removing the two screws 5. Feed Roller 2. Remove the Feed Roller by removing the gear and ADF bearings. - Page 237 Two screws Paper Guide Unscrew two screws and remove the paper guide. (Removing the Paper Guide) 1. Insert the screwdriver in the holes (two) in the paper guide and push the screw- Paper guide driver in the direction of the arrow (1) to release the hooks.

-

Page 238: Scanner (Cis)

Install the paper guide while pressing the PC1 lever. PC1 lever * This is necessary to prevent the lever from sticking. 4.3.16 Scanner (CIS) 1. Remove the CIS assembly by discon- necting one connector. 2. Remove the CIS from the bracket. CIS assembly (* Disengage the hook on the side where there is no connector.) -

Page 239: Speaker

4.3.18 Speaker Remove the speaker with it pushed in the direction of the arrow (1), then disconnect the cable. Caution: Be careful not to damage the portion (2) of the frame indi- cated by the arrow. 4.3.19 Scanner Motor Portion (2) Speaker OKIFAX 5700/5900 4 - 21... -

Page 240: Disassembling The Printer Unit

1. Remove the scanner latch. 2. Remove the motor cable and unscrew two screws (1) to remove the motor along with the bracket. Four motor screws* Caution: Do not remove the four screws* securing the motor. Bracket Motor Scanner latch Two screws 1 3. - Page 241 Drum/Resist Motor 1. Remove the drum motor by unscrewing two screws 1. 2. to Remove the resist motor by unscrew- ing two screws 2. Drum motor Resist motor Motor Bracket Two screws 2 Two screws 1 Remove the bracket by releasing two hooks.

-

Page 242: Led Head

1. Open the stacker cover and open the left-hand latch slightly to pull the LED head out. Next, disconnect flexible LED head cables (two) along with connectors. Latch Stacker cover Caution: Disconnect the flexible cables with them inserted in connec- tors. - Page 243 1. Remove two springs, pull the shield toward you, and remove the LED head cover. Two springs Caution: Do not lose the springs. LED head cover 2. Remove the TLK cover by releasing hooks (four). Caution: Pay attention to two springs. LED head cover 3.

-

Page 244: Fusing Unit

1. Disconnect the flat cable. 2. Remove the Copy Stacker by pressing inward the two latches on it from the two Copy Stacker reset levers. Flat cable 3. Remove the Copy Stacker by spreading it from the lower base. Reset lever Reset lever 4.3.24 Fusing Unit... -

Page 245: Resist Roller, Hopping Roller, Sensor Plates

1. After removing the Lower Base, remove the spring. 2. Lift the left side of the Back-up Roller and pull it out leftwards. Back-up Roller Upper Cover Reset lever (L and R) Spring Caution: - Do not lose the ground washer. - Do not bend the ground plate. - Page 246 (1) Disassembly procedure 1) Resist Roller, Hopping Roller Resist Roller One-way Clutch Gear 1. First, carry out the disassembly proce- dure up to the point of the Lower Base removal. (Refer to sub-item 4.3.23.) 2. Remove the One-way Clutch Gear. 3.

- Page 247 Remove the eject guide assembly by releasing the left-hand hook. Eject guide assembly Hook Reassemby Procedure Carry out reassembly by reversing the disassembly procedure. OKIFAX 5700/5900 4 - 29...

- Page 248 CHAPTER 5 ADJUSTMENTS...

- Page 249 5 . 1 Setting of LED Print Head Drive Time • Adjustment point: Technical Function: Setup No. 26 * To bring the LCD up to Technical Function, press MENU key once, RESOLUTION key twice (In case of no message in memory). Note: When the rank marking of the replaced LED print head (new part) is the same as that of the used LED print head (old part), you do not always have to set the LED print head drive time.

-

Page 250: Confirmation Items

5.2.1 Confirmation Items The clock frequency and power voltage of the machine are not possible to adjust in the field. However, their measurement procedures are described here for confirmation of clock fre- quency and each voltage. Clock Frequency • Measurement point: R76 board;... -

Page 251: Measurement

5.2.2 Measurement 1) Trun the AC power OFF. 2) Carry out the disassembly procedure up to Cover assembly-top, Frame assembly- scanner, and Unit-printer. (Refer to the Mechanical Disassembly and Reassembly in Chapter 4.) 3) Connect extension cables to the R51 board. 4) Connect the frequency counter (for clock frequency), digital voltmeter (for power volt- age) and Oscilloscope (for SIG signal). - Page 252 CHAPTER 6 CLEANING MAINTENANCE...

-

Page 253: Replacement Of Consumable

Reference Item No. Part name Replacement in Fig.6.1 Toner Cartrige 3,000 sheets/4% duty (2,500 sheet for OKI-INT) (ITU-T document sample No.1) (For the second or later cartridge to a new I/D Unit) * The first toner cartridge installed in a new I/D unit will have a decreased yield. - Page 254 (3) Others Table 6.1 Reliability Item Specifications Document feeder Jam occurrence and misfeeds in the automatic document feeder will be less than one in 500 operations for all specified documents. Recording paper feeder Jam occurrence in the automatic paper feeder will be less than one in 1,500 operations and misfeeds will be less than one in 500 operations for all specified recording paper.

-

Page 255: Routine Inspection

Routine Inspection Basically, the routine inspection of following items is performed about half-yearly (or every one year) after the machine is installed. The description of routine inspection is shown in Table 6.2. Table 6.2 Routine Inspection Expected Use Before Reference Item No. Part name Replacement in Fig.6.2... - Page 256 Feed roller (2) ADF roller (4) Separation rubber (1) Scan roller (3) Contact image sensor Document exit Document Paper exit (face down) Paper exit (face up) I/D unit Paper (5) LED head (6) Printer unit Paper Fifure 6.2 Parts of Routine Inspection OKIFAX 5700/5900 6 - 4...

-

Page 257: Printer Counter Display/Clear

Printer Counter Display/Clear Note : The fonts displayed on the LCD operation panel may differ from the fonts written this manual. Purpose A user can clear the image drum unit and check some of the counters (such as the print counter, scan counter) by using the key or key. - Page 258 2-2. Procedure The following shows the case when the service bit has been set OFF & TONER COUNT CLEAR = ON. ENTER/ CLEAR Key C O U N T E R D R U M C O U N T 1 >...

-

Page 259: Printer Counter Display/Clear

Printer Counter Display/Clear Purpose The service personnel can clear and check the following data: • Image Drum • Toner • Image Drum (Total) • Print • Scan Procedure The following shows the case when the service bit has been set ON. ENTER/ CLEAR Key CLEAR Key... -

Page 260: Self-Diagnosis Test

Self-diagnosis Test Purpose To check ROMs, RAMs and printing function. Procedure L O C A L T E S T 1 > S E L F D I A G N O S I S 2 S E N S . C A L I B R A T I O N 3 L E D T E S T ENTER/ S E L F D I A G N O S I S... - Page 261 SELF DIAGNOSIS REPORT 12/24/1998 12:00 ID=0dc Takasaki MAIN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM1 VERSION aaaa HASH hhhh PROGRAM2 VERSION aaaa HASH hhhh LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh DEFAULT TYPE M O D E M VERSION hhhh RAM1...

- Page 262 Note: *1: a indicates an alphanumeric character; n indicates a numeric character (0 to 9); h indicates a hexadecimal number; and b indicates 0 or 1. *2: Printed when the option board is mounted and if not, entry lines following this line are not omitted.

-

Page 263: Sensor Calibration Test

Sensor Calibration Test Purpose To adjust the linearity of output levels of contact image sensor. L O C A L T E S T 1 S E L F D I A G N O S I S 2 > S E N S . C A L I B R A T I O N 3 L E D T E S T ENTER/ Prefeed is completed. -

Page 264: Leds Test

LEDs Test Purpose To check all LEDs on operation panel by lighting. Procedure L O C A L T E S T 2 S E N S . C A L I B R A T I O N 3 > L E D T E S T 4 T O N E S E N D T E S T ENTER/ STOP Key... -

Page 265: Tone Send Test

Tone Send Test Purpose To send the G3 tonal frequencies to the line. Procedure L O C A L T E S T 3 L E D T E S T 4 > T O N E S E N D T E S T 5 M O D E M S E N D T E S T ENTER/ T O N E S E N D T E S T... -

Page 266: High-Speed Modem Send Test

High-speed Modem Send Test L O C A L T E S T 4 T O N E S E N D T E S T 5 > M O D E M S E N D T E S T 6 M O D E M R E C . -

Page 267: High-Speed Modem Receive Test

6.10 High-speed Modem Receive Test Purpose To check the telephone line quality in combination with a remote station programmed to the high-speed modem send test mode. Procedure L O C A L T E S T 5 M O D E M S E N D T E S T 6 >... -

Page 268: Mf Send Test

6.11 MF Send Test Purpose To send the multi-frequencies of tone dialling to the line. Procedure L O C A L T E S T 6 M O D E M R E C . T E S T 7 > M F ( T O N E ) T E S T 8 T O N E ( T / F ) T E S T STOP Key ENTER/... -

Page 269: Tone (Tel/Fax)

6.12 Tone (TEL/FAX) Purpose To check the pseudo-ring back tone of TEL/FAX automatic switching. Procedure L O C A L T E S T 6 M O D E M R E C . T E S T 7 M F ( T O N E ) T E S T 8 >... -

Page 270: Protocol Dump Data Printing

6.13 Protocol Dump Data Printing Purpose To analyze the transmitted/received G3 protocol signals. Procedure • Manual print-out of the last communication. (a) Manual print-out M E N U 7 P R I N T F R O M M E M O R Y 8 >... -

Page 271: System Reset

6.14 System Reset Purpose To clear or initialize the following data: (a) Location data (b) Configuration data (default) Procedure T E C H N I C A L P R G . 2 S E T U P 3 > S Y S T E M R E S E T 4 D E F A U L T T Y P E S E T ENTER/ ENTER/... -

Page 272: Service Codes