Table of Contents

Advertisement

Quick Links

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN

THE AREA.

READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS WOOD INSERT. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

READ AND KEEP THIS MANUAL FOR REFERENCE

Printed in Canada

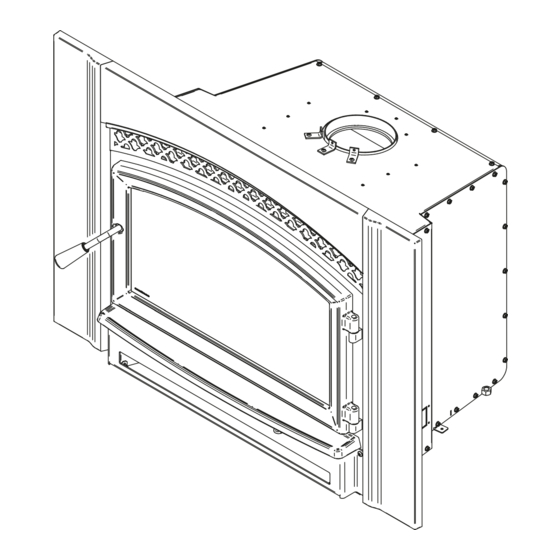

DESTINATION 2.7

INSERT

(EB00058 model)

Installation

and Operation

Manual

Safety tested according to

ULC S628, UL 1482 and

UL 737 by an accredited

laboratory.

US Environmental Protection

Agency phase II certified

wood insert compliant with

2020 cord wood standard.

< ≤

EPA

2.5

g/h

45998A

Advertisement

Table of Contents

Summary of Contents for Enerzone DESTINATION 2.7

- Page 1 Installation and Operation Manual DESTINATION 2.7 INSERT (EB00058 model) Safety tested according to ULC S628, UL 1482 and UL 737 by an accredited laboratory. US Environmental Protection Agency phase II certified wood insert compliant with 2020 cord wood standard. < ≤...

- Page 3 It is also highly recommended to register the warranty online at https://www.enerzone-intl.com/en/warranty/warranty-registration/ Registering the warranty will help to quickly find the information needed on the unit. Installation and Operation Manual - Destination 2.7 Insert Page 3...

-

Page 4: Table Of Contents

7. Masonry Fireplace Requirements ..................27 7.1 Fireplace and Chimney Condition ..................27 7.2 Chimney Caps .........................28 7.3 Adjacent Combustibles .....................28 7.4 Opening Size ........................28 7.5 Masonry Fireplace Throat Damper ..................28 Page 4 Installation and Operation Manual - Destination 2.7 Insert... - Page 5 Appendix 8: Blower Replacement .................... 51 Appendix 9: Removal Instructions .................... 53 Appendix 10: Exploded Diagram and Parts List ..............54 ENERZONE Limited Lifetime Warranty ..................57 Dealer: Installer: Phone Number: Serial Number: Installation and Operation Manual - Destination 2.7 Insert Page 5...

- Page 6 CERTIFICATION PLATE Page 6 Installation and Operation Manual - Destination 2.7 Insert...

-

Page 7: Part A - Operation And Maintenance

This product can expose you to chemicals including carbon monoxide, which is known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to www.P65warnings.ca.gov/ Installation and Operation Manual - Destination 2.7 Insert Page 7... -

Page 8: General Information

This appliance is officially tested and certified by an independent agency. Tested and certified in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and ASTM E3053-17. Carbon monoxide. Page 8 Installation and Operation Manual - Destination 2.7 Insert... -

Page 9: Specifications

CAN/CSA- Z240 MH standard. Tested and certified in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and draft ASTM WK47329-14 and EPA alt-127 (ASTM E3053-17 Installation and Operation Manual - Destination 2.7 Insert Page 9... -

Page 10: Dimensions

Figure 2: Side View - Minimum Insert Projection 4" 17 1/8" 102mm 436mm 2" 51mm 43 3/4" 1113mm 12 5/8" 321mm 24 1/4" 617mm Figure 3: Front View Figure 4: Side View - Maximum Insert Projection Page 10 Installation and Operation Manual - Destination 2.7 Insert... - Page 11 3/16" 17 1/2" 10 1/2" 446mm 268mm 12 3/8" 315mm 15 7/8" 25 3/8" 404mm 645mm 12 7/8" 328mm Figure 6: Door Opening Figure 7: Side View - Combustion Chamber Installation and Operation Manual - Destination 2.7 Insert Page 11...

-

Page 12: Epa Certification Loading

Leave the primary air control open for approximately 5 minutes and then close the primary air control halfway. After another 5 minutes, close the air control completely for the low burn rate and 3/8” open for the medium burn rate. Page 12 Installation and Operation Manual - Destination 2.7 Insert... -

Page 13: Materials

Although the insert may be able to heat the main living areas of the house to an adequate temperature, it is strongly recommended to also have a conventional oil, gas or electric heating system to provide backup heating. Installation and Operation Manual - Destination 2.7 Insert Page 13... -

Page 14: Emissions And Efficiency

The tree species the firewood is produced from is less important than its moisture content. The main difference in firewood from various tree species is the density of the wood. Hardwoods are denser than softwoods. Page 14 Installation and Operation Manual - Destination 2.7 Insert... -

Page 15: Log Length

Continually burning green or unseasoned wood produces more creosote and involves lack of heat and dirty glass door. Firewood with a moisture content between 15% and 20% will allow the insert to produce its highest possible efficiency. Installation and Operation Manual - Destination 2.7 Insert Page 15... -

Page 16: Operating The Insert

• Install the 2" or 4" projection kit (refer to the projection kit installation instructions) • Install the cuttable faceplate (refer to the projection kit installation instructions) • Install the fresh air intake (See «Appendix 4: Optional Fresh Air Intake Kit Installation»). Page 16 Installation and Operation Manual - Destination 2.7 Insert... -

Page 17: Blower Operation

Fresh paint fumes can also trigger false alarms in smoke detectors. When lighting the heater for the first few times, it may be wise to open doors and windows to ventilate the house. Installation and Operation Manual - Destination 2.7 Insert Page 17... -

Page 18: Lighting Fires

Leave the door slightly ajar. Once the fire has ignited, the door can be closed with the air control still fully open. When the kindling is almost completely burned, standard firewood pieces can be added. Page 18 Installation and Operation Manual - Destination 2.7 Insert... -

Page 19: Combustion Cycles

Wood burns best in cycles. A cycle starts when a new load of wood is ignited by hot coals and ends when that load has been consumed down to a bed of charcoal about the same size as it was when the wood was loaded. Installation and Operation Manual - Destination 2.7 Insert Page 19... -

Page 20: Rekindling A Fire

The best time to remove ash is in the morning, after an overnight fire when the insert is relatively cold, but there is still a little chimney draft to draw the ash dust into the insert and prevent going Page 20 Installation and Operation Manual - Destination 2.7 Insert... -

Page 21: Air Intake Control

This kind of fire is good for mild weather and should provide enough heat for up to four hours. Small fires like this are a good time to use softer wood species and avoid overheating the house. Installation and Operation Manual - Destination 2.7 Insert Page 21... - Page 22 North-south loads allow more wood to be loaded at the same time. On the other hand, they break into smaller pieces faster. North-south loading is good for high output, long lasting fires for cold weather. Page 22 Installation and Operation Manual - Destination 2.7 Insert...

-

Page 23: Maintenance

The deposits that form on the glass are the best indication of the fuel quality and success in properly using Installation and Operation Manual - Destination 2.7 Insert Page 23... - Page 24 Peel off more of the backing and rotate the glass. The gasket must not be stretched during installation. Cut the gasket to the required length. Pinch the gasket onto the glass in a U-shape, all around the glass. Page 24 Installation and Operation Manual - Destination 2.7 Insert...

-

Page 25: Door

Remove the split pin by pulling and turning it using pliers. Turn the handle one counterclockwise turn to increase pressure. Reinstall the split pin with a small hammer. Figure 8: Removing the split pin Figure 9: Installing the split pin Installation and Operation Manual - Destination 2.7 Insert Page 25... -

Page 26: Exhaust System

Contact your local municipal or provincial fire authority for information on how to handle a chimney fire. Have a clearly understood plan to handle a chimney fire. Page 26 Installation and Operation Manual - Destination 2.7 Insert... -

Page 27: Part B - Installation

Installation and Operation Manual - Destination 2.7 Insert Page 27... -

Page 28: Chimney Caps

If it is removed from the masonry hearth, the notice plate 27009 must be installed in a visible place, inside the masonry hearth. The plate can be found in the owner’s manual kit. Page 28 Installation and Operation Manual - Destination 2.7 Insert... -

Page 29: Safety Information And Standards

NO PART OF THE INSERT MAY BE LOCATED CLOSER TO THE COMBUSTIBLE THAN THE MINIMUM CLEARANCE FIGURES GIVEN. Installation and Operation Manual - Destination 2.7 Insert Page 29... -

Page 30: Installation Of A Combustible Mantel Shelf

D = B - G, where G = A-C. From door opening. The depth of the hearth extension in front of the insert is included in the calculation of the floor protector’s dimensions. Page 30 Installation and Operation Manual - Destination 2.7 Insert... - Page 31 It is necessary to have a floor protection made of non-combustible materials without R factor respecting the measures indicated in the table below. This table may be used only if the masonry hearth is raised at least 4"(102 mm) above the combustible floor. Installation and Operation Manual - Destination 2.7 Insert Page 31...

- Page 32 (D) must be added. From door opening. The depth of the hearth extension in front of the insert is included in the calculation of the floor protector’s dimensions. Page 32 Installation and Operation Manual - Destination 2.7 Insert...

- Page 33 This R value is larger than the required 1.00 and is therefore acceptable. Information as reported by manufacturers and other resources Horizontal still air can’t be «stack» to accumulate R-values; each layer must be separated with another non-combustible material. Installation and Operation Manual - Destination 2.7 Insert Page 33...

-

Page 34: Minimum Masonry Opening And Clearances To Combustibles

If a fresh air intake is required, it is recommended to add at least 4" to the width of the minimum opening of the hearth. ⅛ ⅛ ⅛ ", otherwise L = 22 If projection kit is used L = 20 " or 18 ". Page 34 Installation and Operation Manual - Destination 2.7 Insert... -

Page 35: The Venting System

6" (150 mm). The reduction of the liner diameter to less than 6" (150 mm) should only be done if the total height of the masonry chimney is greater than 20’ (6,1 m). Installation and Operation Manual - Destination 2.7 Insert Page 35... -

Page 36: Chimney Liner Installation

Insert the chimney liner into the flue collar of the unit and secure the liner to the brackets with three self-tapping screws (not included). Figure 19: Securing the brackets Page 36 Installation and Operation Manual - Destination 2.7 Insert... - Page 37 Then, follow the instructions in the manual provided with the liner offset adapter kit. Figure 21: Securing the brackets Figure 22: Offset liner adaptor Installation and Operation Manual - Destination 2.7 Insert Page 37...

-

Page 38: Minimum Chimney Height

This installation benefits from being enclosed within the warm house environment, produce stronger draft, accumulate fewer creosote deposits and will be unaffected by cold temperatures or harsh winds. Page 38 Installation and Operation Manual - Destination 2.7 Insert... -

Page 39: Supply Of Combustion Air

Check the outdoor air duct for soot deposits when the full system is cleaned and inspected at least once each year. Installation and Operation Manual - Destination 2.7 Insert Page 39... -

Page 40: Appendix 1: Connecting The Blower With A Bx Wire

Remove the screws (B) and the plate (A). Disconnect the wires from the terminal block. Unscrew the screws (D) and remove the plate (C). Install the sleeve (E) to protect the wires. The sleeve is in the insert owner’s manual. Page 40 Installation and Operation Manual - Destination 2.7 Insert... - Page 41 Install the sleeve (H) on the BX wire and run the wire through the connector (J) and screw it into place. BLACK / NOIR GREEN / VERT WHITE / BLANC Installation and Operation Manual - Destination 2.7 Insert Page 41...

- Page 42 Install the connector (J) on the insert. Make the connections as shown below. GREEN / VERT BLACK / NOIR WHITE / BLANC Page 42 Installation and Operation Manual - Destination 2.7 Insert...

-

Page 43: Appendix 2: Faceplate Decorative Panel Installation

APPENDIX 2: FACEPLATE DECORATIVE PANEL INSTALLATION Cut micro-joints and remove part of the top of the insert jacket. MICRO-JOINTS Install the decorative faceplate panel (B) with the screws (A). Installation and Operation Manual - Destination 2.7 Insert Page 43... -

Page 44: Appendix 3: Faceplate Installation

Install the grille (E) with the bolts (B). Bring the faceplate close to the insert and insert the supports into the opening in the front of the insert. Page 44 Installation and Operation Manual - Destination 2.7 Insert... -

Page 45: Appendix 4: Optional Fresh Air Intake Kit Installation

HVAC type, insulated, and must comply with ULC S110 and/or UL 181, Class 0 or Class 1. Installation and Operation Manual - Destination 2.7 Insert Page 45... -

Page 46: Appendix 5: Optional Fire Screen Installation

A fire screen door can be installed on the insert. For more details, refer to the installation manual supplied with the fire screen. Open the door Hold the fire screen by the two handles and bring it close to the door opening. Page 46 Installation and Operation Manual - Destination 2.7 Insert... - Page 47 Warning: Never leave the insert unattended while in use with the fire screen. Installation and Operation Manual - Destination 2.7 Insert Page 47...

-

Page 48: Appendix 6: Air Tubes And Baffle Installation

Repeat for center back tube. Put the baffle in place. Repeat steps 1 and 2 for the two other tubes. To remove the tubes use the above steps in reverse order. Page 48 Installation and Operation Manual - Destination 2.7 Insert... - Page 49 Note that secondary air tubes (A) can be replaced without removing the baffle board (B). See exploded view for tube installation order. Installation and Operation Manual - Destination 2.7 Insert Page 49...

-

Page 50: Appendix 7: Refractory Panels Replacement

Remove the floor refractory panel (E). the two screws (D) holding the andiron (C). Slightly unscrew the slab supports (G) and Remove the sides (1) and back refractory turn the support to release. panel (2). Page 50 Installation and Operation Manual - Destination 2.7 Insert... -

Page 51: Appendix 8: Blower Replacement

Unscrew the two screws (C) at the bottom of the insert. Gently pull the bottom of the faceplate (B) forward. Remove the screws (D) and the air control Remove the air control housing (F). cover (E). Installation and Operation Manual - Destination 2.7 Insert Page 51... - Page 52 Remove the certification plate (G). Unscrew the wing nuts (H) on each side of the blower (J). Remove the blower (J). Page 52 Installation and Operation Manual - Destination 2.7 Insert...

-

Page 53: Appendix 9: Removal Instructions

If installed, remove the cuttable faceplate (C) and the projection kit (D). Remove the three screws securing the pipe connector (H). Unscrew the bolts securing the insert to the floor on each side of the unit (G). Installation and Operation Manual - Destination 2.7 Insert Page 53... -

Page 54: Appendix 10: Exploded Diagram And Parts List

APPENDIX 10: EXPLODED DIAGRAM AND PARTS LIST 53 52 DETAIL D DETAIL C DETAIL E DETAIL B DETAIL F DETAIL A Page 54 Installation and Operation Manual - Destination 2.7 Insert... - Page 55 Never use substitute materials. Use of non-approved parts can result in poor performance and safety hazards. Item Description Qté SE24315 DESTINATION 2.7 DOOR ASSEMBLY AC06500 SILICONE AND 5/8" X 8' BLACK DOOR GASKET KIT SE72072 REPLACEMENT HANDLE WITH LATCH KIT 30898...

- Page 56 BLOWER HOOD 44207 DOUBLE CAGE BLOWER 176 CFM (CLASS H) PL65913 BLOWER MOUNTING PLATE 30484 WING NUT 1/4-20 SE45998 DESTINATION 2.7 INSTRUCTIONS MANUAL KIT 44084 RHEOSTAT WITHOUT NUT AND FLAT WASHER PL72081 RHEOSTAT SUPPORT 44203 RHEOSTAT WASHER 44202 RHEOSTAT NUT 30021 SELF TAPPING SCREW 8-32 "F"...

-

Page 57: Enerzone Limited Lifetime Warranty

Labour cost and repair work to the account of the manufacturer are based on a predetermined rate schedule and must not exceed the wholesale price of the replacement part. Shall your unit or a components be defective, contact immediately your ENERZONE dealer. To accelerate processing of your warranty claim, make sure to have on hand the following information when calling: •... - Page 58 NOTES :...

- Page 59 NOTES :...

- Page 60 Resale is strictly prohibited. The manufacturer may update St-Augustin-de-Desmaures (Québec), Canada this document from time to time and cannot be responsible G3A 2H3 for problems, injuries, or damages arising out of the use 418-908-8002 of information contained in any document obtained from https://www.enerzone-intl.com/en/ unauthorized sources. tech@sbi-international.com...

Need help?

Do you have a question about the DESTINATION 2.7 and is the answer not in the manual?

Questions and answers