Table of Contents

Advertisement

Quick Links

MS200E

H-824 Hexapod Microrobot

User Manual

Version: 2.4.0

Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany

Phone +49 721 4846-0, Fax +49 721 4846-1019, Email info@pi.ws, www.pi.ws

Date: 11.01.2023

This document describes the following products:

H-824.G2

Compacter Hexapod microrobot, gearhead, 10

kg load capacity, 1 mm/s velocity, D-sub

connector

H-824.G2V

Compacter Hexapod microrobot, gearhead,

vacuum compatible to 10

capacity, 0.5 mm/s velocity, D-sub connector

H-824.D2

Compacter Hexapod microrobot, direct drive, 5

kg load capacity, 25 mm/s velocity, D-sub

connector

H-824.D2V

Compacter Hexapod microrobot, direct drive,

vacuum compatible to 10

capacity, 12.5 mm/s velocity, D-sub connector

hPa, 5 kg load

-6

hPa, 2.5 kg load

-6

Advertisement

Table of Contents

Summary of Contents for PI H-824

- Page 1 Compacter Hexapod microrobot, direct drive, vacuum compatible to 10 hPa, 2.5 kg load capacity, 12.5 mm/s velocity, D-sub connector Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany Phone +49 721 4846-0, Fax +49 721 4846-1019, Email info@pi.ws, www.pi.ws...

- Page 2 BiSS is a registered trademark of iC-Haus GmbH. © 2023 Physik Instrumente (PI) GmbH & Co. KG, Karlsruhe, Germany. The text, photographs, and drawings in this manual are protected by copyright. With regard thereto, Physik Instrumente (PI) GmbH & Co. KG retains all the rights.

-

Page 3: Table Of Contents

Contents About this Document Objective and Target Group of this User Manual ............1 Symbols and Typographic Conventions..............1 Figures ........................2 Other Applicable Documents ..................2 Downloading Manuals ....................3 Safety Intended Use ......................5 General Safety Instructions ..................5 Organizational Measures .................... - Page 4 Connecting the Hexapod to the Controller .............. 28 Startup General Notes on Startup ..................33 Starting Up the Hexapod System ................34 Baking Out Vacuum-Compatible Models ..............34 Maintenance Performing a Maintenance Run ................37 Cleaning the Hexapod ....................38 Packing the Hexapod for Transport ................

-

Page 5: About This Document

Downloading Manuals ........................3 Objective and Target Group of this User Manual This user manual contains the information necessary for using the H-824 as intended. We assume that the user has basic knowledge of closed-loop systems, motion control concepts, and applicable safety measures. -

Page 6: Figures

For better understandability, the colors, proportions, and degree of detail in illustrations can deviate from the actual circumstances. Photographic illustrations may also differ and must not be seen as guaranteed properties. Other Applicable Documents The devices and software tools from PI mentioned in this documentation are described in separate manuals. Device/program Document Document content C-887.5xx controller... -

Page 7: Downloading Manuals

Contact our customer service department (p. 53). Downloading manuals 1. Open the website www.pi.ws. 2. Search the website for the product number (e.g., H-824). 3. Click the corresponding product to open the product detail page. 4. Click the Downloads tab. -

Page 9: Safety

The H-824 is built according to state-of-the-art technology and recognized safety standards. Improper use of the H-824 may result in personal injury and/or damage to the H-824. Use the H-824 for its intended purpose only, and only when it is in perfect condition. Read the user manual. -

Page 10: Measures For Handling Vacuum-Compatible Products

2 Safety If you give the H-824 to other users, include this user manual as well as all other relevant information provided by the manufacturer. Do the work only if the user manual is complete. Missing information due to an incomplete user manual can result in minor injury and damage to equipment. -

Page 11: Product Description

No friction and torques from moving cables The hexapod is controlled with a controller that can be ordered separately from PI (p. 16). The position commands to the controller are entered in Cartesian coordinates. H-824 Hexapod Microrobot MS200E... -

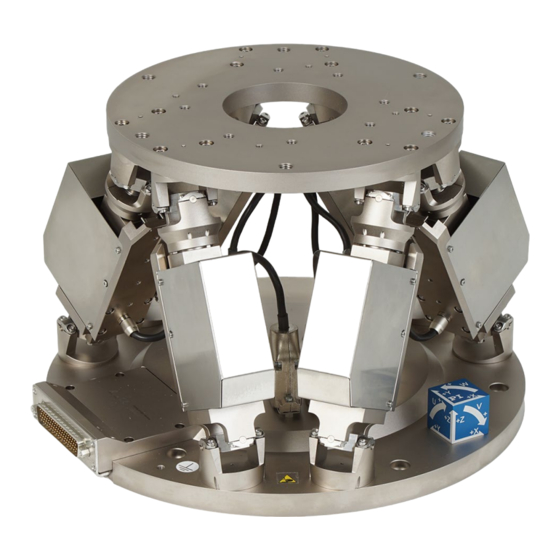

Page 12: Model Overview

10 hPa, D-sub connector, cable set 2 m vacuum side, feedthrough. Air side connecting cables are not included in the scope of delivery and must be ordered separately. Product View Figure 1: Product view Version: 2.4.0 MS200E H-824 Hexapod Microrobot... -

Page 13: Technical Features

The actuator contains the following components: H-824.G2, H-824.G2V: DC motor with gearhead and rotary encoder, drive screw; folded design H-824.D2, H-824.D2V: Direct drive, consisting of DC motor with rotary encoder and drive screw; folded design H-824 Hexapod Microrobot MS200E Version: 2.4.0... -

Page 14: Reference Switch And Limit Switches

3.4.3 Control Der hexapod is intended for operation with a suitable controller from PI (p. 16). The controller makes it possible to command motion of individual axes, combinations of axes or all six axes at the same time in a single motion command. - Page 15 A given rotation in space is calculated from the individual rotations in the order U -> V- > W. For further information on the center of rotation, see the glossary (p. 71). H-824 Hexapod Microrobot MS200E Version: 2.4.0...

- Page 16 The rotation around the U axis tilts the rotational axes V and W. Figure 4: Rotation around the U axis Platform in reference position Platform position: U = 10 (U parallel to spatially-fixed X axis) Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 17 The rotation around the V axis tilts the rotational axes U and W. Figure 5: Rotation around the V axis Platform in reference position Platform position: U = 10, V = –10 (U and V parallel to the platform level) H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 18: Id Chip

(e.g., geometry data and control parameters). The configuration data for customized hexapods is only stored on the controller if the hexapod and controller are delivered together, or if PI was correspondingly informed before delivery of the controller. -

Page 19: Scope Of Delivery

H-824 Hexapod according to your order (p. 8) For the H-824.D2V and H-824.G2V vacuum-compatible models, a 2 m cable set for the vacuum side is included in the scope of delivery. Air side connecting cables are not included in the scope of delivery and must be ordered separately. -

Page 20: Optional Accessories

Model Description C-887.52 6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes C-887.521 6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes, analog inputs Version: 2.4.0 MS200E H-824 Hexapod Microrobot... - Page 21 EtherCAT interface, motion stop C-887.533 6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes, EtherCAT interface, motion stop, analog inputs To order, contact our customer service department (p. 53). H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 23: Unpacking

When handling the vacuum model of the hexapod, attention must be paid to appropriate cleanliness. At PI, all parts are cleaned before assembly. Powder-free gloves are worn during assembly and measuring. In addition, the hexapod is wipe cleaned afterwards and then shrink- wrapped twice in vacuum-compatible film. -

Page 24: Removing The Transport Safeguard

6. Compare the contents with the items listed in the contract and the packing list. If any of the parts are wrong or are missing, contact PI immediately. 7. Inspect the hexapod for signs of damage. If there is any sign of damage, contact PI immediately. - Page 25 8. Grip the hexapod's baseplate and carefully pull both of the transport safeguard's rails out from under the base plate. Store the transport safeguard Keep the transport safeguard as well as all screws, flat washers, and nuts in case the product needs to be transported later. H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 27: Installing

The use of the software is recommended when the hexapod is located in a limited installation space and/or operated with a spatially limiting load. For details on activation and configuration of PIVeriMove, see the C887T0002 technical note (in the scope of delivery of the software). H-824 Hexapod Microrobot MS200E Version: 2.4.0... -

Page 28: Determining The Permissible Load And Workspace

5 Installing Determining the Permissible Load and Workspace Tools and Accessories PC with Windows operating system with the PI Hexapod Simulation Tool installed. For further information, see the A000T0068 technical note. Determining the workspace and the permissible load of the hexapod ... -

Page 29: Mounting The Hexapod On A Surface

Incorrect mounting can warp the base plate. A warped base plate reduces the accuracy. Mount the hexapod onto a flat surface. The recommended flatness of the surface is 200 µm. Figure 8: Mounting holes in the base plate H-824 Hexapod Microrobot MS200E Version: 2.4.0... -

Page 30: Fixing The Load To The Hexapod

(p. 64) together with the load to be mounted. Only use screws that do not project under the motion platform after being screwed in. Only mount the hexapod and the load on the mounting fixtures (holes) intended for this purpose. Version: 2.4.0 MS200E H-824 Hexapod Microrobot... - Page 31 1. Choose the mounting position so that the selected mounting holes in the motion platform (see upper figure and the dimensional drawing (p. 64)) can be used for fixing the load. 2. Fix the load using the screws. H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 32: Optional: Removing The Coordinate Cube

Tools and accessories Data transmission cable and power supply cable, available as accessories (p. 15) If you want to operate a vacuum-compatible hexapod in a vacuum chamber: Suitable tools for installing the vacuum feedthrough Version: 2.4.0 MS200E H-824 Hexapod Microrobot... - Page 33 Figure 11: Vacuum feedthrough for data transmission (4668), dimensions in mm 4 holes, Ø6 x 45° for M3 countersunk screw Install the vacuum feedthrough for data transmission (4668) so that the HD Sub-D 78 socket (f) is in the vacuum chamber. H-824 Hexapod Microrobot MS200E Version: 2.4.0...

- Page 34 Pay attention to the assignment specified on the labeling of the sockets, plug connectors, and cables. Pay attention to the mechanical coding of connectors and sockets. − − Do not use force. − Use the integrated screws to secure the connections against accidental disconnection. Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 35 Socket / connector, female Controller Refer to "Suitable Controllers" (p. 16) Hexapod H-824.D2 or H-824.G2 Power adapter, from the scope of delivery of the controller, 24 V DC output Data transmission cable* Power supply cable* * Must be ordered separately.

- Page 36 Panel plug / connector, male Socket / connector, female Controller Refer to "Suitable Controllers" (p. 16) Hexapod H-824.D2V or H-824.G2V Power adapter, from the scope of delivery of the controller, 24 V DC output Vacuum chamber Data transmission cable* Power supply cable*...

-

Page 37: Startup

Do not place any objects in areas where they can be caught by moving parts. Stop the motion immediately if a controller malfunction occurs. H-824 Hexapod Microrobot MS200E Version: 2.4.0... -

Page 38: Starting Up The Hexapod System

The longer the bakeout and cooling process takes, the more the maintenance runs are necessary. Perform a maintenance run during the bakeout and cooling process at least once a day. Version: 2.4.0 MS200E H-824 Hexapod Microrobot... - Page 39 Bake out the hexapod at maximum 80 °C (176 °F). Perform a maintenance run (p. 37) over the entire travel range during the bakeout and cooling process at least once a day. H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 41: Maintenance

Packing the Hexapod for Transport ..................... 38 Cleaning the Hexapod ........................47 PI offers a range of wraparound services for all their products, many of which are designed to increase the system’s lifetime and uptime: Remote system setup: An expert ensures that your system is optimized and runs ... -

Page 42: Cleaning The Hexapod

Model with direct drive, struts not blocked: Try to move the hexapod carefully by hand so that the transport safeguard can be attached. Model with DC gear motor or struts blocked: Do not attach the transport safeguard. Version: 2.4.0 MS200E H-824 Hexapod Microrobot... -

Page 43: Attaching The Transport Safeguard

Screw the struts with the shorter thread into the rails as shown in the figure. b) Tighten the struts by hand. c) Screw an M8 nut onto each strut up to the end of the thread. d) Put an 8.4 flat washer onto each nut. H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 44 Grip the hexapod's baseplate and carefully push both of the transport safeguard's rails under the base plate. The correct alignment of the rails can be seen in the figure. b) Fix the rails to the base plate with two M6x16 socket head screws. Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 45 6.4 flat washer onto. c) Push an 8.4 flat washer onto each strut. d) Screw an M8 nut onto each strut and tighten by hand. e) Lock each nut above and below the cover for each strut. H-824 Hexapod Microrobot MS200E Version: 2.4.0...

- Page 46 7 Maintenance Steps 5 a and 5 b Figure 17: Fixing the cover with M6x16 screws Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 47 7 Maintenance Steps 5 c to 5 e Figure 18: Fixing the cover with M8 nuts H-824 Hexapod Microrobot MS200E Version: 2.4.0...

- Page 48 7 Maintenance Installation is now complete Figure 19: Transport safeguard is attached Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

-

Page 49: Packing The Hexapod

9. Put the cover onto the outer box, see figure. 10. Secure the outer box on the pallet with two parallel strapping bands. 11. Wrap the box and pallet with stretch film to protect them against moisture, see figure. Step 3 a H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 50 Step 5 The appropriate orientation of the foam cover depends on the hexapod model. Step 6 Only necessary when a cushion made of folded corrugated cardboard is part of the original packaging. Step 8 Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 51 7 Maintenance Step 9 Step 11 The upper box contains the controller. H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 53: Troubleshooting

Faulty motor occurs with maximum or minimum Sensor defective displacement of the platform in Z. Blocked or broken Contact our customer service department joint (p. 53). H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 54 If you do not use the "Motion Stop" functionality: Make sure that the C887B0038 shorting plug from the scope of delivery of the controller is inserted in the E-Stop socket. If you use the "Motion Stop" functionality: Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 55 2. Activate the 24 V Out 7 A output with "Make contact" (for details, refer to the user manual for the controller). If you use the C-887.MSB motion-stop-box from PI: Press the mushroom button first to unlock it, then press the green pushbutton.

- Page 56 "Hexapod does not move" section not possible. reference move. applies to your problem. If the problem with your hexapod is not listed in the table or cannot be solved as described, contact our customer service department (p. 53). Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

-

Page 57: Customer Service Department

9 Customer Service Department Customer Service Department For inquiries and orders, contact your PI sales engineer or send us an email (mailto:service@pi.de). If you have questions concerning your system, provide the following information: − Product and serial numbers of all products in the system Firmware version of the controller (if applicable) −... -

Page 59: Technical Data

Typical velocity in Y 0.5 mm/s 10 mm/s Typical velocity in Z 0.5 mm/s 10 mm/s Typical angular velocity in θX 5.5 mrad/s 55 mrad/s Typical angular velocity in θY 5.5 mrad/s 55 mrad/s H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 60 Stiffness in Y 1.7 N/µm 1.7 N/µm Stiffness in Z 7 N/µm 7 N/µm Maximum holding force, base plate in 50 N any orientation Maximum holding force, base plate 100 N 15 N horizontal Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

-

Page 61: Specifications For Vacuum-Compatible Models

Maximum angular velocity in θX 5.5 mrad/s 135 mrad/s Maximum angular velocity in θY 5.5 mrad/s 135 mrad/s Maximum angular velocity in θZ 5.5 mrad/s 135 mrad/s Typical velocity in X 0.2 mm/s 5 mm/s H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 62 H-824.D2V Tolerance Drive type DC gear motor DC motor Nominal voltage 24 V 24 V Mechanical properties H-824.G2V H-824.D2V Tolerance Stiffness in X 1.7 N/µm 1.7 N/µm Stiffness in Y 1.7 N/µm 1.7 N/µm Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 63 80 °C Drive and sensor Motor Manufacturer: Faulhaber Motor type: DC, 2224R036SR Gearhead H-824.G2V only: 22/5 Reduction ratio 69:1 Encoder Manufacturer: Faulhaber Encoder type: magnetic encoder, IE2-512 Reference switch Magnetic, vacuum-compatible Limit switches Magnetic, vacuum-compatible H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 64: Maximum Ratings

Data Transmission and Power Supply Cables Data transmission Power supply cable, single-side Power supply cable, straight cable angled connector connectors Alle Hexapodtypen H-820, H-824, H-825, H-840, H-850 H-810, H-811, H-206 C-815.82D02 C-815.82P02A C-815.82P02E C-815.82D03 C-815.82P03A C-815.82P03E Version: 2.4.0... - Page 65 2 / 3 / 5 / 7.5 / 10 / 20 Maximum velocity Maximum acceleration Maximum number of bending cycles 1 million Operating temperature range -10 to +70 °C Power supply cable, straight connectors Unit Minimum bending radius in a drag chain H-824 Hexapod Microrobot MS200E Version: 2.4.0...

- Page 66 Data transmission cable Power supply cable, angled connector K040B0254 K060B0132 General Unit Cable length L Operating temperature range -10 to +80 °C Data transmission cable Unit Minimum bending radius with the fixed installation Outer diameter Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

-

Page 67: Ambient Conditions And Classifications

Highest relative humidity of 80% at temperatures of up to 31°C, decreasing linearly to a relative humidity of 50% at 40°C Degree of protection according IP20 to IEC 60529 Area of application For indoor use only Maximum altitude 2000 m H-824 Hexapod Microrobot MS200E Version: 2.4.0... -

Page 68: Dimensions

10 Technical Data 10.3 Dimensions Dimensions in mm. Note that the decimal points are separated by a comma in the drawings. Figure 20: H-824 hexapod, at zero position of nominal travel range Version: 2.4.0 MS200E H-824 Hexapod Microrobot... -

Page 69: Pin Assignment

2-pin LEMO panel plug, male, type ECJ.1B.302.CLD Function 24 V DC 10.4.2 Data Transmission Connection Data transmission between hexapod and controller Panel plug HD Sub-D 78 m Function All signals: TTL H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 70 CH4 B+ OUT CH4 A- OUT CH4 B- OUT CH5 Sign IN CH5 MAGN IN CH5 Ref OUT CH5 LimP OUT CH5 LimN OUT CH5 A+ OUT CH5 B+ OUT CH5 A- OUT CH5 B- OUT Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 71 CH6 MAGN IN CH6 Ref OUT CH6 LimP OUT CH6 LimN OUT CH6 A+ OUT CH6 B+ OUT CH6 A- OUT CH6 B- OUT Brake/Enable ID Chip drive 24 V input Power Good 24 V output H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 73: Old Equipment Disposal

Dispose of your old equipment according to international, national, and local rules and regulations. To fulfill the responsibility as the product manufacturer, Physik Instrumente (PI) GmbH & Co. KG undertakes environmentally correct disposal of all old PI equipment made available on the market after 13 August 2005 without charge. -

Page 75: Glossary

The X, Y and Z axes are also referred to as translational axes. The intersection of the axes X, Y, and Z of the spatially fixed Cartesian coordinate system (0,0,0) is referred to as the origin. H-824 Hexapod Microrobot MS200E Version: 2.4.0... - Page 76 The Z axis is perpendicular to the base plate of the hexapod. The following example figures of the H-810 hexapod show that the coordinate system does not move along with motion of the platform. Figure 21: H-810 hexapod in the reference position. Cable exit Version: 2.4.0 MS200E H-824 Hexapod Microrobot...

- Page 77 12 Glossary Figure 22: H-810 hexapod, the platform of which has been moved in X. Cable exit H-824 Hexapod Microrobot MS200E Version: 2.4.0...

-

Page 79: Appendix

The following test cycles are performed: Motion over the entire travel range with at least 20 measuring points, in at least five cycles. Motion over partial sections, e.g., ±1 mm in increments of for example, 100 µm H-824 Hexapod Microrobot MS200E Version: 2.4.0... -

Page 81: European Declarations Of Conformity

13 Appendix 13.2 European Declarations of Conformity For the H-824, declarations of conformity were issued according to the following European statutory requirements: EMC Directive RoHS Directive The standards applied for certifying conformity are listed below. EMC: EN 61326-1 Safety: EN 61010-1...

Need help?

Do you have a question about the H-824 and is the answer not in the manual?

Questions and answers