Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Reflex Servitec Mini

- Page 1 10.10.2022-Rev. C Servitec Mini GB Operating manual Original operating manual...

-

Page 2: Table Of Contents

6.4.3 Hydraulic connection ..............16 Commissioning ....................17 Requirements for initial commissioning ............17 Adjusting the filling pressure of the system ..........17 Commissioning ....................18 Installation and commissioning certificate ........... 18 2 — English Servitec Mini — 10.10.2022-Rev. C... - Page 3 Cleaning ......................24 Disassembly ....................25 Disposal ......................26 Annex ......................27 13.1 Reflex Customer Service .................. 27 13.2 Conformity and standards ................27 13.3 Guarantee ......................27 Servitec Mini 10.10.2022-Rev. C Servitec Mini — 10.10.2022-Rev. C English — 3...

-

Page 4: Notes On The Operating Manual

This operating manual is an important aid for ensuring the safe and reliable functioning of the device. Reflex Winkelmann GmbH accepts no liability for any damage resulting from failure to observe the information in this operating manual. In addition to the requirements set out in this operating... -

Page 5: Safety

Only specialist personnel or specifically trained personnel may install and operate the equipment. The electric connections and the wiring of the device must be executed by a specialist in accordance with all applicable national and local regulations. Servitec Mini — 10.10.2022-Rev. C English — 5... -

Page 6: Personal Protective Equipment

For use with flammable media. • For use with distilled water. • For use with fully desalinated water. Note! It is not permitted to make any modifications to the hydraulics or the circuitry. 6 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 7: Residual Risks

If necessary, work with a second person during assembly or disassembly. ATTENTION Device damage during transport If the device is not transported correctly, it may be damaged. • Use suitable covers to protect the connections against damage. Servitec Mini — 10.10.2022-Rev. C English — 7... -

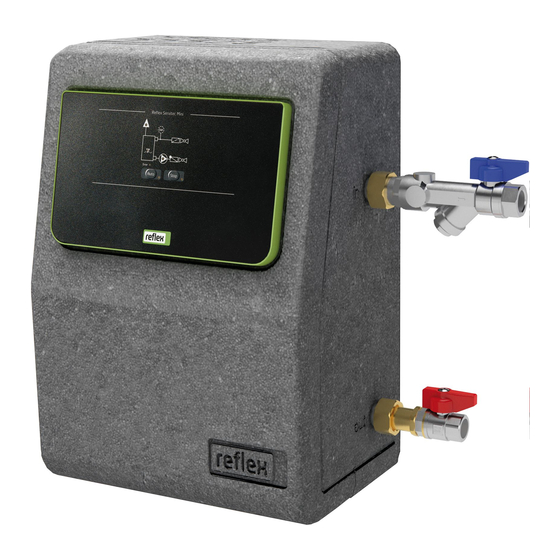

Page 8: Description Of The Device

Description of the device Description of the device The Servitec Mini is a water degassing system for use in small systems of up to 1 m system volume. Overview Venting grille Hinge for folding up Controller Gas-rich water inlet Dirt trap... -

Page 9: Function

Idling time The Reflex Servitec Mini can degas the system water in a spray tube. Gas-rich water is sprayed into the spray tube via a nozzle. A pump sucks the water out of the spray tube and transports it into the system. -

Page 10: Optional Equipment And Accessories

420 mm Width: 295 mm Depth: 220 mm Connection: 1/2 " System volume: 1 m³ Operating pressure: 0.5 - 2.5 bar Permissible operating overpressure: 4 bar Max. permissible operating temperature: 60 °C 10 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 11: Installation

Confirm that installation and start-up have been carried out correctly using the installation and commissioning certificate. This action is a prerequisite for the making of warranty claims. – Have the Reflex Customer Service carry out commissioning and the annual maintenance. Servitec Mini — 10.10.2022-Rev. C English — 11... -

Page 12: Incoming Inspection

Level and solid installation surface for the device. • Frost-free, well-ventilated room. – Room temperature > 0 - 45 °C. • Electric connection. – 230 V~, 50 Hz, 16 A with upstream ELCB (tripping current: 0.03 A). 12 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 13: Connection

Installation Connection Basic system variant Servitec Mini Servitec Mini Gas-rich water Degassed water • Connection 2 x DN 15 • Max. pipe length 5m Note! Shut-off valves must be used at the connection point to the pipe network. Note! ... -

Page 14: Installation Of The Isolation Valves

Isolation valve with filter insert Isolation valve Connection pipe The connection pipes (3, blue) are pre- assembled in the factory. The shut-off valves (1) and (2) are fitted to the device on-site prior to wall mounting. 14 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 15: Wall Mounting

Use the enclosed drilling template and set of screws for wall mounting. Attach the drilling template to the wall with sticky tape. Drill the holes for attaching the device Remove the drilling template. Hang the device on the wall. Servitec Mini — 10.10.2022-Rev. C English — 15... -

Page 16: Hydraulic Connection

• Preferably install on the return side of the system. – The water temperature must be in the range of 0 °C – 60 °C to ensure sufficient degassing capacity. 16 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 17: Commissioning

Circulation through the entire plant system is thus ensured. Adjusting the filling pressure of the system Before the Servitec Mini is commissioned, the system must be filled. The volume of the Servitec Mini must be allowed for in the system. Proceed as follows: Open the device ball valves. -

Page 18: Commissioning

If the system pressure is less than 0.5 bar, a low water error is triggered. Increase the system pressure accordingly. Note! We recommend rechecking of the pressure maintenance target value (system pressure) 2 weeks after commissioning of the Servitec Mini and if necessary, replenishing of the system. Installation and commissioning certificate Note! ... -

Page 19: Operation

The system triggers an error message if Stop mode is activated for more than 4 hours. Restarting Note! Recommissioning after a long shut-down takes place by pressing the ‘Auto’ button. Servitec Mini — 10.10.2022-Rev. C English — 19... -

Page 20: Controller

• For stop mode • Lights up yellow Auto button/LED • For continuous operation • Acknowledge error messages • Lights up green Error LED • Lights up red if an error exists 20 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 21: Messages

Check vacuum pump. (Minimum pressure) • Expansion vessel • Check expansion defective. vessel. Error LED flashes The pressure exceeds the Lower the pressure at the (maximum pressure) maximum pressure of 2.5 bar. transducer. Servitec Mini — 10.10.2022-Rev. C English — 21... -

Page 22: Reset

Ensure that the system is de-pressurised before performing installation, removal or maintenance work at the connection points. The ‘Servitec’ must be serviced annually. Note! Maintenance work must only be carried out and confirmed by specialist personnel. 22 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 23: Maintenance Schedule

Allow the pump to run for not more than 30 seconds. Wait two minutes The process can be repeated by pressing the button again. Clean the dirt trap, see chapter 10.2 "Cleaning" on Dependent on the page 24 operating conditions Servitec Mini — 10.10.2022-Rev. C English — 23... -

Page 24: Cleaning

Open the ball valve (1) upstream of the dirt trap (2). Press 'Auto' on the control panel of the controller. – The device is switched on and the vacuum pump is in operation. 24 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 25: Disassembly

Contact with glycol containing water in plant systems for cooling circuits can result in irritation of the skin and eyes. – Use personal protective equipment (safety clothing, gloves and goggles, for example). Servitec Mini — 10.10.2022-Rev. C English — 25... -

Page 26: Disposal

Note! The following included materials are fully recyclable: • EPP (housing) • ABS (front cover of the controller) • PP (back cover of the controller) 26 — English Servitec Mini — 10.10.2022-Rev. C... -

Page 27: Annex

For questions about our products Telephone number: +49 (0)2382 7069-9546 Monday to Friday 8:00 to 16:30 13.2 Conformity and standards Device conformity declarations are available on the Reflex homepage. www.reflex-winkelmann.com/konformitaetserklaerungen Alternatively, scan the QR code: 13.3 Guarantee The respective statutory guarantee regulations apply. - Page 28 Installation and commissioning certificate - This device has been installed and commissioned in accordance with the instructions provided in the operating manual. The settings in the controller match the local conditions. Typ / Type: Fabr. Nr. / Serial-No. 28 — English Servitec Mini — 10.10.2022-Rev. C...

- Page 30 Reflex Winkelmann GmbH Gersteinstraße 19 59227 Ahlen, Germany +49 (0)2382 7069-0 +49 (0)2382 7069-9546 www.reflex-winkelmann.com...

Need help?

Do you have a question about the Servitec Mini and is the answer not in the manual?

Questions and answers