Summary of Contents for Allied Systems H6H

- Page 1 Please check the Allied Systems website regularly for updates to this manual. www.alliedsystems.com CUSTOMER EDITION P/N 599040W Printed in USA 7/2018...

- Page 2 NOTE: This publication may be translated to different languages for sole purpose of easy reference in non-English speaking locations. Should there be differences in interpretations to the text, please refer to the English language edition published by Allied Systems Company as the controlling document.

-

Page 4: Safety Summary

Safety Summary ® Safety Summary General Safety Notices Safety Regulations Each country has its own safety legislation. It is in the The following pages contain general safety warnings operator’s own interest to be conversant with these which supplement specific warnings and cautions regulations and to comply with them in full. - Page 5 ® If the wire rope and ferrule must be removed from the drum, make sure the end of the wire rope and ferrule are controlled when the ferrule is released. The end of the wire rope can suddenly move from the drum like a compressed spring when the ferrule is released, and cause an injury.

- Page 6 Safety Summary ® • Make sure ground personnel are in plain view of the • Your winch may have temperature shut-off system operator, and at a distance of at least 1½ times the for protection of tractor and winch. Manual override working length of the wire rope.

- Page 7 When ordering replacement parts, give the unit serial number, part number, name of part and quantity required. For any further information on parts, service or ordering, consult your local winch dealer, or contact Allied Systems Company: Allied Systems Company 21433 SW Oregon Street...

-

Page 8: Table Of Contents

Contents ® Contents Safety Summary ..............i Service ................3-1 General ................3-1 General ................1-1 Maintenance ..............3-1 Introduction ................ 1-1 Maintenance Points ............ 3-1 Description ................ 1-1 Maintenance Schedule ..........3-1 Unit Identification ............1-2 Checks Before Operation ........... 3-2 Serial Number Codes .......... - Page 9 Notes ®...

-

Page 10: General

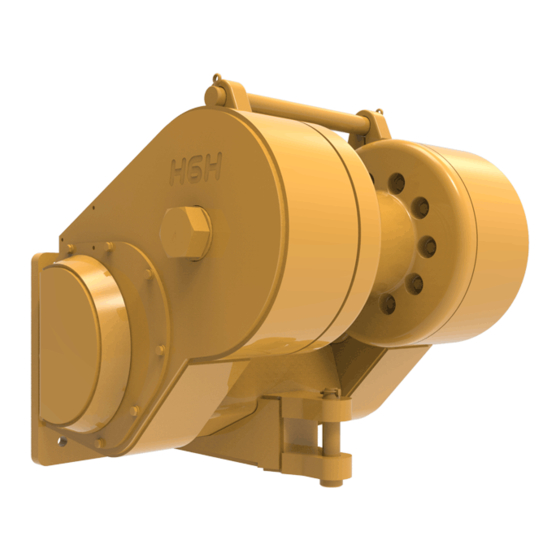

® General Introduction Description This service manual is for the H6H winch. The following The H6H Winch is a Power Forward (LINE-IN) and Power information is included in this manual: Reverse (LINE-OUT) winch. The winch is powered by an internal hydraulic motor connected to the tractor hydraulic Section 1. -

Page 11: Unit Identification

Allied Winch S/N Nameplate Data For Tractor Mountings 1001 Vehicle Code Winch Model See Figure 1-2 H6H = Standard KH6H = Special Design (Contact Factory) Hydraulic Operation Type Sequence Number H = High-Performance Hydrostatic or Hydraulic 2 Speed T = Standard, Tractor Controls & Pump... - Page 12 Section 1 ® Figure 1-2 Tractor or Skidder Identification Codes and Available Gear Ratios Caterpillar- Caterpillar John Deere Dressta Komatsu Liebherr Case Shantui Tigercat TD14/15/16S PR716 Steiger 1650L PR724 PR726 1650M/ PR736 2050M ...

-

Page 13: Serial Number Codes

General ® Serial Number Codes The serial number codes are described on pages 1-2 and 1-3 of this manual. The nameplate with the serial number code is found on the top left hand side of the winch case. The serial number code is also stamped on the left hand side of the winch frame. -

Page 14: Specifications

Other hydraulic oils meeting this specification are: ExxonMobil, Mobiltrans HD-30 Chevron, Chevron Drive Train Fluid HD SAE 30. Oil Capacity The oil capacity for the H6H winch is 4 gallons (15 Figure 1-5 Maintenance Decal liters). 1 - 5... -

Page 15: Torque Specifications

General ® Torque Specifications TORQUE VALUES ITEM ft-lbs. kg-m Housing Covers & Motor Shaft Mounting (M12x1.75 Gr.9) Drum Shaft Assembly Drum Adapter to Drum Capscrews (5/8-UNF Gr. 8) Bearing Retainer Capscrews (1/2-UNF Gr. 8) Motor Shaft Planetary Housing Capscrews (3/8-UNC Gr. 8) Motor &... -

Page 16: Gear Train

Section 1 ® Gear Train (See Fig. 1-7) The tractor pump drives the hydraulic motor. Torque from DRUM GEAR the hydraulic motor is transmitted through a holding brake, planetary speed reducer and two gear reductions to the INTERMEDIATE drum. GEAR WITH FREESPOOL A dental clutch with splines engages the drum pinion gear and the intermediate gear. -

Page 17: Freespool Operation

General ® FREESPOOL Operation (See Fig. 1-9 & 1-10) The FREESPOOL arrangement allows mechanical INTERMEDIATE disengagement of the drum gear from the remainder of the GEAR gear train. When FREESPOOL is selected, a hydraulically- actuated sleeve disengages the dental clutch from the DENTAL CLUTCH intermediate shaft. -

Page 18: Operation And Control

Section 1 ® CONTROL LEVER WINCH-IN/OUT & MODE OF OPERATION DECAL BRAKE-ON DECALS BRAKE-OFF SWITCH FREESPOOL SWITCH (RED) (YELLOW) Figure 1-11 Winch Controls (K49 Shown) Operation & Control (See Fig. 1-11) The switch panel contains two rocker switches to control The H6HT winch is designed to operate on a load sense, FREESPOOL and BRAKE-OFF. -

Page 19: Hydraulic System

General ® Hydraulic System Counterbalance-Relief Manifold Assembly Standard Winch BRAKE-OFF Clutch Hi-Performance Winch BRAKE-OFF Clutch Figure 1-12 Major Components in Hydraulic System 1 - 10... -

Page 20: Motor

Section 1 ® 15, 16 Hydraulic Motor 18. Snap Ring Dry Disc Brake 19. O-Ring Planetary Reducer 20. O-Ring Clutch Housing Assembly 21. Seal Ring Spider Gear 22. Clutch Assembly Fitting 23. Pin Capscrew 24. Spring 25. Capscrew Stud 26. Bearing 10. - Page 21 General ® Retaining Ring Retaining Ring Bearing Oil Seal Cover Plate Spline Shaft Assembly Socket Head Shoulder Bolts Primary Disc Rotor Disc 10. Stator Disc 11. Case Gasket 12. Capscrew 13. Dowel Pin 14. Spring Plate 15. Springs 16. Piston 17.

- Page 22 Section 1 ® Sun Gear Thrust Washer Primary Carrier Assembly Fitting Secondary Carrier Assembly Fitting Ring Gear Fitting Cover 10. Label Figure 1-15 Planetary Reducer Planetary Reducer (See Fig. 1-15) The planetary speed reducer is the first gear reduction output shaft rotation is the same as input shaft rotation between the brake and the gear side of the winch.

-

Page 23: Counterbalance Relief Manifold

General ® Body Counter Balance Valve Relief Valve Orifice Plug Figure 1-16 Counterbalance Relief Manifold Counterbalance Relief Manifold (See Fig. 1-16) counter balance valve allows oil to free flow in the LINE- The counterbalance relief manifold houses the IN mode through a check valve. The high pressure relief counterbalance valve and the high pressure relief valves. -

Page 24: Directional Manifold

Section 1 ® Body Proportional Spool Directional Valve Check Valve Orifice Plug Set Screw Access Plug to Filter Screen Counterbalance Valve Cavity Figure 1-17 Directional Manifold Directional Manifold (See Fig. 1-17) The directional manifold houses the counterbalance valve valve. The direction control valve directs tractor supply and the direction control valve. -

Page 25: Control Manifold

General ® Body Directional Valve Cartridge Valve Shuttle Valve (Located below port plug) Figure 1-18 Control Manifold Control Manifold (See Fig. 1-18) provides release pressure to the brake when the LINE-IN The control manifold is used to communicate pressure signals that control the BRAKE-ON, BRAKE-OFF, and or LINE-OUT control pressure exceeds the pilot setting FREESPOOL. -

Page 26: Operator Control Panel

Section 1 ® CONTROL LEVER WINCH-IN/OUT & MODE OF OPERATION DECAL BRAKE-ON DECALS BRAKE-OFF SWITCH FREESPOOL SWITCH (RED) (YELLOW) Figure 1-19 Winch Controls (K49 Shown) Operator Control Panel (See Fig. 1-19) Depending on the options on the winch, the control panel function is active. -

Page 27: Sequence Of Operation, Option Code B

General ® Sequence of Operation, Option Code B Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-20 Sequence of Operation - BRAKE-ON, Option Code B 1 - 18... -

Page 28: Brake-On

Section 1 ® Sequence of Operation - BRAKE-ON Option Code B, Hi-Performance Winch Option Code B, Standard Winch Hi-performance winches are hydraulically connected directly to the tractor implement pump supply circuit. On standard winches, hydraulic flow to the winch and Hydraulic flow and direction are controlled at the winch direction of flow are controlled by the tractor ripper control directional control manifold. - Page 29 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-21 Sequence of Operation - LINE-IN, Option Code B 1 - 20...

-

Page 30: Line-In

Section 1 ® Sequence of Operation - LINE-IN Option Code B, Hi-Performance Winch Option Code B, Standard Winch The Hi-Performance winch operates similarly to the standard winch except oil flow and direction are controlled Pulling the control lever toward the operator commands at the winch. - Page 31 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-22 Sequence of Operation - LINE-OUT, Option Code B 1 - 22...

-

Page 32: Line-Out

Section 1 ® Sequence of Operation - LINE-OUT Option Code B, Hi-Performance Winch Option Code B, Standard Winch The Hi-Performance winch operates similarly to the standard winch except oil flow and direction are controlled LINE-OUT operation is similar to LINE-IN except pushing at the winch. - Page 33 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-23 Sequence of Operation - BRAKE-OFF, Option Code B 1 - 24...

- Page 34 Section 1 ® Sequence of Operation - BRAKE-OFF WARNING Option Code B BRAKE-OFF should not be used to lower a suspended load or a load that can slide BRAKE-OFF is activated by a switch located on the down a slope. operator console.

- Page 35 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-24 Sequence of Operation - FREESPOOL, Option Code B 1 - 26...

- Page 36 Section 1 ® Sequence of Operation - In FREESPOOL mode, electronic circuitry also commands FEESPOOL BRAKE-OFF operation. This turns on the red brake-off Option Code B light on the console even though the switch is in the off position. By commanding BRAKE-OFF during FREESPOOL is actuated by a switch located on the FREESPOOL operation, any load on the wire rope is operator console.

-

Page 37: Sequence Of Operation, Option Code D

General ® Sequence of Operation, Option Code D Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-25 Sequence of Operation - BRAKE-ON, Option Code D 1 - 28... - Page 38 Section 1 ® Sequence of Operation - BRAKE-ON Pilot pressure is present at the control manifold. All control lines are open to tank. The spring-applied holding brake Option Code D locks the motor shaft from rotating. With control lever centered, the tractor ripper valve blocks flow so no oil is flowing to the winch counterbalance relief manifold.

- Page 39 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-26 Sequence of Operation - LINE-IN, Option Code D 1 - 30...

- Page 40 Section 1 ® Sequence of Operation - LINE-IN valve to the reservoir. Motor pressure from motor port “M5” is directed to the control manifold RI port, through Option Code D the shuttle valve and to the brake release valve. At the set pressure, the brake release valve directs full pilot pressure to release the brake.

- Page 41 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-27 Sequence of Operation - LINE-IN HI-SPEED, Option Code D 1 - 32...

- Page 42 Section 1 ® Sequence of Operation - LINE-IN HI-SPEED Option Code D If the operator selects HI-SPEED mode by the rocker switch on the control panel, an electric solenoid valve on the control manifold sends pilot pressure to the motor port “X1”.

- Page 43 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-28 Sequence of Operation - LINE-OUT, Option Code D 1 - 34...

- Page 44 Section 1 ® Sequence of Operation - LINE-OUT In LINE-OUT operation, oil flowing from motor port “A” to the counterbalance relief manifold is controlled by the Option Code D counterbalance valve. The counterbalance valve maintains sufficient pressure in the motor port “A” line to prevent LINE-OUT operation is similar to LINE-IN except moving uncontrolled lowering of a load.

- Page 45 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-29 Sequence of Operation - BRAKE-OFF, Option Code D 1 - 36...

- Page 46 Section 1 ® Sequence of Operation - BRAKE-OFF WARNING Option Code D BRAKE-OFF should not be used to lower a suspended load or a load that can slide BRAKE-OFF is activated by a switch located on the down a slope. operator console.

- Page 47 General ® Electrical wires running between the control console and the control manifold are not shown for clarity. Figure 1-30 Sequence of Operation - FREESPOOL, Option Code D 1 - 38...

-

Page 48: Freespool

Section 1 ® Sequence of Operation - FREESPOOL Option Code D FREESPOOL is actuated by a switch located on the operator console. An electric signal shifts the freespool solenoid sending pilot pressure to the freespool shifter fork. The shifter fork disengages the drum pinion gear from the intermediate gear disengaging the drum from the gear train so wire rope can be pulled off the drum by hand. - Page 49 General ® Notes 1 - 40...

- Page 50 Section 1 ® HI-PERFORMANCE WINCH CASE QUADTRAC H6HH**R39 Figure 1-31 Hydraulic/Electrical Schematic (Rev. A), H6HH (Hi-Performance) Winch_1 1 - 41...

- Page 51 General ® HI-PERFORMANCE WINCH CASE QUADTRAC H6HH**R39 Figure 1-31 Hydraulic/Electrical Schematic (Rev A), H6HH (Hi-Performance) Winch_2 1 - 42...

- Page 52 Section 1 ® HI-PERFORMANCE/LEVEL 2 WINCH JOHN DEERE 750J/850J & 750K/850K H6HH**E460 Figure 1-32 Hydraulic/Electrical Schematic (Rev. F), H6HH (Hi-Performance) Winch 1 - 43...

- Page 53 General ® HI-PERFORMANCE/LEVEL 2 WINCH JOHN DEERE 750K/850K (E/H CONTROLS) H6HH**E465 Figure 1-33 Hydraulic/Electrical Schematic (Rev. F), H6HH (Hi-Performance) Winch 1 - 44...

- Page 54 Section 1 ® HI-PERFORMANCE/LEVEL 2 WINCH KOMATSU D61-23 H6HH**K471 Figure 1-34 Hydraulic/Electrical Schematic (Rev. A), H6HH (Hi-Performance) Winch 1 - 45...

- Page 55 General ® HI-PERFORMANCE WINCH LIEBHERR PR724 H6HH**L41 Figure 1-35 Hydraulic/Electrical Schematic (Rev. F), H6HH (Hi-Performance) Winch 1 - 46...

- Page 56 Section 1 ® STANDARD WINCH CASE 1650L H6HT**R40 Figure 1-36 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 47...

- Page 57 General ® STANDARD WINCH CASE 1650M/2050M H6HH**R42 Figure 1-37 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 48...

- Page 58 Section 1 ® STANDARD WINCH CATERPILLAR D6N H6HT**C81 WITH HYDRAULIC PILOT CONTROL Figure 1-38 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 49...

- Page 59 General ® STANDARD WINCH CATERPILLAR D6N H6HT**C811 WITH ELECTRONIC/HYDRAULIC CONTROL Figure 1-39 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 50...

- Page 60 Section 1 ® STANDARD WINCH CATERPILLAR D6T-TIER 4i H6HT**C71 Figure 1-40 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 51...

- Page 61 General ® STANDARD/LEVEL 1 WINCH KOMATSU D61-23 H6HT**K471 Figure 1-41 Hydraulic/Electrical Schematic (Rev. A), H6HT (Standard) Winch 1 - 52...

- Page 62 Section 1 ® STANDARD/LEVEL 1 WINCH KOMATSU D65-16/-17 H6HT**K49 Figure 1-42 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 53...

- Page 63 General ® STANDARD WINCH LIEBHERR PR724/PR736 H6HT**L41/L410/L42 Figure 1-43 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 54...

- Page 64 Section 1 ® STANDARD WINCH TIGERCAT 635D H6HT**Y44 Figure 1-44 Hydraulic/Electrical Schematic (Rev. P), H6HT (Standard) Winch 1 - 55...

- Page 65 General ® Notes Notes 1 - 56...

-

Page 66: General

Section 2 ® Troubleshooting General Winch problems generally fall into one of three categories: Check winch hydraulic pressures. Start with control controls, hydraulic system, or mechanical system. Follow pressures, then check main system pressures. the troubleshooting steps below to isolate the probable Inspect the winch gear train for problems. - Page 67 Troubleshooting ® 1.9 Install gauges at motor ports A & B using 0-5000 psi gauges. Disconnect Replace high pressure relief valve the brake line and move the control lever in LINE-IN and LINE-OUT. cartridge and return to step 1.6. If pressure is below 4100 psi, is it possible to adjust the relief valve? Adjust high pressure relief valve (Refer to Section 3 for more details on pressure check procedures.) to 4100 psi.

-

Page 68: Troubleshooting Analysis Check Chart

Section 2 ® Troubleshooting Analysis Check Chart PROBLEM POSSIBLE CAUSE CORRECTION Winch gets very hot Low oil level. Add oil; refer to tractor oil specifications. Improper oil viscosity. Use correct oil grade; refer to tractor oil specifications. Winch coated with dirt. Clean winch. - Page 69 Troubleshooting ® PROBLEM POSSIBLE CAUSE CORRECTION Winch will not generate sufficient line Leak in hydraulic system other than Plug brake line and check that pressure pull or does not line in or line out brake assembly. at motor port A is 4100 psi, and that (Continued from previous page) pressure at motor port B is 3500 psi.

- Page 70 Section 2 ® PROBLEM POSSIBLE CAUSE CORRECTION HI-SPEED function will not operate. Insufficient pilot pressure. Repair pilot supply. No pressure at X1 port D i a g n o s e c o n t r o l l e r o r s u p p l y malfunction, and repair as needed.

- Page 71 Troubleshooting ® Notes 2 - 6...

-

Page 72: Service

Access Cover for Motor and Winch Hydraulics Fill Plug Plug to Check Oil Level Breather Plug to Drain Oil Figure 3-1 H6H Winch Maintenance Points INTERVAL PROCEDURE OR QUANTITY SPECIFICATION 50 hours or weekly Check oil level at plug (item 2). Add oil as See Oil Specifications in Section 1. -

Page 73: Checks Before Operation

Service ® Checks Before Operation the housing with a hammer to make sure the bearing is sliding. Check resistance to rotation after each adjustment. Check that the wire rope and hook are not worn or damaged. Check that the periodic inspection and maintenance have been done at the recommended Hydraulic System Pressure Checks operating hours. -

Page 74: Pilot Supply Pressure Check

Section 3 ® (6895 kPa) and two 5000 psi (34,474 kPa) test gauges. Relief Valve Adjustment: Pilot Supply Pressure Check Leave the brake pressure supply disconnected. Start the engine and operate the winch in LINE-IN With the engine shut off, connect a 1000 psi gauge to the tractor pilot test port (see tractor Service Manual). -

Page 75: Freespool Pressure Check

Service ® Brake Valve Adjustment: will not be active at this pressure. All pressures should be as specified in Figure 3-5 . Slowly meter the control lever into the LINE-IN position. If pressures are not as specified in Figure 3-5, check for: Measure pressure at BR and XI pressure test ports. -

Page 76: Line-In Pressure Check

Section 3 ® If pressures are not as specified in Figure 3-5, check for: If the line out pressure is not as specified in Figure 3-5, check for: Improper pilot supply pressure. Improper pilot supply pressure. Malfunctioning solenoid valve. Malfunctioning control lever. Leaking pressure hoses or fittings. -

Page 77: Hydraulic System Pressure Tests

Service ® Hydraulic System Pressure Tests TEST ITEM CHECK PORT TEST EQUIPMENT CONTROL PRESSURE CORRECTIVE REQUIRED POSITION ACTION Pilot Supply Tractor Pilot 1000 psi (6895 kPa) Tractor blade See Figure 3-6 Adjust tractor pilot Test Port gauge over relief below for details. reducing valve. - Page 78 Section 3 ® Notes 3 - 7...

- Page 79 Service ® Notes 3 - 8...

-

Page 80: Repairs

Section 4 ® Repairs General This section includes the removal and disassembly of WARNING all major assemblies, inspection of components, and reassembly and installation. The wear points detailed in Be careful when you remove the wire rope Figure 4-8 should be inspected at the time of disassembly from the drum. - Page 81 Repairs - Intermediate & FREESPOOL Shaft Removal ® Freespool Shaft Freespool Piston Freespool Shifter Fork O-Ring O-Ring Spring Gear Bushing Freespool Adjust Piston 10. O-Ring 11. Freespool Adjust Housing 12. Intermediate Shaft 13. Pinion Gear 14. Dental Clutch 15. Screw 16.

- Page 82 Section 4 ® Intermediate and FREESPOOL Shaft Removal The intermediate and FREESPOOL shafts can be removed with the winch mounted on the tractor. Withdraw the shaft by rotating counter clockwise and Remove the capscrews securing the shifter shaft remove the fork. cover and take the cover off.

-

Page 83: Intermediate & Freespoool Shaft Removal

Repairs - Intermediate & FREESPOOL Shaft Removal ® Tag shims for reference during reassembly (not Remove bearing cup and cone and the intermediate shown). shaft, while ensuring that the intermediate gear does not fall. Screw a 3/4-16 UNF slide hammer into the end of the intermediate shaft and partially pull it out. - Page 84 Section 4 ® Intentionally Blank 4 - 5...

- Page 85 Repairs - Drum Shaft & Drum Removal ® Drum Shaft & Drum Removal whenever possible. To remove the drum gear it will be Figure 4-2 shows the location of drum and drum shaft necessary to first remove the intermediate shaft (see components.

- Page 86 Section 4 ® Loosen the drum capscrews, then remove capscrews Remove bearing retainer and shim pack. with thimbles, leaving two located 180° apart. Leave Two Capscrews Drum Retainer Located 180° Apart Shim Pack Thimble Capscrew NOTE: Tag shim pack for reference during reassembly. Remove drum shaft locknut, the retainer capscrews Remove retainer ring by removing retainer capscrews and washers.

-

Page 87: Drum Shaft & Drum Removal

Repairs - Drum Shaft & Drum Removal ® Remove roller bearing. Carefully remove the drum from winch frame. Ensure that the adapter does not fall. NOTE: Bearing, cups and spacers are a matched set, and must not be interchanged with other bearing set components. - Page 88 Section 4 ® 10. Remove and discard the piston seal ring from the 12. Using a suitable lifting device, the drum gear can right-hand side of the drum. now be removed. Piston Seal Ring Drum Gear NOTE: This seal must be replaced with a new Allied Systems Company-approved seal during reassembly.

-

Page 89: Hydraulic System Disassembly

Repairs - Hydraulic System Disassembly ® Hydraulic System Disassembly sure to clearly mark the hose ends of any hoses removed Disconnecting the hoses is necessary in order to remove with their corresponding ports. the motor shaft assembly. For easier re-installation, be (PD) (PP) (FS) - Page 90 Section 4 ® (ACCUM A (ACCUM B PORT) PORT) 11, 13 HOSES & WIRE HARNESS PASS THROUGH FRAME HERE (REF) CHARGE WITH SECURE COLORED ZIP-TIES NITROGEN GAS TO HOSES NEAR THE FREE TO 500-550 PSI HOSE END FITTING AS FOLLOWS: RI = YELLOW, RO = ORANGE, PP = GREEN MOTOR (REF)

- Page 91 Repairs - Hydraulic System Disassembly ® Drain oil from winch, remove tube support bracket, Remove motor tube assembly at Ports A and B on and covers as shown. the motor. MOTOR TUBE ASSEMBLY MOTOR (REF) Remove the two freespool hoses. (Other parts not Remove remaining hoses.

- Page 92 Section 4 ® Remove the counterbalance relief manifold. 4 - 13...

-

Page 93: Motor Shaft Removal & Disassembly

Repairs - Motor Shaft Removal & Disassembly ® Motor Shaft Removal and Disassembly housing requires removing the Freespool Shifter Fork and Removal and disassembly of the motor shaft assembly can Intermediate Shaft and Gear first (see Intermediate & be accomplished while the winch is mounted on the tractor. FREESPOOL Shaft Removal section). - Page 94 Section 4 ® Remove the manifold support bracket from frame. Remove the brake. MANIFOLD SUPPORT BRACKET BRAKE ASSEMBLY Remove the hydraulic motor. Remove the cover plate. BEARING COVER HYDRAULIC MOTOR Remove the support bracket. Remove planetary reducer/clutch housing assembly. 4 - 15...

- Page 95 Repairs - Motor Shaft Removal & Disassembly ® Remove and discard the O-ring. Remove the clutch assembly piston and seal ring from the clutch housing. CLUTCH HOUSING (REF) O-RINGS CLUTCH ASSMEBLY PISTON O-RING CLUTCH ASSEMBLY (REF) Remove the clutch housing from the reducer. PLANETARY REDUCER (REF) CLUTCH HOUSING 4 - 16...

- Page 96 Section 4 ® Intentionally Blank 4 - 17...

-

Page 97: Brake-Off Clutch Disassembly

NOTE: Disassembling the clutch while it’s still under its warranty period immediately invalidates the warranty. If the clutch malfunctions before its warranty period expires, please contact Allied Systems Company first before attempting to repair it. Remove capscrews and washers from the plate. - Page 98 Section 4 ® Separate the clutch hub and the pressure plate. PRESSURE PLATE CLUTCH HUB 4 - 19...

-

Page 99: Brake Disassembly

Repairs - Brake Disassembly ® Brake Disassembly expires, please contact Allied Systems Company first NOTE: Disassembling the brake while it’s still under its before attempting to repair it. warranty period immediately invalidates the warranty. If the brake malfunctions before its warranty period... - Page 100 Section 4 ® NOTE: Remove the four socket head capscrews (item 23). A 1. Primary disc is positioned by shoulder bolts suitable holding fixture is useful to keep brake in position. (item 7) and stator discs are positioned on dowel Tap female end of spline shaft assembly (item 6) and pins (item 13).

-

Page 101: Planetary Reducer Disassembly

Repairs - Planetary Reducer Disassembly ® Planetary Reducer Disassembly NOTE: Disassembling the reducer while it’s still its warranty period expires, please contact Allied under its warranty period immediately invalidates Systems Company first before attempting to repair it. the warranty. If the reducer malfunctions before Sun Gear Thrust Washer Primary Carrier Assembly... - Page 102 Section 4 ® Intentionally Blank 4 - 23...

-

Page 103: Winch Assembly

Repairs - Winch Assembly ® Winch Assembly may fail when placed under a load. When in doubt, it is All components should be inspected for wear or damage recommended to install a new bearing. Any component as they are removed. Refer to Figure 4-8, Visual Inspection. that indicates excessive wear or damage should be All seals that were removed should be replaced during replaced. -

Page 104: Visual Inspection

Section 4 ® Figure 4-8 Visual Inspection - 2 ITEM INSPECTION REQUIREMENTS CORRECTIVE ACTION Direction Control Check that all passages and cartridge Clean or replace cartridge valves. Clean all Manifold valves are free of contaminants. hydraulic passages. Logic Control Check that all passages and cartridge Clean or replace cartridge valves. -

Page 105: Planetary Reducer Assembly

Repairs - Planetary Reducer Assembly ® Planetary Reducer Assembly NOTE: Disassembling the reducer while it’s still its warranty period expires, please contact Allied under its warranty period immediately invalidates Systems Company first before attempting to repair it. the warranty. If the reducer malfunctions before Sun Gear Thrust Washer Primary Carrier Assembly... - Page 106 Section 4 ® NOTE: Washer can be secured to cover with a small Clean mating surfaces and apply a bead of silicone amount of grease or silicone sealant. Install the cover sealant to the face of the hub that mates with the ring gear (item 4).

-

Page 107: Brake Assembly

Repairs - Brake Assembly ® Brake Assembly expires, please contact Allied Systems Company first NOTE: Disassembling the brake while it’s still under its before attempting to repair it. warranty period immediately invalidates the warranty. If the brake malfunctions before its warranty period... - Page 108 Section 4 ® NOTE: Lubricate all rubber components with clean 10. Install springs (item 15) according to pattern and hydraulic fluid before reassembly. color recorded during disassembly. Clean all parts thoroughly before assembling. 11. Affix case gaskets (item 11) to pressure plate (item 22) and spring plate (item 14).

-

Page 109: Brake-Off Clutch Assembly

If the motor malfunctions before its warranty period Advance retainer three additional teeth & align with expires, please contact Allied Systems Company first hub splines. before attempting to repair it. Draw a line across adjacent teeth with marker. - Page 110 Section 4 ® Remove retainer noting the number of turns required 13. Install retainer to height “D”. (use the number of turns for removal. required for removal & align marks on teeth). SPRING RETAINER SPRING RETAINER 10. Disassemble clutch. 14. Install frictions, separators, & clutch plate. 11.

- Page 111 Repairs - BRAKE-OFF Clutch Assembly ® 16. Install 1.75” (45 mm) long or longer capscrews into 24. Check final height “D”. it should be +0.012/-0.000 holes with pins. (longer capscrews work better). of original height “D”. 17. Place block underneath retainer so that pressure plate is suspended in the air.

- Page 112 Section 4 ® Intentionally Blank 4 - 33...

-

Page 113: Motor Shaft Assembly & Installation

Repairs - Motor Shaft Assembly & Installation ® Motor Shaft Assembly and Installation Assembly and installation of the motor shaft assembly can but taking out the planetary reducer and reducer housing be accomplished while the winch is mounted on the tractor. must be installed before the Freespool Shifter Fork and The motor and brake can be installed independently of Intermediate Shaft and Gear (see Intermediate Shaft... - Page 114 Section 4 ® Install new O-rings on seal ring and clutch piston, Lower clutch assembly vertically using jib hoist and then install thrust needle roller bearing, thrust ring, M12x1.75 metric eyebolt. and snap ring. Align paint marks on piston and clutch housing. Assembly, Clutch Position seal ring so three locking tabs align with Shaft, Clutch...

- Page 115 Repairs - Motor Shaft Assembly & Installation ® Rotate seal ring clockwise with brass drift and Install clutch housing assembly into reducer. hammer until lock bolt notch aligns with bolt hole. PLANETARY REDUCER (REF) CLUTCH HOUSING Testing clutch 10. Install new O-ring on clutch housing. WARNING Wear safety glasses whenever working around pressurized hydraulics.

- Page 116 Section 4 ® 11. Install planetary reducer assembly into winch frame. 14. Install the brackets. 12. Reinstall cover plate. 15. Install the hydraulic motor. BEARING COVER HYDRAULIC MOTOR 13. Reinstall the brake. 16. Install the manifold support bracket in frame. BRAKE ASSEMBLY MANIFOLD SUPPORT BRACKET 4 - 37...

-

Page 117: Hydraulic System Assembly

Repairs - Hydraulic System Assembly ® Hydraulic System Assembly (PD) (PP) (FS) (WIRE HARNESS CONNECTION YELLOW AND BLACK WIRES) (TP-BRAKE) 1.30 (WIRE HARNESS CONNECTION (BO) ORANGE AND BLACK WIRES) (TO FREESPOOL (BRAKE) SHIFTER FORK) (X1) LOGIC MANIFOLD DETAIL VIEWS (HOSES NOT SHOWN FOR CLARITY) SECURE BRACKET WITH TOP (4 PLCS) ('ORIFICE 1' TO 'PD') - Page 118 Section 4 ® (ACCUM A (ACCUM B PORT) PORT) 11, 13 HOSES & WIRE HARNESS PASS THROUGH FRAME HERE (REF) CHARGE WITH SECURE COLORED ZIP-TIES NITROGEN GAS TO HOSES NEAR THE FREE TO 500-550 PSI HOSE END FITTING AS FOLLOWS: RI = YELLOW, RO = ORANGE, PP = GREEN MOTOR (REF)

- Page 119 Repairs - Hydraulic System Assembly ® Install the counterbalance relief manifold. Leave Follow the motor tube installation procedures below: mounting bolts loose until motor tubes are installed. • Install motor tube assemblies, but do not tighten. • Adjust the manifold fittings as needed. •...

- Page 120 Section 4 ® Install freespool, brake, and brake-off hoses. BRAKE-OFF HOSE FREESPOOL HOSES BRAKE HOSE 4 - 41...

-

Page 121: Drum & Drum Shaft Installation

Repairs - Drum & Drum Shaft Installation ® Drum and Drum Shaft Installation If the drum gear was removed, it must be installed prior to installation of the intermediate shaft and motor shaft assembly. DETAIL A Adapter 10. Piston Seal Ring 20. - Page 122 Section 4 ® Coat seal bore with sealant. Install double-lip oil seal Replace the O-ring inside the spacer, and install with smooth side towards the drum in the right-hand roller bearing, spacer and oil seal into the left-hand side of the frame. side drum bore.

- Page 123 Repairs - Drum & Drum Shaft Installation ® Move the drum into position while being careful not Install drum gear. to loose the piston seal ring. Piston Seal Ring Drum Gear Drum Align adapter and drum holes, then install the Align drum gear with adapter and temporarily secure thimbles and screws.

- Page 124 Section 4 ® Make sure that double-tapered roller bearing, seal 10. Remove the retainer plate and install the bearing and spacer are properly seated in the left-hand side assembly. of the drum, refer to Step 3. Roller Bearing Roller Bearing Drum Shaft (REF.) Spacer, O-Ring...

- Page 125 Repairs - Drum & Drum Shaft Installation ® 12. Set drum retainer into place and tighten capscrews 15. Coat shaft nut threads with anti-seize. Apply silicone (do not tighten to final torque). Measure gap between between the left drum nut and frame, and between retainer and winch frame in three places around the right drum nut and drum retainer.

- Page 126 Section 4 ® Intentionally Blank 4 - 47...

- Page 127 Repairs - Intermediate & FREESPOOL Shaft Installation ® Intermediate & FREESPOOL Shaft Installation Freespool Shaft Freespool Piston Freespool Shifter Fork O-Ring O-Ring Spring Gear Bushing Freespool Adjust Piston 10. O-Ring 11. Freespool Adjust Housing 12. Intermediate Shaft 13. Pinion Gear 14.

- Page 128 Section 4 ® Intermediate & FREESPOOL Shaft Place dental clutch on pinion gear. Ensure chamfered ramp faces pinion. Installation Dental Clutch These figures show the winch removed from the tractor with the clutch shaft and brake shaft removed. Install inner bearing assembly if previously removed. Use a liberal amount of lubriplate or other light lube grease to hold the inner bearing cone in place.

-

Page 129: Intermediate & Freespool Shaft Installation

Repairs - Intermediate & FREESPOOL Shaft Installation ® Install the outer bearing cup and cone. Make sure Coat the winch frame and retainer with silicone or that the cup is firmly seated against the bearing cone. other suitable sealing compound. Install shim pack (if necessary) and cover. - Page 130 Section 4 ® 11. Install hose assembly. 13. Secure the cover and the gasket with washers and capscrews. Hose Assembly Capscrew Washer Cover Gasket Freespool Shifter Fork (REF.) 12. Apply adhesive-sealant to threads of FREESPOOL 14. Install right-hand top cover with gasket, washers and shaft.

-

Page 131: Winch Installation

Repairs - Winch Installation ® Winch installation Align the studs with the mounting holes to prevent thread damage. Thoroughly clean the mounting surfaces on the Loosely install the two top nuts or capscrews before winch and the tractor. Clean the mounting holes and the winch is fully seated against the tractor. - Page 132 Section 4 ® Notes 4 - 53...

- Page 133 ® To find a dealer in your area, Call: (503) 625-2560, Fax: (503) 625-7269 , or Email: marketing@alliedsystems.com, or Visit our website: http://www.alliedsystems.com 599040W 7/2018 Printed in USA...

Need help?

Do you have a question about the H6H and is the answer not in the manual?

Questions and answers