Allied Systems W6G Operating Manual

Towing winch

Hide thumbs

Also See for W6G:

- Quick start manual (2 pages) ,

- Operating manual (46 pages) ,

- Service manual (36 pages)

Summary of Contents for Allied Systems W6G

- Page 1 This manual must be with the vehicle on which this winch is installed. Please check the Allied Systems website regularly for updates to this manual. www.alliedsystems.com P/N 599002W 11/05/2015...

- Page 2 Serial Number Winch Model Date Installed Date Delivered Special Equipment or Attachments A Product of Allied Systems Company Sherwood, Oregon 11/05/2015 U.S.A. Printed in U.S.A.

-

Page 3: Foreword

• Become familiar with the winch and the machine on this Operating Manual, contact your local winch dealer, which it is mounted and see that they are maintained or contact Allied Systems Company: in good condition. Allied Systems Company • Read and understand the SAFETY SUMMARY... - Page 4 Note: For repairs and overhaul, contact your Allied Note: This publication may be translated to different winch dealer. If you maintain your own equipment, a languages for sole purpose of easy reference in service manual is available from our website for your non-English speaking locations.

-

Page 5: Table Of Contents

Wire Rope Selection ........... 4 Checks Before Operation ......... 29 Oil Capacity & Recommended Oil List ....... 5 Checks During Operation ......... 29 W6G Winch Description ..........6 Operating Procedures ..........30 Optional Equipment ............ 7 Power Operation ............33 Serial Number Codes .......... -

Page 6: Contents

Contents Maintenance Operational Differences, Optional Equipment Maintenance Points ..........45 Integral Arch ............. 63 Maintenance Schedule ..........46 Fairlead ..............63 Drawbar ..............64 Operating Techniques, Power Controls Optional Gear Ratios ..........64 Tractor or Skidder Operation ........49 Operating Techniques, Electronic Controls Tractor or Skidder Operation ........ -

Page 7: Safety Summary

Safety Summary Safety Summary General Safety Notices WARNING The following pages contain general safety warnings which supplement specific warnings and cautions T h e “ WA R N I N G ” s y m b o l a p p e a rs appearing elsewhere in this manual. - Page 8 Should the recommendations in this manual deviate from NOTICE those in the user’s country, the national regulations should be followed. The “NOTICE” symbol alerts to a situation that is not related to personal injury but NOTE: All possible safety hazards cannot may cause equipment damage.

- Page 9 Safety Summary Safety Summary Operation, Inspection, and Maintenance Warnings • Inspect the winch before each use: » Make sure that the controls and instruments operate correctly. » Report the need for repairs immediately. Obey the following cautions and warnings before using your winch to »...

- Page 10 • Do not use the control levers as hangers for clothes, • Always inspect wire rope, tail chain and other rigging water bags, grease guns, lunch pails, etc. components for wear, damage, broken strands or abuse before use. • Do not leave the vehicle when the winch wire rope is under tension.

- Page 11 Safety Summary • Stay clear of wire rope entry areas (fairlead or arch • If applying tension to the wire rope manually during rollers, winch drum etc). spooling: » ensure that the operator is winching in slowly, • Make sure ground personnel are in plain view of the operator, and at a distance of at least 1½...

- Page 12 • Use only the lubricants listed in the Recommended Oil List. See Page 5. • Do not weld on any part of the winch. Contact Allied Systems if weld repairs are needed. • The hydraulic system must be kept clean and free of contamination at all times.

- Page 13 Safety Summary Notes...

- Page 14 Notes...

-

Page 15: General

Introduction This Operating Manual contains basic information The winch has hydraulic clutches that are similar to a necessary for the operation and maintenance of the W6G hydraulic (powershift) transmission. Most tractors and winch. skidders have a Power Take-Off (PTO) that is used to connect the power from the engine to the winch. - Page 16 The winch has an intermediate gear assembly that The W6G winch has a maximum line pull capacity of provides a gear reduction and increases the available 266,880 N (60,000 lbf) when there is one layer or less of torque at the winch drum.

-

Page 17: Nameplate

General Nameplate Each winch is shipped from the factory with a nameplate as shown in Figure 1. The nameplate is stamped with: • winch model • winch serial number • maximum bare drum line pull • maximum wire rope diameter DO NOT operate the winch with larger diameter wire rope. -

Page 18: Wire Rope Selection

Wire Rope Selection WARNING Each winch model can have a variety of wire rope sizes The wire rope may disengage from the installed by the user. The maximum wire rope size is shown ferrule pocket if there is a load on the on the nameplate. -

Page 19: Oil Capacity & Recommended Oil List

General Oil Capacity & Recommended Oil List The oil capacity for W6G winch is 19.5 gallons (73.8 liters). The type of oil used in Allied winches affects the line control. Use the following oils in the W6G winch: Recommended Oils* - All Applications (Applications such as equipment rescue, logging, cable plow, and inching applications such as pipe setting, yo-yo, line sagging, etc.) -

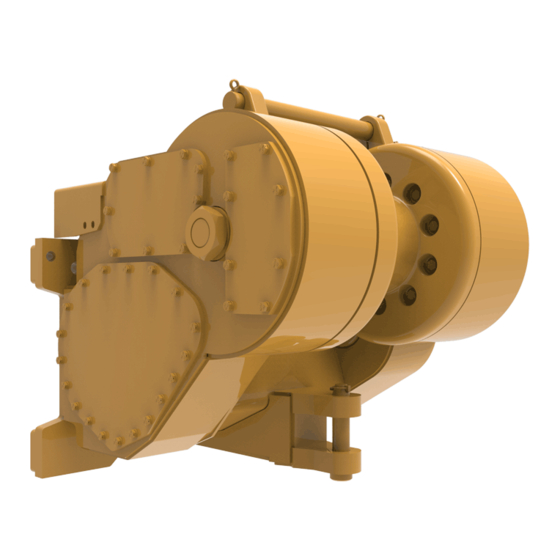

Page 20: W6G Winch Description

3. Access Cover to Hydraulic Valve 9. Bearing Retainer for Intermediate Shaft 4. Plug to Check Oil Level & FREESPOOL Drag Adjuster 5. Plug to Drain Oil 10. Right Side Drum Shaft 6. Tie Rod 11. Breather Figure 4 - W6G Towing Winch... -

Page 21: Optional Equipment

General Optional Equipment • alternate gear ratio • heavy duty extended drawbar The W6G winch may be equipped with the following • electronic controls options: NOTE: Not all optional equipment listed is available • integral arch for each model of tractor •... -

Page 22: Serial Number Codes

The nameplate with the serial number code is found on the left front corner of the winch case. A serial number indicates the following information: 1555 Manufactured By Vehicle Code A = Made by Allied Systems Company See Figure 6 Winch Model Sequence Number W6G = Standard Internal Option... -

Page 23: Tractor & Skidder Identifi Cation Codes

General Figure 6 - Tractor Identifi cation and Gear Ratio Tractor Make Model and Starting Tractor Serial Number Where Applicable Fiat-Hitachi/ Caterpillar John Deere Dresser/ Komatsu Case New Holland Dressta Quadtrac 1650L 750B W/O CAB 850B W/ CAB ... - Page 24 Figure 6 - Tractor Identifi cation and Gear Ratio Tractor Make Model and Starting Tractor Serial Number Where Applicable Fiat-Hitachi/ Caterpillar John Deere Dresser/ Komatsu Case New Holland Dressta TD15E PS 750B W/ CAB 750C I & II TD15E DD ...

- Page 25 General Figure 6 - Tractor Identifi cation and Gear Ratio Tractor Make Model and Starting Tractor Serial Number Where Applicable Fiat-Hitachi/ Caterpillar John Deere Dresser/ Komatsu Case New Holland Dressta FD14E, DX/FD175/195 D6H PS D6H DD ...

- Page 26 Figure 6 - Tractor Identifi cation and Gear Ratio Tractor Make Model and Starting Tractor Serial Number Where Applicable Fiat-Hitachi/ Caterpillar John Deere Dresser/ Komatsu Case New Holland Dressta D6R PS D6R II & III PS; D6T ...

- Page 27 General Figure 6 - Tractor Identifi cation and Gear Ratio Tractor Make Model and Starting Tractor Serial Number Where Applicable Fiat-Hitachi/ Caterpillar John Deere Dresser/ Komatsu Case New Holland Dressta Tractors (C47) with linkage hydraulic valve controls Prior to the following serial numbers, tractor code C47 was used for D6N: D6N--CBJ00400 ALH00735 CCK00500...

- Page 28 Intentionally Blank...

-

Page 29: Operation, Power Controls

The Troubleshooting Chart at the end of this section can be (See Figure 14, Maintenance Schedule, for the W6G used by the operator to identify a problem with the winch winch on page 46.) operation. -

Page 30: Operating Procedures

Operating Procedures The BRAKE-OFF position has a detent and is a neutral position for the clutches. Hydraulic pressure is applied to The control lever assembly has two control levers and the release the brake. The winch will not rotate easily because operation is the same in all confi... - Page 31 OFF and the keyswitch ON may result in accumulator discharge and brake release which will cause loss of load. 1. Power Control Lever 1. Power Control Lever 2. Freespool Lever Figure 7 - W6G Winch Operator Controls_Standard Figure 7.1 - W6G Winch Operator Controls_Freespool Option...

- Page 32 Figure 7.2 - W6G Winch Operator Controls_Dual Axis...

-

Page 33: Power Operation

Operation, Power Controls Power Operation Note: The solid dots indicate the positions of the control levers. The hatched dots indicate the positions of the FREESPOOL control lever. BRAKE-ON position is a neutral position. Neither clutch LINE-OUT position applies the LINE-OUT clutch and is applied. - Page 34 Inching occurs when the power control lever is slowly oil pressure to slowly release the brake and slowly apply moved to a position between BRAKE-ON and LINE-IN or the LINE-IN clutch. As the brake is released, the clutch between BRAKE-ON and LINE-OUT. Inching is used for takes control and begins to move the load.

-

Page 35: Determining Tractor Pto Type

Operation, Power Controls Determining Tractor PTO Type Engine Direct Driven PTOs Allied PTO winches are designed to allow a smooth line Engine direct PTOs require higher RPMs to prevent engine speed transition when starting to move a load, and for stall, which will cause high clutch and brake temperatures bringing a load to a stop. -

Page 36: Torque Converter Driven Ptos

Torque Converter Driven PTOs For LINE-IN Inching Operation: Torque converter driven PTOs allow inching without • Decelerate the tractor engine rpm to idle. excessive clutch and brake heat generation if the correct • Move the winch control lever until the load is moving at procedure is used. -

Page 37: Freespool Operation

Operation, Power Controls FREESPOOL Operation WARNING The control lever normally cannot be moved to the FREESPOOL position if there is a load on the wire rope. If enough force is used to disengage the gear train for the FREESPOOL operation, an uncontrolled release of the load will occur. - Page 38 CAUTION Setting the preload on the intermediate shaft too tight will cause bearing overload. Setting the preload too loose will allow shaft to not be parallel. Extreme care must be used when adjusting FREESPOOL drag. Determine the correct preload by starting with the preload too loose, and gradually increase the preload until the correct resistance to rotation is achieved.

-

Page 39: Troubleshooting Chart

Operation, Power Controls PROBLEM POSSIBLE CAUSE CORRECTION Hydraulic oil is too cold. Put the control lever in the BRAKE-OFF position. Run the engine at 1000 rpm to warm the oil to 80°F before operating the winch. Low oil level. Add hydraulic oil to the correct level. Operation is rough Low oil pressure. - Page 40 PROBLEM POSSIBLE CAUSE CORRECTION Brake is worn. Brake begins to release before clutch See the Service Manual for additional troubleshooting. Pressure modulator needs repair or is applied adjustment. Winch brake does Brake is worn. See the Service Manual for additional not apply or release Low oil pressure.

- Page 41 Operation, Power Controls Intentionally Blank...

- Page 42 Intentionally Blank...

-

Page 43: Operation, Electronic Controls

Operation, Electronic Controls Operation, Electronic Controls Checks Before Operation Checks During Operation • Check the wire rope and hook for wear or damage. • Check the winch indication light: • Check that the periodic inspection and maintenance - Light steady on after oil warmup means some have been done at the recommended operating hours. -

Page 44: Operating Procedures

Operating Procedures FREESPOOL position. The electronic control assembly has one control lever. The The BRAKE-ON position is a neutral position. No hydraulic control lever is connected to the winch through electrical pressure is applied to the brake or the clutches. Springs wiring, an electronic control module, a solenoid actuated apply the brake so that the winch drum will not rotate. - Page 45 TO SIGNAL A SHORTED OR OPEN CONTROL LEVER VALVE COIL CIRCUIT. DECAL ACTIVATION SWITCH THIS LED WILL ALSO ILLUMINATE MOMENTARILY AS A SELF-TEST ON STARTUP. WINCH INDICATOR LIGHT WINCH INDICATOR LIGHT DECAL Figure 10 - W6G Towing Winch Operator Controls (Old Style)

- Page 46 Moving the control lever with the LINE-IN engine OFF and the keyswitch BRAKE-ON ON may result in accumulator discharge and brake release which will cause loss of load. ACTIVATION SWITCH WINCH INDICATOR LIGHT DECAL Figure 10-1 - W6G Towing Winch Operator Controls (New Style)

-

Page 47: Power Operation

Operation, Electronic Controls Power Operation Note: The solid dots indicate the positions of the control levers. Before operation, ensure status of activation switch. CONTROL LEVER POSITION CONTROL LEVER POSITION BRAKE-ON is a neutral position. Neither clutch is applied. LINE-OUT position applies the reverse clutch and The brake is fully applied. - Page 48 As the brake is released, the clutch computer program changes and may be necessary takes control and begins to move the load. for some customer operations. Contact Allied Systems Company if inching needs adjustment. The following paragraphs describe the normal procedures for inching.

-

Page 49: Determining Tractor Pto Type

Operation, Electronic Controls applied when the operator moves the control lever into 3. If the winch drum continues to rotate, the PTO is engine the LINE-OUT position. When the control lever is moved direct driven. If the drum stops turning, the PTO is so that the reverse clutch is engaged, the speed that the torque converter driven. -

Page 50: Torque Converter Driven Ptos

Torque Converter Driven PTOs For LINE-IN Inching Operation: Torque converter driven PTOs allow inching without • Decelerate the tractor engine rpm to idle. excessive clutch and brake heat generation if the correct • Move the winch control lever until the load is moving at procedure is used. -

Page 51: Freespool Operation

Operation, Electronic Controls FREESPOOL Operation FREESPOOL Drag Adjustment The preload on the bearings of the intermediate shaft WARNING controls the resistance to rotation of the drum during the FREESPOOL operation. The resistance to rotation is Moving the lever into FREESPOOL while correct when the drum can be rotated by hand, but the there is a load on the wire rope will cause drum will not rotate more than one-half revolution freely. - Page 52 CAUTION Setting the preload on the intermediate shaft too tight will cause bearing overload. Setting the preload too loose will allow shaft to not be parallel. Extreme care must be used when adjusting FREESPOOL drag. Determine the correct preload by starting with the preload too loose, and gradually increase the preload until the correct resistance to rotation is achieved.

-

Page 53: Troubleshooting Chart

Operation, Electronic Controls PROBLEM POSSIBLE CAUSE CORRECTION Hydraulic oil is too cold. Put the control lever in the BRAKE-OFF position. Run the engine at 1000 rpm to warm the oil before operating the winch. Operation is rough or Low oil level. Add hydraulic oil to the correct level. - Page 54 PROBLEM POSSIBLE CAUSE CORRECTION Worn or damaged clutch. Clutch does not apply See the Service Manual for additional troubleshooting, Control valve failure. correctly. checks and adjustments. Low oil pressure. Clutch does not apply Accumulator not charged. Check accumulator. correctly at low PTO PTO stalled (0 rpm).

- Page 55 Operation, Electronic Controls PROBLEM POSSIBLE CAUSE CORRECTION Defective return spring, worn See the Service Manual for additional troubleshooting. detent parts, or lubricant Control lever does not evacuation. return to neutral when released. Control lever is in detented position Move control lever out of detent. (BRAKE-OFF or FREESPOOL).

- Page 56 PROBLEM POSSIBLE CAUSE CORRECTION Cartridge valve plugged. Replace cartridge if pressure at appropriate gage port Winch will not operate is not close to relief pressure with coil energized. in any function. Loose or worn connector. Check and replace as needed. Relief pressure not being reached.

- Page 57 Intentionally Blank...

- Page 58 Intentionally Blank...

-

Page 59: Maintenance

Use the operating time 1. Access Cover for Control Valve 5. Fill Plug 2. Plug to Check Oil Level 6. Breather 3. Plug to Drain Oil 7. Nameplate 4. Access Cover for Filter and Strainer Figure 13 - W6G Winch Maintenance Points... -

Page 60: Maintenance Schedule

INTERVAL PROCEDURE OR QUANTITY SPECIFICATION 50 hours or weekly Check oil level at plug (item 2). Add oil as necessary See Figure 3 – Recommended Oil List. through fi ll plug (item 5). Do not operate tractor when checking the oil level. Check winch control lever. - Page 61 Intentionally Blank...

- Page 62 Intentionally Blank...

-

Page 63: Operating Techniques, Power Controls

Operating Techniques, Power Controls Operating Techniques, Power Controls Note: The solid dots indicate the positions of the control levers. Tractor or Skidder Operation The hatched dots indicate the positions of the FREESPOOL control lever. • Step 1. The tractor or skidder is moved to an area Step 2. - Page 64 Step 3. The operator can move the control lever to the Step 4. If the tractor or skidder must travel through LINE-IN position. If the load is less than approximately an area with bad traction conditions, the operator can 75% of the maximum line pull, the operator can begin move the control lever to the BRAKE-OFF (DETENT) traveling with the vehicle at the same time.

- Page 65 Operating Techniques, Power Controls Step 5. When the vehicle is on fi rm ground, the operator Step 6. When the operator wants to disconnect can move the control lever to LINE-IN to pull the load from the load, the vehicle is stopped and the control toward the vehicle.

- Page 66 Intentionally Blank...

-

Page 67: Operating Techniques, Electronic Controls

Operating Techniques, Electronic Controls Operating Techniques, Electronic Controls Tractor or Skidder Operation CONTROL CONTROL LEVER LEVER POSITION POSITION CONTROL LEVER POSITION • Step 1. The tractor or skidder is moved to an area Step 2. A load (logs) is connected to the wire rope. where a load will be connected. - Page 68 CONTROL LEVER POSITION CONTROL LEVER POSITION Step 3. The operator can move the control lever to the Step 4. If the tractor or skidder must travel through LINE-IN position. If the load is less than approximately an area with bad traction conditions, the operator can 75% of the maximum line pull, the operator can begin move the control lever to the BRAKE-OFF (DETENT) traveling with the vehicle at the same time.

- Page 69 Operating Techniques, Electronic Controls CONTROL LEVER POSITION CONTROL LEVER POSITION CONTROL LEVER POSITION Step 5. When the vehicle is on fi rm ground, the operator Step 6. When the operator wants to disconnect can move the control lever to LINE-IN to pull the load from the load, the vehicle is stopped and the control toward the vehicle.

- Page 70 Intentionally Blank...

-

Page 71: Operating Techniques, General

Operating Techniques, General How to Move a Disabled Vehicle 4. If the vehicle travels faster than the winch winds the wire rope, disengage the transmission until the winch A. A tractor or skidder often travels in areas where traction wire rope is tightened again. conditions are bad. - Page 72 B. A tractor or skidder equipped with a winch can be used 1. Fasten the winch wire rope to the tow bar of the other to pull another vehicle from mud or other areas where it vehicle. The wire rope must be in a direction that is cannot move using only the drive wheels or tracks.

-

Page 73: Working On A Steep Slope

Operating Techniques, General Working on a Steep Slope A. Moving down the slope: 1. Set the throttle on the tractor for the required engine WARNING speed. The winch and the tractor must be in good 2. Put the tractor in FORWARD. At the same time, move condition for the following procedures. -

Page 74: Other Equipment Is Down The Slope

B. Moving up the slope: Other Equipment is Down the Slope (See Figure 21). 1. Set the throttle on the tractor for the required engine In this operation, the tractor and winch are on stable speed. ground and other equipment is working on a steep slope. - Page 75 Operating Techniques, General A. Lowering the equipment on the slope: B. Raising the equipment on the slope: 1. Set the throttle on the tractor for the required engine 1. Set the throttle on the tractor for the required engine speed. Operator experience is required for this speed.

- Page 76 Intentionally Blank...

-

Page 77: Operational Differences, Optional Equipment

Operational Differences, Optional Equipment Operational Differences, Optional Equipment Integral Arch Fairlead When using an integral arch, the wire rope passes over A fairlead consists of a set of top and bottom horizontal a raised horizontal roller and between a set of smaller rollers and side rollers that the wire rope is passed vertical side rollers and an upper horizontal roller. -

Page 78: Drawbar

Drawbar Optional Gear Ratios Do not use the drawbar as an anchor point for a multi- Lower speed ratios allow better operator control of line part line from the winch. Loads applied to the drawbar are speed. They may also allow the winch to pull in excess of transmitted to the bolts holding the winch to the tractor. - Page 79 Notes Notes...

- Page 80 Notes...

- Page 82 To fi nd a dealer in your area, Call: 503.625.2560, Fax: 503.625.7269, or Email: marketing@alliedsystems.com, or Visit our website: www.alliedsystems.com 599002W 11/05/2015 Printed in U.S.A.

Need help?

Do you have a question about the W6G and is the answer not in the manual?

Questions and answers