Summary of Contents for Allied Systems H6H

- Page 1 This manual must be with the vehicle on which this winch is installed. Please check the Allied Systems website regularly for updates to this manual. www.alliedsystems.com P/N 599038W 7/2018...

- Page 2 Serial Number Winch Model Date Installed Date Delivered Special Equipment or Attachments ® A Product of Allied Systems Company 7/2018 Sherwood, Oregon USA Printed in USA...

-

Page 3: Foreword

• Become familiar with the winch and the machine on this operating manual, contact your local winch dealer, which it is mounted and see that they are maintained or contact Allied Systems Company: in good condition. Allied Systems Company • Read and understand the SAFETY SUMMARY... - Page 4 Should there be differences in interpretations to the text, please refer to the English language edition published by Allied Systems Company as the controlling document.

-

Page 5: Table Of Contents

Contents Contents Foreword ..............i BRAKE-OFF ............. 15 FREESPOOL Operation ........... 16 Contents ..............iii FREESPOOL Drag Adjustment ....... 17 Winch Troubleshooting Chart ........18 Safety Summary ............v Maintenance General Maintenance ............. 19 Introduction ..............1 Maintenance Points ........... 19 Operating Principles of Winch ........ - Page 6 ® Intentionally Blank...

-

Page 7: Safety Summary

Safety Summary Safety Summary General Safety Notices WARNING The following pages contain general safety warnings which supplement specific warnings and cautions The “WARNING” symbol appears appearing elsewhere in this manual. All electrical and wherever incorrect operating procedures hydraulic equipment is dangerous. You must thoroughly or practices could cause serious injury review and understand the Safety Summary before or death. - Page 8 ® NOTE: All possible safety hazards cannot NOTICE be foreseen so as to be included in this manual. Therefore, you must always be alert to potential hazards that could This signal word alerts to a situation that endanger personnel and/or damage the is not related to personal injury but may equipment.

- Page 9 Safety Summary Obey the following cautions and • Inspect the winch before each use: warnings before using your winch, to Make sure that the controls and instruments avoid equipment damage, personal operate correctly. injury or death. Report the need for repairs immediately. •...

- Page 10 ® • Never stand nor permit others to stand in the bight • Do not use winch as a hoist. Tractor and skidder (loop) of a wire rope. mounted winches are designed for towing. • Do not stand nor permit others to be near the winch or wire rope when there is tension on the wire rope.

- Page 11 Safety Summary • Wire rope and tail chain will fail if worn-out, • Make sure ground personnel are in plain view of the overloaded, misused, damaged, improperly operator, and at a distance of at least 1½ times the maintained or abused. Wire rope or tail chain failure working length of the wire rope.

- Page 12 ® • If applying tension to the wire rope manually during • Use only the lubricants listed in the Oil Specifications. spooling: See Page 6. ensure that the operator is winching in slowly, • Do not weld on any part of the winch. Contact Allied Systems if weld repairs are needed.

- Page 13 Safety Summary Notes...

- Page 14 ® Notes...

-

Page 15: General

On the H6H, torque is transmitted through a By moving the control lever to full stroke, HI-SPEED is holding brake, a planetary speed reducer and two gear activated. - Page 16 ® When FREESPOOL is selected, a hydraulically-actuated the motor will automatically increase motor displacement to prevent motor stall. Motor stall will occur when the load sleeve disengages the drum pinion from the intermediate exceeds winch capacity. When the control lever is returned shaft.

-

Page 17: Nameplate

General WARNING BRAKE-OFF should not be used to lower a suspended load or a load that can slide down a slope. Nameplate Each winch is shipped from the factory with a nameplate as shown in Figure 1. The nameplate is stamped with: •... -

Page 18: Wire Rope Selection

® Wire Rope Selection pocket if there is a load on the wire rope with fewer than 3 complete wraps on the drum. This Each winch model can have a variety of wire rope sizes will cause a loss of load and possible injury. When spooling wire rope from the drum, it is installed by the user. -

Page 19: Winch Descriptions

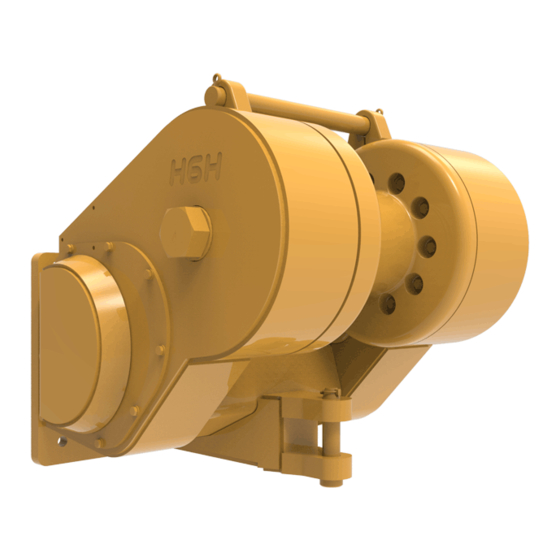

Bearing Retainer for Intermediate Breather Plug to Drain Oil Shaft Maintenance & Warning Decals & FREESPOOL drag Adjuster Plug to Check Oil Level Serial Number Stamp Tie Bar Right Side Drum Shaft Serial Number Plate Figure 4 - H6H Towing Winch... -

Page 20: Oil Specifications

Oil Capacity The hydraulic winch motor and control system operate The oil capacity for H6H winch is 4 gallons (15 liters). off of the tractor implement hydraulic system. The winch gear case is filled with hydraulic transmission oil and is separate from the tractor hydraulic system. -

Page 21: Serial Number Codes

General Serial Number Codes 1001 Winch Model Vehicle Code See Figure 1 H6H = Standard KH6H = Special Design (Contact Factory) Sequence Number Hydraulic Operation Type Internal Options H = High-Performance Hydrostatic or Hydraulic 2 Speed T = Standard, Tractor Controls & Pump... - Page 22 PR724 PR726 1650M/ 2050M PR736 PR736 PR734-4 635D D65-15 750/850J & 750/850K 750/850K with E/H Controls Figure 5 - Tractor Identification Codes and Available Gear Ratios for H6H Winch (1)

- Page 23 D65-16, D65- 17 & D65-18 816/822 D6N* 963D Track Loader * Serial numbers with prefixes GHS, MLW & LJR: ___________________________ Figure 5 - Tractor Identification Codes and Available Gear Ratios for H6H Winch (2)

-

Page 24: Optional Equipment

* See the nameplate for the max wire rope size with arch. • Integral arch • Fairlead assembly • Heavy duty extended drawbar • Optional gear ratios Integral Arch Winch Winch Fairlead Figure 6 - Integral Arch and Fairlead for H6H Winch... -

Page 25: Operation

Operation Operation Checks Before Operation Checks During Operation Check the wire rope and hook for wear or damage. Check The Troubleshooting Chart, Figure 9 on page 18, can that the periodic inspection and maintenance have been be used by the operator to identify a problem with the done at the recommended operating hours. -

Page 26: Operating Procedures

® Operating Procedures BRAKE-ON & LINE-IN The H6H winch is designed to operate on a load sense, The tractor-mounted lever controls LINE-IN, LINE- pilot operated hydraulic system. When the tractor is running, and the auxiliary hydraulic function switch, if OUT and BRAKE-ON functions. When the lever is in... - Page 27 Operation CONTROL LEVER WINCH CONTROL DECAL LINE-IN/OUT DECAL FREESPOOL BRAKE-OFF SWITCH ASSEMBLY SWITCH ASSEMBLY (YELLOW LED) (RED LED) FORWARD (RIGHT-HAND SIDE OF OPERATOR) Figure 7 - H6H Winch Operator Controls (Komatsu D65-16/17/18 - Vehicle Code K49 Shown)

- Page 28 ® CONTROL LEVER BRAKE-OFF LINE-OUT BRAKE-ON LINE-IN DECAL Figure 7.1 - H6H Winch Operator Controls (Case Steiger - Vehicle Code R391 Shown)

-

Page 29: Line-Out

Operation LINE-OUT On certain applications, winches with internal option code D have a HIGH OIL TEMPERATURE warning light LINE-OUT is controlled in the same manner as LINE- at the operator console. If hydraulic oil temperature in IN, except the lever is moved away from the operator. the winch reaches an unsafe level, the light comes on to LINE-OUT speed is also proportional to lever movement. -

Page 30: Freespool Operation

® FREESPOOL Operation WARNING WARNING If the operator leaves the winch in BRAKE- OFF mode, the LINE-IN and LINE-OUT control of the The winch motor will activate if the lever is winch will still operate. However, the holding moved, but the drum will not be in control. brake is locked out and the winch will not hold a suspended load or a load that can slide away. -

Page 31: Freespool Drag Adjustment

Operation switch is turned on, the yellow indicator will light (as well as the red indicator on the brake-off switch). This is because the brake-off clutch is also released in FREESPOOL mode. Adjusting Nut FREESPOOL must be disengaged by the operator or it Jam Nut will stay on. -

Page 32: Winch Troubleshooting Chart

® Troubleshooting Chart PROBLEM POSSIBLE CAUSE CORRECTION Operation is rough or not Hydraulic oil is too cold. Allow tractor hydraulics to warm up. regular. Low oil level. Add oil. Hydraulic oil becomes too hot. Winch is operated for long periods. Allow unit to rest. -

Page 33: Maintenance

Use the operating Maintenance Points Access Cover for Motor and Winch Hydraulics Fill Plug Plug to Check Oil Level Breather Plug to Drain Oil Figure 10 - H6H Winch Maintenance Points... -

Page 34: Maintenance Schedule

® Maintenance Schedule INTERVAL PROCEDURE OR QUANTITY SPECIFICATION 50 hours or weekly Check oil level at plug (item 2). Add oil See Oil Selection and Oil Capacity for details. as necessary through fill plug (item 4). (See Figure 10). Do not operate winch when checking the oil level. -

Page 35: Operating Techniques

Operating Techniques Operating Techniques Tractor Operation (Solid Arrow indicates lever travel direction) Step 1. The tractor or skidder is moved to an area Step 2. A load (logs) is connected to the wire rope. If where a load will be connected. The operator moves the FREESPOOL was used, the operator must deactivate control lever to the LINE-OUT position or activates the the FREESPOOL switch. - Page 36 ® (Solid Arrow indicates lever travel direction) Step 3. The operator can move the control lever to the Step 4. If the tractor or skidder must travel through LINE-IN position. If the load is less than approximately an area with bad traction conditions, the operator can 50% of the maximum line pull, the operator can begin activate the BRAKE-OFF switch.

- Page 37 Operating Techniques (Solid Arrow indicates lever travel direction) Step 5. When the vehicle is on firm ground, the opera- Step 6. When the operator wants to disconnect from tor can deactivate the BRAKE-OFF switch and move the load, the vehicle is stopped and the FREESPOOL the control lever to LINE-IN to pull the load toward the switch is activated to loosen the wire rope.

-

Page 38: How To Move A Disabled Vehicle

® How to Move a Disabled Vehicle Put the control lever in the LINE-IN position to tighten the wire rope. When the wire rope is tight, A. A tractor or skidder often travels in areas where put the vehicle transmission in REVERSE and traction conditions are bad. - Page 39 Operating Techniques B. A tractor or skidder equipped with a winch can be Fasten the wire rope to the tow bar of the other used to pull another vehicle from mud or other areas vehicle. The wire rope must be in a direction that is where it cannot move using only the drive wheels or approximately parallel to the direction of travel of the tracks.

-

Page 40: Working On A Steep Slope

® A. Moving down the slope: Working on a Steep Slope Set the throttle on the tractor for the required engine speed. WARNING Put the tractor in FORWARD. At the same time, The winch and the tractor must be in good move the winch control lever to a position between condition for the following procedures. -

Page 41: Other Equipment Is Down The Slope

Operating Techniques B. Moving up the slope: Other Equipment is Down the Slope (See Figure 15). Set the throttle on the tractor for the required engine In this operation, the tractor and winch are on stable speed. ground and other equipment is working on a steep slope. - Page 42 ® A. Lowering the equipment on the slope: Set the throttle on the tractor for the required engine Set the throttle on the tractor for the required engine speed. Operator experience is required for this speed. Operator experience is required for this operation so that the load is carefully controlled.

-

Page 43: Optional Equipment

Optional Equipment Optional Equipment Integral Arch Fairlead When using an integral arch, the wire rope is routed over A fairlead consists of a set of top and bottom horizontal a raised horizontal roller and through a set of smaller rollers and side rollers that the wire rope is fed through. vertical side rollers and an upper horizontal roller. -

Page 44: Drawbar

® Drawbar Optional Gear Ratios Do not use the drawbar as an anchor point for a multipoint Lower speed ratios allow better operator control of line (over puller) line from the winch. Loads applied to the speed. They may also allow the winch to pull in excess of drawbar are transmitted to the bolts holding the winch wire rope or winch rated capacity. - Page 45 Notes Notes...

- Page 46 ® Notes...

- Page 48 ® To find a dealer in your area, Call: 503.625.2560, Fax: 503.625.7269, or Email: marketing@alliedsystems.com, or Visit our website: www.alliedsystems.com 599038W 7/2018 Printed in USA...

Need help?

Do you have a question about the H6H and is the answer not in the manual?

Questions and answers