Table of Contents

Advertisement

Quick Links

© Panduit Corp. 2020

This manual contains instructions for the following:

• TO REDUCE THE RISK OF INJURY,

Email:

Ga-techsupport@panduit.com

EU Website:

www.panduit.com/emea

EU Email:

emeatoolservicecenter@panduit.com

Rev. 02

PANDUIT LABEL APPLICATOR SYSTEM

OPERATION MANUAL

PLA-100, PLA-H100, PLA-R, and PLA-S

Label Applicator System

WARNING

USER MUST READ INSTRUCTION

MANUAL

www.panduit.com

PLA-100

Original Instructions

For Technical Support

USA & Canada: 1-866-871-4571

Latin America: +52-33-3777-6000

Europe: +31-546-580-452

Asia Pacific Region: 65-6379-6700

Japan: 81-3-6863-6060

PD29768A01

Rev. 02

Jan. 2021

1 / 2021

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Panduit PLA-100

- Page 1 PANDUIT LABEL APPLICATOR SYSTEM OPERATION MANUAL Original Instructions © Panduit Corp. 2020 This manual contains instructions for the following: PLA-100, PLA-H100, PLA-R, and PLA-S Label Applicator System WARNING • TO REDUCE THE RISK OF INJURY, USER MUST READ INSTRUCTION MANUAL...

-

Page 2: Table Of Contents

1: INTRODUCTION ........................3 2: SYSTEM SPECIFICATIONS ....................3 2A: PLA-H100 Applicator Head ....................5 2B: PLA-100 Benchtop Label Applicator ................. 5 2C: PLA-T100X2400 Pressure Sensitive Adhesive Tether ............. 6 2D: PLA-R Label Rewinder ..................... 6 2E: PLA-S English Unit Retractable Scale ................6 2F: PLA-SP Empty Media Spool ..................... - Page 3 PLA-100, PLA-H100 © Panduit Corp. 2020 8: MEDIA SETUP ........................13 9: INSTALLING THE APPLICATOR HEAD ................13 10: INSTALLING THE MEDIA ....................16 11: OPERATION/APPLICATION....................21 12: USER INTERFACE AND ERROR DESCRIPTIONS…………………………………………...23 12A: Applicator Head Error Troubleshooting................24 12B: Peel and Present Error Troubleshooting ................24 12C: Take-Up Error Troubleshooting ..................25...

-

Page 4: 1: Introduction

© Panduit Corp. 2020 1: INTRODUCTION The following are the instructions to setup and operate the Panduit Label Applicator Systems. The Panduit Label Applicator System developed by Panduit Corporation provides customers with a means to apply Panduit self-laminated labels to both rigid and flexible cables for high volume wire harnessing applications. - Page 5 PLA-100, PLA-H100 © Panduit Corp. 2020 SYMBOL EXPLANATION Warning: Hazardous Voltage Disconnect power before servicing Warning: Moving Parts Warning: Wear Safety Glasses Caution WEEE Compliance Read the Manual FUSE 1 / 2021 Rev. 02 Page 4 of 34...

-

Page 6: Pla-H100 Applicator Head

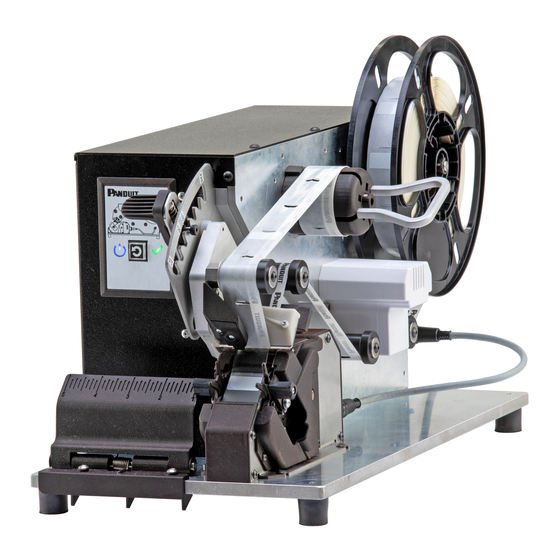

Figure 1 2B: PLA-100 Benchtop Label Applicator The Benchtop Label Applicator is a dispenser that controls the wrapper head operation. The dispenser has an electronic display that provides information to users to identify errors to reduce downtime. The dispenser user interface includes a single button that can be used to reset errors. -

Page 7: Pla-T100X2400 Pressure Sensitive Adhesive Tether

PLA-100, PLA-H100 © Panduit Corp. 2020 2C: PLA-T100X2400 Pressure Sensitive Adhesive Tether The Pressure Sensitive Adhesive Tether is used at the beginning or end of a reel of media to avoid the usage of labels when loading the applicator system. The Tether can also be used to separate customer jobs by connecting a variety of pre-printed strips of media. -

Page 8: Pla-Sp Empty Media Spool

PLA-100, PLA-H100 © Panduit Corp. 2020 2F: PLA-SP Empty Media Spool Figure 6 2G: RMEH1BL-PLA 1” Ribbon Label media match 520ft long for TDP43ME Figure 7 2H: RHEH1BL-PLA 1” Ribbon with typical length for TDP43HE Printer Figure 8 1 / 2021 Rev. -

Page 9: 3: General Power Tool Safety Warnings

NOTE: The term “residual current device (RCD)” may be replaced by the term “ground fault circuit interrupter (GFCI)” or “earth leakage circuit breaker (ELCB)”. Only operate the Panduit Label Applicator System in a clean, dry, indoor environment This unit includes a protective earthing design and has been testing per IEC 60601-1. -

Page 10: Personal Safety

PLA-100, PLA-H100 © Panduit Corp. 2020 3C: Personal Safety STAY ALERT, watch what you are doing and use common sense when operating a stationary tool. Do not use a stationary tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating stationary tools may result in serious personal injury. -

Page 11: Service And Warranty

4: SAFETY PRACTICES ADDENDUM 4A: General Safety Practices Panduit Corp. recommends the tool be used with all installed safety features. Customer assumes all liability for injury that could result from improper use of this tool and responsibility for all necessary training to ensure safe operation of this tool. -

Page 12: 5: Fcc Emission Classifications

© Panduit Corp. 2020 DO NOT operate near anyone's face. DO NOT operate without a wire bundle present on the convey. ONLY OPERATE THE PANDUIT LABEL APPLICATOR SYSTEM IN A CLEAN, DRY, INDOOR ENVIRIONMENT 5: FCC EMISSION CLASSIFICATIONS USA FCC Emissions for Class B This device complies with part 15 of the FCC Rules. -

Page 13: Noise Emission

Storage / Transportation Temperature and -40C(-40F) to +70C (+158F) Max 90% Humidity Non-Condensing NOTE: Any substitution for non-Panduit media or tether may cause serious damage to the system. 7: PACKING LIST Figure 9: Benchtop Label Applicator Figure 9A: PLA-100 Dispenser... -

Page 14: Pla-H100

PLA-100, PLA-H100 © Panduit Corp. 2020 7B: PLA-H100 1. PLA-H100: Applicator Head (1) See Figure 9B 2. 00129EOO: Applicator Head Spyder Coupler (1) The Benchtop Label Applicator primary components are shown and labeled in Figure 10 for reference throughout this guide. - Page 15 PLA-100, PLA-H100 © Panduit Corp. 2020 bolts and then engage the drive coupler on the PLA-100 with the coupler on the PLA-H100. Secure the PLA-H100 to the base plate with (2) 8-32 x 1/4” screws. Hand Tighten. Secure the applicator head cable as seen in figure 10.

- Page 16 PLA-100, PLA-H100 © Panduit Corp. 2020 Slot (4 places) Shaft with Spring Loaded Ball Lock Handle Figure 14B: Take-Up Spool Components Selector Handle Label Length Setting Figure 14C: Media Length Selector 1 / 2021 Rev. 02 Page 15 of 34...

-

Page 17: 10: Installing The Media

PLA-100, PLA-H100 © Panduit Corp. 2020 Figure 15: Media Path 10: INSTALLING THE MEDIA 1. The pre-printed label spool is loaded onto the unwind spindle of the unit. NOTE: Rewound media must not exceed the diameter of the media spool. - Page 18 4. Remove one 24” Panduit Tether from the supplied spool. Figure 17 5. Peel off 1 inch of the pre-cut liner from one end of the Panduit Tether and attach it to the liner side of the labels which has the Panduit logo.

- Page 19 PLA-100, PLA-H100 © Panduit Corp. 2020 6. Load the media onto the unwind spindle and Route the tether and labels around the Guide Rollers and under the Peeling Plate as depicted in Figures 19 and 20. Figure 20 Figure 21 With the free end of the tether, create a loop approximately 1 inch in diameter by adhering the tether to itself.

- Page 20 PLA-100, PLA-H100 © Panduit Corp. 2020 7. Slide the loop formed with the end of the Tether over the shaft of the Take-up Spool. Figure 23 8. While re-attaching the take-up spool cap and thread the tether thru one of the slots and secure the Take-up Spool cap against the spring-loaded locking ball on the shaft.

- Page 21 PLA-100, PLA-H100 © Panduit Corp. 2020 9. Rotate the handle of the take-up spool clockwise to remove the slack in the tether and continue rotating until the edge of the first label can be seen protruding from under the Peeling Plate.

-

Page 22: 11: Operation/Application

PLA-100, PLA-H100 © Panduit Corp. 2020 Figure 26: Applicator Installed with Label Presented for Wrap 11: OPERATION/APPLICATION Turn the power on. The label, now positioned on the Applicator (see Figure 26), falls to the surface of the Applicator Belt while a small patch of the label remains attached to the liner and peel plate to keep the label from moving. - Page 23 PLA-100, PLA-H100 © Panduit Corp. 2020 Note: Labels can be applied at 0.60” from the end of a wire. Customers can apply labels to individual conductors of a multi-conductor cable. Push down with the Cable Guides while securing the cable to contact the presented label (see Figure 27B).

-

Page 24: 12: User Interface And Error Descriptions

Figure 29: Error Location Indicators Figure 28: User Interface The user interface for the Panduit Label Applicator system provides users with operational status. On power-up the user interface illuminates the Power and “Caution” until the initialization of all hardware is completed. -

Page 25: Applicator Head Error Troubleshooting

Using direct lighting at less Please refrain from direct lighting to than 36 inches of the wrapping the side of the system. Contact area may affect sensor Panduit Service Center if issues performance. persist. Applicator head mechanism at Replace wrapper core. Contact end of life >... -

Page 26: Take-Up Error Troubleshooting

PLA-100, PLA-H100 © Panduit Corp. 2020 Label is still presented, at the Contact the cable to the label, more peel plate, and a cable has slowly, to ensure adhesion and label been inserted into the removal, prior to attempting a wrap. -

Page 27: Media Detect Error Troubleshooting

12D: Media Detect Error Troubleshooting Error Location Indicator and State Potential Problem Solution Media Detect Error LED Incompatible Media. Use appropriate Panduit label media On (steady) Media installed incorrectly; Remove spool from unwind spindle, Label facing up. flip the spool over, and re-install the media. -

Page 28: 13: Web Browser Interface

PLA-100, PLA-H100 © Panduit Corp. 2020 Solution: Replace static Brushes on applicator head. Contact Panduit Service Center. Problem: Label underfed due to wrong selector position for label chosen. Solution: Check to determine that label part number and selector position are coordinated correctly. - Page 29 Status states is below. Minor Faults may be corrected by a Reset. Major faults may be corrected by using the Restore Factory Defaults. If normal operation does not follow after a “Restore”, please contact Panduit for technical support or service. Wrapper Status...

-

Page 30: Network

When first accessing the Network and Setting pages on the PLA SYSTEM; or after approximately 30 minutes of inactivity, entry of a Username and Password is required. The default Username is “Panduit PLA” and the default Password is” password”. NETWORK STATUS The Network Status indicates the state of the Ethernet/IP connection. -

Page 31: Network Settings

PLA-100, PLA-H100 © Panduit Corp. 2020 “Change” button immediately to the right. The Device Name can be restored to the factory default value as described in Restore section on Page 32. 13E: Network Settings The Network Settings shows the current method the PLA SYSTEM uses to obtain an IP Address on the network, the current IP Address, the Network Mask and Gateway address values. -

Page 32: Web Browser Settings

PLA-100, PLA-H100 © Panduit Corp. 2020 13F: WEB Browser Settings See Username and Password on Page 29 for username and password authentication. MODEL The Model displays the Model Number of this PLA SYSTEM (PATGEN4.0). RESET The Reset button can be used to restart the PLA SYSTEM in the event of a Minor or Major Fault, or after a change to Network Settings, or performing a Restore Factory Defaults or Firmware Update. - Page 33 © Panduit Corp. 2020 FIRMWARE VERSION The firmware version is displayed. To check for firmware updates, please visit Panduit.com and click on Support and follow the links to the PLA SYSTEM Firmware Update page. UPDATE Clicking on the UPDATE button will prompt the user to browse and locate the firmware file named “image.bin”...

-

Page 34: 14: General Maintenance

PLA-100, PLA-H100 © Panduit Corp. 2020 LANGUAGE The current Language for the WBI is displayed. Clicking on the arrow displays a menu of available Languages. Clicking on a different language followed by clicking on the SAVE button immediately to the right will change the Language setting. After changing the Language, the user should perform a Reset (Page 31) for the new Language to take effect. - Page 35 PLA-100, PLA-H100 © Panduit Corp. 2020 Email: For Technical Support Ga-techsupport@panduit.com USA & Canada: 1-866-871-4571 EU Website: Latin America: +52-33-3777-6000 www.panduit.com/emea Europe: +31-546-580-452 Asia Pacific Region: 65-6379-6700 www.panduit.com EU Email: Japan: 81-3-6863-6060 emeatoolservicecenter@panduit.com ––– 1 / 2021 Rev. 02 Page 34 of 34...

Need help?

Do you have a question about the PLA-100 and is the answer not in the manual?

Questions and answers