Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Teledyne GMI PS200

- Page 1 User Guide User Manual PS200 PORTABLE GAS MONITOR 64171 Revision 12.1...

- Page 2 LEGAL STATEMENT Teledyne, the Teledyne Logo, Gas Measurement Instruments, GMI, and PS200 are registered and/ or unregistered marks of Teledyne Gas Measurement Instruments Ltd, also referred to as “the Company.” All rights reserved. No part of this documentation may be reproduced in any form or by any means or used to make any derivative work (such as translation, transformation, or adaptation) without written permission from the Company.

- Page 3 PS200 PORTABLE GAS MONITOR DISPOSAL ADVICE Dispose of the monitor carefully and with respect for the environment. the Company will dispose of the monitor without charge if the monitor is returned to the Company. AREAS OF USE Exposure to certain chemicals can result in a loss of sensitivity of the flammable sensor. Where such environments are known or suspected it is recommended that more frequent response checks are carried out.

-

Page 4: Table Of Contents

PS200 PORTABLE GAS MONITOR Table of Contents General Information .........................1 1.1........................1 Guide Conventions 1.2. Certifications and Approvals......................2 1.2.1. Label.............................3 1.2.2. Performance.........................3 1.3. General Safety Information .......................3 1.4. Additional Safety Details - CSA ONLY ..................4 General Introduction.........................6 2.1. Description..........................6 2.2. Features............................8 2.3. - Page 5 PS200 PORTABLE GAS MONITOR 4.1.2. Oxygen (O ) Alarm ......................19 4.1.3. Toxic Alarm.........................19 4.2. Acknowledge Gas Alarms ...................... 20 4.3. Mute Alarms ..........................20 4.4. High Flammable Gas Over-range Alarm................20 4.4.1. 10-Second Switch Off.......................21 .......................... 22 Warnings & Faults 5.1.

- Page 6 PS200 PORTABLE GAS MONITOR 9.3. Calibration Validity ........................38 Accessories ............................ 39 ..................40 Operating Parameters & Sensor Types A.1. Parameters....................40 Typical Operating A.2........................42 LEL Sensor Types Technical Support .......................... 43 64171 Revision 12.1...

-

Page 7: General Information

PS200 PORTABLE GAS MONITOR 1. General Information WARNING: READ, UNDERSTAND AND FOLLOW THE ENTIRE CONTENT OF THIS GUIDE PRIOR TO USE. FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH. This guide instructs gas detection personnel on the features and usage of the PS200 Portable Gas Monitor (or “the monitor”), including information on operation, configuration, maintenance, specifications and troubleshooting. -

Page 8: Certifications And Approvals

PS200 PORTABLE GAS MONITOR 1.2. Certifications and Approvals The monitor has the following approvals available: Symbol Notes II 2G Ex ia d IIC T4 Gb (Ta = -20ºC to +50ºC) ATEX IECEx Ex ia d IIC T4 Gb (Ta = -20ºC to +50ºC) or II 1G Ex ia IIC T4 Ga (Ta = -20ºC to +50ºC) ATEX Ex ia IIC T4 Ga (Ta = -20ºC to +50ºC) -

Page 9: Label

PS200 PORTABLE GAS MONITOR 1.2.1 Label Always refer to the rear label for the actual certification of your monitor (see Figure 1: Identification Label). The label also lists the monitor’s serial number, e.g. 241000. Figure 1: Identification Label 1.2.2 Performance This monitor complies with: •... -

Page 10: Additional Safety Details - Csa Only

PS200 PORTABLE GAS MONITOR The Company takes no responsibility for use of its equipment if it is not used in accordance with these instructions. If further operational or maintenance details are required but not provided in this guide, contact the Company or their agent. The Company shall not be liable for any incidental or consequential damages in connection with any modifications, errors or omissions in this guide. - Page 11 PS200 PORTABLE GAS MONITOR Mise en garde: Le replacement d’un composant peut porter atteint à la sécurité intrinsèque de produit. Caution: Do not charge in a hazardous area. Um = 6V. Mise en garde: Ne pas charger en zone dangereuse. Um = 6V. Note: CSA have only assessed the LEL combustible gas detection portion of this monitor for performance.

-

Page 12: General Introduction

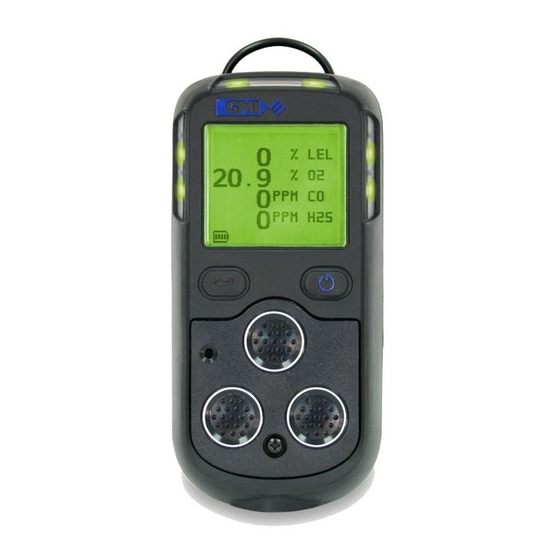

PS200 PORTABLE GAS MONITOR 2. Introduction 2.1. General Description The PS200 Portable Gas Monitor series combines quality, ruggedness and advanced technology in a user friendly, portable gas detector. It is compact, lightweight, water resistant, extremely robust, and is suitably certified to recognized international standards. The monitor is suitable for wide range of personal monitoring and confined space applications. - Page 13 PS200 PORTABLE GAS MONITOR Figure 3: Display Example (4-Gas) NOTE: Character size increases if fewer sensors are configured, as illustrated in Figure 4: Display Examples. Figure 4: Display Examples Instead of displaying current gas readings, the monitor can be configured to display OK, as illustrated in Figure 5: OK Display Example (4-Gas).

-

Page 14: Features

PS200 PORTABLE GAS MONITOR 2.2. Features • Compact, lightweight and robust. • Measurement and display of up to 4 gases. • Simple 2 button operation. • Audible, visual (hi-viz) flashing LED’s and vibrating alarms. • Audible and visual confidence signal (configurable), confirming monitor operation to the user. -

Page 15: Operation

PS200 PORTABLE GAS MONITOR 3. Operation Figure 6: Function Buttons 3.1. Operating Procedure Caution: The monitor can be supplied with a flammable gas sensor. This sensor is designed for use in concentrations of gas not exceeding the Lower Explosive Limit (LEL). Exposing the sensor to concentrations of flammable gas above the LEL will not damage the sensor due to an inbuilt feature. -

Page 16: Quick Configuration Display

PS200 PORTABLE GAS MONITOR Additional: • Perform regular leak checks on pumped instruments by placing your thumb over the sample inlet nozzle and ensuring the monitor displays FLOW FAULT. • Perform regular bump tests. 3.2. Quick Configuration Display This allows configuration information to be viewed without fully switching the monitor ON (see Figure 7: Quick Configuration Display). -

Page 17: Monitor Identification

PS200 PORTABLE GAS MONITOR Figure 8: Flash Screen 3.3.1. Monitor Identification During warm-up, the LCD identifies the serial number, software version, battery status, and calibration gas information, as illustrated in Figure 9: Monitor Identification Display. Figure 9: Monitor Identification Display 3.3.2. -

Page 18: Bump Due Date (Option)

PS200 PORTABLE GAS MONITOR Figure 11: Date and Time 3.3.4. Bump Due Date (Option) This configurable option is disabled by default but can be configured to: • indicate briefly that bump test is due (Figure 12: Bump Due Date); • indicate that bump test is overdue then pause awaiting user acceptance (Figure 13: Bump Overdue);... -

Page 19: Calibration Due Date

PS200 PORTABLE GAS MONITOR 3.3.5. Calibration Due Date The calibration due date feature (shown in Figure 14: Calibration Due Date) is configurable, including the factory-set option to display the number of days remaining until the next calibration is due. Refer to Section 5.7. -

Page 20: Sensor Confirmation Check

PS200 PORTABLE GAS MONITOR When this option is displayed (see Figure 16: Cal Gas Selection), the original gas used to calibrate the monitor is identified between two arrowheads. NOTE: The calibration certificate also identifies the calibration gas type used. Figure 16: Cal Gas Selection To select a different gas: 1. -

Page 21: Switch The Display Backlight On/Off

PS200 PORTABLE GAS MONITOR Figure 18: 4-Gas Normal Operating Display 3.4. Switch the Display Backlight On/Off The display backlight can be manually switched ON when working in poor lighting conditions. Press the R button once to switch ON. After 20 seconds it will automatically switch OFF. 3.5. -

Page 22: Manual Datalog

PS200 PORTABLE GAS MONITOR NOTE: The MIN is only displayed if an Oxygen sensor is fitted in the monitor. 6. MAX/MIN readings can be reset by pressing and holding the R button for 2 seconds when either of the MAX/MIN screens are displayed. After resetting, the monitor will return to the normal operating screen. -

Page 23: Sample Line Connection And Use

PS200 PORTABLE GAS MONITOR NOTE: The operation of the confidence beep and/or LEDs is configurable. 3.8. Sample Line Connection and Use The monitor has an internal pump for remote sensing. Connect the sample line tubing to the sample line connector, as shown in Figure 21: Sample Line Connection. -

Page 24: Self Test

PS200 PORTABLE GAS MONITOR 3.9. Self Test To perform a self test at any time during normal operation, press and hold the L button. The monitor tests the buzzer, the LED’s, and the vibration function. The flammable gas used for calibration is displayed, as illustrated in Figure 23: Self Test. -

Page 25: Alarms

PS200 PORTABLE GAS MONITOR 4. Alarms 4.1. Gas Alarms When an alarm set-point has been reached, the audible, visual, and vibrating alarms will activate to alert the users. All gas alarms are configurable to meet the specific needs of users and only operate once the monitor warm-up is complete. -

Page 26: Acknowledge Gas Alarms

PS200 PORTABLE GAS MONITOR Figure 26: LEL HIHI Alarm 4.2. Acknowledge Gas Alarms After the gas readings have returned to a safe level, press and hold the R button to clear all alarms. 4.3. Mute Alarms If configured, muting the alarm will silence the audible alarm for 60 seconds, as follows: •... -

Page 27: 10-Second Switch Off

PS200 PORTABLE GAS MONITOR Figure 27: Over Range Alarm 4.4.1. 10-Second Switch Off The monitor must be returned to clean air. NOTE: To avoid accidental switch-off in this dangerous state, the off cycle is increased to 10 seconds. Switch OFF by pressing and holding both L and R buttons. A timer counts down from 10 seconds to 0, and the message GET OUT alternates with HIGH GAS, as shown in Figure 28: GET OUT/ HIGH GAS... -

Page 28: Warnings & Faults

PS200 PORTABLE GAS MONITOR 5. Warnings & Faults 5.1. LOW BATTERY LOW BATTERY flashes when approximately 30 minutes of run time remains, as shown in Figure 29: LOW BATTERY Warning. The display turns red, the audible alarm sounds once every two seconds, and the red LED’s flash. -

Page 29: Zero Fault - During Operation

PS200 PORTABLE GAS MONITOR Figure 31: LEL ZERO Fail To acknowledge this fault, press the R button once. This will clear the audible/visual alarms. The wrench symbol will remain on and ZERO FAULT is displayed as shown in Figure 32: LEL ZERO FAULT. -

Page 30: Sensor Faults

PS200 PORTABLE GAS MONITOR 5.4. Sensor Faults If a sensor fault is detected, the backlight illuminates red, audible/visual alarms are activated, and a wrench symbol is shown next to the faulty sensor. 5.4.1. Sensor Fault - LEL or O If a sensor fault is detected for LEL or O , as illustrated in Figure 34: LEL SENSOR FAULT, return the... -

Page 31: Memory Fault

PS200 PORTABLE GAS MONITOR Figure 36: FLOW FAULT 5.5. Memory Fault During warm-up, if the ‘MEMORY FAULT’ screen is displayed, as illustrated in Figure 37: Memory Fault, the monitor has detected a memory fault. The monitor must be returned for service. Figure 37: Memory Fault 5.6. - Page 32 PS200 PORTABLE GAS MONITOR Figure 39: CAL EXPIRED If calibration is overdue, a configurable option only allows the user to switch the monitor off, as shown in Figure 40: Calibration Required. Refer to Section 9. Calibration for calibration options. Figure 40: Calibration Required 64171 Revision 12.1...

-

Page 33: Manual Bump Test Options

PS200 PORTABLE GAS MONITOR 6. Manual Bump Test Options 6.1. Bump Testing A bump test verifies sensor response and alarm operation by exposing the monitor to a known concentration of gas. The monitor has 2 manual bump test options: • QUICK bump test validates sensors respond to gas and alarms are working. •... -

Page 34: Pumped Instruments - Regulator Selection

PS200 PORTABLE GAS MONITOR Figure 42: Apply Gas Screen (4-Gas Model) 6.2.1 Pumped Instruments - Regulator Selection If the monitor has a pump enabled, the user is asked if the pump will be used during the bump test, as illustrated in Figure 43: Regulator Valve Choice. -

Page 35: Quick/Full Bump Test

PS200 PORTABLE GAS MONITOR 6.4. Quick/Full Bump Test Operation now depends on whether QUICK or FULL bump is configured. 6.4.1 Quick Bump Test As the alarm threshold for each range is exceeded, the audible/visual/vibration alarms will activate and a symbol will appear, otherwise a symbol will be displayed. -

Page 36: Bump Test - Fail

PS200 PORTABLE GAS MONITOR 6.5.2 Bump Test – Fail If any range fails the bump test, the CONFIRM ALARMS display will be red and a symbol will be displayed, as shown in Figure 47: Confirm Alarms - Fail. Figure 47: Confirm Alarms - Fail After selecting YES or NO, BUMP TEST FAIL is displayed and the user is instructed to switch the monitor off, as shown in Figure 48: Bump Test Fail - Switch Monitor... -

Page 37: Recharging The Batteries

PS200 PORTABLE GAS MONITOR 7. Recharging the Batteries 7.1. General WARNING: NEVER ATTEMPT TO RECHARGE THE BAT TERIES IN A HAZARDOUS AREA. Caution: Switch the monitor off when charging. Caution: Use only approved chargers to recharge monitor. The battery should be recharged when: •... - Page 38 PS200 PORTABLE GAS MONITOR Figure 50: Connect Cable to Charging/Comms Clip 3. Connect the other end of the charging cable to the USB Power adapter (or suitable USB socket). Figure 51: Connecting the Cable to the USB Power Adapter 4. During charging, the battery symbol and ‘CHARGING’...

-

Page 39: Operator Maintenance

PS200 PORTABLE GAS MONITOR 8. Operator Maintenance 8.1. Cleaning Caution: Do not use polishes that contain silicon or solvent to clean the monitor as these may damage the flammable gas sensor (if fitted). Do not use abrasive chemicals or strong, volatile chemical solutions as these could damage the impact-resistant casing. -

Page 40: Replacing The Sample Inlet (Dust) Filter

PS200 PORTABLE GAS MONITOR Note: Make sure that the locating pegs in the monitor filter recess align with the mating pinholes in the hydrophobic filter. 6. Place the filter cover over the recess and slide it towards the display until the locating lugs engage in the locating slots. -

Page 41: Calibration

PS200 PORTABLE GAS MONITOR 9. Calibration WARNING: ONLY AUTHORIZED PERSONNEL MAY CALIBRATE THE MONITOR. 9.1. General Description The monitor has been calibrated for particular gases. Where any doubt exists, return the monitor to an authorized distributor for calibration. Various calibration options are available: 1. -

Page 42: Quick Calibration

PS200 PORTABLE GAS MONITOR 9.2. Quick Calibration This feature, if enabled, allows calibration without using the monitor’s set-up menu and passcodes. Quick Calibration uses predefined calibration gas cylinder values saved in the monitor. The default values are: • 50% LEL •... - Page 43 PS200 PORTABLE GAS MONITOR 5. Once gas is applied, press and hold the R button to start the calibration. The 60 second countdown will commence (refer to Figure 57: APPLY GAS Screen). After 60 seconds, the monitor will be calibrated to the predefined values. Figure 57: APPLY GAS Screen 6.

-

Page 44: Calibration Validity

PS200 PORTABLE GAS MONITOR 9.3. Calibration Validity Calibration validity remains the responsibility of the user. Individual codes of practice may dictate calibration intervals. Regular calibration establishes a pattern of reliability and enables the calibration check period to be modified in line with operational experience. As a guide, the higher the risk, the more frequently calibration should be checked. -

Page 45: Accessories

PS200 PORTABLE GAS MONITOR 10. Accessories Part Number Description 64136 3.0 meters (9’-9”) PVC Sample Line Tubing & Connector - Pumped monitors Only 64172 Quick Operating Instructions 64247 Power Adapter (c/w USB/mini-USB Cable) 64260 Charging/Comms Clip (mini-USB) 64171 Operation & Maintenance Manual (PDF) 64191 Quick Start Guide (PDF) Part Number... -

Page 46: Operating Parameters & Sensor Types

PS200 PORTABLE GAS MONITOR Appendix A. Operating Parameters & Sensor Types A.1. Typical Operating Parameters Range Resolution Response Time 0 to 100% 15 secs. (IEC 60079-29-1) Oxygen (O 0 to 25% 0.1% 12 secs. (BSEN 50104) Carbon Monoxide (CO) 0 to 1000 ppm 1 ppm <20 secs. - Page 47 PS200 PORTABLE GAS MONITOR Construction High-impact, rubberized polycarbonate case. Can withstand physical impact testing to EN 60079 section 1-5 IP Rating IP67 Datalogging Timed: Minimum of 6 months datalogging* Session: Minimum of 360 logs Calibration: Minimum of 8 logs Bump: Minimum of 360 logs *Based on 1 gas event every 1 hour during a typical 8-hour shift, with a datalogging interval of 1 minute.

-

Page 48: Lel Sensor Types

PS200 PORTABLE GAS MONITOR A.2. LEL Sensor Types There are several LEL sensor types available for the monitor. The following table shows the benefits of each sensor and the combustible gases it will detect: Certification Division/ LEL Sensor Benefit Gas Detected Gas Group Zone Standard... -

Page 49: Technical Support

PS200 PORTABLE GAS MONITOR Appendix B. Technical Support This product is designed to provide you with reliable, trouble-free service. Contact your regional technical support if you have technical questions, need support, or if you need to return a product. Details can be found at: www.teledynegasandflamedetection.com Note: When returning a product, contact Technical Support to obtain a Return MaterialAuthorization (RMA) number prior to shipping. - Page 50 Renfrew, PA4, 9RG Pudang, Shanghai 201206 TX 77381, USA Scotland, UK People’s Republic of China Tel.: +1-713-559-9200 Tel.: +44 (0) 141 812 321 1 Tel.: +86-21-3127-6373 www.teledynegasandflamedetection.com 64171 Revision 12.1 Copyright © 2020 Teledyne Gas and Flame Detection. All rights reserved.

Need help?

Do you have a question about the GMI PS200 and is the answer not in the manual?

Questions and answers