Endress+Hauser Proline Prosonic Flow 91W Brief Operating Instructions

Ultrasonic flow measuring system

Hide thumbs

Also See for Proline Prosonic Flow 91W:

- Technical information (24 pages) ,

- Technical information (44 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Technical Information

Brief Operating Instructions

Proline Prosonic Flow 91W

Ultrasonic flow measuring system

6

These Brief Operating Instructions are not intended to replace the

Operating Instructions provided in the scope of supply.

Detailed information is provided in the Operating Instructions and

the additional documentation on the CD-ROM supplied.

The complete device documentation consists of:

• These Brief Operating Instructions

• Depending on the device version:

– Operating Instructions and the Description of Device Functions

– Approvals and safety certificates

– Special safety instructions in accordance with the approvals for

the device (e.g. explosion protection, pressure equipment

directive etc.)

– Additional device-specific information

KA00049D/06/EN/14.12

71162949

Advertisement

Table of Contents

Summary of Contents for Endress+Hauser Proline Prosonic Flow 91W

- Page 1 Brief Operating Instructions Proline Prosonic Flow 91W Ultrasonic flow measuring system These Brief Operating Instructions are not intended to replace the Operating Instructions provided in the scope of supply. Detailed information is provided in the Operating Instructions and the additional documentation on the CD-ROM supplied.

-

Page 2: Table Of Contents

Proline Prosonic Flow 91W Table of contents 1 Safety instructions ........3 1.1 Designated use . -

Page 3: Safety Instructions

• The manufacturer reserves the right to modify technical data without prior notice. Your Endress+Hauser distributor will supply you with current information and updates to these Operating Instructions. • The information on the warning notices, nameplates and connection diagrams affixed to the device must be observed. -

Page 4: Safety Conventions

Europe, USA, Canada). The nameplate also bears the documentation number of this Ex documentation (XA***D/../..). • Endress+Hauser will be happy to assist in clarifying any questions on approvals, their application and implementation. Safety conventions Warning! “Warning” indicates an action or procedure which, if not performed correctly, can result in injury or a safety hazard. -

Page 5: Installation

Proline Prosonic Flow 91W Installation Installation Installation conditions 2.1.1 Dimensions For the dimensions of the measuring device, see the associated Technical Information on the CD-ROM. Mounting location Correct flow measurement is possible only if the pipe is full. Entrained air or gas forming in the pipe can result in an increase in measuring errors. - Page 6 Installation Proline Prosonic Flow 91W Horizontal In the recommended installation range in a horizontal installation position (View B), gas and air collections at the pipe cover and problematic deposits at the bottom of the pipe have a smaller influence on measurement.

-

Page 7: Preparatory Steps Prior To Installation

Proline Prosonic Flow 91W Installation Inlet and outlet runs If possible, install the sensor well clear of fittings such as valves, T-pieces, elbows, etc. If several flow obstructions are installed, the longest inlet or outlet run must be considered. Compliance with the following inlet and outlet runs is recommended in order to ensure measuring accuracy. -

Page 8: Determining The Necessary Installation Distances

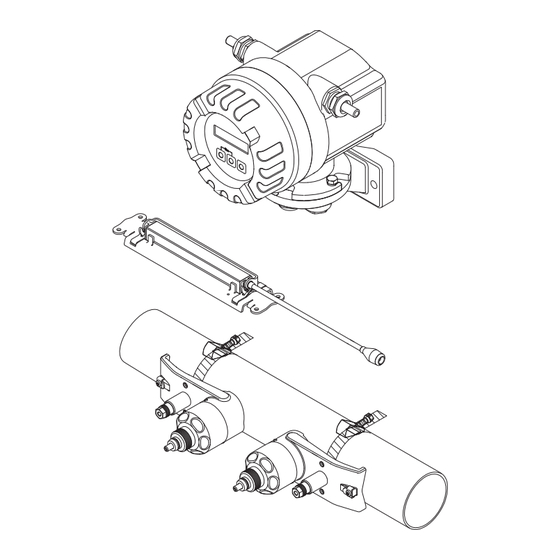

Installation Proline Prosonic Flow 91W Determining the necessary installation distances The installation distances that are necessary for installation depend on: • Insertion version: Clamp On with strapping band, installation in pipe • Number of traverses or single-path/dual-path version DN 50 to 4000 (2 to 160") -

Page 9: Connecting The Power Supply

Proline Prosonic Flow 91W Installation Connecting the power supply Warning! Risk of electric shock. Components carry dangerous voltages. • Never mount or wire the measuring device while it is connected to the power supply. • Before connecting the power supply, check the safety equipment. - Page 10 Installation Proline Prosonic Flow 91W Warning! Risk of damaging plastic or glass pipes if the nuts of the U-shaped screws are tightened too much! The use of a metal half-shell is recommended (on the opposite side of the sensor) when working with plastic or glass pipes.

- Page 11 Proline Prosonic Flow 91W Installation A0011525 Fig. 6: Positioning the sensor holder and mounting the strapping bands A0011526 Fig. 7: Tightening the strapping screws of the strapping bands Endress+Hauser...

- Page 12 Installation Proline Prosonic Flow 91W 2.6.3 Premounting the strapping bands (medium nominal diameters) When mounting on a pipe with a nominal diameter of DN 200 (8") For sensor (DN 50 to 4000 / 2 to 160") First strapping band Fit the mounting bolt over the strapping band.

- Page 13 Proline Prosonic Flow 91W Installation 2.6.4 Premounting the strapping bands (large nominal diameters) When mounting on a pipe with a nominal diameter in the range of DN 600 (24") For sensor (DN 50 to 4000 / 2 to 160") Measure the pipe circumference.

-

Page 14: Installing Prosonic Flow W Sensor

Installation Proline Prosonic Flow 91W Installing Prosonic Flow W sensor 2.7.1 Installing Prosonic Flow W (DN 15 to 65 / ½ to 2½") Prerequisites • The installation distance (sensor distance) is known ä 8. • The sensor holder is already mounted ä 9. - Page 15 Proline Prosonic Flow 91W Installation A0011527 Fig. 11: Fitting the sensor housing Fix the sensor housing with the bracket. – If necessary, the holder and sensor housing can be secured with a screw/nut or Hinweis! a lead-seal (not part of the scope of supply).

- Page 16 Installation Proline Prosonic Flow 91W 2.7.2 Installing Prosonic Flow W (DN 50 to 400 0 / 2" to 160") Installation for measurement via one traverse (DN 600 to 2000 /24" to 80") Prerequisites • The installation distances (sensor distance and wire length) are known ä 8.

- Page 17 Proline Prosonic Flow 91W Installation Take the still movable strapping band, incl. the mounting bolt, and move it until both measuring wires are evenly tensioned and tighten the strapping band so that it cannot slip. A0001113 Fig. 14: Positioning the strapping bands (steps 2 to 4) Loosen the screws of the fixers on the measuring wires and remove the measuring wires from the mounting bolt.

- Page 18 Installation Proline Prosonic Flow 91W A0011373 Fig. 16: Coating the contact surfaces of the sensor with coupling fluid Insert the sensor into the sensor holder. Fit the sensor cover on the sensor holder and turn until: – The sensor cover engages with a click Æ...

- Page 19 Proline Prosonic Flow 91W Installation Installation for measurement via two traverses (DN 50 to 600 /2" to 24") Prerequisites • The installation distance (position sensor) is known ä 8. • The strapping bands are already mounted ä 10. Material • Two strapping bands incl. mounting bolts and centering plates where necessary ...

- Page 20 Installation Proline Prosonic Flow 91W Tighten the strapping band so that it cannot slip. Remove the mounting rail from the mounting bolt. Fit the sensor holders over the individual mounting bolts and tighten securely with the retaining nut. A0001117 Fig. 19: Mounting the sensor Coat the contact surfaces of the sensors with an even layer of coupling fluid approx.

-

Page 21: Post-Installation Check

Proline Prosonic Flow 91W Hardware and software settings A0011376 Fig. 21: Connecting the connecting cable the connecting cables ä 23. This completes the mounting process. The sensors can now be connected to the transmitter via Post-installation check • Are cables or the device damaged (visual inspection)? temperature and pressure, ambient temperature, minimum fluid conductivity, ... -

Page 22: Wiring

Wiring Proline Prosonic Flow 91W Wiring Warning! Risk of electric shock. Components carry dangerous voltages. • Never mount or wire the measuring device while it is connected to the power supply. • Before connecting the power supply, check the safety equipment. -

Page 23: Sensor/Transmitter Connecting Cable

Proline Prosonic Flow 91W Wiring Sensor/transmitter connecting cable Warning! • Risk of electric shock. Switch off the power supply before opening the device. Do not install or wire the device while it is connected to the power supply. Failure to comply with this precaution can result in irreparable damage to the electronics. - Page 24 Wiring Proline Prosonic Flow 91W A0005843 Fig. 22: Connecting the measuring system with two single core connection cables a, b Sensor connecting cables Cable gland cover Rubber seal Cable fixing sleeves Ground disk Cable gland holder Seal Cable holder Endress+Hauser...

- Page 25 Proline Prosonic Flow 91W Wiring 4.1.2 Connecting and Grounding Prosonic Flow W DN (½ to 2½") Multicore cable Note! The Prosonic Flow W DN 15 to 65 (½ to 2½") is grounded via the cable gland. A0015587 Fig. 23: Connecting and grounding the measuring system (DN15 to 65)

- Page 26 Fig. 24: Connecting nameplate for sensor connecting cables (on circuit board (transmitter)) 4.1.3 Cable specification for connecting cable Only use the connecting cables supplied by Endress+Hauser. Operation in areas with strong electrical interference The measuring system complies with the general safety requirements in accordance with EN 61010, the EMC requirements of IEC/EN 61326 "Emission as per Class A requirements"...

-

Page 27: Connecting The Transmitter

Proline Prosonic Flow 91W Wiring Connecting the transmitter Wire the unit using the terminal assignment diagram inside the cover. Warning! • Risk of electric shock. Switch off the power supply before opening the device. Do not install or wire the device while it is connected to the power supply. -

Page 28: Protective Ground Connection

Wiring Proline Prosonic Flow 91W – – (L+) (L-) A0005838 Fig. 25: Connecting the transmitter (aluminum field housing). Cable cross-section: max. 2.5 mm (AWG 14) Electronics compartment cover Cable for power supply: 85 to 250 V AC, 11 to 40 V DC, 20 to 28 V AC Terminal connector for power supply: No. -

Page 29: Degree Of Protection

Proline Prosonic Flow 91W Wiring Degree of protection The devices meet all the requirements for IP 67. After mounting in the field or service work, the following points have to be observed to ensure that IP 67 protection is retained: •... -

Page 30: Commissioning

Commissioning Proline Prosonic Flow 91W Commissioning Switching on the measuring device On completion of the installation (successful post-installation check), wiring (successful post-connection check) and after making the necessary hardware settings, where applicable, the permitted power supply (see nameplate) can be switched on for the measuring device. -

Page 31: Operation

Proline Prosonic Flow 91W Commissioning Operation 5.2.1 Display elements Display lines/fields Main line for primary measured values Additional line for additional measured +48.25 xx/yy variables/status variables +3702.6 x Current measured values Engineering units/time units A0007557 5.2.2 Operating elements Operating keys (–) Minus key for entering, selecting... -

Page 32: Navigating Within The Function Matrix

Commissioning Proline Prosonic Flow 91W Navigating within the function matrix > 3 s – – – – A0007562 Enter the function matrix (starting with measured value display) Select the group (e.g. OPERATION) Confirm selection Select function (e.g. LANGUAGE) Enter code 50 (only for the first time you access the function matrix) Confirm entry... -

Page 33: Group Sensor Setup

Proline Prosonic Flow 91W Commissioning Group Sensor Setup Picklist SENSOR SETUP: • SETUP • LIQUID • PIPE DATA • LINER • CONFIG. CHANEL • POS. SENSOR • QUIT SETUP: LIQUID TEMPERATURE SOUND VEL. LIQUID PIPE MATERIAL SOUND VEL.PIPE CIRCUMFERENCE ... - Page 34 Commissioning Proline Prosonic Flow 91W Endress+Hauser...

- Page 35 Proline Prosonic Flow 91W Commissioning Endress+Hauser...

- Page 36 KA00049D/06/EN/14.12 71162949 FM+SGML 9.0...

Need help?

Do you have a question about the Proline Prosonic Flow 91W and is the answer not in the manual?

Questions and answers