Summary of Contents for Siemens SIPROTEC 7UT613 series

- Page 1 Preface Introduction Functions SIPROTEC Mounting and Commissioning Differential Protection Technical Data 7UT613/63x Appendix V4.60 Literature Manual Glossary Index C53000-G1176-C160-2...

-

Page 2: C53000-G1176-C160

We reserve the right to make technical improvements without SIPROTEC, SINAUT, SICAM and DIGSI are registered trade- notice. marks of SIEMENS AG. Other designations in this manual might be trademarks whose use by third parties for their own purposes would infringe the rights of the owner. -

Page 3: Mounting And Commissioning 3

(Low-voltage directive 73/23 EEC). This conformity has been proved by tests conducted by Siemens AG in accor- dance with Article 10 of the Council Directive in agreement with the generic stan- dards EN 61000-6-2 and EN 61000-6-4 (for EMC directive) and the standard EN 60255-6 (for low-voltage directive). - Page 4 Should further information on the SIPROTEC 4 System be desired or should particular problems arise which are not covered sufficiently for the purchaser's purpose, the matter should be referred to the local Siemens representative. Training Courses Individual course offerings may be found in our Training Catalogue, or questions may be directed to our training centre in Nuremberg.

- Page 5 Preface Definition QUALIFIED PERSONNEL For the purpose of this instruction manual and product labels, a qualified person is one who is familiar with the installation, construction and operation of the equipment and the hazards involved. In addition, he has the following qualifications: •...

- Page 6 Preface External binary output signal with number (device indication) used as input signal Example of a parameter switch designated FUNCTION with the address 1234 and the possible settings ON and OFF Besides these, graphical symbols are used according to IEC 60617-12 and IEC 60617-13 or symbols derived from these standards.

-

Page 7: Table Of Contents

Contents Introduction..............17 Overall Operation . - Page 8 Contents Differential Protection ........... . 104 2.2.1 Functional Description of the Differential Protection .

- Page 9 Contents Dynamic Cold Load Pickup for Time Overcurrent Protection ..... . 191 2.6.1 Function Description ........... . . 191 2.6.2 Setting Notes .

- Page 10 Contents 2.13 Forward Power Supervision..........250 2.13.1 Function Description .

- Page 11 Contents 2.19 Monitoring Functions ........... . . 279 2.19.1 Measurement Supervision.

- Page 12 Contents 2.22 Additional Functions ........... . . 300 2.22.1 Processing of Messages .

- Page 13 Contents Mounting and Commissioning ........... 339 Mounting and Connections .

- Page 14 Contents Technical Data ..............421 General .

- Page 15 Contents 4.23 Dimensions ............491 4.23.1 Panel Surface Mounting (Enclosure Size ) .

- Page 16 Contents Literature ..............631 Glossary.

-

Page 17: Introduction

Introduction Differential ProtectionThe SIPROTEC 4 device 7UT613/63x is introduced in this chap- ter. You are presented with an overview of the scope of application, the properties and functional scope of the 7UT613/63x. Overall Operation Application Scope Characteristics 7UT613/63x Manual C53000-G1176-C160-2... -

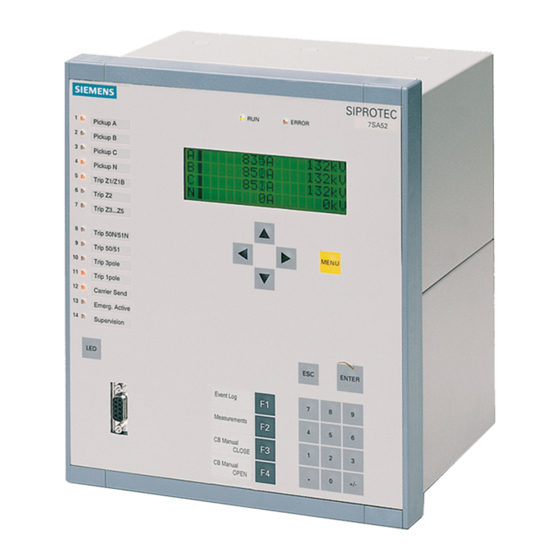

Page 18: Overall Operation

1 Introduction Overall Operation The digital differential protection devices SIPROTEC 4 7UT613/63x are equipped with a powerful microprocessor system. This provides fully numerical processing of all functions in the device, from the acquisition of the measured values up to the output of commands to the circuit breakers Figure 1-1 Hardware structure of the digital differential current protection relay 7UT613/63x... - Page 19 1.1 Overall Operation and earth, or other single-phase measuring currents. One or two additional inputs can be designed for highly sensitive current detection, This, for example, allows the detec- tion of small tank leakage currents of power transformers or - with an external series resistor - the detection of a voltage (e.g.

- Page 20 1 Introduction Binary Inputs and Binary inputs and outputs from and to the computer system are routed via the I/O Outputs modules (inputs and outputs). The computer system obtains the information from the system (e.g remote resetting) or from other devices (e.g. blocking commands). These outputs include, in particular, trip commands to switchgear and signals for remote an- nunciation of important events and conditions.

-

Page 21: Application Scope

1.2 Application Scope Application Scope The numerical differential protection SIPROTEC 4 7UT613/63x is a fast and selective short-circuit protection for transformers of all voltage levels, for rotating machines, for series and shunt reactors, or for short lines and mini-busbars with 2 to 5 feeders (de- pending on the version). - Page 22 1 Introduction at the ends of the protected zone feed a common (external) high-ohmic resistor The current in this resistor is measured using a high-sensitive current input 7UT613/63x. The device provides backup time overcurrent protection functions for all types of pro- tected objects.

-

Page 23: Characteristics

1.3 Characteristics Characteristics General Features • Powerful 32-bit microprocessor system. • Complete digital measured value processing and control, from the sampling and digitalization of the analogue input quantities to the initiation of outputs for tripping or closing circuit breakers. • Complete galvanic and reliable separation between the internal processing circuits of the device and the external measurement, control, and power supply circuits because of the design of the analog input transducers, binary input and output mod- ules, and the DC/DC or AC/DC converters. - Page 24 1 Introduction Busbar Protection • 1-phase differential protection for a busbar with up to 9 or 12 feeders (depending on the version) • Either one relay per phase or one relay connected via interposed summation current transformers • Tripping characteristic with current restraint •...

- Page 25 1.3 Characteristics • Instantaneous tripping possible at any stage when closing onto a short-circuit • Inrush restraint using the second harmonic of the measured current • Dynamic switchover of the time overcurrent protection settings, e.g. during cold- load start-up of the power plant •...

- Page 26 1 Introduction Thermal Overload • Thermal replica of current-initiated heat losses Protection • True RMS current calculation • Can be assigned to any desired side of the protective object • Adjustable thermal warning stage • Adjustable current warning stage • With or without including the ambient or coolant temperature (by means of external resistance temperature detector via RTD-box) •...

- Page 27 1.3 Characteristics Frequency Protec- • Three underfrequency stages and one overfrequency stage tion (devices with • Frequency measurement via the positive sequence component of the voltages measured voltage inputs) • Insensitive to harmonics and abrupt phase angle changes • Adjustable undervoltage threshold Circuit Breaker •...

- Page 28 1 Introduction User-defined Logic • Freely programmable combination of internal and external signals for the imple- Functions (CFC) mentation of user-defined logic functions • All usual logic functions • Time delays and limit value inquiries Commissioning, • Isolation of one side or measuring point for maintenance work: the isolated line or Operation measuring point is withdrawn from the differential protection system processing, without affecting the remainder of the protection system...

- Page 29 1.3 Characteristics • Communication with central control and data storage equipment possible via serial interfaces (depending on the individual ordering variant) by means of data cable, modem or optical fibres Various transmission protocols are provided for this pur- pose. ■ 7UT613/63x Manual C53000-G1176-C160-2...

- Page 30 1 Introduction 7UT613/63x Manual C53000-G1176-C160-2...

-

Page 31: Functions

Functions This chapter describes the individual functions available on the SIPROTEC 4 device 7UT613/63x. It shows the setting possibilities for each function in maximum configu- ration. Guidelines for establishing setting values and, where required, formulae are given. Additionally, on the basis of the following information, it may be defined which functions are to be used. - Page 32 2 Functions 2.23 Average Values, Minimum and Maximum Values 2.24 Command Processing 7UT613/63x Manual C53000-G1176-C160-2...

-

Page 33: General

2.1 General General A few seconds after the device is switched on, the default display appears on the LCD. In the 7UT613/63x the measured values are displayed. The function parameters, i.e. settings of function options, threshold values, etc., can be entered via the front panel of the device or by means of a PC connected to the op- erator or service interface of the device utilising DIGSI. -

Page 34: Device

2 Functions 2.1.1 Device 2.1.1.1 Setting Notes The parameters for the tripping logic of the entire device and the circuit breaker test have already been set in section 2.1.4. Address 201 FltDisp.LED/LCD also decides whether the alarms that are allocated to local LEDs and the spontaneous displays that appear on the local display after a fault should be displayed on every pickup of a protection function (Target on PU) or whether they should be stored only when a tripping command is given (Target on... -

Page 35: En100-Modul 1

2.1 General Information Type of In- Comments formation >Reset LED >Reset LED >Test mode >Test mode >DataStop >Stop data transmission Device OK Device is Operational and Protecting ProtActive IntSP At Least 1 Protection Funct. is Active Reset Device Reset Device Initial Start Initial Start of Device Resume... -

Page 36: Information List

2 Functions 2.1.2.3 Information List Information Type of In- Comments formation 009.0100 Failure Modul IntSP Failure EN100 Modul 009.0101 Fail Ch1 IntSP Failure EN100 Link Channel 1 (Ch1) 009.0102 Fail Ch2 IntSP Failure EN100 Link Channel 2 (Ch2) 2.1.3 Configuration of the Functional Scope The devices 7UT613/63x contain a series of protective and additional functions. - Page 37 2.1 General If the parameter group changeover function is desired, address 103 Grp Chge Parameter Group OPTION should be set to Enabled. In this case, it is possible to apply up to four dif- Changeover Func- tion ferent groups of settings for the function parameters. During normal operation, a con- venient and fast switch-over between these setting groups is possible.

- Page 38 2 Functions Figure 2-1 Transformer bank, consisting of 3 single-phase auto-transformers with current comparison via each single phase • Such current comparison is more sensitive to 1-phase earth faults in one of the transformers than the normal differential protection. This has a certain importance considering that 1-phase earth faults are the most probable faults in such banks.

- Page 39 2.1 General The Restricted earth fault protection (address 113 REF PROT.) com- Restricted Earth Fault Protection pares the sum of the phase currents flowing into the three-phase protected object together with the current flowing into the earthed starpoint. Further information is given in section 2.3.

- Page 40 2 Functions Time Overcurrent There is another earth current time overcurrent protection which is independent from Protection for Earth the before-described zero sequence time overcurrent protection. This protection, to be configured in address 124 DMT/IDMT Earth, acquires the current connected to a Current single-phase current measuring input.

- Page 41 2.1 General lates the overtemperature in the protected object from the flowing current, with refer- ence to the permissible temperature. This method is characterised by its easy han- dling and a low number of setting values. Detailed knowledge about the protected object, the environment and cooling is re- quired for overcurrent protection with hot-spot calculation in accordance with IEC 60354;...

- Page 42 2 Functions former, allows for a reasonable calculation of the active power. The definition of the reverse direction is explained in detail elsewhere. The forward power monitoring (address 151 FORWARD POWER) can monitor a protect- Forward Power Monitoring ed object with regard to undershooting as well as exceeding of a preset active power. It can only be used in three-phase protected objects, thus not at address 105 PROT.

-

Page 43: Settings

2.1 General External Trip The possibilities of two trip commands from external sources can be configured in ad- dresses 186 EXT. TRIP 1 and 187 EXT. TRIP 2. Command Flexible Functions 7UT613/63x provides flexible functions that can be used for protection, monitoring or measuring tasks. - Page 44 2 Functions Addr. Parameter Setting Options Default Setting Comments DMT 1PHASE Disabled Disabled DMT 1Phase Enabled DMT/IDMT Phase2 Disabled Disabled DMT / IDMT Phase 2 Definite Time TOC IEC TOC ANSI User Defined PU User def. Reset DMT/IDMT Phase3 Disabled Disabled DMT / IDMT Phase 3 Definite Time...

-

Page 45: Power System Data 1

2.1 General Addr. Parameter Setting Options Default Setting Comments FREQUENCY Prot. Disabled Disabled Over / Underfrequency Protection Enabled BREAKER FAILURE Disabled Disabled Breaker Failure Protection Enabled BREAKER FAIL. 2 Disabled Disabled Breaker Failure Protection 2 Enabled DISCON.MEAS.LOC Disabled Disabled Disconnect measurment location Enabled M.V. - Page 46 2 Functions Terminology The large variety of connection facilities of the device requires to create an exact image of the topology of the protected object. The device must be informed in which way the measured quantities derived from the measured value inputs of the device have to be processed by the different protection functions.

- Page 47 2.1 General The main protected object is a two-winding transformer YNd with an earthed starpoint at the Y-side. Side S1 is the upper voltage side (Y), side S2 is the lower voltage side (d). This definition of the sides for the main protected object (and only for it) is the basis for the formation of the differential and restraint currents used in the differential pro- tection.

- Page 48 2 Functions Figure 2-2 Example for the terminology of a topology Sides: High voltage side of the main protected object (power transformer) Low voltage side of the main protected object (power transformer) Measuring locations 3-phase, assigned: Measuring location, assigned to the main protected object, side 1 Measuring location, assigned to the main protected object, side 1 Measuring location, assigned to the main protected object, side 2 Measuring location, assigned to the main protected object, side 2...

- Page 49 2.1 General single-phase overcurrent protection is an autonomous protection function without any relation to a specific side. Figure 2-3 shows an example of a topology which in addition to the main protected object (the three-winding transformer) has another protected object (the neutral reac- tor) with a three-phase measuring location and an additional 1-phase measuring lo- cation assigned to it.

- Page 50 2 Functions Determining the You have to determine the topology of the main protected object and further objects Topology (if applicable). The following clarifications are based on the examples given above and the terminology defined above. Further examples will be given where needed. The necessary and possible settings depend on the type of main protected object as defined during configuration of the scope of functions (section 2.1.3).

- Page 51 2.1 General Note The determination of the sides and measuring locations is imperative for all further setting steps. It is also important that the currents from the measuring locations (cur- rent transformers) are connected to the associated analogue current inputs of the device: The currents of measuring location M1 must be connected to the device at measuring locations I (in single-phase transformers I...

- Page 52 2 Functions Figure 2-4 Example of a topology on a three-winding transformer Sides: High voltage side of the main protected object (power transformer) Low voltage side of the main protected object (power transformer) Tertiary winding side of the main protected object (power transformer) Measuring locations 3-phase, assigned: Measuring location, assigned to the main protected object, side 1 Measuring location, assigned to the main protected object, side 2...

- Page 53 2.1 General Figure 2-5 Topology of an auto-transformer with a compensation winding which is used as tertiary winding Sides: High voltage side of the main protected object (auto-transformer) Low voltage side of the main protected object (auto-transformer) Tertiary winding side (accessible compensation winding) of the main protected object Measuring locations 3-phase, assigned: Measuring location, assigned to the main protected object, side 1 Measuring location, assigned to the main protected object, side 1...

- Page 54 2 Functions The sum of the three currents measured in the starpoint leads can be connected to an auxiliary 1-phase current input of the device (illustrated dotted) in order to use it for restricted earth fault protection and/or time overcurrent protection. This auxiliary mea- suring location X3 is then assigned to both sides S1 and S2, since the current entering the protected object at X3 must be compared with the sum of the currents at both sides.

- Page 55 2.1 General Current comparison for common winding of an auto-transformer: If during configuration of the functional scope in section 2.1.3 a pure current compar- ison via each winding has been selected, then the example of figure 2-7 applies. Besides the common winding terminals of the sides S1 (full winding) and S2 (tap) with the assigned 3-phase measuring locations M1 and M2, one more side S3 is defined at the starpoint terminals with the 3-phase measuring location M3.

- Page 56 2 Functions Figure 2-7 Topology of a transformer bank consisting of 3 single-phase auto-transformers, topology definitions for a current comparison protection for each phase Sides: High voltage side of the auto-connected winding of the main protected object Low voltage side (tap) of the auto-connected winding of the main protected object Starpoint side of the auto-connected winding of the main protected object Measuring locations 3-phase, assigned: Measuring location, assigned to the main protected object, side 1...

- Page 57 2.1 General If the global data are implausible, the device does not find any meaningful combination of assignment possibilities. In this case you will find address 230 ASSIGNM. ERROR, which shows one of the following options: • No AssigMeasLoc the number of assigned measuring locations is implausible; •...

- Page 58 2 Functions Address 224 ASSIGNM. 4M,3S appears if 4 assigned measuring locations (address 212) have been selected for 3 sides (address 213). The following options are possi- ble: • M1+M2,M3,M4, i.e. the 4 measuring locations are assigned: M1 and M2 to side S1, M3 to side S2, M4 to side S3.

- Page 59 2.1 General • M1,M2,M3+M4,M5, i.e. the 5 measuring locations are assigned: M1 to side S1, M2 to side S2, M3 and M4 to side S3, M5 to side S4. • M1,M2,M3,M4+M5, i.e. the 5 measuring locations are assigned: M1 to side S1, M2 to side S2, M3 to side S3, M4 and M5 to side S4.

- Page 60 2 Functions In the example in figure 2-6 is for a PROT. OBJECT = Autotransf. the side S3 the tertiary winding, thus the accessible and load capable compensation winding. In this example the setting would be: Address 243 SIDE 3 = compensation. This option is only possible for PROT.

- Page 61 2.1 General • 1st case: It is essential to assign the 1-phase input to that side of the main protected object whose incoming phase currents are to be compared with the earth fault cur- rent. Make sure that you assign the 1-phase input to the correct side. In case of transformers, this can only be a side with an earthed starpoint (directly or via a neutral earthing transformer in the protected zone).

- Page 62 2 Functions • 4th and 5th case: In these cases you set the parameter for the assignment of the auxiliary measuring location to conn/not assig. (connected but not assigned). The auxiliary measuring location is then assigned to neither a specific side of the main protected object nor to any other 3-phase measuring location.

- Page 63 2.1 General forward power monitoring, the frequency protection, or for measuring tasks like the display of voltages or the calculation and output of power and energy metering. Figure 2-8 shows the various possible voltage assignments (which, of course do not occur all at the same time in practice).

- Page 64 2 Functions If the voltage transformers represented as Ua do not exist in your system, you can, for instance, use the voltages at Measuring loc.2 (represented as Ub), as they are electrically identical (assuming that the circuit breaker is closed). The device then assigns the voltage automatically to side 1 and calculates the power of the side from this voltage and the current of side S1, which is the sum of the currents from the mea- suring locations M1 and M2.

-

Page 65: General Power System Data (Power System Data 1)

2.1 General As different connections are possible, you must now specify in the device how the con- nected 1-phase voltage should be interpreted. This is done at address 263 VT U4 TYPE. Set Udelta transf. if the voltage assigned acc. to address 262 is a dis- placement voltage. - Page 66 2 Functions Please observe the definition of the sides which you have performed during setting of the topology of the main protected object (cf. Determining the Topology). Generally, side 1 is the reference winding having a current phase angle of 0° and no vector group indicator.

- Page 67 2.1 General For side 2, the same considerations apply as for the side 1: The primary rated voltage UN-PRI SIDE 2 (under address 321), the starpoint condition STARPNT SIDE 2 (under address 323). Observe strictly the assignment of the side according to the to- pological definitions made before.

- Page 68 2 Functions For the winding assigned to side 3, the following data are relevant: • Address 331 UN-PRI SIDE 3 the primary rated voltage (consider regulating range), • Address 332 SN SIDE 3 the primary rated apparent power, • Address 333 STARPNT SIDE 3 the starpoint treatment, •...

- Page 69 2.1 General The primary rated voltage (phase-to-phase) 370 UN BUSBAR is important for voltage- dependent protection functions (such as overexcitation protection, voltage protection, frequency protection, power protection functions). It also influences the calculation of the operational measured values. The feeders of a busbar may be rated for different currents. For instance, an overhead line may be able to carry higher load than a cable feeder or a transformer feeder.

- Page 70 2 Functions Object Data with These busbar data are only required if the device is used for single-phase busbar dif- Busbars (1-phase ferential protection. When configuring the scope of functions (see Scope of Functions, address 105), the following must have been set: PROT. OBJECT = 1ph Busbar. In Connection) with up to 6 or 9 or 12 cases other than that, these settings are not available.

- Page 71 2.1 General which relate to the non-assigned measuring locations, according to the set topology. Since the main protected object provides at least 2 measuring locations (differential protection would make no sense with fewer), M1 and M2 will never appear here. Address 403 I PRIMARY OP M3 requests the rated primary operating current at the measuring location M3 provided this is not assigned to the main protected object.

- Page 72 2 Functions Figure 2-13 Position of CT starpoints at 3-phase measuring locations - example 7UT613/63x Manual C53000-G1176-C160-2...

- Page 73 2.1 General Similar applies for the further measuring locations (assigned or non-assigned to the main protected object). Only those addresses will appear during setting which are available in the actual device version. Measuring Location 2 • Address 521 STRPNT->OBJ M2 starpoint position of CTs for measuring location •...

- Page 74 2 Functions Current Transform- The operational nominal currents of each feeder have already been set under margin er Data for Single- heading „Object Data with Busbars (1-phase Connection) with up to 9 or 12 Feeders“. phase Busbar Pro- The feeder currents are referred to these nominal feeder currents. However, the rated tection currents of the current transformers may differ from the nominal feeder currents.

- Page 75 2.1 General Feeder 1 • Address 561 STRPNT->BUS I1 = transformer starpoint versus busbar for feeder 1, • Address 562 IN-PRI CT I1 = rated primary transformer current for feeder 1, • Address 563 IN-SEC CT I1 = rated secondary transformer current for feeder 1. Feeder 2 •...

- Page 76 2 Functions Feeder 11 • Address 661 STRPNT->BUS I11 = transformer starpoint versus busbar for feeder • Address 662 IN-PRI CT I11 = rated primary transformer current for feeder 11, • Address 663 IN-SEC CT I11 = rated secondary current for feeder 11. Feeder 12 •...

- Page 77 2.1 General Polarity check for 1-phase current inputs IX1 Figure 2-16 The following applies for the (max. 4, dependent on device version on connections) 1-phase current inputs: For the auxiliary measuring input X1 • Address 711 EARTH IX1 AT with the options Terminal Q7 or Terminal Q8, •...

- Page 78 2 Functions Table 2-4 Terminal designation with surface mounted housing Corresponds to surface mounted housing, terminal 1-phase current Flush mounted input housing 7UT613 7UT633 7UT635 Terminal Q7 Terminal Q8 Terminal N7 Terminal N8 Terminal R7 Terminal R8 Terminal P7 – –...

-

Page 79: Assignment Of Protection Functions To Measuring Locations / Sides

2.1 General If the U4 transformer set is a Uen transformer, then address 817 Uph(U4)/Udelta must be set. 817 Uph(U4)/Udelta (0.10-9.99 ; without 0) 2.1.4.3 Assignment of Protection Functions to Measuring Locations / Sides Main Protection The main protected object, i.e. the protected object which has been selected at address 105 PROT. - Page 80 2 Functions Since the assignment of the 3-phase measuring locations and of the auxiliary measur- ing location is also defined by the topology, you only need to set auto-connected for the restricted earth fault protection REF PROT. AT. This is also true if the auto- connected winding has more than one tap.

- Page 81 2.1 General As the above examples show, the protection function can be assigned as desired. Generally speaking: • Where a 3-phase protection function is assigned to a measuring location, the cur- rents are acquired at this location, regardless of whether it is assigned to the main protected object or not.

- Page 82 2 Functions The same applies to the second overload protection that is assigned to a side under address 444 THERM. O/L 2 AT. The overexcitation protection (section 2.11) is only possible for devices with voltage connection, and requires a measuring voltage to be connected and declared in the to- pology (section „Topology of the Protected Object“...

-

Page 83: Circuit Breaker Data

2.1 General Address 427 DMT 1PHASE AT assigns the single-phase time overcurrent protection (section 2.7). This protection function is mainly used for high-sensitivity current mea- surement, e.g. for tank leakage protection or high-impedance differential protection. Therefore a high-sensitivity 1-phase additional measuring input is particularly suited for it. -

Page 84: Settings

2 Functions Example: The group „Control Devices“ of the configuration matrix contains a double-point indi- cation „Q0“. Assuming this should be the breaker to be monitored, you have deter- mined during configuration the physical inputs of the device at which the feedback in- dications of the breaker Q0 arrive. - Page 85 2.1 General Addr. Parameter Setting Options Default Setting Comments NUMBER OF ENDS Number of Ends for 1 Phase Busbar ASSIGNM. 2M,2S M1,M2 M1,M2 Assignment at 2 assig.Meas.Loc./ 2 Sides ASSIGNM. 3M,2S M1+M2,M3 M1+M2,M3 Assignment at 3 assig.Meas.Loc./ M1,M2+M3 2 Sides ASSIGNM.

- Page 86 2 Functions Addr. Parameter Setting Options Default Setting Comments AUX. CT IX1 Not connected Not connected Auxiliary CT IX1 is used as conn/not assig. Side 1 earth Side 2 earth Side 3 earth Side 4 earth MeasLoc.1 earth MeasLoc.2 earth MeasLoc.3 earth MeasLoc.4 earth AUX.

- Page 87 2.1 General Addr. Parameter Setting Options Default Setting Comments VT U4 Not connected Measuring loc.1 VT U4 is assigned conn/not assig. Side 1 Side 2 Side 3 Measuring loc.1 Measuring loc.2 Measuring loc.3 Busbar VT U4 TYPE Udelta transf. Udelta transf. VT U4 is used as UL1E transform.

- Page 88 2 Functions Addr. Parameter Setting Options Default Setting Comments VECTOR GRP S2 Vector Group Numeral of Side 2 UN-PRI SIDE 3 0.4 .. 800.0 kV 11.0 kV Rated Primary Voltage Side 3 SN SIDE 3 0.20 .. 5000.00 MVA 10.00 MVA Rated Apparent Power of Transf.

- Page 89 2.1 General Addr. Parameter Setting Options Default Setting Comments UN-PRI SIDE 5 0.4 .. 800.0 kV 11.0 kV Rated Primary Voltage Side 5 SN SIDE 5 0.20 .. 5000.00 MVA 10.00 MVA Rated Apparent Power of Transf. Side 5 STARPNT SIDE 5 Earthed Earthed Starpoint of Side 5 is...

- Page 90 2 Functions Addr. Parameter Setting Options Default Setting Comments PHASE SELECTION Phase 1 Phase 1 Phase selection Phase 2 Phase 3 I PRIMARY OP M3 1 .. 100000 A 200 A Primary Operating Current Meas. Loc. 3 I PRIMARY OP M4 1 ..

- Page 91 2.1 General Addr. Parameter Setting Options Default Setting Comments DMT/IDMT E AT no assig. poss. AuxiliaryCT IX1 DMT / IDMT Earth assigned to AuxiliaryCT IX1 AuxiliaryCT IX2 AuxiliaryCT IX3 AuxiliaryCT IX4 DMT 1PHASE AT no assig. poss. AuxiliaryCT IX1 DMT 1Phase assigned to AuxiliaryCT IX1 AuxiliaryCT IX2 AuxiliaryCT IX3...

- Page 92 2 Functions Addr. Parameter Setting Options Default Setting Comments UNBAL. LOAD AT Side 1 Side 1 Unbalance Load (Neg. Seq.) as- Side 2 signed to Side 3 Side 4 Side 5 Measuring loc.1 Measuring loc.2 Measuring loc.3 Measuring loc.4 Measuring loc.5 THERM.

- Page 93 2.1 General Addr. Parameter Setting Options Default Setting Comments IN-SEC CT M2 CT Rated Secondary Current Meas. Loc. 2 STRPNT->OBJ M3 CT-Strpnt. Meas. Loc.3 in Dir. of Object IN-PRI CT M3 1 .. 100000 A 2000 A CT Rated Primary Current Meas. Loc.

- Page 94 2 Functions Addr. Parameter Setting Options Default Setting Comments IN-PRI CT I5 1 .. 100000 A 200 A CT Rated Primary Current I5 IN-SEC CT I5 CT Rated Secondary Current I5 0.1A STRPNT->BUS I6 CT-Starpoint I6 in Direction of Busbar IN-PRI CT I6 1 ..

- Page 95 2.1 General Addr. Parameter Setting Options Default Setting Comments EARTH IX1 AT Terminal Q7 Terminal Q7 Earthing electrod IX1 connected to Terminal Q8 IN-PRI CT IX1 1 .. 100000 A 200 A CT rated primary current IX1 IN-SEC CT IX1 CT rated secondary current IX1 EARTH IX2 AT Terminal N7...

-

Page 96: Information List

2 Functions Addr. Parameter Setting Options Default Setting Comments SwitchgCBaux M1 (Setting options depend None Switchgear / CBaux at Measuring on configuration) Loc. M1 SwitchgCBaux M2 (Setting options depend None Switchgear / CBaux at Measuring on configuration) Loc. M2 SwitchgCBaux M3 (Setting options depend None Switchgear / CBaux at Measuring... -

Page 97: Setting Notes

2.1 General More details on how to navigate between the setting groups, to copy and reset setting groups, and how to switch over between the setting groups during operation, can be found in the SIPROTEC 4 System Description /1/. The preconditions for switching from one setting group to another via binary inputs is described in the Subsection „Mounting and Commissioning“. - Page 98 2 Functions the polarity of currents thus needs to be ensured by means of the polarity settings set out in the section General System Data. Apart from currents and voltages, protection and additional functions use the same definition of current direction as a matter of principle. This applies to 7UT613/63x thus also to reverse power protection, forward power monitoring, operational measured values for power and work, and, if required, user-defined flexible protection functions.

- Page 99 2.1 General Address 1121 PoleOpenCurr.M1 for measuring location 1, Address 1122 PoleOpenCurr.M2 for measuring location 2, Address 1123 PoleOpenCurr.M3 for measuring location 3, Address 1124 PoleOpenCurr.M4 for measuring location 4, Address 1125 PoleOpenCurr.M5 for measuring location 5. If parasitic currents (e.g. through induction) can be excluded when the circuit breaker is open, these settings may normally be very sensitive.

-

Page 100: Settings

2 Functions 2.1.6.2 Settings The table indicates region-specific presettings. Column C (configuration) indicates the corresponding secondary nominal current of the current transformer. Addr. Parameter Setting Options Default Setting Comments 1107 P,Q sign not reversed not reversed sign of P,Q reversed 1111 PoleOpenCurr.S1 0.04 .. -

Page 101: Information List

2.1 General Addr. Parameter Setting Options Default Setting Comments 1136 PoleOpenCurr I6 0.04 .. 1.00 A 0.04 A Pole Open Current Threshold End 6 0.20 .. 5.00 A 0.20 A 0.1A 0.004 .. 0.100 A 0.004 A 1137 PoleOpenCurr I7 0.04 .. - Page 102 2 Functions Information Type of In- Comments formation FaultConfig/Set Fault in configuration / setting GenErrGroupConn Gen.err.: Inconsistency group/connection GenErrEarthCT Gen.err.: Sev. earth-CTs with equal typ GenErrSidesMeas Gen.err.: Number of sides / measurements Relay PICKUP Relay PICKUP Relay TRIP Relay GENERAL TRIP command PU Time Time from Pickup to drop out TRIP Time...

- Page 103 2.1 General Information Type of In- Comments formation 30257 IL1M3: Primary fault current IL1 meas. loc. 3 30258 IL2M3: Primary fault current IL2 meas. loc. 3 30259 IL3M3: Primary fault current IL3 meas. loc. 3 30260 IL1M4: Primary fault current IL1 meas. loc. 4 30261 IL2M4: Primary fault current IL2 meas.

-

Page 104: Differential Protection

2 Functions Differential Protection The differential protection represents the main protection feature of the device. It is based on current comparison under consideration of the transformation ratio of the transformer.7UT613/63x is suitable for unit protection of transformers, generators, motors, reactors, short lines, and (under observance of the available number of ana- logue current inputs) and (under observance of the available number of analogue current inputs) busbars. - Page 105 2.2 Differential Protection All following considerations are based on the convention that all currents flowing into the protected zone are defined as positive unless explicitly stated otherwise. Basic Principle with For protected objects with three or more sides or for busbars, the differential principle more than Two is expanded in that the total of all currents flowing into the protected object is zero in Sides...

- Page 106 2 Functions = |I | + |I stab The current sum definition is extended for more than 2 measurement locations, e.g. for 4 measuring locations (figure 2-18 or 2-19), therefore: = |I diff = |I | + |I | + |I | + |I stab is derived from the fundamental frequency current and produces the tripping effect...

- Page 107 2.2 Differential Protection Figure 2-21 Tripping characteristic of the differential protection and fault characteristic Add-on Restraint Saturation of the current transformers caused by high fault currents and/or long during External system time constants are uncritical for internal faults (fault in the protected zone), Faults since the measured value deformation is found in the differential current as well in the restraint current, to the same extent.

- Page 108 2 Functions The add-on restraint acts individually per phase. It can be determined by a setting pa- rameter whether only the phase with detected external fault is blocked when this re- straint criterion is fulfilled or also the other phases of the differential stage. A further stabilisation (restraint) comes into effect when differential secondary currents are simulated by different transient behaviour of the current transformer sets.

- Page 109 2.2 Differential Protection Fast Unrestrained High-current faults in the protected zone may be cleared instantaneously without Trip with High- regard to the restraint currents when the current amplitude excludes an external fault. Current Faults If the protected object has a high direct impedance (transformers, generators, series reactors), a threshold can be found which can never be exceeded by a through-fault current.

- Page 110 2 Functions Figure 2-22 Increase of pickup value of the stage on startup Tripping Character- Figure 2-23 illustrates the complete tripping characteristic of the 7UT613/63x. The istic characteristic branch a represents the sensitivity threshold of the differential protection (setting I-DIFF>) and considers constant error currents such as magnetising cur- rents.

- Page 111 2.2 Differential Protection Differential currents above branch d cause immediate trip regardless of the restraining quantity and harmonic content (setting I-DIFF>>). This is the operating range of the „Fast Unrestrained Trip with High-current Faults“. The area of add-on restraint is the operational area of the saturation indicator (see margin heading „Add-on Restraint during External Faults“).

- Page 112 2 Functions Figure 2-25 Tripping logic of the differential protection (simplified) 7UT613/63x Manual C53000-G1176-C160-2...

-

Page 113: Differential Protection For Transformers

2.2 Differential Protection A dropout is detected when, during 2 cycles, pick-up is no longer recognised in the dif- ferential value, i.e. the differential current has fallen below 70 % of the set value, and the other pickup conditions are no longer fulfilled either. If a trip command has not been initiated, the fault is considered ended on dropout. - Page 114 2 Functions Concerning power transformers with more than two windings, the windings may have different power ratings. In order to achieve comparable currents for the differential pro- tection, all currents are referred to the winding (= side) with the highest power rating. This apparent power is named the rated power of the protected object.

- Page 115 2.2 Differential Protection Non-earthed Trans- Figure 2-28 illustrates an example for a power transformer Yd5 (wye-delta with 150° former Starpoint phase displacement) without any earthed starpoint. The figure shows the windings (above) and the vector diagrams of symmetrical currents (below). The general form of the matrix equation is: Matrix of the matched currentsI Constant factor for magnitude matching,...

- Page 116 2 Functions Earthed Starpoint Differential protection makes use of the fact that the total of all currents flowing into the protected object is zero in healthy operation. If the starpoint of a power transformer winding is connected to earth, a current can flow into the protected zone across this earth connection in case of earth faults.

- Page 117 2.2 Differential Protection · (2 I – 1 I – 1 I · (3 I – I – I – I · (3 I – 3 I – I ) = (I Zero sequence current elimination achieves that fault currents which flow via the transformer during earth faults in the network in case of an earth point in the protected zone (transformer starpoint or starpoint former by neutral earth reactor) are rendered harmless without any special external measures.

- Page 118 2 Functions Figure 2-31 Example of an earth fault outside the protected transformer with a neutral earth- ing reactor within the protected zone The disadvantage of elimination of the zero sequence current is that the protection becomes less sensitive (factor because the zero sequence current amounts to in case of an earth fault in the protected area.

- Page 119 2.2 Differential Protection the differential protection in case of earth faults in the protected zone is less sensitive by the factor , because the zero sequence current is of the fault current. If, however, the starpoint current is accessible and connected to the device, then all currents flowing into the protected zone are available.

- Page 120 2 Functions Figure 2-34 Example of a single-phase transformer with current definition Like with three-phase power transformers, the currents are matched by programmed coefficient matrices which simulate the difference currents in the transformer wind- ings. The common form of these equations is: = k·...

-

Page 121: Differential Protection For Generators, Motors, And Series Reactors

2.2 Differential Protection The matrix equation in this cases is as follows: Where I is the current measured in the „Starpoint“ connection. The zero sequence current is not eliminated. Instead of this, for each phase half of the starpoint current I is added. -

Page 122: Differential Protection For Shunt Reactors

2 Functions Figure 2-37 Definition of current direction with transverse differential protection The currents flow into the protected object even in case of healthy operation, in con- trast to all other applications. For this reason, the polarity of one current transformer set must be reversed, i.e. -

Page 123: Differential Protection For Mini-Busbars And Short Lines

2.2 Differential Protection Figure 2-38 Definition of current direction on a shunt reactor 2.2.5 Differential Protection for Mini-Busbars and Short Lines A mini-busbar or branch-point is defined here as a three-phase, coherent piece of con- ductor which is limited by sets of current transformers. Examples are short stubs or mini-busbars. -

Page 124: Single-Phase Differential Protection For Busbars

2 Functions Figure 2-41 Definition of current direction at busbar with 4 feeders The differential protection feature of the 7UT613/63x refers all currents to the rated current of the protected object. The device is informed during setting about the rated current of the protected object (in this case the busbar or line), and about the primary rated CT currents. - Page 125 2.2 Differential Protection Phase Dedicated For each of the phases, a 7UT613/63x is used in case of single-phase connection. The Connection fault current sensitivity is equal for all types of faults. 7UT613 and 7UT633 are suitable for up to 9, 7UT635 for up to 12 feeders. The differential protection feature of the 7UT613/63x refers all currents to the rated current of the protective object.

- Page 126 2 Functions Figure 2-43 Busbar protection with connection via summation current transformers (SCT) Different schemes are possible for the connection of the current transformers. The same CT connection method must be used for all feeders of a busbar. The scheme as illustrated in figure 2-44 is the most commonly used. The three input windings of the summation transformer are connected to the CT currents I .

- Page 127 2.2 Differential Protection Figure 2-45 Summation of the currents in the summation transformer on connection L1-L3-E For the connection L1-L3-E (see figure 2-44), the weighting factors W of the summa- tion currents IM for the various fault conditions and the ratios to that given by the three- phase symmetrical faults are shown in table 2-5.

- Page 128 2 Functions Figure 2-46 Summation transformer connection L1-L2-L3 with decreased earth fault sensi- tivity Figure 2-47 Summation of the currents in the summation transformer on connection L1-L2- Table 2-6 Fault conditions and weighting factors for the CT connection L1-L2-L3 for I Fault W/√3 = 100 mA...

-

Page 129: Setting Notes

2.2 Differential Protection current of the 7UT613/63x) amounts to I = 0.1 A at nominal conditions, with correct matching. Figure 2-48 Winding arrangement of summation and matching transformers 4AM5120 Differential Current Whereas a high sensitivity of the differential protection is normally required for trans- Monitoring formers, reactors, and rotating machines in order to detect even small fault currents, high fault currents are expected in case of faults on a busbar so that a higher pickup... - Page 130 2 Functions Note When delivered from factory, the differential protection is switched OFF. The reason is that the protection must not be in operation unless at least the connection group (of a transformer) and the matching factors have been set before. Without proper set- tings, the device may show unexpected reactions (incl.

- Page 131 2.2 Differential Protection Differential Current With busbar protection or short-line protection differential current can be monitored. At address 1208 I-DIFF> MON. the monitoring can be set to ON and OFF. Its use is Monitoring only sensible if one can distinguish clearly between operational error currents caused by missing transformer currents and fault currents caused by a fault in the protected object.

- Page 132 2 Functions Figure 2-49 Tripping characteristic of the differential protection The tripping characteristic comprises two further branches. The base point of the first branch is determined by address 1242 BASE POINT 1 and its slope by address 1241 SLOPE 1. This parameter can only be set with DIGSI under Additional Settings. This branch covers current-proportional errors.

- Page 133 2.2 Differential Protection The increase of the The increase of the pickup value on startup serves as an additional safety against pickup value on overfunctioning when a non-energised protection object is connected. At address 1205 INC.CHAR.START it can be switched to ON or OFF. Especially for motors or mo- startup tor/transformer units in block connection it should be set to ON.

- Page 134 2 Functions mentioned address. The restraint with harmonics does not influence the stage I- DIFF>>. The inrush restraint can be extended by the so-called "crossblock" function. This means that on harmonic content overshoot in only one phase all three phases of the differential stage I stage are blocked.

-

Page 135: Settings

2.2 Differential Protection 2.2.8 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Ad- ditional Settings. Addr. Parameter Setting Options Default Setting Comments 1201 DIFF. PROT. Differential Protection Block relay 1205 INC.CHAR.START Increase of Trip Char. During Start 1206 INRUSH 2.HARM. -

Page 136: Information List

2 Functions Addr. Parameter Setting Options Default Setting Comments 1271 2. HARMONIC 10 .. 80 % 15 % 2nd Harmonic Content in I-DIFF 2 .. 1000 Cycle; 0; ∞ 1272A CROSSB. 2. HARM 3 Cycle Time for Cross-blocking 2nd Harm. 1276 n. - Page 137 2.2 Differential Protection Information Type of In- Comments formation 5684 Diff>> L1 Diff. prot: IDIFF>> L1 (without Tdelay) 5685 Diff>> L2 Diff. prot: IDIFF>> L2 (without Tdelay) 5686 Diff>> L3 Diff. prot: IDIFF>> L3 (without Tdelay) 5691 Diff> TRIP Differential prot.: TRIP by IDIFF> 5692 Diff>>...

-

Page 138: Restricted Earth Fault Protection

2 Functions Restricted Earth Fault Protection The restricted earth fault protection detects earth faults in power transformers, shunt reactors, neutral earthing transformers/reactors, or rotating machines, the starpoint of which is led to earth. It is also suitable when a starpoint former is installed within a pro- tected zone of a non-earthed power transformer. - Page 139 2.3 Restricted Earth Fault Protection Figure 2-52 Restricted earth fault protection on a non-earthed transformer winding with neutral reactor (starpoint former) within the protected zone Figure 2-53 Restricted earth fault protection on an earthed shunt reactor with CTs in the reactor leads 7UT613/63x Manual C53000-G1176-C160-2...

- Page 140 2 Functions Figure 2-54 Restricted earth fault protection on an earthed shunt reactor with 2 CT sets (treated like an auto-transformer) Figure 2-55 Restricted earth fault protection on an earthed auto-transformer 7UT613/63x Manual C53000-G1176-C160-2...

-

Page 141: Function Description

2.3 Restricted Earth Fault Protection Figure 2-56 Restricted earth fault protection on a generator or motor with earthed starpoint The restricted earth fault protection can operate on one of the sides of the main pro- tected object (power transformer, generator, motor, reactor) or on a further protected object, according to the topology configured. - Page 142 2 Functions Figure 2-57 Example for an earth fault in a transformer with current distribution When an earth fault occurs outside the protected zone (Figure 2-58), a starpoint current I will flow equally; but an equal current 3 I must flow through the phase Ctrl current transformers.

- Page 143 2.3 Restricted Earth Fault Protection Figure 2-59 Principle of Restricted Earth Fault Protection For auto-transformers 3I " is valid as the sum of all phase currents flowing to auto-con- nected winding (full winding and tap(s)). When an earth fault occurs outside the protected zone, another earth currents flows through the phase current transformers.

- Page 144 2 Functions 1. Through-fault current on an external earth fault: " is in phase opposition with 3I ' and of equal magnitude, i.e 3I " = –3I = |3I from = |3I ' + 3I '| – |3I ' – 3I '| = 2 ·...

- Page 145 2.3 Restricted Earth Fault Protection It was assumed in the above examples that the currents 3I " and 3I ' are in counter- phase for external earth faults which is only true for the primary measured quantities. Current transformer saturation may cause phase shifting between the fundamental waves of the secondary currents which reduces the restraint quantity.

- Page 146 2 Functions Figure 2-62 Tripping characteristic of the restricted earth fault protection depending on the phase angle between 3I ” and 3I ' at 3I ” = 3I ' (180 = external fault) It is possible to increase the tripping value in the tripping area proportional to the arith- metic sum of all currents, i.e.

-

Page 147: Setting Notes

2.3 Restricted Earth Fault Protection Figure 2-64 Logic diagram of the earth fault protection (simplified) 2.3.3 Setting Notes General Note The first restricted earth fault protection is described in the setting instructions. The pa- rameter addresses and message numbers of the second restricted earth fault protec- tion are described at the end of the setting instructions under „Additional Restricted Earth Fault Protection Functions“. - Page 148 2 Functions Note When delivered from factory, the restricted earth fault protection is switched OFF. The reason is that the protection must not be in operation unless at least the assigned side and CT polarity have been properly set before. Without proper settings, the device may show unexpected reactions (incl.

-

Page 149: Settings

2.3 Restricted Earth Fault Protection 2.3.4 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Ad- ditional Settings. Addr. Parameter Setting Options Default Setting Comments 1301 REF PROT. Restricted Earth Fault Protection Block relay 1311 I-REF>... -

Page 150: Time Overcurrent Protection For Phase And Residual Currents

2 Functions Time Overcurrent Protection for Phase and Residual Currents The overcurrent protection is used as backup protection for the short-circuit protection of the main protected object and provides backup protection for external faults which are not promptly disconnected and thus may endanger the protected object. It can also be used as short-circuit protection for a further protected object if it has been as- signed to corresponding measuring locations (see Subsection 2.1.4 in „Assignment of Protection Functions to Measuring Locations/Sides“... - Page 151 2.4 Time Overcurrent Protection for Phase and Residual Currents Figures 2-65 and 2-66 show the logic diagrams for the high-set stages I>> and 3I0>>. Figure 2-65 Logic diagram of the high-set stages I>> for phase currents (simplified) 7UT613/63x Manual C53000-G1176-C160-2...

- Page 152 2 Functions Figure 2-66 Logic diagram of the high-set stages I>> for residual current (simplified) Each phase current and the zero sequence current 3·I0 are, additionally, compared with the setting value I> (common setting for the three phase currents) and 3I0> (in- dependent setting for 3·I0).

- Page 153 2.4 Time Overcurrent Protection for Phase and Residual Currents Figure 2-67 Logic diagram of the overcurrent stage I> for phase currents (simplified) 7UT613/63x Manual C53000-G1176-C160-2...

-

Page 154: Inverse Time Overcurrent Protection

2 Functions Figure 2-68 Logic diagram for the overcurrent stage 3I0> for residual current (simplified) The pickup values of all stages I> (phases), 3I0> (zero sequence current), I>> (phases), 3I0>> (zero sequence current) and the time delays associated for each stage can be set individually. - Page 155 2.4 Time Overcurrent Protection for Phase and Residual Currents lected tripping characteristic. After expiration of this time period, a trip command is output as long as no inrush current is detected or inrush restraint is disabled. If inrush restraint is enabled and inrush current is detected, there will be no tripping. Neverthe- less, an annunciation is generated indicating that the time expired.

- Page 156 2 Functions Figure 2-69 Logic diagram of the inverse overcurrent protection for phase currents — example of IEC characteristic (simplified) 7UT613/63x Manual C53000-G1176-C160-2...

- Page 157 2.4 Time Overcurrent Protection for Phase and Residual Currents Figure 2-70 Logic diagram of the definite time overcurrent protection for zero sequence current — example of IEC char- acteristic (simplified) Dropout You can determine whether the dropout of a stage is to follow right after the threshold is undershot or whether it is to be evoked by disk emulation.

-

Page 158: Manual Close Command

2 Functions User-Specified When user-defined curves are utilized, the tripping curve may be defined point by Curves point. Up to 20 pairs of values (current, time) may be entered. With these values the device approximates the characteristic by means of linear interpolation. If required, the dropout characteristic can also be defined. -

Page 159: Inrush Restraint

2.4 Time Overcurrent Protection for Phase and Residual Currents Overcurrent Protection“. The alternative pickup values themselves can be set for each of the stages of the time overcurrent protection. 2.4.1.5 Inrush Restraint When switching unloaded transformers or shunt reactors on a live busbar, high mag- netising (inrush) currents may occur. -

Page 160: Fast Busbar Protection Using Reverse Interlocking

2 Functions Since the harmonic restraint operates individually per phase, the protection is fully op- erative even when e.g. the transformer is switched onto a single-phase fault, whereby inrush currents may possibly be present in one of the healthy phases. However, it is also possible to set the protection such that not only the phase with inrush current ex- hibiting harmonic content in excess of the permissible value is blocked but also the other phases of the associated stage are blocked (so called "cross-block function"). -

Page 161: Time Overcurrent Protection For Phase Currents

2.4 Time Overcurrent Protection for Phase and Residual Currents Figure 2-74 Fast busbar protection using reverse interlock — principle 2.4.2 Time Overcurrent Protection for Phase Currents The function and operation of the definite-time overcurrent protection and of the inverse-time overcurrent protection for residual current is discussed in detail in section „Overcurrent Time Protection - General“... - Page 162 2 Functions characteristic can be performed here. The definite time stages I>> and I> are available in all cases. If a second or third phase overcurrent protection is used, this must be configured ac- cordingly in address 130 DMT/IDMT Phase2 and 132 DMT/IDMT Phase3. Each protection function must be assigned to a side of the main protected object or another 3-phase current measuring location.

- Page 163 2.4 Time Overcurrent Protection for Phase and Residual Currents Example: Transformer used in the infeed of a bus supply with the following data: Transformer YNd5 35 MVA 110 kV/20 kV = 15 % Current Transformer 200 A / 5 A on the 110 kV side The time overcurrent protection is assigned to the 110 kV side (= feeding side).

- Page 164 2 Functions < I>> < I 1.6 · I startup k 2pol The potential increase in starting current caused by overvoltage conditions is already accounted for by the 1.6 factor. The I>> stage can trip instantaneously (T I>> = 0.00 s), since there is no saturation of shunt reactance for motors, other than for transformers.

- Page 165 2.4 Time Overcurrent Protection for Phase and Residual Currents If under address 2225 TOC DROP-OUT the Disk Emulation are set, dropout is pro- duced in accordance with the dropout characteristic, as set out in the functional de- scription of the inverse time overcurrent protection in section „Dropout Behaviour“. Overcurrent Stages The inverse time stage, depending on the configuration of the functional scope with ANSI char-...

- Page 166 2 Functions For the stages the following alternative values are set: • For definite time overcurrent protection (phases): address 2111 or 2112 for pickup value I>>, address 2113 for delay time T I>>, address 2114 or 2115 for pickup value I>, address 2116 for delay time T I>, •...

- Page 167 2.4 Time Overcurrent Protection for Phase and Residual Currents Table 2-7 Preferred values of standardized currents for user-defined trip characteristics = 1 to 1.94 = 2 to 4.75 = 5 to 7.75 = 8 to 20 1.00 1.50 2.00 3.50 5.00 6.50 8.00...

- Page 168 2 Functions For specification of a dropout characteristic please note the following: • For currents select the values from table 2-8 and add the corresponding time values. Deviating values I/I are rounded. This, however, will not be indicated. • Currents greater than the current value of the largest characteristic point do not lead to a prolongation of the dropout time.

-

Page 169: Settings

2.4 Time Overcurrent Protection for Phase and Residual Currents Addresses of the Addresses of the dynamic Message no. parameters parameters 1. Overcurrent protection for phase currents 20xx 21xx 023.xxxx(.01) 2. Overcurrent protection for phase currents 30xx 31xx 207.xxxx(.01) 3. Overcurrent protection for phase currents 32xx 33xx 209.xxxx(.01) - Page 170 2 Functions Addr. Parameter Setting Options Default Setting Comments 2021 0.10 .. 4.00 A 2.00 A Ip Pickup 0.50 .. 20.00 A 10.00 A 2022 0.10 .. 4.00 I/InS 2.00 I/InS Ip Pickup 0.05 .. 3.20 sec; ∞ 2023 T Ip 0.50 sec T Ip Time Dial 0.50 ..

-

Page 171: Information List

2.4 Time Overcurrent Protection for Phase and Residual Currents Addr. Parameter Setting Options Default Setting Comments 2121 0.10 .. 4.00 A 4.00 A Ip Pickup 0.50 .. 20.00 A 20.00 A 2122 0.10 .. 4.00 I/InS 4.00 I/InS Ip Pickup 0.05 .. -

Page 172: Time Overcurrent Protection For Residual Current

2 Functions 2.4.3 Time Overcurrent Protection for Residual Current The function and operation of the definite-time overcurrent protection and of the inverse-time overcurrent protection for residual current is discussed in detail in the section „Time Overcurrent Protection - General“ above (see subsection 2.4.1). The fol- lowing paragraphs contain the specific information for setting the overcurrent protec- tion for residual current 3I0 O/C. - Page 173 2.4 Time Overcurrent Protection for Phase and Residual Currents In address 2202 InRushRest. 3I0 inrush restraint (inrush restraint with 2nd har- monic) is enabled or disabled. Set ON if the residual current stage of the time overcur- rent protection is applied at the supply side of a transformer whose starpoint is earthed.

- Page 174 2 Functions Inverse Time Over- The inverse time stage, depending on the configuration of the functional scope, address 122 (see 2.1.3.1), enables the user to select different characteristics. current Stage3I0p with IEC Character- With the IEC characteristics (address 122 DMT/IDMT 3I0 = TOC IEC) the following istics options are available at address 2226 IEC CURVE: •...

- Page 175 2.4 Time Overcurrent Protection for Phase and Residual Currents This means that a pickup will only occur if a current of about 1.1 times the setting value is present. The current value is set in address 2221 or 2222 3I0p. The most relevant for this setting is the minimum appearing earth fault current.

-

Page 176: Settings

2 Functions protection is activated on the earthed supply side, this inrush restraint is required. Function parameters of the inrush restraint are set in „Inrush“. The inrush restraint is based on the evaluation of the 2nd harmonic present in the inrush current. - Page 177 2.4 Time Overcurrent Protection for Phase and Residual Currents Addr. Parameter Setting Options Default Setting Comments 0.05 .. 35.00 A; ∞ 2211 3I0>> 1.00 A 3I0>> Pickup 0.25 .. 175.00 A; ∞ 5.00 A 0.05 .. 35.00 I/InS; ∞ 1.00 I/InS 2212 3I0>>...

-

Page 178: Information List

2 Functions Addr. Parameter Setting Options Default Setting Comments 2321 3I0p 0.05 .. 4.00 A 1.00 A 3I0p Pickup 0.25 .. 20.00 A 5.00 A 2322 3I0p 0.05 .. 4.00 I/InS 1.00 I/InS 3I0p Pickup 0.05 .. 3.20 sec; ∞ 2323 T 3I0p 0.50 sec... -

Page 179: Time Overcurrent Protection For Earth Current

2.5 Time Overcurrent Protection for Earth Current Time Overcurrent Protection for Earth Current 2.5.1 General The time overcurrent protection for earth current is assigned to a 1-phase measured current input of the device. It can be used for any desired single-phase application. Its preferred application is the detection of an earth current between the starpoint of a pro- tective object and its earth electrode (that's why the description). - Page 180 2 Functions Pickup, Trip Two definite time stages are available for the earth current. For the IE>> stage, the current measured at the assigned 1-phase current input is compared with the setting value IE>>. Current above the pickup value is detected and annunciated.

-

Page 181: Inverse Time Overcurrent Protection

2.5 Time Overcurrent Protection for Earth Current Figure 2-79 Logic diagram of the overcurrent stage I > for earth current (simplified) 2.5.3 Inverse Time Overcurrent Protection The inverse time overcurrent stage operates with a characteristic either according to the IEC- or the ANSI-standard or to a user-defined characteristic. The characteristics and their equations are given in the „Technical Data“. - Page 182 2 Functions Figure 2-80 Logic Diagram of the Inverse Overcurrent Protection for Earth Currents — example of IEC characteristic (simplified) Dropout You can determine whether the dropout of the stage is to follow right after the thresh- old undershot or whether it is evoked by disk emulation. "Right after" means that the pickup drops out when approx.

-

Page 183: Manual Close Command

2.5 Time Overcurrent Protection for Earth Current User-defined Char- When user-defined curves are utilised, the tripping curve may be defined point by acteristics point. Up to 20 pairs of values (current, time) may be entered. The device then approx- imates the characteristics by linear interpolation. If required, the dropout characteristic can also be defined (see function description for „Dropout“. -

Page 184: Setting Notes

2 Functions Figure 2-81 Logic diagram of the inrush restraint feature (simplified) 2.5.7 Setting Notes General Note The first time overcurrent protection for earth current is described in the setting instruc- tions. The parameter addresses and message numbers of the second and third time overcurrent protection are described at the end of the setting instructions under „Ad- ditional Time Overcurrent Protection Functions for Earth Current“. - Page 185 2.5 Time Overcurrent Protection for Earth Current If time overcurrent protection is applied on the feeding side of a transformer, select the higher stage IE>>, which does not pick up by the inrush current or set the manual close feature to Inactive. At address 2402 InRushRestEarth inrush restraint (inrush restraint with 2nd har- monic) is enabled or disabled.

- Page 186 2 Functions If the inverse time trip characteristic is selected, it must be noted that a safety factor of about 1.1 has already been included between the pickup value and the setting value. This means that a pickup will only occur if a current of about 1.1 times of the setting value is present.

- Page 187 2.5 Time Overcurrent Protection for Earth Current Since this stage also picks up with earth faults in the network, the time delay (address 2423 D IEp) has to be coordinated with the grading coordination chart of the network for earth faults. In most cases, shorter tripping times than for phase currents may be set since a galvanic separation of the zero sequence systems of the connected power system sections is ensured by a transformer with separate windings.

-

Page 188: Settings

2 Functions If the current exceeds the value indicated in address 2442 I Max InRr. E, no re- straint will be provoked by the 2nd harmonic. Additional Overcur- In the aforementioned description, the first overcurrent protection is described respec- rent Protection tively. -

Page 189: Information List

2.5 Time Overcurrent Protection for Earth Current Addr. Parameter Setting Options Default Setting Comments 2426 ANSI CURVE Very Inverse Very Inverse ANSI Curve Inverse Short Inverse Long Inverse Moderately Inv. Extremely Inv. Definite Inv. 1.00 .. 20.00 I/Ip; ∞ 2431 I/IEp PU T/TEp Pickup Curve IE/IEp - 0.01 .. - Page 190 2 Functions Information Type of In- Comments formation 024.2522 IE> picked up IE> picked up 024.2523 IEp picked up IEp picked up 024.2524 IE> InRush PU IE> InRush picked up 024.2525 IEp InRush PU IEp InRush picked up 024.2529 Earth InRush PU Earth InRush picked up 024.2541 IE>>...

-

Page 191: Dynamic Cold Load Pickup For Time Overcurrent Protection

2.6 Dynamic Cold Load Pickup for Time Overcurrent Protection Dynamic Cold Load Pickup for Time Overcurrent Protection With the dynamic cold load pickup feature, it is possible to dynamically increase the pickup values of the time overcurrent protection stages when dynamic cold load over- current conditions are anticipated, i.e. - Page 192 2 Functions made with the „normal“ setpoints. The function is inactive and the fast reset time, if ap- plied, is reset. If overcurrent elements are picked up while Active Time is running, the fault gener- ally prevails until pickup drops out, using the dynamic pickup values. Only then are the parameters set back to „normal“.

-

Page 193: Setting Notes

2.6 Dynamic Cold Load Pickup for Time Overcurrent Protection Figure 2-83 Logic diagram for dynamic cold load pickup feature — illustrated for phase overcurrent protection stage on side 1 (simplified) 2.6.2 Setting Notes General Dynamic cold load pickup can only be enabled if during configuration of the functional scope was set at the address 117 COLDLOAD PICKUP. -

Page 194: Settings

2 Functions rion, the feedback information of the assigned breaker must inform the device about the breaker position. The time overcurrent protection for earth current allows the breaker criterion only if an unequivocal relationship exists between its assigned side or measuring location and the feedback information of the breaker (SwitchgCBaux S1, SwitchgCBaux S2 to SwitchgCBaux M5, addresses 831 to 840). -

Page 195: Information List

2.6 Dynamic Cold Load Pickup for Time Overcurrent Protection 2.6.4 Information List Information Type of In- Comments formation 025.2413 I Dyn.set. ACT Dynamic settings O/C Phase are ACTIVE 026.2413 IE Dyn.set. ACT Dynamic settings O/C Earth are ACTIVE 049.2404 >BLOCK CLP >BLOCK Cold-Load-Pickup 049.2411 CLP OFF Cold-Load-Pickup switched OFF... -

Page 196: Single-Phase Time Overcurrent Protection

2 Functions Single-Phase Time Overcurrent Protection The single-phase time overcurrent protection can be assigned to either of the single- phase measured additional current inputs of the device. This may be a „normal“ input or a high-sensitivity input. In the latter case, a very sensitive pickup threshold is pos- sible (smallest setting 3 mA at the current input). - Page 197 2.7 Single-Phase Time Overcurrent Protection Figure 2-84 Two-stage tripping characteristic of the single-phase time overcurrent protec- tion Figure 2-85 Logic diagram of the single-phase overcurrent protection — example for detection of the current at input II 7UT613/63x Manual C53000-G1176-C160-2...

-

Page 198: High-Impedance Differential Protection

2 Functions 2.7.2 High-impedance Differential Protection Application With the high-impedance scheme all current transformers at the limits of the protection Example zone operate parallel to a common relatively high-ohmic resistance R whose voltage is measured. With 7UT613/63x the voltage is registered by measuring the current through the external resistor R at the high-sensitivity single-phase current measuring input. - Page 199 2.7 Single-Phase Time Overcurrent Protection Figure 2-87 Earth fault protection using the high-impedance principle In case of an earth fault in the protection zone (figure2-87 right) a starpoint current I will certainly be present. The earthing conditions in the rest of the network determine how strong a zero sequence current from the system is.

-

Page 200: Tank Leakage Protection

2 Functions For protection against overvoltages it is also important that the device is directly con- nected to the earthed side of the current transformers so that the high voltage at the resistor can be kept away from the device. For generators, motors and shunt reactors high-impedance differential protection can be used analogously. - Page 201 2.7 Single-Phase Time Overcurrent Protection Protection Functions“) and the properties of the 1-phase measuring inputs (section 2.1.4 under „Topology of the Protected Object“, margin heading „High-sensitive 1-phase Additional Measuring Inputs“). • If you have declared the type of the corresponding 1-phase current input as (ad- dress 255 and/or 256) as 1A/5A input, set the pickup value 1Phase I>>...

- Page 202 2 Functions The internal burden is often stated in the test report of the current transformer. If not known, it can be derived from a DC measurement on the secondary winding. Calculation Example: = 0.3 Ω Current transformer 800/5; 5P10; 30 VA with R = 5 Ω...

- Page 203 2.7 Single-Phase Time Overcurrent Protection The voltage across R is then · ( 2R Furthermore, it is assumed that the pickup value of the 7UT613/63x corresponds to half the knee-point voltage of the current transformers. The extreme case is thus This results in a stability limit I , i.e.

- Page 204 2 Functions The required short-term power of the resistor is derived from the knee-point voltage and the resistance: As this power only appears during earth faults for a short period of time, the rated power can be smaller by approx. factor 5. The varistor (see figure below) must be dimensioned in such manner that it remains high-ohmic up to the knee-point voltage, e.g.

-

Page 205: Settings

2.7 Single-Phase Time Overcurrent Protection Note In the following parameter overview the addresses 2703 and 2706 apply to a high- sensitive current measuring input and are independent from the rated current. 2.7.5 Settings The table indicates region-specific presettings. Column C (configuration) indicates the corresponding secondary nominal current of the current transformer. -

Page 206: Unbalanced Load Protection

2 Functions Unbalanced Load Protection Unbalanced load protection (negative sequence protection) detects unbalanced loads on the system. In addition, this protection function may be used to detect interruptions, faults, and polarity problems with current transformers. Furthermore, it is useful in de- tecting phase-to-earth, phase-to-phase, and double phase-to-earth faults with magni- tudes lower than the maximum load current. - Page 207 2.8 Unbalanced Load Protection Figure 2-92 Tripping characteristic of the definite time unbalanced load protection Inverse Time Stage The inverse time overcurrent stage operates with a tripping characteristic either ac- cording to the IEC or the ANSI standard. The characteristics and their equations are given in the „Technical Data“.

- Page 208 2 Functions Figure 2-93 Inverse time characteristic for unbalanced load protection Dropout It can be determined whether the dropout of the stage is to follow right after the thresh- old undershot or whether it is evoked by disk emulation. "Right after" means that the pickup drops out when approx.

- Page 209 2.8 Unbalanced Load Protection Figure 2-94 Logic diagram of the unbalanced load protection - illustrated for IEC characteristic Thermal Stage With the aid of the thermal stages the unbalanced load protection can be well adapted to the thermal loading of the electrical motor rotor during asymmetric load. Pickup, Warning The permissible continuous load imbalance is determined with the setting „I2 Permis- sible“.

- Page 210 2 Functions Thermal Characteris- The thermal characteristic allows an approximate calculation of the thermal loading of the electrical motor rotor by load imbalance in the stator. This follows the simplified equation: with: Tripping time Asymmetry factor Negative sequence current Rated current of the protective object N Obj The asymmetry factor K designates how long a negative sequence current may flow at nominal machine current.

- Page 211 2.8 Unbalanced Load Protection Figure 2-95 Resulting characteristic of the thermal asymmetrical load protection Logic Figure 2-96 shows the logic diagram for the breaker failure protection with the thermal stage and the definite time I >> stage. The I > stage is not represented. It is available in this operating mode, but is generally not required because an own warning level is available.

-

Page 212: Setting Notes

2 Functions Figure 2-96 Logic diagram of the asymmetrical load protection - illustrated for the thermal stage with I>> stage (simpli- fied) 2.8.2 Setting Notes General Unbalanced load protection only makes sense with three-phase protected objects. For PROT. OBJECT = 1ph Busbar or 1 phase transf. (address 105) the following settings are not available. - Page 213 2.8 Unbalanced Load Protection The unbalanced load protection must have been assigned to a side of the main pro- tected object or another 3-phase current measuring location (Subsection 2.1.4 under margin heading „Further 3-Phase Protection Functions“). Consider also the assign- ment of the measured current inputs of the device against the measuring locations (current transformer sets) of the power plant (section 2.1.4 under margin heading „As- signment of 3-phase Measuring Locations“).

- Page 214 2 Functions for 1-pole faults: I2> = 0.1 A, i.e. earth fault current as from approx. 0.3 A. = 5 A results in 5 times the secondary value. Consider the current transformer ratios when setting the device with primary values. For a power transformer, unbalanced load protection may be used as sensitive pro- tection for low magnitude phase-to-earth and phase-to-phase faults.

- Page 215 2.8 Unbalanced Load Protection I2>> = 0.55 · 545 A = 300 A primary or Setting 0.55· 545 A · (1/600) = 0.50 A secondary Delay T I2>> = 1 s The inverse curves (see below) permit a consideration of load imbalance per unit of time.

- Page 216 2 Functions This means that a pickup will only occur if an unbalanced load of about 1.1 times the setting value of I2p (address 4021 or 4022) is present. The corresponding time multiplier is accessible via address 4024 D I2p. The time multiplication factor may also be set to ∞.

- Page 217 2.8 Unbalanced Load Protection In example, figure 2-97, the permanently permissible asymmetrical load amounts to 11 % of the machine internal current and the K-factor K = 20. As the relevant measur- ing location for asymmetrical load is usually assigned to the side of the machine to be protected, the setting can be effected directly under address 4034 FACTOR K: FACTOR K = 20.

-

Page 218: Settings

2 Functions heatup time of the object to be protected. There is the following connection between the asymmetrical factor K and the cool-down time: Example: For asymmetry factor K = 20 s and a permanently permissible asymmetrical load of = 11 % a corresponding cool-down time is derived This value does not depend on whether the respective values were set to secondary values, as the current transformation ratios are reduced in numerator and denomina- tor. -

Page 219: Information List

2.8 Unbalanced Load Protection Addr. Parameter Setting Options Default Setting Comments 0.50 .. 15.00 ; ∞ 4024 D I2p 5.00 D I2p Time Dial 4025 I2p DROP-OUT Instantaneous Instantaneous I2p Drop-out Characteris- Disk Emulation 4026 IEC CURVE Normal Inverse Extremely Inv. IEC Curve Very Inverse Extremely Inv. -

Page 220: Thermal Overload Protection

2 Functions Thermal Overload Protection The thermal overload protection prevents damage to the protected object caused by thermal overloading, particularly in case of transformers, rotating machines, power re- actors and cables. This protection is not applicable to single-phase busbar protection. It can be assigned to any of the sides of the main protected object, however, not to a non-assigned measuring point. - Page 221 2.9 Thermal Overload Protection The protection function thus represents a thermal profile of the equipment being pro- tected (overload protection with memory capability). Both the previous history of an overload and the heat loss to the environment are taken into account. In steady-state operation the solution of this equation is in an e-function whose asymp- tote represents the final temperature Θ...

- Page 222 2 Functions Motor Startup On startup of electrical machines the overtemperature calculated by the thermal replica may exceed the alarm overtemperature or even the trip overtemperature. In order to avoid an alarm or trip, the starting current is acquired and the resulting in- crease of temperature rise is suppressed.

-

Page 223: Overload Protection Using A Thermal Replica With Ambient Temperature Influence