Summary of Contents for Siemens SIPROTEC 7UM62

- Page 1 Preface Contents Introduction SIPROTEC Functions Multifunctional Machine Mounting and Commissioning Protection 7UM62 Technical Data Appendix V4.6 Literature Manual Glossary Index C53000-G1176-C149-7...

- Page 2 SIPROTEC, SINAUT, SICAM and DIGSI are registered trademarks Document Version V04.63.00 of Siemens AG. Other designations in this manual might be trade- marks whose use by third parties for their own purposes would in- Release date 03.2010 fringe the rights of the owner.

- Page 3 Council Directive 2004/108/EC) and concerning electrical equipment for use within specified voltage limits (Low-voltage directive 2006/95 EC). This conformity is proved by tests conducted by Siemens AG in accordance with the Council Directives in agreement with the generic standards EN61000-6-2 and EN 61000-6-4 for the EMC directive, and with the standard EN 60255-27 for the low-voltage directive.

- Page 4 Additional Support Should further information on the System SIPROTEC 4 be desired or should particular problems arise which are not covered sufficiently for the purchaser's purpose, the matter should be referred to the local Siemens rep- resentative. Our Customer Support Center provides a 24-hour service.

- Page 5 Preface Safety Information This manual does not constitute a complete index of all required safety measures for operation of the equip- ment (module, device), as special operational conditions may require additional measures. However, it com- prises important information that should be noted for purposes of personal safety as well as avoiding material damage.

- Page 6 The operational equipment (device, module) may only be used for such applications as set out in the catalogue and the technical description, and only in combination with third-party equipment recommended or approved by Siemens. The successful and safe operation of the device is dependent on proper handling, storage, installation, opera- tion, and maintenance.

- Page 7 Preface Typographic and Symbol Conventions The following text formats are used when literal information from the device or to the device appear in the text flow: Parameter Names Designators of configuration or function parameters which may appear word-for-word in the display of the device or on the screen of a personal computer (with operation software DIGSI), are marked in bold letters in monospace type style.

- Page 8 Preface Besides these, graphical symbols are used in accordance with IEC 60617-12 and IEC 60617-13 or similar. Some of the most frequently used are listed below: analog input values AND-gate operation of input values OR-gate operation of input values Exclusive OR gate (antivalence): output is active, if only one of the inputs is active Coincidence gate: output is active, if both inputs are active or inactive at the same time...

-

Page 9: Table Of Contents

Contents Introduction................21 Overall Operation. - Page 10 Contents Definite-Time Overcurrent Protection (I>, ANSI 50/51) with Undervoltage Seal-In....65 2.8.1 Function Description ............65 2.8.2 Setting Notes .

- Page 11 Contents 2.15 Earth Current Differential Protection (ANSI 87GN,TN) ........128 2.15.1 Function Description .

- Page 12 Contents 2.23 Frequency Protection (ANSI 81) ........... . . 181 2.23.1 Functional Description .

- Page 13 Contents 2.31 100-%-Stator Earth Fault Protection with 20 Hz Voltage Injection (ANSI 64G - 100%) ... .223 2.31.1 Function Description ............223 2.31.2 Setting Notes .

- Page 14 Contents 2.39 Inadvertent Energization (ANSI 50, 27) ..........268 2.39.1 Functional Description .

- Page 15 Contents 2.46 Temperature Detection by Thermoboxes..........316 2.46.1 Function Description .

- Page 16 Contents 2.50 Command Processing............. 349 2.50.1 Control Device.

- Page 17 Contents Commissioning ..............400 3.3.1 Test Mode / Transmission Block .

- Page 18 Contents 4.10 Underexcitation (Loss-of-Field) Protection (ANSI 40) ........482 4.11 Reverse Power Protection (ANSI 32R) .

- Page 19 Contents 4.39 Dimensions ..............525 4.39.1 Panel Flush and Cubicle Mounting (Housing Size ) .

- Page 20 Contents A.10 Measured Values ..............616 Literature.

-

Page 21: Introduction

Introduction This chapter introduces the SIPROTEC 4 7UM62. It provides an overview of the scopes of application, features and of the functional scope. Overall Operation Application Scope Characteristics SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010... -

Page 22: Overall Operation

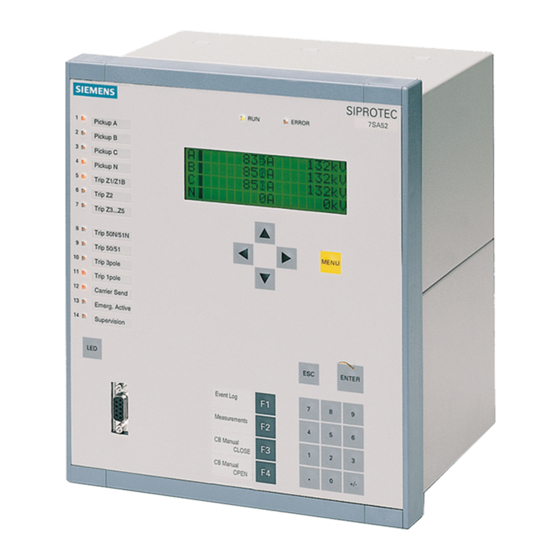

Introduction 1.1 Overall Operation Overall Operation The digital multifunctional protective relay 7UM62 is equipped with a high performance microprocessor. All tasks such as the acquisition of the measured values and issuing of commands to circuit breakers and other switching equipment are processed digitally. Figure 1-1 shows the basic structure of the device. Analog Inputs The measuring inputs (MI) section effect a gavanic isolation. - Page 23 Introduction 1.1 Overall Operation The device has 8 current and 4 voltage inputs. Three current inputs are used on each side of the protected object for measuring of the phase currents. 2 current inputs are equipped with sensitive input transformers (I and can measure secondary currents in the mA range.

- Page 24 Introduction 1.1 Overall Operation Front Elements Light-emitting diodes (LEDs) and a display (LCD) on the front panel provide information on the functional status of the device and report events, states and measured values. The integrated control keys and numeric keys in conjunction with the LCD enable local interaction with the device.

-

Page 25: Application Scope

Introduction 1.2 Application Scope Application Scope The SIPROTEC 4 7UM62 is a numerical machine protection unit from the „7UM6 Numerical Protection“ series. It provides all functions necessary for protection of generators, motors and transformers. As the scope of func- tions of the 7UM62 can be customized, it is suited for small, medium-sized and large generators. The device fulfills the protection requirements for the two typical basic connections: •... - Page 26 Introduction 1.2 Application Scope Messages and Measured Values; Recording of Event and Fault Data The operational indications provide information about conditions in the power system and the device itself. Measurement quantities and resulting computed values can be displayed locally and communicated via the serial interfaces.

-

Page 27: Characteristics

Introduction 1.3 Characteristics Characteristics General Features • Powerful 32-bit microprocessor system. • Complete digital processing of measured values and control, from sampling and digitalization of measured quantities to tripping circuit breakers or other switchgear devices. • Total galvanic and disturbance-immune separation between the internal processing stages of the device and the measuring, control and supply circuits of the system using measurement transducers, binary input and output modules and and the DC converters. - Page 28 Introduction 1.3 Characteristics Thermal Overload Protection 49 • Temperature image of current heat losses (overload protection with full memory capability, single body thermal model). • Additional adjustable warning levels based on temperature rise and current magnitude. • Consideration of coolant and ambient temperatures possible. Negative Sequence Protection 46-1, 46-2, 46-TOC •...

- Page 29 Introduction 1.3 Characteristics Reverse Power Protection • Calculation of power from positive sequence components. • Highly sensitive and precise active power measurement (detection of small motoring powers even with low power factor cos ϕ, angle error compensation). • Insensitive to power fluctuations. •...

- Page 30 Introduction 1.3 Characteristics Frequency Protection 81 O/U • Monitoring on undershooting (f<) and/or overshooting (f>) with 4 frequency limits and delay times that are independently adjustable. • Insensitive to harmonics and abrupt phase angle changes. • Settable undervoltage threshold. Overexcitation Protection •...

- Page 31 Introduction 1.3 Characteristics 100 % Stator Earth Fault Protection with 20 Hz Bias Voltage • Evaluation of the 20 Hz measurement (7XT33 and 7XT34). • Warning and trip stage R< and R<<. • Trip stage with earth current. • High sensitivity also with large stator earth capacitances. Earth Current Protection B •...

- Page 32 Introduction 1.3 Characteristics Restart Inhibit for Motors 66 • Approximate computation of rotor overtemperature. • Startup is permitted only if the rotor has sufficient thermal reserves for a complete startup • Calculation of waiting time until restarting is enabled. • Different prolongation of cooldown time constants for standstill/operation period is taken into consideration. •...

- Page 33 Introduction 1.3 Characteristics User-defined Functions • Internal and external signals can be logically combined to establish user-defined logic functions. • All common logic functions (AND, OR, NOT, Exclusive OR, etc.). • Time delays and limit value interrogations. • Processing of measured values, including zero suppression, adding a knee characteristic for a transducer input, and live-zero monitoring.

- Page 34 Introduction 1.3 Characteristics SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 35: Functions

Functions This chapter describes the individual functions of the SIPROTEC 4 device 7UM62. It shows the setting possi- bilities for each function in maximum configuration. Guidelines for establishing setting values and, where re- quired, formulae are given. Based on the following information, it can also be determined which of the provided functions should be used. Introduction, Reference Power System Device Ethernet EN100 Modul... - Page 36 Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) 2.27 Jump of Voltage Vector 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) 2.29 Sensitive Earth Fault Protection (ANSI 51GN, 64R) 2.30 100-%-Stator Earth Fault Protection with 3rd Harmonics (ANSI 27/59TN 3rd Harm.) 2.31 100-%-Stator Earth Fault Protection with 20 Hz Voltage Injection (ANSI 64G - 100%) 2.32...

-

Page 37: Introduction, Reference Power System

Functions 2.1 Introduction, Reference Power System Introduction, Reference Power System The following section will explain the individual protection and additional functions and provide information about the setting values. 2.1.1 Functional Description Generator The calculation examples are based on two reference power systems with the two typical basic configurations busbar connection and unit connection. - Page 38 Functions 2.1 Introduction, Reference Power System Technical Data of the Reference Power Systems Generator = 5.27 MVA N, G = 6.3 kV N, G = 483 A N, G cos ϕ = 0.8 Current transformer: = 500 A; = 1 A N,prim N, sec Toroidal c.t.:...

-

Page 39: Device

Functions 2.2 Device Device The device can issue a serie of general annunciations about itself and the substation. These annunciations are listed in the following information list. Most annunciations are self-explanatory. The special cases are described below: Reset: Device is reset on each Power ON. Initial Start: Initial start occurs after initialization of the device by DIGSI. -

Page 40: Settings

Functions 2.2 Device Note Setting address 610 FltDisp.LED/LCD to (Target on TRIP) is only reasonable if address 615 T MIN LED HOLD is set to 0. Figure 2-3 Creation of the resetting command for stored LEDs / relays Default display of a 4-line display After startup of the device featuring a 4-line display, measured values are displayed by default. -

Page 41: Information List

Functions 2.2 Device 2.2.3 Information List Information Type of In- Comments formation Reset LED IntSP Reset LED Test mode IntSP Test mode DataStop IntSP Stop data transmission UnlockDT IntSP Unlock data transmission via BI >Light on >Back Light on SynchClock IntSP_Ev Clock Synchronization HWTestMod... -

Page 42: Ethernet En100 Modul

Functions 2.3 Ethernet EN100 Modul Ethernet EN100 Modul 2.3.1 Functional Description An Ethernet EN100 Modul allows to integrate the 7UM62 into 100 Mbit Ethernet communication networks used by process control and automation systems and running IEC 61850 protocols. This standard provides consistent inter-relay communication without gateways or protocol converters. -

Page 43: Functional Scope

Functions 2.4 Functional Scope Functional Scope The 7UM62 device incorporates numerous protection and supplementary functions. The hardware and firm- ware provided is designed for this scope of functions. Nevertheless a few restrictions apply to the use of the earth fault current and earth fault voltage inputs I and U respectively. -

Page 44: Setting Notes

Functions 2.4 Functional Scope 2.4.2 Setting Notes Peculiarities Most settings are self-explanatory. The special cases are described below. If the setting group change function has to be used, address 103 Grp Chge OPTION must be set to enabled. In this case, it is possible to apply two groups of settings for function parameters (refer also to Section 2.6) al- lowing convenient and fast switch-over between these setting groups. - Page 45 Functions 2.4 Functional Scope Protection function Side 1 Side 2 L1S1 L2S1 L1S2 L2S2 L3S1 L3S2 Out-of-Step Protection (ANSI 78) Fixed – – – Fixed – – Undervoltage Protection Fixed – – – – – – Overvoltage Protection Fixed – –...

- Page 46 Functions 2.4 Functional Scope Figure 2-4 Use as Generator Differential Protection Figure 2-5 Use as Block Differential Protection (Overall Protection) For the following application, the settings of the generator data under P.System Data 1 must be same as for the transformer data of side 2: Figure 2-6 Use as Transformer Differential Protection For the following application, the differential protection of device A must be set to Generator/Motor, in the...

- Page 47 Functions 2.4 Functional Scope Figure 2-7 Use as Redundant Overall Protection For earth fault protection, Address 150 S/E/F PROT. presents the options non-dir. U0, non-dir. U0&I0 and directional, unless the whole function is Disabled. The first option evaluates only the displacement voltage (to be used with unit connection).

-

Page 48: Settings

Functions 2.4 Functional Scope 2.4.3 Settings Addr. Parameter Setting Options Default Setting Comments Grp Chge OPTION Disabled Disabled Setting Group Change Option Enabled FAULT VALUE Disabled Instant. values Fault values Instant. values RMS values O/C PROT. I> Disabled Side 2 Overcurrent Protection I>... - Page 49 Functions 2.4 Functional Scope Addr. Parameter Setting Options Default Setting Comments INV.UNDERVOLT. Disabled Enabled Inverse Undervoltage Protection Enabled Up< df/dt Protect. Disabled 2 df/dt stages Rate-of-frequency-change protec- 2 df/dt stages tion 4 df/dt stages VECTOR JUMP Disabled Enabled Jump of Voltage Vector Enabled S/E/F PROT.

- Page 50 Functions 2.4 Functional Scope Addr. Parameter Setting Options Default Setting Comments ANALOGOUTP B1/1 Disabled Disabled Analog Output B1/1 (Port B) I1 [%] I2 [%] IEE1 [%] IEE2 [%] U1 [%] U0 [%] U03H [%] |P| [%] |Q| [%] |S| [%] f [%] U/f [%] PHI [%]...

- Page 51 Functions 2.4 Functional Scope Addr. Parameter Setting Options Default Setting Comments ANALOGOUTP D1/1 Disabled Disabled Analog Output D1/1 (Port D) I1 [%] I2 [%] IEE1 [%] IEE2 [%] U1 [%] U0 [%] U03H [%] |P| [%] |Q| [%] |S| [%] f [%] U/f [%] PHI [%]...

- Page 52 Functions 2.4 Functional Scope Addr. Parameter Setting Options Default Setting Comments RTD-BOX INPUT Disabled Disabled External Temperature Input Port C Port D RTD CONNECTION 6 RTD simplex 6 RTD simplex Ext. Temperature Input Connec- 6 RTD HDX tion Type 12 RTD HDX ANALOGOUTP B1/2 Disabled Disabled...

-

Page 53: Power System Data 1

Functions 2.5 Power System Data 1 Power System Data 1 The device requires some plant and power system data to adapt its functions to the actual application. These include, for instance, rated power system and transformer data, measured quantity polarities and connection, breaker properties etc. - Page 54 Functions 2.5 Power System Data 1 Figure 2-9 Current transformer starpoints in transverse differential protection - Example Nominal Values of the Transformers on Side 1 At addresses 202 IN-PRI I-SIDE1 and 203 IN-SEC I-SIDE1 information is entered regarding the primary and secondary nominal currents of the CTs of side 1.

- Page 55 Functions 2.5 Power System Data 1 Connection At address 223 UE CONNECTION, the user specifies to the device which type of voltage is connected to the input. The device establishes from this information the type of processing involved. The U input is used for either the various stator earth fault protection functions or for rotor earth fault protection using the rated frequen- cy measurement method (see Section 2.34).

- Page 56 Functions 2.5 Power System Data 1 In this context, U is the primary voltage (generally phase-ground voltage) and U is the secondary VT, prim E, sec displacement voltage applied to the device. If a voltage divider is used, its division ratio also influences this factor.

- Page 57 Functions 2.5 Power System Data 1 For the overcurrent protection functions (Sections 2.8, 2.9, and 2.10) and for the breaker failure protection, sides 1 and 2 can be allocated freely. If the differential protection is set to 120 3 phase transf., the following normalizing factors apply for the primary side protection settings in DIGSI.

- Page 58 Functions 2.5 Power System Data 1 Phase Rotation Address 271 PHASE SEQ. is used to change the default phase sequence (L1 L2 L3 for clockwise rotation), if your power system permanently has an anti-clockwise phase sequence (L1 L3 L2). A temporary reversal of rotation is also possible using binary inputs (see Section 2.47).

- Page 59 Functions 2.5 Power System Data 1 Measuring Transducer 1 Measuring transducer 1 is provided for DC voltage/DC current protection or the rotor earth fault protection with ). Depending on the application, select at address 295 TRANSDUCER 1 one of the alternatives 1 to 3 Hz (U Control 10 V, 4-20 mA or 20 mA.

-

Page 60: Settings

Functions 2.5 Power System Data 1 2.5.2 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. Addr. -

Page 61: Information List

Functions 2.5 Power System Data 1 Addr. Parameter Setting Options Default Setting Comments SN TRANSFORMER 0.20 .. 5000.00 MVA 5.30 MVA Rated Apparent Power of the Transformer UN GEN/MOTOR 0.40 .. 800.00 kV 6.30 kV Rated Primary Voltage Generator/Motor SN GEN/MOTOR 0.20 .. -

Page 62: Change Group

Functions 2.6 Change Group Change Group Two independent groups of parameters can be set for the device functions. During operation, the user can switch between setting groups locally using the operator panel, binary inputs (if so configured), the operator and service interface from a personal computer or via the system interface. A setting group comprises the setting values for all functions that have been configured as Enabled (see Section 2.4). -

Page 63: Power System Data 2

Functions 2.7 Power System Data 2 Power System Data 2 The general protection data (P.System Data 2) include settings associated with all functions rather than a specific protection or monitoring function. Parameter settings P.System Data 2 can be switched using the setting group. -

Page 64: Information List

Functions 2.7 Power System Data 2 2.7.4 Information List Information Type of In- Comments formation Relay PICKUP Relay PICKUP Relay TRIP Relay GENERAL TRIP command IL1 S1: Primary fault current IL1 Side1 IL2 S1: Primary fault current IL2 Side1 IL3 S1: Primary fault current IL3 Side1 IL1 S2: Primary fault current IL1 Side2... -

Page 65: Definite-Time Overcurrent Protection (I>, Ansi 50/51) With Undervoltage Seal-In

Functions 2.8 Definite-Time Overcurrent Protection (I>, ANSI 50/51) with Undervoltage Seal-In Definite-Time Overcurrent Protection (I>, ANSI 50/51) with Undervoltage Seal-In The time-overcurrent protection is used as backup protection for the short-circuit protection of the protected object. It also provides backup protection for downstream network components if faults there are not discon- nected in time thus endangering the protected object. -

Page 66: Setting Notes

Functions 2.8 Definite-Time Overcurrent Protection (I>, ANSI 50/51) with Undervoltage Seal-In Figure 2-12 Logic Diagram of the Overcurrent Stage I> with Undervoltage Seal-In 2.8.2 Setting Notes General Overcurrent protection is only effective and available if address 112 O/C PROT. I> is set to Side 1 or Side 2 during configuration. - Page 67 Functions 2.8 Definite-Time Overcurrent Protection (I>, ANSI 50/51) with Undervoltage Seal-In Undervoltage Seal-In The 1205 U< undervoltage stage (positive-sequence voltage) is set to a value below the lowest phase-to-phase voltage admissible during operation, e.g. 80 V. The seal-in time 1206 T-SEAL-IN limits the pickup seal-in introduced by the overcurrent/undervoltage. It must be set to a value higher than the T I>...

-

Page 68: Settings

Functions 2.8 Definite-Time Overcurrent Protection (I>, ANSI 50/51) with Undervoltage Seal-In 2.8.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. -

Page 69: Definite-Time Overcurrent Protection (I>>, Ansi 50, 51, 67) With Direction Detection

Functions 2.9 Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection The time-overcurrent protection is used as backup protection for the short-circuit protection of the protected object. It also provides backup protection for downstream network components if faults there are not discon- nected in time thus endangering the protected object. - Page 70 Functions 2.9 Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection Figure 2-14 Cross-Polarized Voltages for Direction Determination The phase carrying the highest current is selected for the direction decision. With equal current levels, the phase with the smaller number is chosen (I before I before I ).

- Page 71 Functions 2.9 Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection Figure 2-15 Logic Diagram of I>> Stage with Direction Element SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 72: Setting Notes

Functions 2.9 Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection 2.9.2 Setting Notes General The high-current stage I>> of the overcurrent protection is only effective and accessible if it has been assigned within the framework of configuration at address 113 O/C PROT. I>> to either side 1 or side 2, i.e. if either set = NonDirec. - Page 73 Functions 2.9 Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection Current Trans-former on the Output Side (with direction detection) If at address 113 O/C PROT. I>> was configured as directional, the addresses 1304 Phase Direction and 1305 LINE ANGLE are accessible. The inclination of the direction straight line (see figure 2-16) represent- ing the separating line between the tripping and the blocking zone can be adapted to the network conditions by way of the LINE ANGLE parameter.

-

Page 74: Settings

Functions 2.9 Definite-Time Overcurrent Protection (I>>, ANSI 50, 51, 67) with Direction Detection Figure 2-17 I>> Stage as 'Differential Protection' 2.9.3 Settings The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. Addr. -

Page 75: Inverse-Time Overcurrent Protection (Ansi 51V)

Functions 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) The inverse-time overcurrent protection protects extra-low voltage and low-voltage machines against short cir- cuits. For larger machines it is used as back-up protection for the machine short-circuit protection (differential protection and/or impedance protection). - Page 76 Functions 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) Figure 2-18 Pick-up Value Voltage Dependency The Ip reference value is decreased proportional to the voltage decrease. Consequently, for a constant current I, the I/Ip ratio is increased and the trip time is reduced. Compared with the standard characteristics represent- ed in the „Technical Data“...

- Page 77 Functions 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) Figure 2-19 Logic Diagram of the Inverse Time Overcurrent Protection without Undervoltage Influencing Figure 2-20 Logic Diagram of the Voltage Controlled Inverse Time Overcurrent Protection The changeover to the lower current pickup value on decreasing voltage (loop release) is performed on a phase by phase basis in accordance with Table 2-4.

- Page 78 Functions 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) Figure 2-21 Logic Diagram of the Voltage Restraint Inverse Time Overcurrent Protection The reduction of the current pick-up threshold in case of a decreasing voltage (control voltage assignment) is performed phase by phase according to table 2-4. SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 79: Setting Notes

Functions 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) 2.10.2 Setting Notes General The inverse overcurrent time protection is only effective and available if this function was allocated to the input CTs of either side 1 or side 2 during configuration (see Section 2.4), i.e. if address 114 O/C PROT. Ip was set to IEC SIDE 1, ANSI SIDE 1, IEC SIDE 2 or ANSI SIDE 2. -

Page 80: Settings

Functions 2.10 Inverse-Time Overcurrent Protection (ANSI 51V) 2.10.3 Settings The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. Addr. Parameter Setting Options Default Setting Comments 1401 O/C Ip Inverse O/C Time Protec- tion Ip Block relay 1402... -

Page 81: Thermal Overload Protection (Ansi 49)

Functions 2.11 Thermal Overload Protection (ANSI 49) 2.11 Thermal Overload Protection (ANSI 49) The thermal overload protection prevents thermal overloading of the stator windings of the machine being pro- tected. 2.11.1 Functional Description Thermal Profile The device calculates the overtemperature in accordance with a single-body thermal model, based on the fol- lowing differential equation: with Actual operating temperature expressed in percent of the operating temperature correspond-... - Page 82 Functions 2.11 Thermal Overload Protection (ANSI 49) Coolant Temperature (Ambient Temperature) With 7UM62, the thermal model considers an external temperature value. Depending on the application, this temperature can be the coolant or ambient temperature or, in the case of gas turbines, the entry temperature of the cold gas.

- Page 83 Functions 2.11 Thermal Overload Protection (ANSI 49) Blocking The thermal memory may be reset via a binary input („>RM th.rep. O/L“). The current-induced excessive temperature value is reset to zero. The same is achieved by entering a blocking („>BLK ThOverload“); in that case the overload protection is blocked completely, including the current alarm stage.

- Page 84 Functions 2.11 Thermal Overload Protection (ANSI 49) Figure 2-22 Logic of the Overload Protection Function SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 85: Setting Notes

Functions 2.11 Thermal Overload Protection (ANSI 49) 2.11.2 Setting Notes General Overload protection is only effective and accessible if address 116 Therm.Overload is set to Enabled during configuration. If the function is not required, it is set to Disabled. Transformers and generators are especially prone to damage by extended overloads. These overloads cannot and should not be detected by short-circuit protection. - Page 86 Functions 2.11 Thermal Overload Protection (ANSI 49) Time Constant The overload protection tracks overtemperature progression, employing a thermal differential equation whose steady state solution is an exponential function. The TIME CONSTANT τ (address 1603) is used in the calcu- lation to determine the threshold of excess temperature and thus the tripping temperature. If the overload characteristic of the generator to be protected is pre-determined, the user must select the pro- tection trip characteristic so that it largely corresponds the overload characteristic, at least for small overloads.

- Page 87 Functions 2.11 Thermal Overload Protection (ANSI 49) Emergency Start The run-on time to be entered at address 1616 T EMERGENCY must be sufficient to ensure that after an emer- gency startup and dropout of binary input „>Emer.Start O/L“ the trip command is blocked until the thermal replica is again below the dropout threshold.

- Page 88 Functions 2.11 Thermal Overload Protection (ANSI 49) If the temperature input is used, the trip times change if the coolant temperature deviates from the internal ref- erence temperature of 40 °C. The following formula can be used to calculate the trip time: with TIME CONSTANT (address 1603) τ...

-

Page 89: Settings

Functions 2.11 Thermal Overload Protection (ANSI 49) 2.11.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. Addr. -

Page 90: Information List

Functions 2.11 Thermal Overload Protection (ANSI 49) 2.11.4 Information List Information Type of In- Comments formation 1503 >BLK ThOverload >BLOCK thermal overload protection 1506 >RM th.rep. O/L >Reset memory for thermal replica O/L 1507 >Emer.Start O/L >Emergency start O/L 1508 >Fail.Temp.inp >Failure temperature input 1511... -

Page 91: Unbalanced Load (Negative Sequence) Protection (Ansi 46)

Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) The unbalanced load protection detects asymmetrical loads of three-phase induction machines. Unbalanced loads create a counter-rotating field which acts on the rotor at double frequency. Eddy currents are induced on the rotor surface, leading to local overheating at the transition between the slot wedges and the winding bun- dles. - Page 92 Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) Cool Down A cool-down time with adjustable parmeters starts as soon as the constantly permissible unbalanced load I2> is undershot. The tripping drops out on dropout of the pickup. However, the counter content is reset to zero with the cooling time parameterized at address 1705 T COOL DOWN.

- Page 93 Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) Logic The following figure shows the logic diagram of the unbalanced load protection. The protection may be blocked via a binary input („>BLOCK I2“). Pickups and time stages are reset and the metered values in the thermal replica are cleared.

-

Page 94: Setting Notes

Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) 2.12.2 Setting Notes General Unbalanced load protection is only in effect and accessible if address 117 UNBALANCE LOAD is set to Enabled during configuration. If the function is not required, it is set to Disabled. The address 1701 UNBALANCE LOAD serves to switch the unbalanced load protection ON or OFF or to block only the trip command (Block relay). - Page 95 Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) Conversion to Secondary Values The factor K can be derived from the unbalanced load characteristic according to the figure below by reading the time corresponding to the FACTOR K at the point I = 1.

- Page 96 Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) Cool-down Time The parameter 1705 T COOL DOWN establishes the time required by the protection object to cool down under admissible unbalanced load I2> to the initial value. If the machine manufacturer does not provide this informa- tion, the setting value can be calculated by assuming an equal value for cool-down time and heatup time of the object to be protected.

-

Page 97: Settings

Functions 2.12 Unbalanced Load (Negative Sequence) Protection (ANSI 46) 2.12.3 Settings Addr. Parameter Setting Options Default Setting Comments 1701 UNBALANCE LOAD Unbalance Load Protection Block relay 1702 I2> 3.0 .. 30.0 % 10.6 % Continously Permissible Current 1703 T WARN 0.00 .. -

Page 98: Startup Overcurrent Protection (Ansi 51)

Functions 2.13 Startup Overcurrent Protection (ANSI 51) 2.13 Startup Overcurrent Protection (ANSI 51) Gas turbines can be started by means of a startup converter. A controlled converter feeds a current into the generator creating a rotating field of gradually increasing frequency. This causes the rotor to turn and thus drive the turbine. -

Page 99: Setting Notes

Functions 2.13 Startup Overcurrent Protection (ANSI 51) The startup overcurrent protection is a short-circuit protection function that operates below 10 Hz. Its operating range is designed for 2 Hz to approx. 10 Hz (change to operational condition 1). Beyond this range the above short-circuit protection functions are active. - Page 100 Functions 2.13 Startup Overcurrent Protection (ANSI 51) Figure 2-28 Short-circuit currents in the generator during startup (generator: 300 MVA, 15.75 kV, 50 Hz) Delay Since the generator circuit breaker is open during startup, there is no need to coordinate the delay time with the network.

-

Page 101: Settings

Functions 2.13 Startup Overcurrent Protection (ANSI 51) Figure 2-29 Operating range and possible pickup threshold of short-circuit protection functions 2.13.3 Settings The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. Addr. -

Page 102: Differential Protection And Its Protected Objects

Functions 2.14 Differential Protection and Its Protected Objects 2.14 Differential Protection and Its Protected Objects The numerical current differential protection of the 7UM62 is a high speed selective short-circuit protection for generators, motors and transformers. The individual application can be configured, which ensures optimum matching to the protected object. - Page 103 Functions 2.14 Differential Protection and Its Protected Objects Current Stabilization When an external fault causes heavy currents to flow through the protected zone, differences in the magnetic characteristics of the current transformers CT1 and CT2 under conditions of saturation may cause a significant current to flow through the element M, which can cause a tripping.

- Page 104 Functions 2.14 Differential Protection and Its Protected Objects Figure 2-32 Tripping Characteristic of the Differential Protection with Fault Characteristic Quantitative Matching of Measured values The rated CT currents are matched to the rated current of the protected object, regardless of what that object is.

- Page 105 Functions 2.14 Differential Protection and Its Protected Objects The currents II and I are compared by the differential protection with the operating characteristic according diff stab to the following figure. If these values result result in a point within the tripping area, a trip signal is issued. If the current conditions I appear near the fault characteristic (≥...

- Page 106 Functions 2.14 Differential Protection and Its Protected Objects Add-On Stabilization During Current Transformer Saturation During an external fault which produces a high through-flowing short-circuit current causing current transformer saturation, a considerable differential current can be simulated, especially when the degree of saturation is dif- ferent at the two measuring points.

- Page 107 Functions 2.14 Differential Protection and Its Protected Objects Figure 2-35 Add-on Stabilization During Current Transformer Saturation Identification of DC Components A further stabilization (restraint) comes into effect when differential secondary currents are simulated by differ- ent transient behaviour of the current transformer sets. This differential current is caused by different DC time constants in the secondary circuits during through-current conditions, i.e.

- Page 108 Functions 2.14 Differential Protection and Its Protected Objects Besides the second harmonic, another harmonic can be selected in the 7UM62 to cause stabilization. A choice can be made between the third and fifth harmonic for harmonic stabilization. Steady-state overexcitation is characterized by odd harmonics. The 3rd or 5th harmonic is suitable to detect overexcitation.

- Page 109 Functions 2.14 Differential Protection and Its Protected Objects Figure 2-37 Increase of pickup value for stage I on startup DIFF> Fault Detection, Dropout The differential protection does not normally use a "pickup", since the detection of a fault is identical with the tripping condition.

- Page 110 Functions 2.14 Differential Protection and Its Protected Objects For special cases, the trip command can be delayed. The following figure shows a simplified diagram of the tripping logic. A dropout is detected when, during 2 cycles, pick-up is no longer recognized in the differential value, i.e. the differential current has fallen below 70 % of the set value, and the other pickup conditions are no longer fulfilled either.

- Page 111 Functions 2.14 Differential Protection and Its Protected Objects Figure 2-39 Logic Diagram of the Tripping Logic in Differential Protection SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 112: Setting Notes

Functions 2.14 Differential Protection and Its Protected Objects 2.14.1.2 Setting Notes General Differential protection is only effective and available if the type of protected object for this function was set during protective function configuration (Section 2.4, address 120, DIFF. PROT. = Generator/Motor or 3 phase transf.). -

Page 113: Information List

Functions 2.14 Differential Protection and Its Protected Objects Addr. Parameter Setting Options Default Setting Comments 2042A BASE POINT 1 0.00 .. 2.00 I/InO 0.00 I/InO Base Point for Slope 1 of Charac. 2043A SLOPE 2 0.25 .. 0.95 0.50 Slope 2 of Tripping Characteristic 2044A BASE POINT 2 0.00 .. - Page 114 Functions 2.14 Differential Protection and Its Protected Objects Information Type of In- Comments formation 5663 Block Iflt.L2 Diff. prot.: Blocked by CT fault L2 5664 Block Iflt.L3 Diff. prot.: Blocked by CT fault L3 5666 Diff in.char.L1 Diff: Increase of char. phase L1 5667 Diff in.char.L2 Diff: Increase of char.

-

Page 115: Protected Object Generator Or Motor

Functions 2.14 Differential Protection and Its Protected Objects 2.14.2 Protected Object Generator or Motor The following section describes the special features of the generator and motor as the protection objects. 2.14.2.1 Functional Description Definition and Matching of Measured Quantities The differential protection function of the 7UM62 can be used as longitudinal or as transverse differential pro- tection. -

Page 116: Setting Notes

Functions 2.14 Differential Protection and Its Protected Objects The CTs also determine the limits of sensitivity in the case of motors. In asynchronous motors, the startup op- eration may be modelled in different ways by the CTs, so that major differential currents occur (see also side title "Increase of Pickup Value on Startup"). - Page 117 Functions 2.14 Differential Protection and Its Protected Objects The second branch produces a higher stabilization in the range of high currents which may lead to current transformer saturation. Its base point is set at address 2044 BASE POINT 2. The gradient is set at address 2043 SLOPE 2.

-

Page 118: Protected Object Transformer

Functions 2.14 Differential Protection and Its Protected Objects 2.14.3 Protected Object Transformer Transformers are subject to a number of influences that induce differential currents even during normal opera- tion: 2.14.3.1 Functional Description Mismatching of CTs Differences in the matching of CTs to the transformer rated current are not uncommon. These differences result in an error that leads to a differential current. - Page 119 Functions 2.14 Differential Protection and Its Protected Objects Quantitative matching of Measured values The input currents are converted in relation to the power transformer rated current. The nominal values of the transformer, i.e. rated apparent power, rated voltages and primary rated CT currents, are entered in the protec- tive device, and a correction factor k is calculated according to the following formula: with...

- Page 120 Functions 2.14 Differential Protection and Its Protected Objects Figure 2-43 Vector group matching for a Yd5 transformer (isolated starpoint) Deducting on side 2 the currents I – I , results in the current I , which has the same direction as I on side 1.

- Page 121 Functions 2.14 Differential Protection and Its Protected Objects Figure 2-44 Vector group matching for Y(N) d5 (with earthed starpoint) In the following figure on the left-hand side, a zero sequence current will occur in case of e.g. an external fault; on the right-hand side, it will not.

-

Page 122: Setting Notes

Functions 2.14 Differential Protection and Its Protected Objects 2.14.3.2 Setting Notes Requirement A precondition for the transformer differential protection function is that on configuration address 120 DIFF. PROT. was set to 3 phase transf.. To ensure the correct polarity for the formation of the differential current, the polarity of the sets of CTs must be specified. - Page 123 Functions 2.14 Differential Protection and Its Protected Objects Zero Sequence Current Treatment The treatment of the winding starpoints is of no concern if the zero sequence current is eliminated from the phase currents. By this means fault currents which flow through the CTs during earth faults in the network if there is an earthing point in the protected zone (transformer starpoint or starpoint earthing transformer) are neu- tralized without any special external measures.

- Page 124 Functions 2.14 Differential Protection and Its Protected Objects The harmonic restraint operates individually per phase. However, it is also possible – as it is for the inrush re- straint – to set the protection such that not only the phase with harmonics content in excess of the permissible value is stabilized but also the other phases of the differential stage IDIFF>...

- Page 125 Functions 2.14 Differential Protection and Its Protected Objects The second branch produces a higher restraint in the range of high currents which may lead to current trans- former saturation. Its base point is set at address 2044 BASE POINT 2 and is referred to the rated power transformer current.

-

Page 126: Current Transformer Requirements

Functions 2.14 Differential Protection and Its Protected Objects 2.14.4 Current Transformer Requirements The differential protection is of decisive importance for the requirements that the current transformers must meet. The high-speed trip stage (IDiff >>) uses instantaneous values and can therefore reliably trip high-current internal short-circuits. - Page 127 Functions 2.14 Differential Protection and Its Protected Objects Table 2-6 Transformer Requirements Transformer Generator Transient dimensioning factor K ≥ 4 > (4 to 5), with τ > 100 ms with τ ≤ 100 ms Symmetrical short circuit current I pSSC Example = 0.1 ’’...

-

Page 128: Earth Current Differential Protection (Ansi 87Gn,Tn)

Another application would be transformer windings in wye connection. For applications such as auto-transformers, starpoint earthing transformers and shunt reactors, Siemens rec- ommends that the 7UT612 protective device be used instead. - Page 129 Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) Measuring Principle The 2 possible implementations of the earth fault differential protection differ only in their method of determining the zero sequence current. This is shown in the following picture. This figure also shows the definition of the current direction.

- Page 130 Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) Figure 2-49 Example of an external fault When an external non-earthed fault causes heavy currents to flow through the protected zone, differences in the magnetic characteristics of the phase current transformers under conditions of saturation may cause a sig- nificant summation current which resembles an earth current flowing into the protected zone.

- Page 131 Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) Figure 2-50 Tripping and restraint characteristic In applications with direct measurement of the starpoint current (e.g. earth current differential protection for transformers), the starpoint current is queried in addition to evaluation of the characteristic. This provides ad- ditional restraint against CT problems such as wrong zero sequence current modeling of the phase current transformers on side 1.

- Page 132 Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) Figure 2-51 Operating ranges of the direction criterion • Phase current monitoring To exclude spurious tripping due to CT saturation in the presence of external faults, the protection function is blocked as soon as a maximum phase current is reached. For this purpose, the phase currents of side 1 are monitored.

-

Page 133: Setting Notes

Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) Figure 2-52 Logic Diagram of the Earth Current Differential Protection with 1) Use of generator: always side 1 LxSm Use of transformer: I according to allocation of sides LxSm 2.15.2 Setting Notes General A precondition for the operation of the earth current differential protection is that during the configuration of the scope of functions (Section 2.4) the correct selection for the application in hand was made at address 121 REF... - Page 134 Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) Note When using the I input, it must be kept in mind that this is a sensitive current input. The current amplitude is limited to approx. √2 1.6 A. A secondary rated current of 1 A is to be used for the starpoint CT. If a 5-A trans- former is used, the appropriate transformation ratio has to be set.

-

Page 135: Settings

Functions 2.15 Earth Current Differential Protection (ANSI 87GN,TN) 2.15.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 2101 REF PROT. Restricted Earth Fault Protection Block relay 2102 REF I>... -

Page 136: Underexcitation (Loss-Of-Field) Protection (Ansi 40)

Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) The underexcitation protection protects a synchronous machine from asynchronous operation in the event of faulty excitation or regulation and from local overheating of the rotor. Furthermore, it prevents that the network stability is endangered by underexcitation of large synchronous machines. - Page 137 Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) Figure 2-54 Stator circuit criterion: Pick–Up Characteristic in Admittance Diagram A further characteristic (1/xd CHAR.3 /α can be matched to the dynamic stability characteristic of the synchro- nous machine. Since stable operation is impossible if this characteristic is exceeded, immediate tripping is then required (time stage T CHAR 3).

- Page 138 Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) Undervoltage Blocking The admittance calculation requires a minimum measurement voltage. During a severe collapse (short-circuit) or failure of stator voltages, the protection is blocked by an integrated AC voltage monitor whose pickup thresh- old 3014 Umin is set on delivery to 25 V.

-

Page 139: Setting Notes

Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) 2.16.2 Setting Notes General The underexcitation protection is only effective and available if this function was set during protective function configuration (Section 2.4), address 130, UNDEREXCIT. is set to Enabled. If the function is not required Disabled is set. - Page 140 Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) Figure 2-57 Capability Curve of a Salient-Pole Generator, Indicated per Unit Example: = 6300 V 5270 kVA 50.0 Hz 1500 RPM cos ϕ = 0,800 2,470 1,400 The primary setting values can be read out directly from the diagram. The related values must be converted for the protection setting.

- Page 141 Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) Instead of 1/x the approximate value I can be used (with I = short-circuit current at no-load excita- d Mach tion). Setting example: Machine = 6.3 kV N Mach /√3 U = 5270 kVA/√3 · 6.3 kV = 483 A N Mach = 2.47 d Mach...

- Page 142 Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) Delay Times If the static limit curve consisting of the characteristics 1 and 2 is exceeded, the voltage regulator must first have the opportunity of increasing the excitation. For this reason, a warning message due to this criterion is "long- time"...

-

Page 143: Settings

Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) 2.16.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 3001 UNDEREXCIT. Underexcitation Protection Block relay 3002 1/xd CHAR. 1 0.20 .. -

Page 144: Information List

Functions 2.16 Underexcitation (Loss-of-Field) Protection (ANSI 40) 2.16.4 Information List Information Type of In- Comments formation 5323 >Exc. BLOCK >BLOCK underexcitation protection 5327 >Char. 3 BLK. >BLOCK underexc. prot. char. 3 5328 >Uexc fail. >Exc. voltage failure recognized 5329 >Char. 1 BLK. >BLOCK underexc. -

Page 145: Reverse Power Protection (Ansi 32R)

Functions 2.17 Reverse Power Protection (ANSI 32R) 2.17 Reverse Power Protection (ANSI 32R) Reverse power protection is used to protect a turbo-generator unit on failure of energy to the prime mover when the synchronous generator runs as a motor and drives the turbine taking motoring energy from the network. This condition leads to overheating of the turbine blades and must be interrupted within a short time by tripping the network circuit-breaker. -

Page 146: Setting Notes

Functions 2.17 Reverse Power Protection (ANSI 32R) Figure 2-59 Logic Diagram of the Reverse Power Protection 2.17.2 Setting Notes General Reverse power protection is only effective and available if this function was set during protective function con- figuration (Section 2.4), address 131, REVERSE POWER is set to Enabled. If the function is not required Disabled is set. - Page 147 Functions 2.17 Reverse Power Protection (ANSI 32R) The pickup value 3102 P> REVERSE is set in percent of the secondary apparent power rating S = √3 · U Nsek Nsec · I . If the primary motoring energy is known, it must be converted to secondary quantities using the following Nsec formula: with...

-

Page 148: Settings

Functions 2.17 Reverse Power Protection (ANSI 32R) 2.17.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 3101 REVERSE POWER Reverse Power Protection Block relay 3102 P>... -

Page 149: Forward Active Power Supervision (Ansi 32F)

Functions 2.18 Forward Active Power Supervision (ANSI 32F) 2.18 Forward Active Power Supervision (ANSI 32F) The machine protection 7UM62 includes an active power supervision which monitors whether the active power falls below one settable value as well as whether a separate second settable value is exceeded. Each of these functions can initiate different control functions. -

Page 150: Setting Notes

Functions 2.18 Forward Active Power Supervision (ANSI 32F) 2.18.2 Setting Notes General Forward active power protection is only effective and available if this function was set during protective function configuration (Section 2.4, address 132, FORWARD POWER is set to Enabled). If the function is not required Disabled is set. -

Page 151: Settings

Functions 2.18 Forward Active Power Supervision (ANSI 32F) 2.18.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 3201 FORWARD POWER Forward Power Supervision Block relay 3202 Pf<... -

Page 152: Impedance Protection (Ansi 21)

Functions 2.19 Impedance Protection (ANSI 21) 2.19 Impedance Protection (ANSI 21) Machine impedance protection is used as a selective time graded protection to provide the shortest possible tripping times for short-circuits in the synchronous machine, on the terminal leads as well as in the unit trans- former. - Page 153 Functions 2.19 Impedance Protection (ANSI 21) Loop Selection The corresponding phase-earth loop is used for a 1-pole pickup With a 2-pole pickup, the phase-phase loop with the corresponding phase-to-phase voltage is used for impedance calculation. With a 3-pole pickup, the phase-earth loop with the highest current value is used and with equal current amplitudes, the procedure described in the last row of the following table is applied.

- Page 154 Functions 2.19 Impedance Protection (ANSI 21) Figure 2-61 Logic Diagram of the Pickup Stage of the Impedance Protection Tripping Characteristic The tripping characteristic of the impedance protection is a polygon (see also Figure 2-62). It is symmetrical even though a fault in reverse direction (negative R and/or X values) is physically impossible provided the usual connection to the current transformers at the star-point side of the generator is used.

- Page 155 Functions 2.19 Impedance Protection (ANSI 21) Figure 2-62 Tripping Characteristics of the Impedance Protection Tripping Logic The T END time delay is started subsequent to the protection pickup, establishing the fault loop. The loop im- pedance components are compared with the limit values of the zones previously set. The tripping is executed if the impedance is within its zone during the course of the corresponding time stage.

- Page 156 Functions 2.19 Impedance Protection (ANSI 21) Figure 2-63 Logic Diagram of the Impedance Protection SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 157: Power Swing Blocking

Functions 2.19 Impedance Protection (ANSI 21) 2.19.2 Power Swing Blocking General Dynamic occurrences such as sudden load changes, short circuits, automatic reclosure or switching operations within the power system may cause power swings. Therefore impedance protection is complemented by a power swing blocking function to avoid spurious tripping. -

Page 158: Setting Notes

Functions 2.19 Impedance Protection (ANSI 21) Figure 2-64 Logic Diagram for the Power Swing Blocking of the Impedance Protection Z(Tent) First value inside the power swing polygon (at the moment of Tent) Z(Tent-Δt) Last value outside the power swing polygon P/SPOL Power swing polygon TPOL... - Page 159 Functions 2.19 Impedance Protection (ANSI 21) Impedance Stages The protection has the following characteristics which may be set independently: 1. Zone (fast tripping zone Z1 ) with parameters ZONE Z1 Reactance = reach, T-Z1 = 0 or short delay, if required. Overreach zone Z1B, externally controlled via binary input, with parameters ZONE Z1B Reactance = reach,...

- Page 160 Functions 2.19 Impedance Protection (ANSI 21) Example: Transformer data: = 7 % = 5.3 MVA = 6.3 kV Transformation ratios: Current transformer ratio = 500 A / 1 A This results for a 70 % reach for zone 1 in: The following secondary side setting value of zone 1 results at address 3306 ZONE Z1: Note: The following ratio would result from the connection of a 5 A device to a 5 A transformer: Likewise the following primary reactance results for a 100 % reach for zone 2:...

- Page 161 Functions 2.19 Impedance Protection (ANSI 21) Figure 2-65 Time Grading for Machine Impedance Protection – Example Z1B Overreach Zone The Z1B overreach zone (address 3308 ZONE Z1B) is an externally controlled stage. It does not influence the Z1 zone normal stage. Consequently there is no changeover, but the overreach zone is enabled or disabled depending on the position of the high-voltage side circuit breaker.

- Page 162 Functions 2.19 Impedance Protection (ANSI 21) The following relation allows estimation of the rate of change: Definitions: Reactance between the sources of the power swing Swing frequency Swing angle δ Figure 2-66 shows an example of how the rate of change evolves as a function of the power swing angle. For an angle of 180°...

-

Page 163: Settings

Functions 2.19 Impedance Protection (ANSI 21) If safety factor 4 is chosen, dZ/dt should never be set higher than 500 Ω/s (or 100 Ω/s for 5 A transformers). The default setting for dZ/dt is 300 Ω/s, which should be adequate for most applications. This is also the basis for the minimum distance P/SPOL - TPOL, assuming that for detection of a power swing there must be one impedance value between P/SPOL and TPOL. -

Page 164: Information List

Functions 2.19 Impedance Protection (ANSI 21) Addr. Parameter Setting Options Default Setting Comments 3307 T-Z1 0.00 .. 60.00 sec; ∞ 0.10 sec Impedance Zone Z1 Time Delay 3308 ZONE Z1B 0.01 .. 13.00 Ω 0.99 Ω Impedance Zone Z1B 0.05 .. 65.00 Ω 4.95 Ω... -

Page 165: Out-Of-Step Protection (Ansi 78)

Functions 2.20 Out-of-Step Protection (ANSI 78) 2.20 Out-of-Step Protection (ANSI 78) Depending on power network conditions and feeding generators, dynamic occurrences such as load jumps, short-circuits not disconnected quickly enough, auto-reclosure or switching actions, may cause system swings. Such power swings endanger power network stability. Stability problems often result from active power swings which can lead to pole-slipping and generator overloading. - Page 166 Functions 2.20 Out-of-Step Protection (ANSI 78) Thus, this results in: where δ is the phase shift angle between the generator voltage and the network equivalent voltage. Under normal conditions, this angle depends on the load situation and is largely constant. In the event of an out-of- step condition, however the angle fluctuates continually and can vary between 0°...

-

Page 167: Out-Of-Step Protection Logic

Functions 2.20 Out-of-Step Protection (ANSI 78) Figure 2-68 Impedance Trajectory at Measurement Location m 2.20.2 Out-of-Step Protection Logic The following figure shows the power swing polygon in greater detail. For transparency purposes the inclination angle ϕ is assumed to be 90°. The setting parameters of impedances Z and (Z –Z ) determine the... - Page 168 Functions 2.20 Out-of-Step Protection (ANSI 78) Figure 2-69 Polygonal Out-of-Step Characteristic with Typical Power Swings Detection of an out-of-step condition requires, additionally, that the impedance vector enters a power swing characteristic at one side, passes through the imaginary axis or characteristic dividing line, and exits the polygon at the opposite side (loss of synchronism, cases (1) and (2)).

-

Page 169: Setting Notes

Functions 2.20 Out-of-Step Protection (ANSI 78) Figure 2-70 Logic Diagram of the Out-of-Step Protection 2.20.3 Setting Notes General Out-of-step protection is only effective and available if this function was set during protective function configu- ration (Section 2.4, address 135, OUT-OF-STEP is set to Enabled. If the function is not required Disabled is set. - Page 170 Functions 2.20 Out-of-Step Protection (ANSI 78) Impedance Values The measured impedances perceived by the protection device are decisive for the settings. For the direction to the machine (as viewed from the location of the voltage transformers), the power swing reactance of the machine must be considered, which is approximately the transient reactance X ' of the machine.

- Page 171 Functions 2.20 Out-of-Step Protection (ANSI 78) Table 2-11 Transient Machine Reactances (Referred to Secondary Side) Generator Type = 100 V/ I = 1 A = 120 V/ I = 1 A = 100 V/ I = 5 A = 120 V/ I = 5 A Non-salient pole 0,13...0,35 7.5 Ω...20.2 Ω...

- Page 172 Functions 2.20 Out-of-Step Protection (ANSI 78) Figure 2-72 Power swing polygon and impedance vectors with angle δ Maximum power swing frequency The polygon width Z determines also the maximum detectable power swing frequency. Considering that even with rapid power swings, at least two impedance values must have been established within the power swing polygon (which in a limit case differ by the width of the polygon), the following approximative formula can be used for the maximum detectable power swing frequency f At a rated frequency of 50 Hz (i.e.

- Page 173 Functions 2.20 Out-of-Step Protection (ANSI 78) Transformation ratios: Current Transformer = 500 A/1 A Ratio This gives the secondary transient reactance of the generator: ≈ X ' thus determines the setting of address 3505 Zb. The secondary short circuit reactance of the unit transformer is derived by considering the transformation ratios: If characteristic 1 covers 85 % of the transformer reactance, this results in the setting of Z ≈...

-

Page 174: Settings

Functions 2.20 Out-of-Step Protection (ANSI 78) 2.20.4 Settings The table indicates region-specific presettings. Column C (configuration) indicates the corresponding second- ary nominal current of the current transformer. Addr. Parameter Setting Options Default Setting Comments 3501 OUT-OF-STEP Out-of-Step Protection Block relay 3502 I1>... -

Page 175: Undervoltage Protection (Ansi 27)

Functions 2.21 Undervoltage Protection (ANSI 27) 2.21 Undervoltage Protection (ANSI 27) The undervoltage protection function detects voltage dips on electrical machines and prevents inadmissible op- erating states and a possible loss of stability. Two-pole short circuits or ground faults cause a dip in asymmet- rical voltages. -

Page 176: Setting Notes

Functions 2.21 Undervoltage Protection (ANSI 27) Figure 2-73 Logic diagram of the undervoltage protection 2.21.2 Setting Notes General The undervoltage protection is only effective and available if this function was set during protective function configuration (Section 2.4, address 140, UNDERVOLTAGE is set to Enabled). If the function is not required Disabled is set. -

Page 177: Settings

Functions 2.21 Undervoltage Protection (ANSI 27) 2.21.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 4001 UNDERVOLTAGE Undervoltage Protection Block relay 4002 U< 10.0 .. 125.0 V 75.0 V U<... -

Page 178: Overvoltage Protection (Ansi 59)

Functions 2.22 Overvoltage Protection (ANSI 59) 2.22 Overvoltage Protection (ANSI 59) Overvoltage protection serves to protect the electrical machine and connected electrical plant components from the effects of inadmissible voltage increases. Overvoltages can be caused by incorrect manual operation of the excitation system, faulty operation of the automatic voltage regulator, (full) load shedding of a generator, separation of the generator from the system or during island operation. -

Page 179: Setting Notes

Functions 2.22 Overvoltage Protection (ANSI 59) 2.22.2 Setting Notes General Overvoltage protection is only effective and available if this function was set during protective function config- uration (Section 2.4, address 141, OVERVOLTAGE is set to Enabled. If the function is not required Disabled is set. -

Page 180: Settings

Functions 2.22 Overvoltage Protection (ANSI 59) 2.22.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 4101 OVERVOLTAGE Overvoltage Protection Block relay 4102 U> 30.0 .. 170.0 V 115.0 V U>... -

Page 181: Frequency Protection (Ansi 81)

Functions 2.23 Frequency Protection (ANSI 81) 2.23 Frequency Protection (ANSI 81) The frequency protection function detects abnormally high and low frequencies in the generator. If the frequen- cy lies outside the permissible range, appropriate switching actions are initiated, e.g. separating the generator from the system. -

Page 182: Setting Notes

Functions 2.23 Frequency Protection (ANSI 81) Figure 2-75 Logic diagram of the frequency protection 2.23.2 Setting Notes General Frequency protection is only in effect and accessible if address 142 FREQUENCY Prot. is set to Enabled during configuration of protective functions. If the function is not required Disabled is set. Address 4201 O/U FREQUENCY serves to switch the function ON or OFF or to block only the trip command (Block relay). -

Page 183: Settings

Functions 2.23 Frequency Protection (ANSI 81) Further application examples are covered under power stations. The frequency values to be set mainly depend, also in these cases, on power system/power station operator specifications. In this context, frequency decrease protection ensures the power station's own demand by disconnecting it from the power system on time. The turbo regulator regulates the machine set to the nominal speed. -

Page 184: Information List

Functions 2.23 Frequency Protection (ANSI 81) Addr. Parameter Setting Options Default Setting Comments 4209 f3 PICKUP 40.00 .. 66.00 Hz 59.50 Hz f3 Pickup 4210 T f3 0.00 .. 100.00 sec 20.00 sec T f3 Time Delay 4211 f4 PICKUP 40.00 .. -

Page 185: Overexcitation (Volt/Hertz) Protection (Ansi 24)

Functions 2.24 Overexcitation (Volt/Hertz) Protection (ANSI 24) 2.24 Overexcitation (Volt/Hertz) Protection (ANSI 24) Overexcitation protection is used to detect inadmissibly high induction in generators and transformers, espe- cially in power station unit transformers. The protection must intervene when the limit value for the protected object (e.g. - Page 186 Functions 2.24 Overexcitation (Volt/Hertz) Protection (ANSI 24) Figure 2-76 Tripping Range of the Overexcitation Protection The characteristic resulting from the device default settings is shown in the Technical Data Section Overexci- tation Protection. Figure 2-76 illustrates the behaviour of the protection on the assumption that within the frame- work of configuration the setting for the pickup threshold (parameter4302 U/f >) was chosen higher or lower than the first setting value of the thermal characteristic.

-

Page 187: Setting Notes

Functions 2.24 Overexcitation (Volt/Hertz) Protection (ANSI 24) Figure 2-77 Logic Diagram of the Overexcitation Protection 2.24.2 Setting Notes General Overexcitation protection is only effective and available if address 143 OVEREXC. PROT. is set to Enabled during configuration. If the function is not required, it is set to Disabled. Address 4301 OVEREXC. PROT. serves to switch the function ON or OFF or to block only the trip command (Block relay). - Page 188 Thermal tripping time characteristic (with default settings) The characteristic of a Siemens standard transformer was selected as a default setting for the parameters 4306 to 4313. If the protection object manufacturer did not provide any information, the preset standard char- acteristic should be used.

-

Page 189: Settings

Functions 2.24 Overexcitation (Volt/Hertz) Protection (ANSI 24) 2.24.3 Settings Addr. Parameter Setting Options Default Setting Comments 4301 OVEREXC. PROT. Overexcitation Protection (U/f) Block relay 4302 U/f > 1.00 .. 1.20 1.10 U/f > Pickup 4303 T U/f > 0.00 .. 60.00 sec; ∞ 10.00 sec T U/f >... -

Page 190: Inverse-Time Undervoltage Protection (Ansi 27)

Functions 2.25 Inverse-Time Undervoltage Protection (ANSI 27) 2.25 Inverse-Time Undervoltage Protection (ANSI 27) The inverse undervoltage protection mainly protects consumers (induction machines) from the consequences of dangerous voltage drops in island networks thus avoiding inadmissible operating conditions and possible loss of stability. It can also be used as a criterion for load shedding in interconnected networks. Two-pole short circuits or earth faults cause asymmetrical voltage collapse. -

Page 191: Setting Notes

Functions 2.25 Inverse-Time Undervoltage Protection (ANSI 27) Figure 2-79 Logic Diagram of the Inverse-Time Undervoltage Protection 2.25.2 Setting Notes General The inverse-time undervoltage protection is only effective and available if this function was set during protective function configuration (Section 2.4, address 144, INV.UNDERVOLT. is set to Enabled. If the function is not required Disabled is set. -

Page 192: Settings

Functions 2.25 Inverse-Time Undervoltage Protection (ANSI 27) 2.25.3 Settings Addr. Parameter Setting Options Default Setting Comments 4401 INV. UNDERVOLT. Inverse Undervoltage Protection Up< Block relay 4402 Up< PICKUP 10.0 .. 125.0 V 75.0 V Up< Pickup 4403 T MUL 0.10 .. 5.00 sec; 0 1.00 sec Time Multiplier for Characteristic 4404... -

Page 193: Rate-Of-Frequency-Change Protection Df/Dt (Ansi 81R)

Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) With the rate-of-frequency-change protection, frequency changes can be quickly detected. This allows a prompt response to frequency dips or frequency rises. A trip command can be issued even before the pickup threshold of the frequency protection (see Section 2.23) is reached. - Page 194 Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) Figure 2-80 Logic Diagram of the Rate-of-Frequency-Change Protection SIPROTEC, 7UM62, Manual C53000-G1176-C149-7, Release date 03.2010...

-

Page 195: Setting Notes

Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) 2.26.2 Setting Notes General The rate-of-frequency-change protection is only effective and accessible if during the configuration address 145 df/dt Protect. has been set accordingly. The user can select between 2 or 4 stages. The default setting is 2 df/dt stages. - Page 196 Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) Time Delays The delay time should be set to zero wherever the protection function is supposed to respond very quickly. This will be the case with high setting values. For the monitoring of small changes (< 1Hz/s), on the other hand, a small delay time can be useful to avoid overfunctioning.

-

Page 197: Settings

Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) 2.26.3 Settings Addresses which have an appended "A" can only be changed with DIGSI, under Additional Settings. Addr. Parameter Setting Options Default Setting Comments 4501 df/dt Protect. Rate-of-frequency-change pro- tection Block relay 4502 df1/dt >/<... -

Page 198: Information List

Functions 2.26 Rate-of-Frequency-Change Protection df/dt (ANSI 81R) 2.26.4 Information List Information Type of In- Comments formation 5503 >df/dt block >BLOCK Rate-of-frequency-change prot. 5504 >df1/dt block >BLOCK df1/dt stage 5505 >df2/dt block >BLOCK df2/dt stage 5506 >df3/dt block >BLOCK df3/dt stage 5507 >df4/dt block >BLOCK df4/dt stage... -

Page 199: Jump Of Voltage Vector

Functions 2.27 Jump of Voltage Vector 2.27 Jump of Voltage Vector Consumers with their own generating plant, for example, feed power directly into a network. The incoming feeder line is usually the technical and legal ownership boundary between the network operator and these con- sumers/producers. - Page 200 Functions 2.27 Jump of Voltage Vector Measuring Principle The vector of the positive sequence system voltage is calculated from the phase-to-earth voltages, and the phase angle change of the voltage vector is determined over a delta interval of 2 cycles. The presence of a phase angle jump indicates an abrupt change of current flow.

-

Page 201: Setting Notes

Functions 2.27 Jump of Voltage Vector Figure 2-83 Logic diagram of the vector jump detection 2.27.2 Setting Notes General The vector jump protection is only effective and available if address 146 VECTOR JUMP is set to Enabled during configuration. Address 4601 VECTOR JUMP serves to switch the function ON or OFF or to block only the trip command (Block relay). -

Page 202: Settings

Functions 2.27 Jump of Voltage Vector Time Delays The time delay T DELTA PHI (address 4603) should be left at zero, unless you wish to transmit the trip indi- cation with a delay to a logic (CFC), or to leave enough time for an external blocking to take effect. After expiry of the timer T RESET (address 4604), the protection function is automatically reset. -

Page 203: Stator Earth Fault Protection (Ansi 59N, 64G, 67G)

Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) The stator earth fault protection detects earth faults in the stator windings of three-phase machines. The machine can be operated in busbar connection (directly connected to the network) or in unit connection (via unit transformer). - Page 204 Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) Figure 2-84 Unit Connection with Neutral Transformer Loading resistance Voltage divider Displacement Voltage Generator earth capacitance Line earth capacitance Unit transformer earth capacitance Unit transformer coupling capacitance coup Figure 2-85 Unit Connection with Earthing Transformer Loading resistance Voltage divider...

- Page 205 Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) Earth Current Direction Detection For machines in busbar connection, it is not possible to differentiate between network earth faults and machine earth faults using the displacement voltage alone. In this case the earth fault current is used as a further crite- rion, and the displacement voltage as a necessary enabling condition.

- Page 206 Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) The protection then detects a machine earth fault if the following three criteria are fulfilled: • Displacement voltage larger than set value U0>, • Earth fault current across the measurement location larger than set value 3I0>, •...

- Page 207 Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) Earth Current Detection (Earth Differential Protection with Displacment Voltage as the Pickup Criterion) In the industrial sector, busbar systems are designed with high or low resistance, switchable starpoint resis- tances. For earth-fault detection, the starpoint current and the total current are detected via toroidal current transformers and transmitted to the protective device as current difference.

-

Page 208: Setting Notes

Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) Figure 2-89 Logic Diagram of 90 % Stator Earth Fault Protection 2.28.2 Setting Notes General 90 % stator earth fault protection is only effective and available if address 150 S/E/F PROT. is set to directional;... - Page 209 Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) Delay The stator earth fault trip is delayed by the time set under address 5005 T S/E/F. For the delay time, the overload capacity of the load equipment must be considered. All set times are additional delay times and do not include operating times (measurement time, reset time) of the protection function itself.

-

Page 210: Settings

Functions 2.28 90-%-Stator Earth Fault Protection (ANSI 59N, 64G, 67G) For a protected zone of 90 %, the protection should already operate at 1/10 of the full displacement voltage, whereby only 1/10 of the earth fault current is generated: In this example 3I0> is set to 11 mA. For the displacement voltage setting, 1/10 of the full displacement voltage is used (because of the 90% protected zone). -

Page 211: Sensitive Earth Fault Protection (Ansi 51Gn, 64R)

Functions 2.29 Sensitive Earth Fault Protection (ANSI 51GN, 64R) 2.29 Sensitive Earth Fault Protection (ANSI 51GN, 64R) The sensitive earth current protection detects earth faults in systems with isolated or high-impedance earthed starpoint. This stage operates with the magnitudes of the earth current. It is therefore useful in applications where the magnitude of the earth current is an indicator of the earth fault. - Page 212 Functions 2.29 Sensitive Earth Fault Protection (ANSI 51GN, 64R) Figure 2-90 Application example as rotor earth fault protection Note 3PP13 is only necessary if more than 0.2 A are flowing permanently; (rule: Uerr load > 150 V). In this case the internal resistors Rpre inside the 7XR61 must be shorted. Figure 2-91 Logic Diagram of the Sensitive Earth Fault Detection Parameters and indications are only visible if Rotor Earth Fault Protection R, fn...

-

Page 213: Setting Notes

Functions 2.29 Sensitive Earth Fault Protection (ANSI 51GN, 64R) 2.29.2 Setting Notes General The sensitive earth fault protection is only effective and available if address 151 O/C PROT. IEE> = with IEE1 or with IEE2 is assigned. If when configuring the 90 % stator earth fault protection (150 S/E/F PROT., see subsection 2.4) one of the options with current value is chosen, the sensitive current measuring inpu of the device 7UM62 is thus occupied. -

Page 214: Settings

Functions 2.29 Sensitive Earth Fault Protection (ANSI 51GN, 64R) 2.29.3 Settings Addr. Parameter Setting Options Default Setting Comments 5101 O/C PROT. IEE Sensitive Earth Current Protec- tion Block relay 5102 IEE> 2 .. 1000 mA 10 mA IEE> Pickup 5103 T IEE>... -

Page 215: Stator Earth Fault Protection With 3Rd Harmonics (Ansi 27/59Tn 3Rd Harm.)