Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Stratasys uPrint

- Page 1 Plus ® ® uPrint SE and uPrint SE Plus ® ® Service Manual Part No. 209010-0001, Rev D...

- Page 2 Dimension BST, Dimension SST, WaveWash, and Ecoworks are registered trademarks of Stratasys Inc. FDM Technology, Fused Deposition Modeling, ABSplus, Catalyst EX, and Smart Supports are trademarks of Stratasys, Inc. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products.

- Page 3 About This Guide This service guide is designed to help you easily find the information you need to successfully service Dimension BST and SST systems. This guide is arranged in chapters with tabs for easy reference. When viewing the electronic PDF version, you can easily hyperlink to specific headings or chapters using the following methods: •...

-

Page 4: Table Of Contents

Table of Contents Safety _______________________________________________________ 1-1 Hazard Classifications ________________________________________________________ 1-1 Product Safety Symbols_______________________________________________________ 1-1 Safety Devices _______________________________________________________________ 1-1 System Overview ____________________________________________ 2-1 What happens when...________________________________________________________ 2-2 Powering up _____________________________________________________________ 2-2 Powering Down __________________________________________________________ 2-3 Loading Material _________________________________________________________ 2-3 Building a Part____________________________________________________________ 2-3 Electronics Overview _________________________________________________________ 2-5 Single Board Computer ___________________________________________________ 2-6 Controller Board__________________________________________________________ 2-7... - Page 5 Software _____________________________________________________ 3-1 Software Architecture ________________________________________________________ 3-2 Operating System ________________________________________________________ 3-2 Display Driver_____________________________________________________________ 3-2 Comm Server ____________________________________________________________ 3-2 System Manager _________________________________________________________ 3-3 Move Compiler __________________________________________________________ 3-3 Feeder___________________________________________________________________ 3-3 Event/Command Monitor_________________________________________________ 3-3 DataStatEX __________________________________________________________________ 3-4 CatalystEX ___________________________________________________________________ 3-5 CatalystEX Overview _____________________________________________________ 3-5 Conventional Help File ____________________________________________________ 3-5 Dynamic Help ____________________________________________________________ 3-5 MaracaEX Help ______________________________________________________________ 3-6...

- Page 6 Maintenance Preparation ____________________________________________________ 4-3 Read these warnings before performing service on printer!______________ 4-3 Required Tools list ____________________________________________________________ 4-4 Distributer/Reseller supplied Tools __________________________________________ 4-4 Supplied by Stratasys _____________________________________________________ 4-4 Pre-Maintenance Procedures _________________________________________________ 4-4 Exterior Components _________________________________________________________ 4-5 Top Panel ________________________________________________________________ 4-5...

- Page 7 Y EOT (End of Travel) Sensor ______________________________________________ 4-92 X Motor _________________________________________________________________ 4-93 Y Motor ________________________________________________________________ 4-100 Y Motor Belt ____________________________________________________________ 4-103 Y Drive Rod ____________________________________________________________ 4-110 XY Table _______________________________________________________________ 4-117 Z Stage Components ______________________________________________________ 4-137 Z Home Sensor _________________________________________________________ 4-137 Z EOT (End of Travel) Sensor _____________________________________________ 4-138 Chamber Fans _________________________________________________________ 4-139 Chamber Heaters ______________________________________________________ 4-141...

- Page 8 Controller Initialization Failed Minor Errors (19.XX) _______________________ 6-24 Door Unlatch Failed (20.XX)___________________________________________ 6-24 Controller Communications Failed Sub Errors (22.XX) ___________________ 6-24 Universal Device Name Error (23.XX) __________________________________ 6-24 3.0 Non-Code Errors _____________________________________________________ 6-25 What happens during Power Up / Boot________________________________ 6-33 4.0 Connector Pinouts and Signals________________________________________ 6-40 Umbilical cable diagram _____________________________________________ 6-40 Umbilical cable pinouts ______________________________________________ 6-41...

- Page 9 Illustrated Parts List ___________________________________________ 8-1 Front Door Area Components _________________________________________________ 8-2 Electronics Bay Components _________________________________________________ 8-3 Head Area Components _____________________________________________________ 8-5 XY Table Area Components __________________________________________________ 8-8 Z Stage Area Components___________________________________________________ 8-10 Chamber Heater Area components __________________________________________ 8-11 Material Bay ________________________________________________________________ 8-12 Cables _____________________________________________________________________ 8-13 Checklists ___________________________________________________ 9-1 Hard Drive Installation Checklist_______________________________________________ 9-2...

-

Page 10: Safety

• Liquefier T/C alarm – activated for a bad or missing thermocouple • Power shut down signal from the PDB – activated if any thermal limit switches trip • Thermal snap switch located on the Head Board. • Main thermal fuse uPrint/uPrint SE Service Manual... -

Page 12: System Overview

LEDs__________________________________________________________ 2-11 Power Distribution Board (PDB) ____________________________________ 2-12 Chamber Temperature Control ________________________________ 2-13 Test Points and LED’s __________________________________________ 2-13 I/O Card _________________________________________________________ 2-16 Head Board ______________________________________________________ 2-17 Printer overview _____________________________________________________ 2-18 Finding more information ___________________________________________ 2-23 uPrint/uPrint SE Service Manual... -

Page 13: What Happens When

What happens when... Powering up Once the unit is ready to build, the display will show (no part in the queue) or Idle Ready to followed by the part name. Once a part is started the appropriate liquefier will begin to build heat. -

Page 14: Powering Down

From the printer, press the button to begin building the displayed part. Start Model Remote - You send a part to the printer from your CatalystEX ‘Start Model’: work station. The part automatically begins to build. uPrint/uPrint SE Service Manual... - Page 15 From the printer, press the button. Wait for Part Note: Make sure an empty modeling base is installed, then answer to the prompt Is Model Base Installed? is displayed in the upper window. Press to exit Wait for Part Cancel if you wish the remote start mode.

-

Page 16: Electronics Overview

Electronics Overview Figure 2-1: Electronics Overview detail Controller Board Support heater +120 +5 and +12 VDC power +24 VDC VDC Power supply power supply Supply AC Input 120-240 VAC 120-240 VAC uPrint/uPrint SE Service Manual... -

Page 17: Single Board Computer

Single Board Computer The single board computer (SBC) is the main processor in the system. See Figure 2-2. showing the board layout. The TCP/IP network interface connects directly to the RJ-45 connector on the SBC. The network interface supports both 10baseT and 100baseT operation. The hardware differentiates automatically. -

Page 18: Controller Board

Their position and rotation are precisely known at all times. Temperature Control The controller board reads the three thermocouple (T/C) inputs/signals - 2 for the head, 1 for the chamber. uPrint/uPrint SE Service Manual... -

Page 19: Liquefier Temperature Control

Liquefier Temperature Control The liquefier T/C connects to the controller board through the power distribution board. The T/C generates a variable low level current that depends on the temperature of the T/C. This analog signal from the T/C is amplified by the head distribution. It is then sent down the umbilical cable to the PDB, and then to the controller board. -

Page 20: Actuators, Switches & Optical Sensors

The input and output signals are passed through the PDB and then processed by the controller board. The non-motor actuators on a uPrint system are 24 volt solenoids. The 24 volt power is supplied by the PDB which in turn is controlled by the controller board. The following is a list of actuators: •... -

Page 21: Reset Button

Figure 2-4: Controller board connection detail Reset Button Located on the lower right side of the board, the reset button will do a hard reset of the controller board. Before continuing with normal operation after resetting the board, system power must be cycled before building. The reset button should only be used after using TeraTerm. -

Page 22: Sw6

During normal operation, D13 will blink approximately once every two seconds to indicate that the watchdog is monitoring the system and everything is operational. LED Label Description +3.3 VDC Supply +5 VDC Supply +12 VDC Supply D6-D12 Debug LEDs (software use only) Coldfire processor heartbeat uPrint/uPrint SE Service Manual 2-11... -

Page 23: Power Distribution Board (Pdb)

Power Distribution Board (PDB) Figure 2-5: PDB Detail AC Power In Power Switch/Thermostat Chamber Heaters Auxiliary 120VDC power supply Z BOT, Z EOT, Chamber Fans, Frame ID, Filament detect sensor (not used) Z motor I/O board connection I/O board connection 24VDC input Test points and LEDs (see detail in this section) 5/12VDC input... -

Page 24: Chamber Temperature Control

TP20 for support, and TP28 for the chamber NOTE: 10 mV = 1 degree C. Test Points and LED’s Test points and LED’s are very useful for troubleshooting the system. The test points and LED’s are listed below with a brief description. See Figure 2-6. Figure 2-7. uPrint/uPrint SE Service Manual 2-13... - Page 25 Figure 2-6: Test points and LEDs detail Component Test Pt Description TP29 Power fail signal from external UPS +5V REF TP24 Head T/C service reference Door Switch TP15 State of the door (open or closed) On/Off Switch TP14 State of power down switch Power Enable Enables power to circuitry (normally high) Model Toggle...

- Page 26 + 5 VDC + 5VDC is present +12 VDC + 12VDC is present +12 VDC SW + 12VDC Switching is present +24 VDC + 24VDC is present +24 VDC SW + 24VDC Switching is present uPrint/uPrint SE Service Manual 2-15...

-

Page 27: I/O Card

I/O Card Figure 2-8: I/O card detail J510 PDB Board connection J511 PDB Board connection J507 Chamber thermocouple J501 Y Motor J502 X Motor J503 Y BOT and Y EOT sensors J504 Head blower fan, power on/off switch, left and right chamber lights, LCD display, door solenoid, door switch. -

Page 28: Head Board

Umbilical Cable J102 Support Heater U303 X Home Sensor J305 Toggle Sensor Support 120VDC LED (120 VDC present if on) Model 120VDC LED (120 VDC present if on) U304 X EOT Sensor J202 Model Heater uPrint/uPrint SE Service Manual 2-17... -

Page 29: Printer Overview

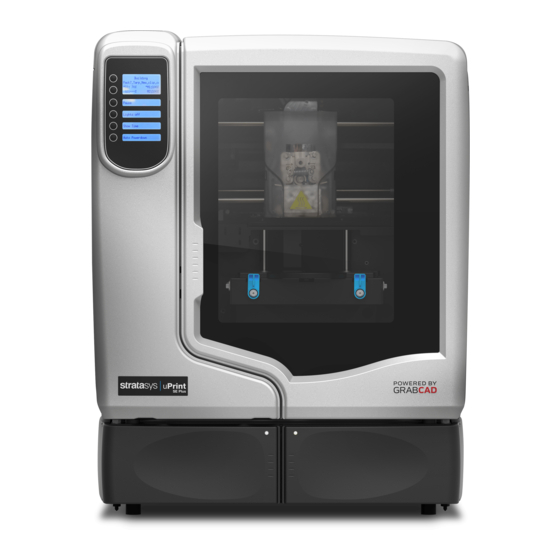

SE build a maximum part size of 203 x 152 x 152 mm (8 x 6 x 6 in). uPrint Plus and uPrint SE Plus build a maximum part size of 203 x 203 x 152 mm (8 x 8 x 6 in). Each uPrint and uPrint Plus material carrier contains 492 cc (30 cu. - Page 30 Figure 2-11: Interior chamber - front view Extrusion Head Tip wipe assembly Purge bucket Z stage platen Modeling base retainers (x2) Modeling base Z stage guide rods Z stage lead screw Extrusion Tips uPrint/uPrint SE Service Manual 2-19...

- Page 31 Figure 2-12: Rear view of printer Model Material Y Connector Support Material Tube Model Material Tube UPS Connection AC Power Cord Connector Material Bay Cable Connector Circuit Breaker RJ-45 Network Connector Material Bay Diagnostics Cable Connector Optional Model Material Tube Material Bay Communications Cable Optional Material Bay Optional Material Bay Communications Cable...

- Page 32 Figure 2-14: Modeling base Modeling base Caution: DO NOT reuse modeling bases. If a modeling base is reused, calibration errors, poor part quality, and loss of extrusion may occur. Additional modeling bases are available from your reseller. uPrint/uPrint SE Service Manual 2-21...

- Page 33 Figure 2-15: Startup Kit contents Gloves Power cord (Euro) Power cord (US) Crossover cable (orange) Network cable (blue) Tip replacement kit (A. Support tip B. Model tip C. 8 Tip shields D. 4 Tip wipe assemblies) 10x magnifier loupe Wire brush Cutters 1/8 inch T-Handle wrench (red) 7/64 inch T-Handle wrench (yellow)

-

Page 34: Finding More Information

CatalystEX Online Help Simple operating instructions for CatalystEX are available in CatalystEX Dynamic Help. You can also see CatalystEX Help from the menu bar - Help>Contents World Wide Web Additional information is available at: http://www.uprint3dprinting.com uPrint/uPrint SE Service Manual 2-23... - Page 35 2-24...

-

Page 36: Software

Gantry ____________________________________________________________ 3-9 Temperatures ____________________________________________________ 3-10 Outputs __________________________________________________________ 3-10 Table ____________________________________________________________ 3-10 Get Calibration___________________________________________________ 3-11 Send Calibration _________________________________________________ 3-11 Get Config _______________________________________________________ 3-11 Test Parts _________________________________________________________ 3-11 Reset Password___________________________________________________ 3-11 Connect _________________________________________________________ 3-12 Help _____________________________________________________________ 3-12 uPrint/uPrint SE Service Manual... -

Page 37: Software Architecture

Software Architecture Figure 3-16. shows the major software components that control the system. The software that runs on the Controller Board is EPROM based. The software that runs on the single board computer is stored on the HDD and loaded during power up. Like all PC compatible computers, the SBC runs a brief self-test on power up and then loads the operating system followed by the system’s application components. -

Page 38: System Manager

This software handles all non-motion control interactions between the SBC and the Controller Board. Events are printer status information being sent to the SBC. Commands come from the SBC telling the Controller Board to do something such as find home. uPrint/uPrint SE Service Manual... -

Page 39: Datastatex

DataStatEX DataStatEX is a “condensed” version of MaracaEX. It was developed to: • Aid in troubleshooting system problems by allowing the customer to view and report specific system information. • Allow the customer to adjust Z Tip to Tip (difference in tip heights) •... -

Page 40: Catalystex

CatalystEX Help in a separate window containing standard Help tools - TOC, Search, Index, and personally selected Favorites. Dynamic Help Dynamic Help is available from within the CatalystEX application window. The right side of the application window is dedicated to Dynamic Help. uPrint/uPrint SE Service Manual... -

Page 41: Maracaex Help

MaracaEX Help Overview MaracaEX is a program used for machine configuration and troubleshooting. It is intended for use by trained service personnel only. Caution: It is possible, using this program, to damage the controller software and make the machine non-functional. Using MaracaEX you can select a modeler to work with, modify machine-specific configuration parameters, download new calibration file data, download new test parts, and test the machine's operation. -

Page 42: Modeler Setup

The model liquefier temperature and its set point in C. Head PWM Not used. Support Temp The support liquefier temperature and its set point in C (SST only). Support PWM Not used. Chamber Temp The actual chamber temperature and its set point in C. uPrint/uPrint SE Service Manual... -

Page 43: Versions

Versions Product Version The current version number for the complete software release. Build Version The build number for current SBC software. Firmware Version The current version for the 186/Controller software. PLD Version The current version of the programmable logic devices on the 186 or Controller boards. Product serial number The serial number of the complete system. -

Page 44: Setting The Serial Number

P400R - is a standard release material. P400SR - is a standard soluble release material. Manufacturing Lot This is a lot code used by Stratasys to control the manufacturing process. Manufacturing Date This is the date that the cartridge was manufactured. -

Page 45: Part Calibration

Part Calibration Left Measured on left side of modeling base, front to back. Right Measured on right side of modeling base, front to back. Front Measured on front side of modeling base, left to right. Back Measured on back side of modeling base, left to right. Left Front Measured from front left corner to rear right corner. -

Page 46: Get Calibration

Reset Password This button resets the administrator password to null. This turns off password control of the queue. This is used for clearing a forgotten password. uPrint/uPrint SE Service Manual 3-11... -

Page 47: Connect

Connect If the system is not available over the network, when MaracaEX first loads, MaracaEX will only try to connect one time. This allows you to interact with MaracaEX when it is not connected to a machine. The Connect button allows you to request additional connection attempts. -

Page 48: Service Procedures

Service Procedures Maintenance Preparation ____________________________________________ 4-3 Required Tools list ____________________________________________________ 4-4 Distributer/Reseller supplied Tools ___________________________________ 4-4 Supplied by Stratasys ______________________________________________ 4-4 Pre-Maintenance Procedures _________________________________________ 4-4 Exterior Components _________________________________________________ 4-5 Top Panel _________________________________________________________ 4-5 Side Panels________________________________________________________ 4-7 Display Panel______________________________________________________ 4-9 Front Panel _______________________________________________________ 4-11... - Page 49 Toggle Sensor ____________________________________________________ 4-69 Toggle Bar _______________________________________________________ 4-71 Head Board______________________________________________________ 4-76 TC Amp board ___________________________________________________ 4-82 Umbilical Hose ___________________________________________________ 4-84 Material Tubes ___________________________________________________ 4-88 Umbilical Cable __________________________________________________ 4-89 XY Table Components _______________________________________________ 4-91 Y Home Sensor ___________________________________________________ 4-91 Y EOT (End of Travel) Sensor _______________________________________ 4-92 X Motor __________________________________________________________ 4-93 Y Motor _________________________________________________________ 4-100 Y Motor Belt _____________________________________________________ 4-103...

-

Page 50: Maintenance Preparation

Note: All references within this procedure to ‘Left’ or ‘Right’ are made assuming that the printer is being viewed from the ‘Front’ (the door and user interface panel side). uPrint/uPrint SE Service Manual... -

Page 51: Required Tools List

Nut driver set Dial indicator Serial data cable (for issuing TeraTerm commands) Supplied by Stratasys Belt tension gauge (for adjusting XY table drive belts) Y-Motor belt tensioning tool (for adjusting belt Y table motor belt) Head dial indicator bracket (for XY table and Z stage leveling) -

Page 52: Exterior Components

” nut driver or standard screwdriver, remove the 3 mounting screws. See Figure 4-17. Figure 4-17: Top panel mounting screw location Remove the 3 top panel mounting screws Lift up and slide the top panel towards the back of the printer to remove. See Figure 4-18. uPrint/uPrint SE Service Manual... - Page 53 Figure 4-18: Top panel removal Slide top panel toward the back of the printer and lift up to remove. Installing the top panel Slide the top panel towards the front and in to place, then push down. Using a ⁄ ”...

-

Page 54: Side Panels

Slide panel towards the back of the printer and pull outward to remove. See Figure 4-20. Figure 4-20: Removing the left side panel Slide top panel toward the back of the printer and pull outward to remove the left side panel. uPrint/uPrint SE Service Manual... - Page 55 Removing the right side panel Using a ⁄ ” nut driver or standard screwdriver, remove the 3 mounting screws. See Figure 4-21. Figure 4-21: Right side panel mounting screw locations Remove the 3 right side panel mounting screws. Slide towards the back of the printer and pull outward to remove. See Figure 4-22.

-

Page 56: Display Panel

Figure 4-23: Opening the display panel access hatch Reach behind the display panel and press the tab to release the display panel. See Figure 4-24. Figure 4-24: Removing the display Disconnect J1 connector. See Figure 4-25. uPrint/uPrint SE Service Manual... - Page 57 Figure 4-25: Disconnecting the J1 connector Remove the display panel. Installing the display panel Connect the J1 Connector. Gently push the display panel into place. Close the display panel access hatch. Close the chamber door. 4-10...

-

Page 58: Front Panel

Figure 4-26: Front panel mounting screw locations Remove the 2 mounting screws from behind the display panel Using a ⁄ ” nut driver or standard screwdriver, remove the 6 mounting screws from the front panel. See Figure 4-27. uPrint/uPrint SE Service Manual 4-11... - Page 59 Figure 4-27: Front panel mounting screw locations Remove the 6 mounting screws for the front panel Remove the front panel by pulling outward. Installing the front panel Align the front panel with the mounting holes. Using a ⁄ ” nut driver or standard screwdriver, reinstall the 6 mounting screws. Using a ⁄...

-

Page 60: Door Solenoid

Push the solenoid pin out and slide door solenoid into place on the mounting plate. Reconnect the DRSOL cable. Reinstall the front panel. See Installing the front panel on page 4-12. Reinstall the display panel. See Installing the display panel on page 4-10. uPrint/uPrint SE Service Manual 4-13... -

Page 61: Door Sensor

Door Sensor Required Tools • ⁄ ” nut driver or standard screwdriver. Removing the door sensor Remove the display panel. See Removing the display panel on page 4-9. Remove the front panel. See Removing the front panel on page 4-11. Disconnect the DRSW cable. See Figure 4-30. -

Page 62: Electronics Bay Components

Figure 4-32: Removing the filament tubes from the Y connectors Using a ⁄ ” nut driver or standard screwdriver, remove the 3 mounting screws on the top of the electronics bay cover. See Figure 4-33. uPrint/uPrint SE Service Manual 4-15... - Page 63 Figure 4-33: Electronics bay cover mounting screw locations Remove the 3 mounting screws Gently pull the electronics bay cover down. See Figure 4-34. Figure 4-34: Electronics bay with cover lowered Closing the electronics bay Gently push the electronics bay cover back in to the closed position. Using a ⁄...

-

Page 64: Upper Electronics Bay Cover

Figure 4-35: Upper electronics bay cover top mounting screw locations Loosen but do not remove the 2 mounting screws Using a ⁄ ” nut driver or standard screwdriver, remove the bottom left and right mounting screws. See Figure 4-36. uPrint/uPrint SE Service Manual 4-17... - Page 65 Figure 4-36: Upper electronics bay cover bottom mounting screw locations Remove the bottom left and right mounting screws Lift the cover up and off of the top mounting screws. Installing the upper electronics bay cover Slide the cover down on to the top left and right side mounting screws. Using a ⁄...

-

Page 66: Removing The Electronics Bay

Figure 4-37: I/O card cable locations I/O Card cable Chamber thermocouple locations wire location Remove the left and right side electronics bay mounting screws with a ⁄ ” nut driver or standard screwdriver. See Figure 4-38. uPrint/uPrint SE Service Manual 4-19... - Page 67 Figure 4-38: Electronics Bay mounting screw locations Remove the 4 left side Remove the 4 right mounting screws side mounting screws Slide the electronics bay out 3 inches (76mm) and disconnect the cables from the rear of the power distribution board. See Figure 4-39.

-

Page 68: Electronics Bay Cooling Fan

Touch the metal plate of the electronics bay cover to discharge any static electricity. Disconnect the P1 cable from the fan. See Figure 4-40. Figure 4-40: Electronics bay cooling fan connector location P1 Connector Using a ⁄ ” allen wrench, remove the 4 mounting screws. See Figure 4-41. uPrint/uPrint SE Service Manual 4-21... - Page 69 Figure 4-41: Electronics bay cooling fan mounting screw locations Remove the 4 mounting screws Remove the cooling fan. Installing the electronics bay cooling fan Align the cooling fan with the 4 mounting holes. Using a ⁄ ” allen wrench, reinstall the 4 mounting screws. Reconnect the P1 cable.

-

Page 70: Controller Board

Figure 4-42: Controller board ribbon cable locations Remove the 3 ribbon cables Using a standard screwdriver, loosen the 2 screws that hold the diagnostics DB-9 cable in place. Then gently pull the cable out of the connector. See Figure 4-43. uPrint/uPrint SE Service Manual 4-23... - Page 71 Figure 4-43: Remove the 2 screws that hold the Diagnostics DB-9 cable in place Remove the DB-9 connector Using a Phillips screwdriver, remove the 6 controller board mounting screws. See Figure 4-44. Figure 4-44: Controller board mounting screw locations Remove the (6) mounting screws Gently lift the controller board up from the single board computer (SBC) at the P104 connector.

- Page 72 Insert the printer firmware CD into the workstation CD drive. From the Printer Services tab, click on the Update Software button. Navigate CatalystEX to the Upgrade (.UPG) file on the printer firmware CD. The printer will load, reboot and verify the upgrade. uPrint/uPrint SE Service Manual 4-25...

-

Page 73: Single Board Computer (Sbc)

Single Board Computer (SBC) Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Hardware • 6-32 x ⁄ ” Phillips pan head screws (x4) Removing the single board computer Open the electronics bay. See Opening the electronics bay on page 4-15. Touch the metal plate of the electronics bay cover to discharge any static electricity. - Page 74 Remove the 4 mounting screws Lift the SBC and disconnect the IDE ribbon cable by pulling out of the socket. See Figure 4-49. Figure 4-49: SBC IDE ribbon cable location Disconnect the IDE ribbon cable uPrint/uPrint SE Service Manual 4-27...

- Page 75 Using a standard screwdriver, loosen the display cable mounting screws. See Figure 4- Disconnect the display cable from the SBC. See Figure 4-50. Figure 4-50: SBC display cable location Disconnect the Display cable Installing the single board computer Reconnect the display cable. Using a standard screwdriver, tighten the display cable mounting screws.

-

Page 76: Power Distribution I/O Card

Figure 4-51: I/O card cable locations Disconnect all 6 of the cables Disconnect the thermocouple from the back side of the I/O card by pulling outward. See Figure 4-52. Figure 4-52: Chamber thermocouple wire location Disconnect the chamber thermocouple uPrint/uPrint SE Service Manual 4-29... - Page 77 Using a Phillips screwdriver, remove the 3 mounting screws from the I/O card. See Figure 4-53. Figure 4-53: I/O card mounting screw locations Remove the 3 mounting screws Gently pull the I/O card out from the power distribution board sockets. Installing the I/O card Gently slide the I/O card in to the power distribution board sockets.

-

Page 78: Power Distribution Board (Pdb)

3 inches (76mm). See Figure 4-55. Figure 4-55: Electronics bay mounting screw locations Remove the 4 left Remove the 4 right side mounting screws side mounting screws uPrint/uPrint SE Service Manual 4-31... - Page 79 Disconnect the 4 cables from the back side of the power distribution board. See Figure 4- Figure 4-56: Power distribution board rear cable locations Disconnect the 4 cables on the back of the Slide the Electronics Bay back into place. Disconnect the 10 cables from the front of the PDB.

- Page 80 Installing the I/O card on page 4-30. Close the electronics bay. See Closing the electronics bay on page 4-16. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-33...

-

Page 81: Hard Drive

Hard Drive Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Hardware • 6-32 x ⁄ ” Phillips pan head screws (x8) Removing the SATA Hard Drive Open the electronics bay. See Opening the electronics bay on page 4-15. Touch the metal plate of the electronics bay cover to discharge any static electricity. - Page 82 Slide the hard drive up and out of the electronics bay. Using a Phillips screwdriver, remove the mounting brackets from the hard drive. See Figure 4-62. Figure 4-62: Hard drive mounting bracket screw locations Remove mounting brackets uPrint/uPrint SE Service Manual 4-35...

- Page 83 Installing the SATA hard drive Using a Phillips screwdriver, reinstall the 2 mounting brackets. Push the hard drive in the slots and down into position. Using a Phillips screwdriver, reinstall the 4 mounting screws. Reconnect the SATA cable. Reconnect the power input cable. Close the electronics bay.

- Page 84 Disconnect the SATA cable by pressing the metal tab in and pulling down. See Figure 4- Figure 4-64: IDE cable location Disconnect the IDE ribbon cable Using a Phillips screwdriver, remove the 4 mounting screws. See Figure 4-61. uPrint/uPrint SE Service Manual 4-37...

- Page 85 Figure 4-65: Hard drive mounting screw locations Remove the mounting Remove the mounting screws screws Slide the hard drive up and out of the electronics bay. Using a Phillips screwdriver, remove the mounting brackets from the hard drive. See Figure 4-62. Figure 4-66: Hard drive mounting bracket screw locations Remove mounting brackets...

- Page 86 Cycle power on the printer. Replace the CD into the electronics bay. Perform Offset calibrations, see Offset Calibrations on page 5-2. Perform Part Based calibration, see Part Based Calibration on page 5-7. uPrint/uPrint SE Service Manual 4-39...

-

Page 87: Line Filter

Line Filter Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Hardware • 6-32 x ⁄ ” Phillips pan head screws (x3) Removing the line filter Open the electronics bay. See Opening the electronics bay on page 4-15. Touch the metal plate of the electronics bay cover to discharge any static electricity. - Page 88 Reconnect the L2-1 and N2-1 spade connectors to the left side of the board. Reconnect the LF2-P and LF2-N spade connectors to the right side of the board. Close the electronics bay. See Closing the electronics bay on page 4-16. uPrint/uPrint SE Service Manual 4-41...

-

Page 89: Circuit Breaker

Circuit Breaker Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Removing the circuit breaker Open the electronics bay. See Opening the electronics bay on page 4-15. Touch the metal plate of the electronics bay cover to discharge any static electricity. Remove the Load and CB1 spade connectors from the circuit breaker by pulling up on the connectors. - Page 90 Push the circuit breaker through the electronics bay panel until it locks in place. Reconnect the CB1 and CB2 spade connectors to the circuit breaker. Reconnect the Load and CB1 spade connectors to the circuit breaker. Close the electronics bay. See Closing the electronics bay on page 4-16. uPrint/uPrint SE Service Manual 4-43...

-

Page 91: Ac Input

AC Input Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Hardware • ⁄ ” x 6mm Phillips pan head screws (x2) Removing the AC Input Open the electronics bay. See Opening the electronics bay on page 4-15. Touch the metal plate of the electronics bay cover to discharge any static electricity. - Page 92 Install the 2 AC Input mounting screws with a Phillips screwdriver. 2. Connect the LF-P (black) spade connector. 3. Connect the LF-N (white) spade connector. 4. Connect the LF-G (green) spade connector. 5. Close the electronics bay. See Closing the electronics bay on page 4-16. uPrint/uPrint SE Service Manual 4-45...

-

Page 93: Power Switch

Power Switch Required Tools • ⁄ ” nut driver or standard screwdriver. Hardware • 10-32 x ⁄ ” slotted screws (x2) Removing the Power Switch Remove the top panel. See Removing the top panel on page 4-5. Remove the left side panel. See Side Panels on page 4-7. - Page 94 ⁄ ” nut driver or standard screwdriver, reinstall the 2 mounting screws. Reinstall the left side panel. See Installing the side panels on page 4-8. Install the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-47...

-

Page 95: 24Vdc Power Supply

24VDC Power Supply Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Hardware • 10-32 x ⁄ ” slotted screws (x3) • 6-32 x ⁄ ” Phillips pan head screws (x2) Removing the 24VDC Power Supply Remove the top panel. - Page 96 Figure 4-81: Closing the rear panel of the electronics bay Remove the 2 mounting screws Open the rear panel of the electronics bay and remove the 2 board mounting screws from the top of the panel using a Phillips screwdriver. See Figure 4-82. uPrint/uPrint SE Service Manual 4-49...

- Page 97 Figure 4-82: Removing the 2 mounting screws from the top of the panel Remove the 2 mounting screws Remove the 24VDC power supply. Installing the 24VDC power supply Align the 24VDC power supply with the top of the rear panel of the electronics bay and the tab to the right of the mounting location.

-

Page 98: 5/12Vdc Power Supply

Open the rear panel of the electronics bay. Touch the metal plate of the electronics bay cover to discharge any static electricity. Disconnect the J2 spade connector by lifting up on the connector. See Figure 4-85. uPrint/uPrint SE Service Manual 4-51... - Page 99 Figure 4-85: J2 spade connector location Disconnect the SK2 connector by pressing the tab and lifting up on the connector. See Figure 4-86. Figure 4-86: SK2 connector location Disconnect the power input cable by pressing the tab and lifting up on the connector. See Figure 4-87.

- Page 100 Reinstall the electronics bay. See Installing the electronics bay on page 4-20. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-53...

-

Page 101: 120Vdc Power Supply

120VDC Power Supply Required Tools • ⁄ ” nut driver or standard screwdriver. • Phillips screwdriver Hardware • 10-32 x ⁄ ” slotted screws (x3) • 6-32 x ⁄ ” Phillips pan head screws (x3) Removing the 120VDC power supply Remove the top panel. - Page 102 Reinstall the electronics bay. See Installing the electronics bay on page 4-20. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-55...

-

Page 103: Head Components

Head Components Head Cooling Fan Required Tools • ⁄ ” nut driver or standard screwdriver. • ⁄ ” allen wrench. Hardware • 6-32 x 1 ⁄ ” flat head cap screws (x2) Removing the head cooling fan Remove the top panel. See Removing the top panel on page 4-5. - Page 104 Install the upper electronics bay cover. See Installing the upper electronics bay cover on page 4-18. Install the side panels. See Installing the side panels on page 4-8. Install the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-57...

-

Page 105: Toggle Head Assembly

Toggle Head Assembly Required Tools • ⁄ ” nut driver or standard screwdriver. • Cutters Hardware • Wire tie (x1) • 10-32 x ⁄ ” slotted screws (x7) • 10-32 x ⁄ ” slotted screws (x4) Removing the toggle head assembly Remove the top panel. - Page 106 Press in tab Press in tab to release air to release air plenum plenum Disconnect the material tubes by pressing down on the retaining ring and lifting up the material tubes. See Figure 4-97. uPrint/uPrint SE Service Manual 4-59...

- Page 107 Figure 4-97: Material tubes and retaining rings Press down Lift the on the material retaining tubes out of rings the rings Disconnect the thermocouples from the TC Amp board and remove the wires from the wire retainer. See Figure 4-98 Figure 4-99.

- Page 108 Disconnect the toggle sensor cable from the head board. See Figure 4-102. Figure 4-102: Toggle sensor cable location Disconnect the toggle sensor cable from the head board Cut the wire tie holding the drive motor cables in place. See Figure 4-103. uPrint/uPrint SE Service Manual 4-61...

- Page 109 Figure 4-103: Wire tie location Cut and remove the wire tie from the head motor Disconnect the 3 cables from the rear of the head board by pressing the tabs in and pulling outward. See Figure 4-104. Figure 4-104: Rear head board cable locations Disconnect the 3 cables Using a...

- Page 110 Z Tip to Tip field in the Tip Offset window. Click on the green check mark button. Cycle power to the printer. From the display panel press Maintenance > Machine > Tips Perform Z calibration. Perform XY Offset calibration. uPrint/uPrint SE Service Manual 4-63...

-

Page 111: Substrate Sensor

Substrate Sensor Required Tools • ⁄ ” nut driver or standard screwdriver. • ⁄ ” allen wrench. Hardware • Wire tie (x1) • 10-32 x ⁄ ” slotted screws (x7) • 4-40 x ⁄ ” slotted screws and # 4 split lock washer (x4) Removing the substrate sensor Remove the top panel. - Page 112 Using a ⁄ ” allen wrench, remove the 4 substrate sensor mounting screws. See Figure 4- 110. Figure 4-110: Substrate sensor mounting screw locations Remove the 4 mounting screws Remove the substrate sensor. uPrint/uPrint SE Service Manual 4-65...

- Page 113 Installing the substrate sensor Align the substrate sensor with the mounting holes. Using a ⁄ ” allen wrench, reinstall the 4 substrate sensor mounting screws. Reconnect the substrate sensor wire to the head board. Reinstall the wire tie around the head motor and wires. See Figure 4-111.

-

Page 114: Z Foam Level Assembly

Push the Z foam level assembly actuator up into the assembly and slide the Z foam level bar to the right until it is clear of the assembly. See Figure 4-112. Figure 4-112: Removing the Z foam level bar uPrint/uPrint SE Service Manual 4-67... - Page 115 Using a ⁄ ” allen wrench, remove the 4 Z foam level assembly mounting screws and washers. See Figure 4-113. Note: Be careful not to lose the washers. Figure 4-113: Z foam level assembly mounting screw locations 4 mounting screws Remove the Z foam level assembly and discard.

-

Page 116: Toggle Sensor

Figure 4-114: Right side access panel mounting screw locations Remove the 7 mounting screws. Gently disconnect the toggle sensor wire by pulling outwards. See Figure 4-115. Figure 4-115: Toggle sensor wire connector location Gently disconnect the toggle sensor cable uPrint/uPrint SE Service Manual 4-69... - Page 117 Using a standard screwdriver, remove the 2 toggle sensor mounting screws. See Figure 4-116. Figure 4-116: Toggle sensor mounting screw locations Remove the 2 mounting screws Remove the toggle sensor. Installing the toggle sensor Align the toggle sensor with the mounting holes. Using a standard screwdriver, reinstall the 2 mounting screws.

-

Page 118: Toggle Bar

• .141” ID, .625” OD x .031” Washer • 8mm ID, 18mm OD x 1mm Washer • .195” ID, .50” OD x .059” PEEK HPV Washer (x2) Removing the toggle bar Unload model and support material. Power the printer down. uPrint/uPrint SE Service Manual 4-71... - Page 119 Open chamber door and remove the head cover. See Figure 4-117. Figure 4-117: Head cover tab locations Press tab in to Press tab in to release head release head cover cover Using a ⁄ ” allen wrench, loosen but do not remove the 4 tip mounting screws. See Figure 4-118.

- Page 120 ” allen wrench, remove the upper spring screw. Remove the screw, washer and spring. See Figure 4-121. Figure 4-121: Upper spring location Upper spring screw Using a ⁄ ” allen wrench, remove the lower spring screw. Remove the screw, spring and washer. See Figure 4-122. uPrint/uPrint SE Service Manual 4-73...

- Page 121 Figure 4-122: Lower spring location Lower spring screw Pull the toggle assembly away from the translator until the toggle assembly is at the end of the post. See Figure 4-123. Figure 4-123: Toggle assembly positioning Remove the washer from the toggle bar. Remove the toggle bar by sliding out.

- Page 122 Reinstall the model tip (right side) and support tip (left side) by pushing up into place. Using a ⁄ ” allen wrench tighten the tip mounting screws. Reinstall the head cover. Power the printer up. Perform calibrations. See Offset Calibrations on page 5-2. uPrint/uPrint SE Service Manual 4-75...

-

Page 123: Head Board

Head Board Required tools • ⁄ ” nut driver or standard screwdriver • ⁄ ” nut driver Hardware • 10-32 x ⁄ ” slotted screws (x7) • 6-32 x ⁄ ” slotted screws (x6) Removing the head board Remove the top panel. See Removing the top panel on page 4-5. - Page 124 Figure 4-129: Material tube and retaining ring locations Press down on Lift the the retaining material rings tubes out of the rings Remove the thermocouple wires from the wire retaining clip on the head board. See Figure 4-130. uPrint/uPrint SE Service Manual 4-77...

- Page 125 Figure 4-130: Retaining clip location Remove the thermocouple wires from the retaining clip Disconnect the umbilical cable by pressing in on the tab and pulling upwards. See Figure 4-131. Figure 4-131: Umbilical cable location Disconnect the umbilical cable Disconnect the model and support heater cables by pressing in on the tabs and pulling outward.

- Page 126 ” nut driver or standard screwdriver, remove the toggle sensor cable retaining clips. See Figure 4-135. Figure 4-135: Toggle sensor cable retaining clip locations Remove the 2 toggle sensor cable retaining clips Feed the toggle sensor cable out through the head board. See Figure 4-136. uPrint/uPrint SE Service Manual 4-79...

- Page 127 Figure 4-136: Removing the toggle sensor cable from the head board Feed toggle sensor cable through the head board Disconnect the substrate sensor cable and filament motor cables from the rear of the head board by pressing the tabs in and pulling outward. See Figure 4-137.

- Page 128 Reinstall the air plenum. Reinstall the head cover. Reinstall the right side access cover. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-81...

-

Page 129: Tc Amp Board

TC Amp board Required Tools • ⁄ ” nut driver or standard screwdriver • ⁄ ” nut driver Hardware • 10-32 x ⁄ ” slotted screws (x7) • 6-32 x ⁄ ” slotted screws (x3) Removing the TC Amp board Remove the top panel. - Page 130 Reconnect the model and support thermocouple wires. Reconnect the umbilical cable. Reinstall the right side access panel. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-83...

-

Page 131: Umbilical Hose

Umbilical Hose Required Tools • ⁄ ” nut driver or standard screwdriver • ⁄ ” nut driver • ⁄ ” allen wrench • Cutters Hardware • Wire tie • 10-32 x ⁄ ” slotted screws (x7) • ⁄ - 20 x ⁄... - Page 132 Press in tab to Press in tab to release air plenum release air plenum Press in tab to Press in tab to release air plenum release air plenum Disconnect the model and support material tubes. See Figure 4-147. uPrint/uPrint SE Service Manual 4-85...

- Page 133 Figure 4-147: Material tube and retaining ring locations Press down on Lift the material the retaining tubes out of the rings rings Cut the wire tie from around the umbilical hose. See Figure 4-148. Figure 4-148: Umbilical hose wire tie location Cut and remove the wire tie Remove the energy chain mounting screws from the translator with a...

- Page 134 Reinstall the upper electronics bay cover. See Installing the upper electronics bay cover on page 4-18. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-87...

-

Page 135: Material Tubes

Material Tubes Required Tools • ⁄ ” nut driver or standard screwdriver • ⁄ ” nut driver • ⁄ ” allen wrench • Cutters Removing the material tubes Remove the top panel. See Removing the top panel on page 4-5. Remove the side panels. See Side Panels on page 4-7. -

Page 136: Umbilical Cable

I/O card Disconnect the umbilical cable from the head board by pressing in on the tab and pulling upward. See Figure 4-152. Figure 4-152: Head board connector location Disconnect the umbilical cable uPrint/uPrint SE Service Manual 4-89... - Page 137 Disconnect the umbilical cable from the TC Amp board by pressing in on the tab and pulling outward. See Figure 4-153. Figure 4-153: TC Amp connector location Disconnect the umbilical cable Feed the umbilical cable out through the energy chain. Installing the umbilical cable Feed the umbilical cable through the energy chain.

-

Page 138: Xy Table Components

Align the Y Home Sensor with the mounting hole. 2. Using a ⁄ ” nut driver or standard screwdriver, reinstall the mounting screw. 3. Reconnect the Y Home cable. 4. Install the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-91... -

Page 139: Y Eot (End Of Travel) Sensor

Y EOT (End of Travel) Sensor Required Tools • ⁄ ” nut driver or standard screwdriver. Hardware • 6-32 x ⁄ ” slotted screw (x1) Removing the Y EOT sensor Remove the top panel. See Removing the top panel on page 4-5. Disconnect the Y EOT cable by pressing in on the tab and pulling outward. -

Page 140: Motor

Remove the side panels. See Side Panels on page 4-7. Using a ⁄ ” nut driver or standard screwdriver, remove the 7 left side access panel mounting screws and remove the left side access panel. See Figure 4-158. uPrint/uPrint SE Service Manual 4-93... - Page 141 Figure 4-158: Left side access panel mounting screw locations Remove the 7 mounting screws. Using a ⁄ ” nut driver or standard screwdriver, remove the 7 right side access panel mounting screws and remove the right side access panel. See Figure 4-159.

- Page 142 Figure 4-162. Figure 4-162: X motor cable connector location Disconnect X motor cable Using a ⁄ ” nut driver or standard screwdriver, remove the 2 X energy chain mounting bracket mounting screws. See Figure 4-163. uPrint/uPrint SE Service Manual 4-95...

- Page 143 Figure 4-163: X motor energy chain mounting bracket mounting screw locations Remove the 2 mounting screws Using a ⁄ ” nut driver or standard screwdriver, remove the 4 mounting screws from the X motor mounting bracket. See Figure 4-164. Figure 4-164: X motor mounting bracket mounting screw locations Remove the 4 mounting screws Using a...

- Page 144 ‘zero’ reading: The large hand should be on 0 and the small hand on 5. Tighten the adjustment screw (do not over tighten the screw) and recheck the reading. Remove the zero block gauge block from the fixture. uPrint/uPrint SE Service Manual 4-97...

- Page 145 Figure 4-167: Tension gauge zero setting Adjustment screw Zero gauge block Position the dial indicator on the rear section of the X-Drive belt - centered between the Head Assembly and the left side of the build envelope. See Figure 4-168. Figure 4-168: X belt tension location Check the tension: The large hand on the gauge should read between 25 and 35 mils, and the small hand...

- Page 146 Figure 4-170: X-Drive Belt Tension Adjustment X belt tension bolt Remove the belt fixture and run the head back and forth several times. Continue to adjust and check the tension until the tension meets specification. uPrint/uPrint SE Service Manual 4-99...

-

Page 147: Y Motor

Y Motor Required Tools • ⁄ ” nut driver or standard screwdriver. • ⁄ ” allen wrench. Hardware • 10-32 x ⁄ ” slotted screws (x11) • 8-32 x ⁄ ” socket head cap screws (x4) Removing the Y motor Remove the top panel. - Page 148 See Figure 4-173. Figure 4-173: Y motor mounting bracket mounting screw locations Remove the 4 mounting screws Using a ⁄ ” allen wrench, remove the 4 Y motor mounting screws. See Figure 4-174. uPrint/uPrint SE Service Manual 4-101...

- Page 149 Figure 4-174: Y motor mounting screw locations Remove the 4 mounting screws Remove the Y motor. Installing the Y motor Align the Y motor with the Y motor mounting bracket, making sure the Y motor cable faces the back of the printer. Using a ⁄...

-

Page 150: Y Motor Belt

Remove the upper electronics bay cover. See Removing the upper electronics bay cover on page 4-17. Remove the left side access panel. See Figure 4-175. Figure 4-175: Left side access panel mounting screw locations Remove the 7 mounting screws. uPrint/uPrint SE Service Manual 4-103... - Page 151 Disconnect the material bay cable from the printer. Remove the Front Panel. See Removing the front panel on page 4-11. Remove the Electronics Bay. See Removing the electronics bay on page 4-19. Using a ⁄ ” nut driver or standard screwdriver, remove the right side access panel mounting screws and remove the right side access panel.

- Page 152 Disconnect the head cooling fan. See Figure 4-180. Figure 4-180: Disconnect head cooling fan J258 Disconnect J258 Using a ⁄ ” nut driver or standard screwdriver, remove the head cooling fan mounting bracket screws. See Figure 4-181. uPrint/uPrint SE Service Manual 4-105...

- Page 153 Figure 4-181: Head cooling fan mounting bracket screw locations Let head cooling fan hang off to side. Using a ⁄ ” nut driver or standard screwdriver, remove the 4 foam insert retaining screws and washers. See Figure 4-182. Figure 4-182: Foam insert retaining screw locations Remove the foam insert.

- Page 154 Figure 4-184. Figure 4-184: Y motor belt location Locate the 2 lower Y drive rod mounting screws. See Figure 4-185. Figure 4-185: Lower Y drive rod mounting screw locations Lower Y drive rod mounting screw locations uPrint/uPrint SE Service Manual 4-107...

- Page 155 Using a ⁄ ” nut driver or standard screwdriver, remove the 2 Y drive rod mounting screws. See Figure 4-186. Figure 4-186: Y drive rod mounting screws Right side mounting screw Left side mounting screw Locate and remove the 4 upper Y drive rod mounting screws with a ⁄...

- Page 156 Installing the front panel on page 4-12. Reinstall the Side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. Reconnect the material bay cable, network cable and power cable. uPrint/uPrint SE Service Manual 4-109...

-

Page 157: Y Drive Rod

Y Drive Rod Required Tools • ⁄ ” nut driver or standard screwdriver. • Dial indicator and belt tension gauge assembly Hardware • 10-32 x ⁄ ” slotted screws (x30) • 3-16 x 1” fender washer Removing the Y Drive Rod Remove the top panel. - Page 158 ⁄ ” box wrench, loosen, but do not remove, the inner Y belt retaining clip mounting screws from the right side. See Figure 4-192. Pull the right side Y belt out from the retaining clip. uPrint/uPrint SE Service Manual 4-111...

- Page 159 Figure 4-192: Right side Y belt retaining clip mounting screw locations Remove the outer mounting screws Loosen, but do not remove the inner mounting screws Decrease the Y belt tension by turning the tensioning nut. See Figure 4-193. Figure 4-193: Y drive belt tension adjustment Y-Drive Belt Tension Adjusting Nut...

- Page 160 Figure 4-196: Foam insert retaining screw locations Remove the foam insert. Using a ⁄ ” nut driver or standard screwdriver, loosen but do not remove the 4 Y motor mounting bracket mounting screws. See Figure 4-197. uPrint/uPrint SE Service Manual 4-113...

- Page 161 Figure 4-197: Y motor mounting bracket screw locations Remove the Y motor belt from the Y motor pulley. See Figure 4-198. Figure 4-198: Y motor belt location Locate the 2 lower Y drive rod mounting screws. See Figure 4-199. Figure 4-199: Lower Y drive rod mounting screw locations Lower Y drive rod mounting screw locations 4-114...

- Page 162 See Figure 4-201. Figure 4-201: Upper Y drive rod mounting screw locations Lift the Y drive rod, slide out through the Y belts and discard. See Figure 4-202. Figure 4-202: Remove Y drive rod uPrint/uPrint SE Service Manual 4-115...

- Page 163 Installing the Y Drive Rod Slide the Y drive rod through the Y belts and into position. Align Y drive rod with the 6 mounting holes. Using a ⁄ ” nut driver or standard screwdriver, reinstall the 6 Y drive rod mounting screws.

-

Page 164: Xy Table

” allen wrench. • ⁄ ” allen wrench. • Cutters. • Z Guide rod stand off (x2) • Head bracket, dial indicator and belt tension gauge assembly • Y rod spacer (x2) • Leveling wrench uPrint/uPrint SE Service Manual 4-117... - Page 165 Hardware • Wire tie • 10-32 x ⁄ ” slotted screws (x14) • 10-32 x ⁄ ” slotted screws (x4) • 10-32 x ⁄ ” socket head cap screws (x4) • 8-32 x ⁄ ” socket head cap screws (x4) •...

- Page 166 Figure 4-205: Umbilical hose wire tie location Cut and remove the wire tie Using a ⁄ ” allen wrench, remove the 2 energy chain mounting screws. See Figure 4-206. Figure 4-206: Energy chain mounting screw locations Remove the 2 mounting screws uPrint/uPrint SE Service Manual 4-119...

- Page 167 Remove the substrate sensor. See Removing the substrate sensor on page 4-64. Using a ⁄ ” box wrench, remove the X belt tension adjuster by loosening the inside nut and then backing the bolt out of the mount. See Figure 4-207. Remove the tensioning fork and pulley from the X motor belt.

- Page 168 ⁄ ” box wrench, loosen, but do not remove, the inner Y belt retaining clip mounting screws from the right side. See Figure 4-212. Pull the right side Y belt out from the retaining clip. uPrint/uPrint SE Service Manual 4-121...

- Page 169 Figure 4-212: Right side Y belt retaining clip mounting screw locations Remove the outer mounting screws Loosen, but do not remove the inner mounting screws Move the translator to the rear of the printer. Using a ⁄ ” nut driver, remove the right side X guide rod mounting screws. See Figure 4-213.

- Page 170 Figure 4-217: Left side front Y guide rod mounting screw location Remove the left front Y guide rod mounting screw Using a ⁄ ” allen wrench, remove the left side rear Y guide rod mounting screw. See Figure 4-218. uPrint/uPrint SE Service Manual 4-123...

- Page 171 Figure 4-218: Left side rear Y guide rod mounting screw location Remove the left rear Y guide rod mounting screw Lift the front of the left Y guide rod upward until it is near the top of the frame. Rotate the left side Y guide rod towards the center of the printer and lower the guide rod. Pull the left side Y guide rod out towards the door opening.

- Page 172 Figure 4-220. Adjust (increase/decrease) the tension by turning the tensioning nut (Figure 4-222.) so that the dial indicator reads between 0.425 and 0.435 mils. Figure 4-222: Y drive belt tension adjustment Y-Drive Belt Tension Adjusting Nut uPrint/uPrint SE Service Manual 4-125...

- Page 173 Remove the belt fixture and move the belt forward and back several times. Reattach the belt tension gauge and recheck the tension. Continue to adjust and check the tension until the tension meets specification. Push the left side Y guide rod in towards the back of the printer. Rotate the left side Y guide rod towards the left side of the printer and raise the guide rod to the top of the frame.

- Page 174 Move 1 alignment bracket to the front of the printer. See Figure 4-225. Move the translator to the center of the XY table. Move 1 alignment bracket to the rear of the printer. See Figure 4-225. uPrint/uPrint SE Service Manual 4-127...

- Page 175 Figure 4-225: XY Table alignment bracket mounting locations Place an alignment Place an alignment bracket at the front bracket at the back of the printer of the printer Using a ⁄ ” nut driver or standard screwdriver, loosen but do not remove the left side X guide rod mounting screws.

- Page 176 Using a black marker or pen, mark the 4 corners of the Z stage. See Figure 4-228. Figure 4-228: Marking the 4 corners of the Z stage Mark the 4 corners of the Z stage Attach the XY leveling bracket and dial indicator to the head. See Figure 4-229. uPrint/uPrint SE Service Manual 4-129...

- Page 177 Move the dial indicator to the back right corner and write down the value. Enter the values that are written down into the XY level worksheet. Use the 8x6 worksheet for uPrint and uPrint SE, see Figure 4-230. Use the 8x8 worksheet for uPrint Plus and uPrint SE Plus, see Figure 4-231.

- Page 178 Figure 4-230: uPrint and uPrint SE measurement points and worksheet uPrint/uPrint SE Service Manual 4-131...

- Page 179 Figure 4-231: uPrint Plus and uPrint SE Plus measurement points and worksheet 4-132...

- Page 180 Loosen the adjustment screw and insert the dial indicator into the fixture. Adjust the depth of the dial indicator so the gauge reads 0.500 mils and tighten the adjustment screw. Recheck the reading. Remove the zero block gauge block from the fixture. uPrint/uPrint SE Service Manual 4-133...

- Page 181 Figure 4-233: Tension gauge zero setting Adjustment screw Zero gauge block Position the dial indicator on the rear section of the X-Drive belt - centered between the Head Assembly and the left side of the build envelope. See Figure 4-234. Figure 4-234: X belt tension location Check the tension: The gauge should read between 0.425 and 0.435 mils.

- Page 182 Remove the belt fixture and run the head back and forth several times. Continue to adjust and check the tension until the tension meets specification. Repeat steps 68 - 71 to zero the dial indicator. Reinstall a wire tie around the umbilical hose. See Figure 4-237. uPrint/uPrint SE Service Manual 4-135...

- Page 183 Perform XY Offset calibration. See XY Tip Calibration on page 5-5. Perform Part Based calibration. See Performing part based calibration for uPrint, uPrint SE, uPrint Plus and uPrint SE Plus from the Service Calibration menu (Firmware version 9.1 or newer) on page 5-7. 4-136...

-

Page 184: Z Stage Components

Installing the Z home sensor Align the Z home sensor with the mounting hole. Reinstall the mounting screw with a 1/4” nut driver or standard screwdriver. Reconnect the Z home cable. Close the chamber door. uPrint/uPrint SE Service Manual 4-137... -

Page 185: Z Eot (End Of Travel) Sensor

Z EOT (End of Travel) Sensor Required Tools • ⁄ ” nut driver or standard screwdriver. Hardware • 6-32 x ⁄ ” slotted screw (x1) Removing the Z EOT sensor Open the chamber door. Raise the Z stage all of the way up. Disconnect the Z EOT sensor cable by pressing in on the tab and pulling outward. -

Page 186: Chamber Fans

Remove the 4 mounting screws Using a ⁄ ” box wrench, remove the 2 chamber fan mounting screws. See Figure 4-243. Figure 4-243: Right side chamber fan mounting screw locations Remove the 2 mounting screws uPrint/uPrint SE Service Manual 4-139... - Page 187 Installing the right side chamber fan Align chamber fan with mounting holes. Using a ⁄ ” box wrench, reinstall the 2 chamber fan mounting screws. Align the right side heater panel with the mounting holes. Using a ⁄ ” nut driver or standard screwdriver, reinstall the 4 mounting screws for the right side heater panel.

-

Page 188: Chamber Heaters

Figure 4-246. Figure 4-246: Right side heater panel mounting screw locations Remove the 4 mounting screws Remove the black power wire from the right mounting post with a ⁄ ” nut driver. See Figure 4-247. uPrint/uPrint SE Service Manual 4-141... - Page 189 Remove the white power wire from the left mounting post with a ⁄ ” nut driver. See Figure 4-247. Figure 4-247: Power wire locations Remove the white power wire Remove the black power wire Remove the left and right mounting screws with a ⁄...

- Page 190 Remove the white power wire Using a ⁄ ” nut driver or standard screwdriver, remove the left and right mounting screws. Do not lose the insulating washers as they are need for reinstallation. See Figure 4-251. uPrint/uPrint SE Service Manual 4-143...

- Page 191 Figure 4-251: Left side heater mounting screw locations Remove the mounting screws Remove the heater. Installing the left side heater Align the heater with the mounting posts. Insert the insulating washers and reinstall the mounting screws using a ⁄ ” nut driver or standard screwdriver.

-

Page 192: Thermal Fuses

Figure 4-252: Right side heater panel mounting screw locations Remove the 4 mounting screws Disconnect the RTH1 and RTH2 spade connectors by pulling outward. See Figure 4-253. Figure 4-253: RTH1 and RTH2 spade connector locations Disconnect Disconnect RTH1 RTH2 uPrint/uPrint SE Service Manual 4-145... - Page 193 Using a standard screwdriver, remove the 2 mounting screws. See Figure 4-254. Figure 4-254: Right side thermal fuse mounting screw locations Remove the mounting screws Remove the thermal fuse. Installing the right side thermal fuse Align the thermal fuse with the mounting holes. Using a standard screwdriver, reinstall the mounting screws.

- Page 194 Using a ⁄ ” nut driver or standard screwdriver, reinstall the 4 mounting screws. Reinstall the side panels. See Installing the side panels on page 4-8. Reinstall the top panel. See Installing the top panel on page 4-6. uPrint/uPrint SE Service Manual 4-147...

-

Page 195: Chamber Thermocouple

Chamber Thermocouple Required Tools • ⁄ ” nut driver. • standard screwdriver. Removing the chamber thermocouple Remove the top panel. See Removing the top panel on page 4-5. Remove the side panels. See Side Panels on page 4-7. Remove the upper electronics bay cover. See Removing the upper electronics bay cover on page 4-17. -

Page 196: Z Motor

Remove the electronics bay. See Removing the electronics bay on page 4-19. Using a ⁄ ” nut driver or standard screwdriver, remove the 4 Z stage panel mounting screws and remove the Z stage panel. See Figure 4-260. uPrint/uPrint SE Service Manual 4-149... - Page 197 Figure 4-260: Removing the Z stage panel Remove the 4 Z motor energy chain mounting screws with a ⁄ ” allen wrench. See Figure 4-261. Cut the tie wraps holding from around Z stage energy chain. See Figure 4-261. Figure 4-261: Remove the Z motor energy chain Cut the Remove the 2 wire tie...

- Page 198 Figure 4-263: Remove the leadscrew Remove the 4 Z stage motor mounting screws with a ⁄ ” allen wrench and remove the motor. See Figure 4-264. Figure 4-264: Removing the Z stage motor Remove the 4 mounting screws uPrint/uPrint SE Service Manual 4-151...

- Page 199 Installing the Z motor Place the Z motor in its mounting location and loosely fasten the mounting screws with a ⁄ ” allen wrench. Insert the leadscrew and turn clockwise until the leadscrew clears the bottom of the motor. Raise the Z stage to the upper limit and tighten the leadscrew mounting bracket set screws.

-

Page 200: Z Stage

Z Stage The uPrint and uPrint SE printers have a Z stage pan that is 8 x 6 inches. The uPrint Plus and uPrint SE Plus printers have a Z stage pan that is 8 x 8 inches. The physical replacement is the same for both printers. - Page 201 • Z guide rod alignment fixture Hardware • 10-32 x ⁄ ” slotted screws (x4) Removing the Z stage Remove the top panel. See Removing the top panel on page 4-5. Remove the side panels. See Side Panels on page 4-7. Remove the electronics bay. See Removing the electronics bay on page 4-19.

- Page 202 Figure 4-268: Z stage guide rod alignment fixture locations Z Stage guide rod alignment fixtures Using a ⁄ ” socket driver or ⁄ ” box wrench, securely fasten the lower Z stage guide rod mounting screws. uPrint/uPrint SE Service Manual 4-155...

- Page 203 Using a ⁄ ” nut driver or standard screwdriver, securely fasten the upper Z stage guide rod mounting screws. Remove the upper and lower Z stage guide rod alignment fixtures. Using a 3/32” allen wrench, reinstall the Z motor. Do not tighten the screws completely at this time.

- Page 204 Note: If the Z stage is binding, loosen the Z stage motor mounting screws and the Z stage leadscrew mounting bracket screws, then repeat steps 10-24. Raise the Z stage up near the XY table and hold in place using 2 Z guide rod stand off’s. Figure 4-272. uPrint/uPrint SE Service Manual 4-157...

- Page 205 Figure 4-272: Z guide rod stand off locations Using a black marker or pen, mark the 4 corners of the Z stage. See Figure 4-273. Figure 4-273: Marking the 4 corners of the Z stage Mark the 4 corners of the Z stage Attach the XY leveling bracket and dial indicator to the head.

- Page 206 Move the dial indicator to the back right corner and write down the value. Enter the values that are written down into the XY level worksheet. Use the 8x6 worksheet for uPrint and uPrint SE, see Figure 4-275. Use the 8x8 worksheet for uPrint Plus and uPrint SE Plus, see Figure 4-276.

- Page 207 Figure 4-275: uPrint and uPrint SE measurement points and worksheet 4-160...

- Page 208 Figure 4-276: uPrint Plus and uPrint SE Plus measurement points and worksheet uPrint/uPrint SE Service Manual 4-161...

- Page 209 Move the dial indicator to the front left of the Z stage and zero the dial indicator. Using the XY guide rod leveling fixture, adjust the rod up or down until the dial indicator reads the value the calculator has given. See Figure 4-277.

-

Page 210: Calibrations & Adjustments

Adjusting Z Calibration and XY Tip Offset ____________________________ 4-2 XY Tip Calibration__________________________________________________ 4-5 Part Based Calibration _____________________________________________ 4-7 Tensioning the X & Y Drive Belts ______________________________________ 4-36 Get/Send Calibration Files ___________________________________________ 4-40 XY Table Leveling ___________________________________________________ 4-42 Head Alignment Procedure __________________________________________ 4-46 uPrint/uPrint SE Service Manual... -

Page 211: Offset Calibrations

Offset Calibrations Adjusting Z Calibration and XY Tip Offset Z calibration is needed to adjust the slight differences in tip heights. XY Tip Offset is required to correct for the slight differences in tip alignment. Failure to perform these calibrations will result in poor part quality and possible LOE’s. Z and Tip Offset calibrations are mandatory whenever the tips are replaced. - Page 212 Note: The value for ZT2B must be between -0.1500” and 0.0000”. When finished, press Done... Press the button. Next... Press the button. Save and reboot The printer will reboot and return to idle. Perform automatic Z calibration. See Z Calibration on page 5-2. uPrint/uPrint SE Service Manual...

- Page 213 Entering Z Calibration values manually (Firmware version 9.1 or newer) Z tip to tip (ZT2T) ZT2T is the Z distance from the model tip to the support tip. A positive ZT2T means the support tip is higher than the model tip. If a support layer on top of model is too thick, add 0.010”...

-

Page 214: Xy Tip Calibration

This example requires an adjustment of X = + 2 mils, Y = - 4 mils Note: Unusual circumstances may require that the XY tip calibration values be entered manually. To change these values, see Entering XY Tip Calibration values manually (Firmware version 9.1 or newer) on page 5-6. uPrint/uPrint SE Service Manual... - Page 215 Entering XY Tip Calibration values manually (Firmware version 9.1 or newer) XY Tip is the XY distance from model tip to the support tip. To move support roads to the right (+X), apply a positive offset. To move support roads to the back (+Y), apply a positive offset.

-

Page 216: Part Based Calibration

Part Based calibration needs to be performed after replacing the XY table assembly. Part Based calibration is performed to eliminate any skewing in the X and Y axes. Performing part based calibration for uPrint, uPrint SE, uPrint Plus and uPrint SE Plus from the Service Calibration menu (Firmware version 9.1 or newer) - Page 217 Locate the filled circle, this indicates the front of the substrate, see Figure 5-282. Figure 5-282: Locating the Filled Circle (B) Using a digital caliper, measure and record the diameter of circle B along the center line between A and C, see Figure 5-283.

- Page 218 G. See Figure 5-287. Figure 5-287: Measuring distances from outside edges of F and G Measure and record the diameter of circle F along the center line between E and G. See Figure 5-288. uPrint/uPrint SE Service Manual...

- Page 219 Figure 5-288: Measuring diameter of circle F Add the lengths derived from steps (E-F and F-G) and then subtract the width of circle F derived from step 16. Record this total as “GRear” Measure and record the distance from the outside edges of circles C and G. Ensure the caliper is not seated on the small bump of circles C or G.

- Page 220 Figure 5-291: Measuring distances from outside edges of C and D Measure and record the distance from the outside edge of the small bump on circle E to the outside edge of circle D. See Figure 5-292. uPrint/uPrint SE Service Manual 5-11...

- Page 221 Figure 5-292: Measuring distances from outside edges of D and E Measure and record the diameter of circle D along the center line between C and E. See Figure 5-293. Figure 5-293: Measuring diameter of circle D Add the lengths derived from steps (C-D and D-E) and then subtract the width of circle D derived from step 21.

- Page 222 Done... not appear until the value is within the acceptable range. Press the button. Enter the value recorded from step by pressing the GRight Increment buttons. Decrement Next Digit When finished, press Done... uPrint/uPrint SE Service Manual 5-13...

- Page 223 The printer will reboot and return to idle. Build a sample part to verify proper operation. Performing part based calibration for uPrint and uPrint SE with MaracaEX Open MaracaEX and select the current modeler from the pull down menu. Open Gantry Calibration Dialog box in MaracaEX.

- Page 224 Next measure and record the distance from the outside edges of circle A and B, see Figure 5-299. Ensure that the caliper is not seated on the small bump of circle A. Figure 5-299: Measuring distance from outside edges of A and B uPrint/uPrint SE Service Manual 5-15...

- Page 225 Next measure and record the distance from the outside edges of circle B and C, see Figure 5-300. Ensure that the caliper is not seated on the small bump of circle C. Figure 5-300: Measuring distance from outside edges of B and C Add the lengths derived from steps (A-B and B-C) and then subtract the width of circle B.

- Page 226 Figure 5-305: Measuring distances from outside edges of A and E Measure and record the distance from the outside edge of the small bump on circle C to the outside edge of circle D. See Figure 5-306. uPrint/uPrint SE Service Manual 5-17...

- Page 227 Figure 5-306: Measuring distances from outside edges of C and D 21. Measure and record the distance from the outside edge of the small bump on circle E to the outside edge of circle D. See Figure 5-307. Figure 5-307: Measuring distances from outside edges of D and E Measure and record the diameter of circle D along the center line between C and E.

- Page 228 Figure 5-310: Measuring distances from outside edges of D and G Measure and record the diameter of circle D along the center line between A and G. See Figure 5-311. Figure 5-311: Measuring diameter of circle D uPrint/uPrint SE Service Manual 5-19...

- Page 229 Add the lengths derived from steps (A-D and D-G) and then subtract the width of circle D derived from step 26. Record this total as “Left Front” Open MaracaEX and select the Current Modeler from the pull down menu. Open the Dialog box in MaracaEX.

- Page 230 Left Rear: _______ + ______ - ____ = ________ (C + D) + (D + E) - D Left Front: _______ + ______ - ____ = _______ (A + D) + (D + G) - D Figure 5-312: Part based calibration measurement locations uPrint/uPrint SE Service Manual 5-21...

- Page 231 Performing part based calibration for uPrint Plus and uPrint SE Plus from the Service Calibration menu While the printer is at , enter standby mode by pressing the button. Idle Standby... Enter the Service Calibration menu by pressing the following button sequence on the display panel: .

- Page 232 B. Record this total as “GFront” Measure and record the distance from the outside edges of circles E and F. Ensure the caliper is not seated on the small bump of circle E. See Figure 5-318. uPrint/uPrint SE Service Manual 5-23...

- Page 233 Figure 5-318: Measuring distances from outside edges of C and F Measure and record the distance from the outside edges of circles F and I. See Figure 5- 319. Figure 5-319: Measuring distances from outside edges of F and G Measure and record the diameter of circle F along the center line between C and I.

- Page 234 Measure and record the distance from the outside edges of circles D and G. See Figure 5- 322. Figure 5-322: Measuring distances from outside edges of D and G Measure and record the diameter of circle D along the center line between A and G. See Figure 5-323. uPrint/uPrint SE Service Manual 5-25...

- Page 235 Figure 5-323: Measuring diameter of circle D Add the lengths derived from steps (A-D and D-G) and then subtract the width of circle D derived from step 19. Record this total as “GLeft” Measure and record the distance from the outside edge of circle G to the outside edge of circle H.

- Page 236 Figure 5-328: Measuring distances from outside edges of E and G Measure and record the diameter of circle E along the center line between C and G. See Figure 5-329. Figure 5-329: Measuring diameter of circle E uPrint/uPrint SE Service Manual 5-27...

- Page 237 Add the lengths derived from steps (C-E and E-G) and then subtract the width of circle E derived from step 27. Record this total as “GLR” Measure and record the distance from the outside edge of circle A to the outside edge of circle E.

- Page 238 Press the button until you reach the last page. Next... Press the button. Done... Press the button. Save and reboot The printer will reboot and return to idle. Build a sample part to verify proper operation. uPrint/uPrint SE Service Manual 5-29...

- Page 239 Performing part based calibration for uPrint Plus and uPrint SE Plus with MaracaEX Open MaracaEX and select the current modeler from the pull down menu. Open Gantry Calibration Dialog box in MaracaEX Set the X adjust value to 0. In the Part Calibration section, there are six boxes: LEFT, RIGHT, FRONT, REAR, LEFT FRONT and LEFT REAR.

- Page 240 Figure 5-337: Measuring distances from outside edges of C and F Measure and record the distance from the outside edges of circles F and I. See Figure 5- 338. Figure 5-338: Measuring distances from outside edges of F and I uPrint/uPrint SE Service Manual 5-31...

- Page 241 Measure and record the diameter of circle F along the center line between C and I. See Figure 5-339. Figure 5-339: Measuring diameter of circle F Add the lengths derived from steps (C-F and F-I) and then subtract the width of circle F derived from step 16.

- Page 242 (G-H and H-I) and then subtract the width of circle H derived from step 24. Record this total as “Rear” Measure and record the distance from the outside edge of circle C to the outside edge of circle E. See Figure 5-346. uPrint/uPrint SE Service Manual 5-33...

- Page 243 Figure 5-346: Measuring distances from outside edges of C and E Measure and record the distance from the outside edge of circle E to the outside edge of circle G. See Figure 5-347. Figure 5-347: Measuring distances from outside edges of E and G Measure and record the diameter of circle E along the center line between C and G.

- Page 244 Figure 5-350: Measuring distances from outside edges of E and I Measure and record the diameter of circle E along the center line between A and I. See Figure 5-351. Figure 5-351: Measuring diameter of circle E uPrint/uPrint SE Service Manual 5-35...

- Page 245 Add the lengths derived from steps (A-E and E-I) and then subtract the width of circle E derived from step 32. Record this total as “Left Front” Open MaracaEX and select the Current Modeler from the pull down menu. Open the Dialog box in MaracaEX.

-

Page 246: Tensioning The X & Y Drive Belts