Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Stratasys UV800

- Page 1 User Guide UV800 User Guide DOC-60015 Rev. A...

- Page 2 No part of this document may be photocopied, reproduced, or translated into any human or computer language in any form, nor stored in a database or retrieval system, without prior permission in writing from Stratasys. This document may be printed for internal use only. All copies shall contain a full copy of this copyright notice.

-

Page 3: Table Of Contents

ID Plate..........................7 Technical Specifications ...................... 7 Weights and Dimensions..................... 8 Installation, Start-up, and Initialization ............8 Installation ........................... 8 Moving the UV800....................... 8 Safe Start-up and Shutdown Sequences ................8 Ventilation..........................9 Extraction ..........................9 Controls ....................... 10 Start / Stop ........................10 User Interface........................ - Page 4 Contents Cleaning ..........................20 Lamp Replacement ......................20 Customer Service ..................21 Servicing and Repairs ....................... 21 Product Warranty....................... 21 Contacting Stratasys ......................21 Product Disposal ....................... 22 FCC Compliance Statement ................ 22 Page iv...

-

Page 5: Revision Log

First release of this document. Safety To reduce the risk of injury, read these instructions carefully before using the UV800. Always observe the safety guidelines listed in this manual. Protection of the user is impaired if safety instructions are ignored, or used in a manner not specified in this document. -

Page 6: Conventions Used In This Guide

Product Guide Conventions Used in this Guide This guide provides information for installing and operating the powder retrieval station. This guide also provides instructions for unpacking and preliminary set-up. Information of particular importance is presented in one of three formats: A Warning: indicates a procedure that can cause injury to an operator if the procedure is not followed. - Page 7 Product Guide Table 1: Warning symbols Image/Symbol Description ELECTRIC SHOCK: AC voltage adjacent to, or behind this label.Injury or death from electric shock can result if you ignore these hazard labels. UV RADIATION HAZARD: UV radiation emission if panel removed while in operation.

-

Page 8: Uv Safety

Figure 2: Detailed drawing UV Safety The UV800 is a UV radiation source. Exposure to UV radiation can irreversibly damage eyes and skin. UV radiation is safely contained when all panels are in place and doors are closed (normal operating conditions). Removal of outer panels should only be performed by qualified personnel. -

Page 9: Electrical Safety

Product Guide Electrical Safety Please refer to the Technical Specification section for electric supply specification. • Connect equipment to a grounded facility power source. Do not defeat or bypass the ground lead. • Know the location of equipment branch circuit interrupters or circuit breakers and how to turn them on and off in case of emergency. -

Page 10: Material Safety

Wipe off any resin spills immediately using a cloth dampened with isopropanol. • Temperature range: 17-25 ˚C • Protect the UV800 from dust and corrosive vapours or substances. • Avoid strong electromagnetic fields and static electricity. • For further details please refer to “Technical Specifications”... -

Page 11: Overview

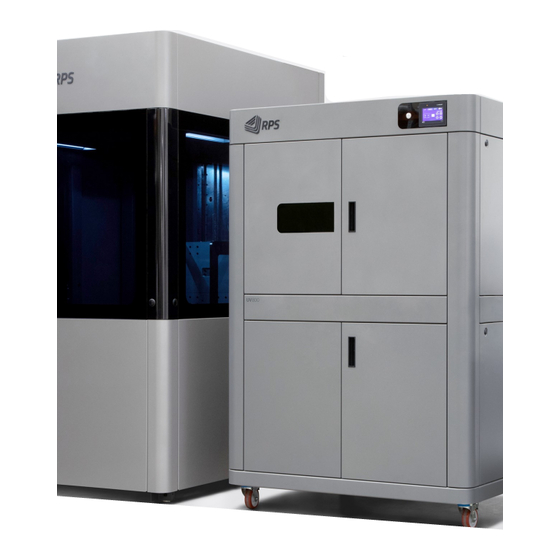

Stratasys reserves the right to update this operating manual at any time and without notification. Product Overview The UV800 is an ancillary device to the Neo Stereolithography (SL) printer range. The UV800 is designed for the final, post cure stage of SL part production. Post curing SL parts serves 2 functions: •... -

Page 12: Id Plate

Product Guide Overview ID Plate The UV800 ID plate which includes the machine serial number is found on the rear panel: Figure 3: ID plate Technical Specifications Figure 4: Electrical requirements The UV800 is protected at inlet with two 10 A, anti-surge (T) fuses. -

Page 13: Weights And Dimensions

Installation of the UV800 should be performed by a trained Stratasys representative. Moving the UV800 The UV800 is fitted with 4 castor wheels for easy relocation. The front pair of castors are fitted with brakes. Release the brakes before attempting to move the UV800. -

Page 14: Ventilation

Ventilation Free airflow must always be ensured around the ventilation grilles. Always ensure a minimum gap of ≥100 mm (4 in) at the rear of the UV800. Refer to Figure 2 (page Do not obstructed airflow from the heat exhaust/extraction port. Refer to... -

Page 15: Controls

Product Guide Controls Stratasys will not bear responsibility, or costs of damage to the UV800 and/or contents resulting from an incorrectly performing or operating extraction system. Controls Figure 6: Controls Start / Stop Unlit: UV chamber idle. Press and release: Starts program selected on the User Interface. -

Page 16: User Interface

Product Guide User Interface User Interface Figure 7: User interface (UI) 1. Oven Tab 2. Heat Box Tab 3. Information Tab Page 11... -

Page 17: Uv Chamber Tab

Product Guide User Interface UV Chamber Tab Figure 8: UV Chamber tab UV Chamber Screen is split into several sections: 4. Manual Mode 5. Quick Set Mode 6. Door State Manual Mode Selecting the minute or second icon will allow the user to input a custom cure cycle time. The desired minutes and seconds must be set independently on the popup keypad. - Page 18 User Interface • To deselect the keypad, click ESC. Figure 9: Manual mode Quick Set The UV800 has four preprogrammed cure cycle times: Five minutes cycle Ten minutes cycle Fifteen minutes cycle Twenty minutes cycle Selecting one of the icons will automatically set that specific cure cycle time up in the Manual Mode display box To deselect, reselect the highlighted icon.

-

Page 19: Heated Chamber Tab

Product Guide User Interface Door State The Closed Door state occurs when the UV chamber door is closed and the interlock is engaged, enabling normal operations. The Door Open, Flashing state occurs when the UV chamber door is open or the interlock is disengaged, preventing UV cure cycle operation. - Page 20 Product Guide User Interface 8. Current Temperature Set Temperature Selecting the Set Temperature box will allow the user to input a desired temperature on the pop up keypad. See Figure 11. A maximum temperature of 30°C can be set. • To confirm the desired time, click Enter.

-

Page 21: Information Tab

11. Bulb Time Reset Bulb Time Reset To reset the UV800 Bulb – Total Time, select the RPS Logo which will provide admin permissions for up to 30 seconds. Select the Bulb Time Reset button, which will pop up a second stage warning button. - Page 22 Product Guide User Interface Proceed to click ‘Reset’ which will override the current total time to zero. Figure 13: Bulb Time Reset Page 17...

-

Page 23: Normal Operation

Parts will remain tacky if they are post cured before dry. Selecting Correct Cure Cycle Time Materials typically require 10~30 minutes total cure cycle time. Cycle times differ by material, so it is important to contact Stratasys or your material supplier for best practice for your chosen material. Operation Gloves must be worn when handling parts until the cure cycle is complete. - Page 24 Caution: Damage to Equipment. Do not manually spin the turntable to reach parts. This can cause damage to the turntable clutch assembly. 11. Once the UV800 has been stopped the part can be removed from the UV chamber. Page 19...

-

Page 25: Maintenance And Support

2. Clean using a cloth dampened with Isopropyl alcohol. Lamp Replacement The output from the lamps will reduce, as the hours of use accumulate. Stratasys recommend replacement every 2000 to 3000 hours. It is recommended that all the lamps are changed at the same time. -

Page 26: Customer Service

• If the machine has been altered If the machine must first be brought into a serviceable state by Stratasys (e.g. by removing customer-added parts or cleaning the machine) before servicing can begin, then the customer must bear the additional cost. -

Page 27: Product Disposal

Alternatively the product can be returned to Stratasys for a fee, to be properly disposed of in compliance with environmental regulations. - Page 28 _____ c-support@stratasys.com THE 3D PRINTING SOLUTIONS COMPANY...

Need help?

Do you have a question about the UV800 and is the answer not in the manual?

Questions and answers