Table of Contents

Advertisement

Available languages

Available languages

Quick Links

¡IMPORTANTE!

IMPORTANT!

NO DESTRUIR

DO NOT DESTROY

Installation

Manual

and

de Instalación

Maintenance

y

Manual

Mantenimiento

con Información sobre Seguridad

with Safety Information

y Lista de Refacciones

and Parts List

LAS REFACCIONES RECOMENDADAS SE RESALTAN EN GRIS

RECOMMENDED SPARE PARTS HIGHLIGHTED IN GRAY

Effective November 2013

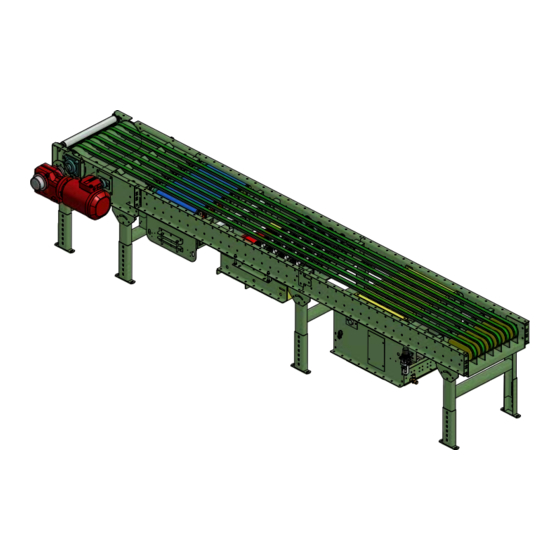

Model ProSort MRT

(Supercedes October 2007)

Bulletin #656

Hytrol Conveyor Co., Inc.

Jonesboro, Arkansas

© COPYRIGHT 2007–HYTROL CONVEYOR CO., INC.

PRESS OPTImIzEd fOR THE ENVIRONmENT

(ImpresIón OptImIzada para prOteger el medIO ambIente)

Advertisement

Chapters

Table of Contents

Summary of Contents for HYTROL ProSort MRT

- Page 1 RECOMMENDED SPARE PARTS HIGHLIGHTED IN GRAY Effective November 2013 Model ProSort MRT (Supercedes October 2007) Bulletin #656 Hytrol Conveyor Co., Inc. Jonesboro, Arkansas © COPYRIGHT 2007–HYTROL CONVEYOR CO., INC. PRESS OPTImIzEd fOR THE ENVIRONmENT (ImpresIón OptImIzada para prOteger el medIO ambIente)

-

Page 2: Table Of Contents

ProSort mRT Parts drawing ....9 ProSort mRT Parts List .....9 ProSort mRT drive Parts drawing . -

Page 3: Safety Information

In an effort to reduce the possibility of injury to personnel working around HYTROL conveying equipment, safety labels are placed at • Operation various points on the equipment to alert them of potential hazards. -

Page 4: Installation

34268 CONVEYOR F.O. # 34268 ITEM ITEM of incline will determine where the knee HYTROL CONVEYOR CO. INC. HYTROL CONVEYOR CO. INC. JONESBORO, AR JONESBORO, AR brace mounting brackets are to be placed when required. NOTE: ALLOW FOR BELT THICKNESS WHEN ADJUSTING SUPPORTS (NOTA: DEJE ESPACIO SUFICIENTE PARA EL ESPESOR DE LA BANDA CUANDO AJUSTE LOS SOPORTES) 4. -

Page 5: Belt Installation

• Belt Installation STATIONARY IDLER CAUTION! Excessive slippage will reduce belt (RODILLO ESTACIONARIO) life and damage drive pulley lagging. Never FIGURE 5A PIVOTING IDLER apply more tension than is needed. Over- (RODILLO PIVOTE) tension will cause extra wear to belt and bear- INTERMEDIATE TAIL SECTION DRIVE SECTION... -

Page 6: Racked Sections

• Racked Sections SIDE CHANNEL FIGURE 6A It is important that each bed section CROSSBRACING (LONG ROD) (Canal lateral) be checked for a “racked” or out- (tIrante tensOr [VarIlla larga]) of-square condition. If conveyor is not square, tracking problems will "... -

Page 7: Hypowercabling Installation

• HyPower Cabling Installation FIGURE 7B FIGURE 7A INCOMING THREE-PHASE POWER HYPOWER CONNECTIONS (CORRIENTE TRIFÁSICA ENTRANTE) (CONEXIONES HYPOWER) INCOMING THREE-PHASE POWER (CORRIENTE TRIFÁSICA ENTRANTE) GROUND (TIERRA) L1 L2 L3 GROUND (TIERRA) GROUND GROUND (TIERRA) (TIERRA) • HyPower Cabling Components Double-Ended HyPower Extension Cable Supplies power from the disconnect box down the conveyor to each HyPower T-Connector. -

Page 8: Transfer Adjustment

• Transfer Adjustment 1. The height of the transfer should be preset at factory. 2. The height of the transfer may be adjusted to proper height by raising or lowering the cylinder-mounting channel. Loosen 3/8 in. bolts holding the cylinder- mounting channel. -

Page 9: Prosort Mrt Parts Drawing

• Model ProSort MRT Parts Drawing and Parts List Dibujo de Partes del Modelo ProSort MRT Ref No. Part No. description B-11302 mounting Angle for filter/Regulator #094.194 049.110 SPRING LOCK PIN - 5/32 in. dIA. X 7/8 in. LONG 069.7265 Belt - 15/16 in. -

Page 10: Prosort Mrt Drive Parts Drawing

• Model ProSort MRT Drive Parts Drawing and Parts List Dibujo de Partes de la Unidad Motriz del Modelo ProSort MRT REf NO. PART NO. dESCRIPTION WA-036553 BEd SPACER CHANNEL WELdmENT (SPECIfY BR) THIS DRAWING CONTAINS CONFIDENTIAL HYTROL SA-038509 8 in. dIA. dRIVE PULLEY ASSEmBLY (SPECIfY BR) -

Page 11: Prosort Mrt Take-Up Parts Drawing

• Model ProSort MRT Pneumatic Take-Up Parts Drawing and Parts List Dibujo de Partes del Tensionador del Modelo ProSort MRT REf NO. PART NO. dESCRIPTION DWG N THIS DRAWING CONTAINS CONFIDENTIAL WA-009141 PIVOT SHAfT WELdmENT (SPECIfY BR x 8) HYTROL... -

Page 12: Prosort Mrt Section Parts Drawing

• Model ProSort MRT Section Parts Drawing and Parts List Dibujo de Partes de Sección del Modelo ProSort MRT REf NO. PART NO. dESCRIPTION WA-025804 Brace Channel Weldment (Specify BR x 8) WA-025834 Tail Idler Weldment (Specify BR x 8) WA-025999 Brace Channel Weldment “discharge End”... -

Page 13: Prosort Mrt 90 Transfer Parts Drawing

• Model ProSort MRT 90° Transfer Parts Drawing and Parts List Dibujo de Partes de 90° Transferencia del Modelo ProSort MRT REf NO. PART NO. dESCRIPTION WA-025802 ROLLER fRAmE WELdmENT (SPECIfY BR) WA-025817 BASE CHANNEL WELdmENT (SPECIfY BR) SA-036881-137 VULCANIzEd 138 ROLLER ASSEmBLY - 17- 1/8 in. BR... -

Page 14: Prosort Mrt 30 Transfer Parts Drawing

• Model ProSort MRT 30° Transfer Parts Drawing and Parts List Dibujo de Partes de 30° Transferencia del Modelo ProSort MRT REf NO. PARTS NO. dESCRIPTION PT-112594 CYLINdER SUPPORT CHANNEL (SPECIfY BR) THIS DRAWING CONTAINS CONFIDENTIAL dIVERTER SUPPORT ANGLE HYTROL... -

Page 15: Hypower Cabling Parts List And Drawing

• HyPower Cabling Parts List and Drawing Lista y Dibujo de Partes del Cableado HyPower REf NO. PART NO. dESCRIPTION EB-000001 Single-Sided disconnect Box EB-000002 double-Sided disconnect Box double-Ended HyPower Extension Cable 941.430301 double-Ended HyPower Extension Cable - 1 meter 941.430302 double-Ended HyPower Extension Cable - 2 meter 941.430303... -

Page 16: Spanish Version

. . . . . . . . . . . . . . . . . -

Page 17: Instalación

HYTROL. Por favor, revise el equipo e identifique todas las etiquetas de seguridad. arranque inesperado . -

Page 18: Instalación De La Banda

• Instalación de Banda FIGURE 18A TOP FLAT INSTALANDO LA BANDA BELT IDLER la correa de transmisión del transportador es una cinta continua GREEN (TOP TENSOR DE LA BELT GUIDE CORREA PLANA) de aramida verde . para instalar la correa siga las instrucciones a SURFACE (GUIADE BANDA) (SUPERFICIE... -

Page 19: Reeplazo De Banda

• Reeplazo de Banda SET SCREW FIGURE 19A (TORNILLO DE FIJACIÓN) ADVERTENCIA: No cambie la correa con la cámara encendida, quitar el aire de recogida. 1 . retire (4) pernos que sujetan el desgaste canal de BEARING SUPPORT soporte de la banda en su lugar y retire canal deslizando CHANNEL hacia el extremo de descarga del transportador . -

Page 20: Instalación De La Cableado Hypower

• Instalación de Cableado HyPower el dispositivo de parada de emergencia debe actuar directamente en el control del transportador concerniente y no debe depender de la parada de cualquier ADVERTENCIA: No conecte o desconecte ningún componente del otro equipo . los dispositivos de parada de emergencia deben ser instalados de tal cableado HyPower cuando el equipo este prendido! forma que no puedan ser anulados desde otras localidades . -

Page 21: Alineación De La Transferencia

• Componentes de Cableado HyPower FIGURE 21A SINGLE DICONNECT MOTOR (VFD) (MOTOR) MALE SINGLE END HYPOWER CABLE MALE SINGLE END (CABLE HYPOWER MACHO DE HYPOWER CABLE TERMINACIÓN “SINGLE-END”) (CABLE HYPOWER MACHO SINGLE SIDED DISCONNECT BOX DE TERMINACIÓN “SINGLE-END”) (CAJA DE DESCONEXIÓN DE UN SOLO LADO ) FEMALE SINGLE END HYPOWER CABLE (CABLE HYPOWER HEMBRA DE TERMINACIÓN “SINGLE-END”) -

Page 22: Resolviendo Problemas

• Resolviendo Promblemas RESOLVIENDO PROBLEMAS DE TRANSMISION prOblema CaUsa sOlUCIOn el transportador no arranca 1) revise si hay sobrecarga del transportador . 1) el motor está sobrecargado . o el motor se detiene 2) revise los circuitos e interruptores de protección y sobrecarga, y cámbielos si es necesario . 2) el motor pasa demasiada corriente . -

Page 24: Lista De Mantenimiento Preventivo

Check for Pressure (Comprobar la presión) Check Bowl (Comprobar bowl) ( 8 7 0 ) 9 3 5 . 3 7 0 0 2020 HYTROL STREET W W W . H Y T R O L . C O M JONESBORO, ARKANSAS 72401...

Need help?

Do you have a question about the ProSort MRT and is the answer not in the manual?

Questions and answers