Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Printronix SLPA7000e

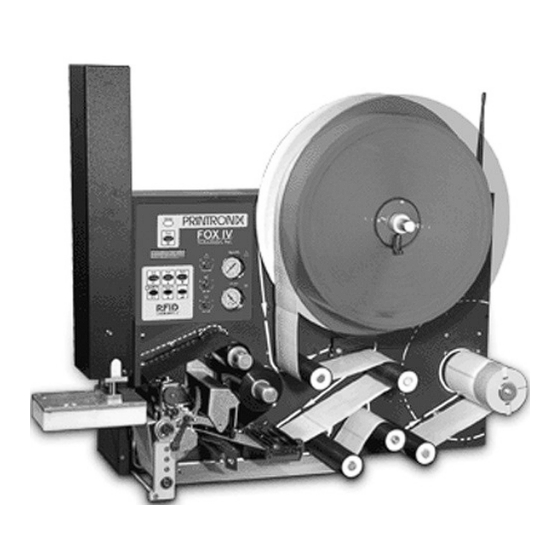

- Page 1 Operator’s Reference Training Manual SLPA7000 Smart Label Printer Applicator...

- Page 3 Operator’s Reference Training Manual SLPA7000 Smart Label Printer Applicator...

- Page 4 THERMAL PRINTHEAD Printronix warrants the printhead for a period of one hundred eighty (180) days, or 1,000,000 linear inches for direct thermal use, or 2,000,000 linear inches for thermal transfer use, whichever comes first.

-

Page 5: Table Of Contents

Table of Contents 1 Setup Procedures ..........7 Removing Label Backing..............7 Threading The Label Roll ..............8 Loading Ribbon .................. 16 Positioning The Air Jets..............19 Calibrating The Printer ............... 20 Running Auto Calibrate ..............21 2 Control Panel ............. 23 LCD .................... - Page 6 Table of Contents System Adjustments................49 Printhead Pressure Adjustment ............ 49 Printhead Pressure Block Adjustments ......... 50 Positioning The Media Sensors ............ 50 Sensing Different Media Types ............. 52 Calibrating The Media Sensors ............. 57 5 Illustrated Parts Breakdown ....... 61 Organization Of This Chapter.............

-

Page 7: Setup Procedures

Setup Procedures Removing Label Backing If the media rewind spool needs to be unloaded during operation, proceed as follows: 1. Press the Pause key to take the SLPA offline. Disable the product sensor if necessary. 2. Tear the label backing near the media rewind hub, then reach around the rewound backing, placing your fingers behind the hub of the media rewind spool. -

Page 8: Threading The Label Roll

Chapter Threading The Label Roll Threading The Label Roll Pivoting Deck Deck Lock Lever Figure 1. The Printhead Assembly 1. Press the Pause key to take the SLPA offline as outlined in “Control Panel” on page 23. 2. Open the pivoting deck by rotating the deck lock lever fully clockwise. - Page 9 Label Roll Core Label Roll Retainer Label Roll Hub Label Roll Hub Collar Cam Lock Figure 2. Mounting Label Media 3. Loosen the cam lock located on the collar of the label roll hub. 4. Slide the label roll retainer off the label roll hub. 5.

- Page 10 Chapter Threading The Label Roll Label Roll Back Stop Label Roll Spindle Label Roll Retainer Label Collar Label Roll Cam Lock Figure 3. Loading Label Media 6. Slide the new label roll onto the label roll hub (unwinding counterclockwise) and against the label roll back stop. 7.

- Page 11 Label Roll Retainer Label Roll Brake Assembly Printhead Platen Label Backing (Liner) Path Media Damper Figure 4. Loading Labels 9. Unwind approximately 3.0 feet (91cm) of media from the label roll. If your label roll does not have a leader, remove the labels from the backing. The empty backing (leader) will act as a leader to thread the media through the SLPA components.

- Page 12 Chapter Threading The Label Roll Lower Media Sensor Leader Media Guard Fixed Guide Media Sensor Media Width Handle Guide Media Damper Figure 5. Threading Media Through the Printhead Assembly 12. Slide the media width guide close to the outside end of the media damper.

- Page 13 Printhead Assembly Upper Sensor Visible Red Beam Lower Sensor Upper Sensor Handle Platen Roller Figure 6. Threading the Leader 17. Slide the upper sensor directly over the lower sensor. 18. Thread the leader between the printhead assembly and across the top of the platen roller.

- Page 14 Chapter Threading The Label Roll Media Edge Platen Peel Bar Figure 7. Aligning Media 19. Align the inside edge of the media with the inside edge of the peel bar. 20. Thread the leader over the peel bar, then between the lower print roller and the air jet.

- Page 15 Pivoting Deck Deck Lock Lever Figure 8. Locking the Pivoting Deck 25. Ensure that the label path is clear of obstructions, then close the pivoting deck and rotate the deck lock lever fully counterclockwise. This locks the pivoting deck and printhead assembly into the printing position. IMPORTANT Ensure the pivoting deck is down and locked before attempting to advance media or print.

-

Page 16: Loading Ribbon

Chapter Loading Ribbon Loading Ribbon Ribbon Take-Up Core Ribbon Take-Up Spindle Pivoting Deck Ribbon Supply Spindle Ribbon Roll Deck Lock Lever Figure 9. Loading Ribbon 1. Press the Pause key to take the SLPA offline. 2. Install the ribbon take-up core on the ribbon take-up spindle. NOTE: The first ribbon take-up fiberboard core comes with the SLPA. - Page 17 Ribbon Printhead Rear Ribbon Guide Roller Figure 10. Threading Ribbon Through the Printhead Assembly 5. Thread the end of the ribbon under the rear ribbon guide roller, then between the platen and the printhead.

- Page 18 Chapter Loading Ribbon Ribbon Take-up Core Ribbon Ribbon Take-up Spindle Figure 11. Attaching the Ribbon to the Take-up Core 6. Wrap the ribbon from the front of the printhead assembly to the top of the ribbon take-up spindle. Attach the ribbon to the take-up core on the ribbon take-up spindle with tape.

-

Page 19: Positioning The Air Jets

Positioning The Air Jets When a printed label is being fed from the SLPA onto the applicator pad, it must be held against the pad so that it can be properly positioned. The air jets located on the air jet tube direct air at the label while it is being fed, so that it does not bend or fall from the pad. -

Page 20: Calibrating The Printer

Chapter Calibrating The Printer FEED Position the lower media sensor in the grey shaded area. Avoid Pre-Printing Avoid Rounded Die Cut Label Corner Calibrating The Printer For printers not using smart labels, an Auto Calibrate should be sufficient to properly calibrate the printer (see next section). To calibrate printers that are using smart labels: 1. -

Page 21: Running Auto Calibrate

Running Auto Calibrate Running Auto Calibrate IMPORTANT Since manufacturing differences in media and ribbon can decrease the printer’s TOF (top-of-form) sensing reliability, you must run an Auto Calibrate to provide optimum sensor threshold values for the installed media and ribbon. 1. - Page 22 Chapter Calibrating The Printer...

-

Page 23: Control Panel

Control Panel The operation and system status of the SLPA are provided on the control panel. Information concerning the SLPA is displayed on the liquid crystal display (LCD), while commands are given to the SLPA through the control panel keypad. Control valves are provided for refined adjustments to the pneumatic system. -

Page 24: Lcd

Chapter The LCD is a 2 line by 16 character per line reflective display with a light emitting diode (LED) backlight. The LCD displays system information on the SLPA when performing system set-up procedures, print batch status during operation, and system information in a fault condition. Keypad The keypad is used to place the SLPA in operation, to perform calibration or testing, or to modify the systems operating parameters. - Page 25 Table 1. Control Panel Keys Indicator or Description Online Mode Offline Mode Menu Mode Print key Print key Prints the next None Scrolls left label in the through current – (decrease) key buffer. menu options. in Menu mode. Decreases option values in submenus.

-

Page 26: Key And Indicator Descriptions

Chapter Key and Indicator Descriptions Key and Indicator Descriptions For the locations of these keys and indicators, refer to Figure 13 on page 23. Online Status Indicator The SLPA is online when the Online status indicator light is on. When the SLPA is offline, the light is off. -

Page 27: Cancel Key

Menu Key and Data Indicator Light When the SLPA is either online or offline, the Menu key takes the SLPA offline and into Menu mode. In Menu mode, the Menu key scrolls through the Main menu of the SLPA’s operating system. It permits the operator to set or change various operating parameters. -

Page 28: Pneumatic Control Valves And Gauges

Chapter Pneumatic Control Valves And Gauges Pneumatic Control Valves And Gauges Air Cylinder Regulator NOTE: You may also adjust the cylinder delay time through the Applicator Delay menu. See “Applicator Delay Menu” on page 29. The air cylinder regulator (CYLINDER valve) is used to regulate the air to the applicator cylinder. -

Page 29: Applicator Delay Menu

Applicator Delay Menu ↵ With the SLPA online, press the key to enter the Applicator Delay menu. Press ↑ or ↓ to scroll through the submenus: Cycle Delay, Cylinder Extend, ↵ and Vacuum Delay. Press + or – to adjust the values. Press to set a new value. -

Page 30: Quick Setup Menu

Chapter QUICK SETUP Menu QUICK SETUP Menu QUICK SETUP Print Intensity –3* –15 to 15 Print Speed 6 ips* 2 to 10 ips Print Mode Transfer* Direct Media Handling Tear-Off Strip* Tear-Off Peel-Off Continuous Paper Feed Shift –0.50 to X inches 0.00 inches* 3, 5 Label Length... -

Page 31: Quick Setup Menu Items

QUICK SETUP Menu Items QUICK SETUP (cont. from previous page) Validator Funct. Enable* Disable Active IGP Emul IGP/PGL* PPI/ZGL PPI/TGL PPI/IGL PPI/STGL IGP/VGL Save Config. 1 to 8 Power-Up Config. Factory* 1 to 8 NOTE: Many QUICK SETUP menu items are available in other main menus. (Refer to the User’s Manual .) Changes made in the QUICK SETUP menu are updated in the other main menus, and vice versa. -

Page 32: Print Mode

Chapter QUICK SETUP Menu Print Mode This menu item specifies the type of printing to be done. • Transfer. Indicates thermal transfer printing (ribbon installed). • Direct. Indicates direct thermal printing (no ribbon) and requires special heat sensitive media. The default is Transfer, unless your printer is shipped as direct thermal only (no ribbon motors installed). -

Page 33: Label Length

QUICK SETUP Menu Items Label Length In most applications, the user-selected Label Length will match the physical label length. Physical label length is the actual label length of the media installed. Following is a list of different media types: • Die cut labels: measurable length of the removable label (leading edge to trailing edge). - Page 34 Chapter QUICK SETUP Menu 4 inches FEED 6 inches Leading Edge • Landscape. Landscape refers to horizontal orientation, where the width of a page is greater than its height. The top edge of the image is parallel to the left edge of the media. The following example is viewed from the front of the printer.

- Page 35 QUICK SETUP Menu Items Trailing Edge 4 inches The top edge of FEED the image is parallel to the trailing edge of the 6 inches media. Leading Edge • Inv. Landscape. Inverse Landscape refers to horizontal orientation, where the width of a page is greater than its height. The top edge of the image is parallel to the right edge of the media.

- Page 36 Chapter QUICK SETUP Menu • Gap. Select when using media with a liner space between die cut labels or when using tag stock with notches or holes as label length indicators on white background media. The top-of-form position is the leading edge of the die cut label (trailing edge of the gap, notch, or hole).

-

Page 37: Saving The Configuration

QUICK SETUP Menu Items Saving The Configuration After customizing your settings, save them as a configuration: 1. Press the key to enter the QUICK SETUP menu. 2. Press ↑ or ↓ until Save Config. / 1* displays. 3. If necessary, press + or – until the desired configuration displays. ↵... - Page 38 Chapter Loading A Saved Configuration...

-

Page 39: Printing And Applying Labels

Labels Printing And Applying Labels WARNING Printronix has provided the necessary guards and warnings within the confines of the SLPA, but cannot anticipate each customer’s individual installation and operational environments. It is the customer’s responsibility to provide in-house safety guards to provide adequate worker safety for their respective production settings. - Page 40 Chapter Printing And Applying Labels Flow Control Valve Air Shut Off Valve Figure 14. Return Speed Control Valve 2. Use the flow control valve (located on the air cylinder) to adjust the speed of the return stroke. (Figure 14.) Increase the speed by rotating the valve counterclockwise and decrease the speed by rotating the valve clockwise.

-

Page 41: Adjusting The Cylinder Extend Time

Adjusting The Cylinder Extend Time 4. Place the product sample on the conveyor and allow it move past the SLPA. The label that is applied will be used as a reference point for positioning the rest of the labels. 5. To move the label toward the leading edge of the product, decrease the Cycle Delay time. -

Page 42: The Print And Apply Process

Chapter Printing And Applying Labels • If the applicator pad remains on the product for too long (if the stroke time is too long): Decrease the Cylinder Extend time using the Applicator Delay menu. Begin by increasing the time in intervals of 6 msec, then fine tune in increments of 1 msec. -

Page 43: Preventive Maintenance And Cleaning

Never use metallic tools to clean the interior of the SLPA. Dust the exterior of the SLPA regularly. It is preferable to use a Printronix cleaning kit to clean the exterior of the SLPA, or a soft cloth dampened with isopropyl alcohol. - Page 44 Chapter Cleaning Pivoting Deck Printhead Heating Elements Printhead Cover/ Upper Media Sensor (not visible) Lower Media Sensor Deck Lock Lever Platen Rollers Print Element Upper Sensor Figure 15. Cleaning the Printhead...

-

Page 45: Cleaning The Printhead, Platen Roller And Media Sensors

Cleaning The Printhead, Platen Roller And Media Sensors Cleaning The Printhead, Platen Roller And Media Sensors Printhead Cleaning As you use your SLPA, the printhead may become dirty which can result in poor print quality. Clean the printhead each time you install new ribbon (thermal transfer print mode) or install new media (direct thermal print mode). -

Page 46: Cleaning The Applicator Pad

Chapter Cleaning Cleaning The Applicator Pad Hex Screw (4 or 6) Top Pad Gasket Bottom Pad Figure 16. The Applicator Pad Assembly The applicator pad must be clean to ensure that labels will properly dispense. Use isopropyl alcohol and a clean soft cloth. No other cleaning agent should be used to clean the applicator pad. -

Page 47: Cleaning/Replacing The Vacuum Generator

Cleaning/Replacing The Vacuum Generator Cleaning/Replacing The Vacuum Generator Air flow through the vacuum generator creates the vacuum for the applicator pad, allowing the label to be held in place. If the label is not retained on the pad and the pad has already been inspected for leaks, then the vacuum generator should be cleaned as follows. -

Page 48: Cleaning Schedule

Printhead Elements Weekly or as Wipe with a Printronix printhead cleaning pen or a needed cotton swab moistened with isopropyl alcohol. See Figure 15 on page 44. Printhead cleaning needs depend upon the print mode which is being used. -

Page 49: System Adjustments

Printhead Pressure Adjustment System Adjustments This portion of the manual covers all general aspects of printhead and system adjustment and replacement. Printhead Pressure Adjustment Right Pressure Block Right Pressure Left Pressure Block Pointer Block Lead Screw Knob Left Pressure Block Handle Bold Mark Printhead Pressure... -

Page 50: Printhead Pressure Block Adjustments

Chapter System Adjustments Printhead Pressure Block Adjustments These adjustments to the left and right pressure blocks are typically made when the print quality is not even across the surface of the label, and may be necessary when replacing the printhead. NOTE: Make no changes or adjustments while the SLPA is in operation. - Page 51 Positioning The Media Sensors The upper media sensor, located in the slot under the printhead cover (see Figure 18 on page 49), should be located directly over the lower media sensor. The lower media sensor should not be placed in the path of media features that could cause false gap detection or paper out faults.

-

Page 52: Sensing Different Media Types

Chapter System Adjustments Sensing Different Media Types The SLPA’s media sensors can detect the different types of label length indicators on a large variety of media types. This requires changes to the Gap/Mark Sensor menu item in the CALIBRATE CTRL menu: 1. - Page 53 Sensing Different Media Types Sensing Media with Horizontal Black Marks (Mark) Visible Red Beam from Lower Sensor Lower Sensor Black Mark (underside of media) Sensor Handle Media Guard Opening Figure 21. Media with Horizontal Black Marks Position the lower media sensor for detecting horizontal black marks located on the underside of media.

- Page 54 Chapter System Adjustments Sensing Media with Gaps, Notches, or Holes (Gap) Visible Red Beam from Lower Sensor Media Guard Opening Figure 22. Media with Gaps, Notches, or Holes Position the lower media sensor for detecting gaps, notches, or holes in media with a white background.

- Page 55 Sensing Different Media Types Sensing Media with Dark Background Labels with Gaps (Advanced Gap) Fixed Upper Sensor Visible Red Beam Lower Sensor Media Guard Opening Figure 23. Dark Background Media with Gaps NOTE: Ribbon is not displayed in this illustration. The upper and lower sensors are designed to function with or without ribbon installed.

- Page 56 Chapter System Adjustments Sensing Dark Background Media with Notches or Holes (Advanced Notch) Fixed Upper Sensor Visible Red Beam Lower Sensor Black line on underside of media Media Guard Opening Figure 24. Dark Background Media with Notches or Holes NOTE: Ribbon is not displayed in this illustration. The upper and lower sensors are designed to function with or without ribbon installed.

-

Page 57: Calibrating The Media Sensors

Calibrating The Media Sensors Calibrating The Media Sensors Due to manufacturing differences in media and ribbon, the media sensors may have difficulty differentiating between the label and the liner or the label and the black mark. When this occurs, the SLPA may intermittently skip a label or display a fault message such as GAP NOT DETECTED / See Manual or PAPER OUT / Load Paper. -

Page 58: Running Manual Calibrate

Chapter System Adjustments 5. Auto Calibrate is successful when the Sensed Distance value correctly matches that of the installed media: • Gap/Mark Sensor = Gap, Advanced Gap, or Advanced Notch: The Sensed Distance value is the physical length of one label plus the length of one gap, notch, or hole. - Page 59 Calibrating The Media Sensors If you try to do a Manual Calibrate when Peel-Off Media Handling is enabled, the LCD will display, CANNOT CALIBRATE / Disable Peel- Off. Before you can do a Manual Calibrate, you must select another media handling mode. 1.

- Page 60 Chapter System Adjustments...

-

Page 61: Illustrated Parts Breakdown

Illustrated Parts Breakdown Organization Of This Chapter This chapter contains drawings of the electromechanical assemblies comprising the SLPA. The table following each illustration lists the illustrated parts and their part numbers. Items marked “Ref” (reference) are not spared, are part of another assembly, or are shown elsewhere. - Page 62 Chapter 5 Illustrated Parts Breakdown Figure 25. Ribbon Drive Assembly...

- Page 63 Item Part No. Description Notes Ribbon Spindle Tube Ribbon Motor Spacer Ribbon Gear Drive Block External RR 0.250 inch Shaft (E Ring) Ring Ret Ext Ser 5304 0.375 D (E-Style) SHSS #10-32x0.375 Lg Flat Washer 1/4 inch SHCS M4 x 0.70 x 20 mm 172264-001 Field Kit, Ribbon Spindle, 4 inch 750569-001...

- Page 64 Chapter 5 Illustrated Parts Breakdown Figure 26. Pneumatic Assembly...

- Page 65 Item Part No. Description Notes Gauge Clamp Manifold, 1.250 inch Reg. Spacing 1/8 NPT Pipe Plug, Socket H Close Nipple 1/8 NPT 178631-001 Pressure Gauge, 100 psi 178632-001 Vacuum Gauge, 30 hg 1/4 x 0.159 Tubing-Blue Polyurethane 1/4 Tube 1/8 NPT Elbow #10 Male Elbow Fitting #10 Male Fitting Air Cyl.

- Page 66 Chapter 5 Illustrated Parts Breakdown Figure 27. Brake Assembly...

- Page 67 Item Part No. Description Notes Media Roller Sub-Assembly 178518-001 Brake Pad Brake Shaft Spring Post Block 4601 Brake Arm Ring Ret. Ext. Ser. 5100 0.375 D FHSCS #10-32x0.500 Lg BHCS #6-32x0.375 Lg SHCS #8-32x0.500 Lg SHCS #8-32x0.625 Lg Extension Spring 3.25 Lg Ball Bearing 0.375 ID x 0.875 OD Sleeve Bearing 3/8 inch ID x 7/16 inch OD x 3/8 inch Long...

- Page 68 Chapter 5 Illustrated Parts Breakdown Figure 28. 14 inch Cylinder Assembly...

- Page 69 Item Part No. Description Notes 178499-901 Cylinder Assy, Swing, 14 inch/356 mm Includes all items shown in Figure 28. Cylinder Cover, 14 inch Solid State Swith Assy, 14 inch Cylinder Bracker, 20 mm SHCS 1/4-20x0.750 Lg Washer Splitlock 0.250 BHCS M5x0.08x10mm Lg BHCS M6x1.00x12mm Lg SS FW M5 SS LW M5 SS...

- Page 70 Chapter 5 Illustrated Parts Breakdown...

- Page 71 Index Control panel status, keypad, 24 Control valves, pneumatic, 28 Adjustments CYLINDER control valve, 28 cylinder extend time, 41 Cylinder extend time adjustments, 41 label application, 39 media sensor, 50 pressure block, left, 50 Dark background labels with gaps, 55 pressure block, right, 50 Dark background media with notches or holes, 56 printhead pressure, 49...

- Page 72 Mode Applicator delay menu, 29 Key descriptions, 26 menu, 27 Keypad offline, 26 control panel status, 24 online, 26 functions, 24 indicators, 24 Notches, media sensing, 54 Numbers, part, replaceable parts, 61 Label application adjustments, 39 process, 42 Offline mode, 26 Label backing, remove, 7 Online mode, 26 Label Length option, 33...

- Page 73 Remove label backing, 7 Replacement parts, 61 Replacing vacuum generator, 47 Ribbon loading, 16 Right pressure block adjustment, 50 Roll, label threading, 8 Running auto calibrate, 57 manual calibrate, 58 Running auto calibrate, 21 Save Config. option, 36 Saving the configuration, 37 Schedule, cleaning, 48 Sensing different media types, 52 Spare parts and part numbers, 61...

- Page 76 For technical assistance, contact your Distributor/VAR/Reseller for service. For further assistance, contact the Printronix Customer Support Center. Printronix Customer Support Center Americas (714) 368-2686 Web site: http://www.printronix.com/public/servicessupport/default.aspx Printronix Supplier Center Americas (800) 733-1900 Web site: http://www.printronix.com/public/supplies/default.aspx Printronix, Inc. 14600 Myford Road P.O.

Need help?

Do you have a question about the SLPA7000e and is the answer not in the manual?

Questions and answers