Advertisement

Table of Contents

- 1 Table of Contents

- 2 General

- 3 Visual Check

- 4 Light Indicators and Audible Sound

- 5 Power Supply Adequacy

- 6 Kv-Verification

- 7 Tube Current Verification

- 8 Exposure Time Verification

- 9 Exposure Time Verification

- 10 Checking and Adjusting the X-Ray Beam for Panorama Exposure

- 11 Phantom Radiograph

- 12 Checking the Ear Olives

- 13 Checking the X-Ray Beam for Tele-Exposure

- 14 Checking the Laser Light Beam

- Download this manual

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Sirona Orthophos 3

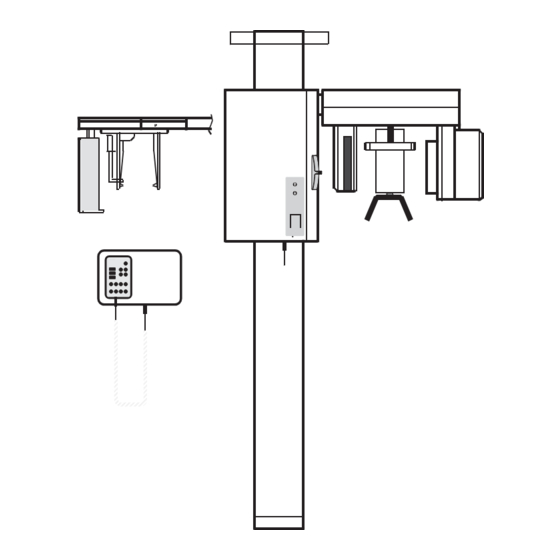

- Page 1 loqelmelp=P=L=P=`ÉéÜ j~áåíÉå~åÅÉ=fåëíêìÅíáçåë...

- Page 2 Maintenance Instructions Sirona Dental Systems GmbH ATTENTION ! Proper shielding of room and operator position is essential. Since these requirements vary from state to state it is the assembler's/installer's responsibility that all local radiation safety requirements are met. 59 01 603 D3285...

-

Page 3: Table Of Contents

Sirona Dental Systems GmbH Maintenance Instructions General ® To stay in compliance with the DHHS requirements the ORTHOPHOS 3 / 3 Ceph must be maintained an- nually following date of installation. It is the responsibility of the user to insure that the equipment is maintained with the manufacturer's recommended Maintenance Instructions to insure compliance with the Federal Performance Standard. -

Page 4: Visual Check

Verify that all labels are affixed and legible. Verify that all labels are affixed and legible. Defaced labels must be replaced. Defaced labels must be replaced. Order same from Sirona (address, see rear) Order same from Sirona (address, see rear) in writing stating: in writing stating:... -

Page 5: Light Indicators And Audible Sound

Sirona Dental Systems GmbH Maintenance Instructions Ceph-mode only X-RAY Unit ON LED Ready LED Multitimer Light Indicators , Audible Sound at the Multitimer at the Unit • Unit ON LED: Depress the main switch into the ” ” position to turn unit ON. - Page 6 Maintenance Instructions Sirona Dental Systems GmbH CAUTION RADIATION ! Radiation Observe indication Radiation Protection Guide Lines X-ray see Operating Instructions Exposure Multitimer X-RAY Ready LED Return key R • Make a panorama exposure: (diaphragm 1 is set at the diaphragm wheel) - X-ray head must be in the initial position (If not, press return key R).

-

Page 7: Power Supply Adequacy

Sirona Dental Systems GmbH Maintenance Instructions metal cover 6 screws 6.– 9. For details see Installation Instructions, same chapter or 300VAC Operating Instructions. Power Supply Adequacy • To determine power supply adequacy, the line voltage drop during exposure must be measured. -

Page 8: Kv-Verification

Maintenance Instructions Sirona Dental Systems GmbH 4.– 7. 20VDC com. For details see Operating Instructions. KV– KV – kV – Verification, kV–ramp during panoramic exposure • During exposure the kV is encreased in the central region depending on kV/mA selected up to 12%. - Page 9 Sirona Dental Systems GmbH Maintenance Instructions ramp 1.6s nominal 7.9 V nominal 7.2 V 4.1s±0.4s 7.3s±0.6s 5.65s±0.5s 11.3s complete P1 exposure time exposure time kV – ramp diagram with program P1 and 72kV/10mA set on the Multitimer. ATTENTION The kV - ramp can be changed at the customer’s request.

-

Page 10: Tube Current Verification

Maintenance Instructions Sirona Dental Systems GmbH 20mADC com. 4./6. MA – MA – jumper Tube Current Verification 1. Remove jumper from MA+/MA – test points on PC-board DX1. 2. Connect digital ammeter to MA+ and MA– and select range 20 mADC. -

Page 11: Exposure Time Verification

Sirona Dental Systems GmbH Maintenance Instructions No 1 Pulse counter 6./ 7. Multitimer com. 110VAC power receptacle Exposure Time Verification for Panorama Exposure • The diaphragm 1 for panorama exposure is still adjusted at the diaphragm wheel. 1. Connect test point T1 of terminal on PCB DX1 to L of 110V power receptacle. - Page 12 Maintenance Instructions Sirona Dental Systems GmbH Pulse counter Multitimer com. 110VAC power receptacle 59 01 603 D3285 D3285.103.04.02.02...

-

Page 13: Exposure Time Verification

Sirona Dental Systems GmbH Maintenance Instructions Exposure Time Verification for Tele – Exposure • The pulse counter is still connected as described on previous page. 1. Prepare unit for tele-exposure: Adjust diaphragm 3 for tele-exposure on the diaphragm wheel. Swing panorama cassette holder out of x-rax path. -

Page 14: Checking And Adjusting The X-Ray Beam For Panorama Exposure

Maintenance Instructions Sirona Dental Systems GmbH X-RAY Beam alignment tool Checking and Adjusting the X-Ray Beam 1. Place beam alignment tool vertically in the cassette carriage and move behind the slit cover plate. 2. Set the diaphragm 1 on the wheel. - Page 15 Sirona Dental Systems GmbH Maintenance Instructions Multitimer X-RAY X-RAY X-RAY 0 0 7 S. 0 I S. 0 2 2 – 4 – 1 Memory X-RAY X-RAY S.0 2 3.2 0 2. S23 twice • Select service routine S.02 at the Multitimer (X-ray head and cassette carriage remain stationary): 4.

- Page 16 Maintenance Instructions Sirona Dental Systems GmbH Wheel ε Correct position of X-ray beam FilmPAN X-RAY 15x30cm 6x12 in. 3.2 0 SID=49,7 • Darken the room. 10. Activate X-radiation to check correct position of X-ray beam. CAUTION RADIATION! • If X-ray beam is not in correct position adjust the X-ray beam position to the corresponding mark 1 of the alignment tool.

-

Page 17: Phantom Radiograph

Sirona Dental Systems GmbH Maintenance Instructions Cassette Paper Film Paper RADIATION Process film X-RAY exposed margin ±0.5mm ±1/50” 84 - 85.5mm Line distances 3 5/16” - 3 6/16” Phantom Radiograph • Diaphragm 1 is still adjusted at the diaphragm wheel. -

Page 18: Checking The Ear Olives

Maintenance Instructions Sirona Dental Systems GmbH Transparent cap small ball X-RAY Black cap 2.0 0 Checking the Ear Olives • Metal balls in the adjustment caps show up as dots on an exposed film. Both dots must coincide. 1. Attach an intraoral film with adhesive tape to the cassette holder. -

Page 19: Checking The X-Ray Beam For Tele-Exposure

Sirona Dental Systems GmbH Maintenance Instructions RADIATIO X-RAY 4.0 0 Left and lower On all sides an even margin unexposed unexposed margin. 1/8” +1/16” Checking the X-Ray Beam Positon for Tele – Exposure 1. Move the ear olive holder out of the X-ray beam path. -

Page 20: Checking The Laser Light Beam

The light beam must meet the FH line of a sheet of paper which is fixed in the head support. It must be moveable in the vertical direction by moving the laser module at the cover of ORTHOPHOS 3. Unwan- ted movement of the FH-light localizer is not permitted. - Page 21 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 22 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 23 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 24 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 25 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 26 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 27 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 28 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 29 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 30 loqelmelp=P=L=P=`ÉéÜ vÉ~êäó=j~áåíÉå~åÅÉ=`ÜÉÅâäáëí Customer: _________________________ Address: ________________________ Dealer: ____________________________ Address: ________________________ Date of original installation: ____________ Date of inspection: ________________ Report of Assembly FD 2579 # _________ _______ ___________________________________ Remarks SCHEDULE All manuals are present Test instruments as required Manufacturer Model Accuracy Last calibrated Voltmeter...

- Page 32 «=páêçå~=aÉåí~ä=póëíÉãë=dãÄe=NVVU mêáåíÉÇ=áå=dÉêã~åó aPOURKNMPKMQKMOKMO====MPKOMMV ûJkêKW=NNN=NRU fãéêáã¨=Éå=^ääÉã~ÖåÉ páêçå~=aÉåí~ä=póëíÉãë=dãÄe áå=íÜÉ=rp^W RV=MN=SMP==aPOUR c~Äêáâëíê~≈É=PN páêçå~=aÉåí~ä=póëíÉãë=ii` lêÇÉê=kç SQSOR=_ÉåëÜÉáã QUPR=páêçå~=aêáîÉI=pìáíÉ=NMM dÉêã~åó `Ü~êäçííÉI=k`=OUOTP ïïïKëáêçå~KÅçã...

Need help?

Do you have a question about the Orthophos 3 and is the answer not in the manual?

Questions and answers

what type of lubricant is required on the screw shaft that controls the height of machine for sirona orthophos3.