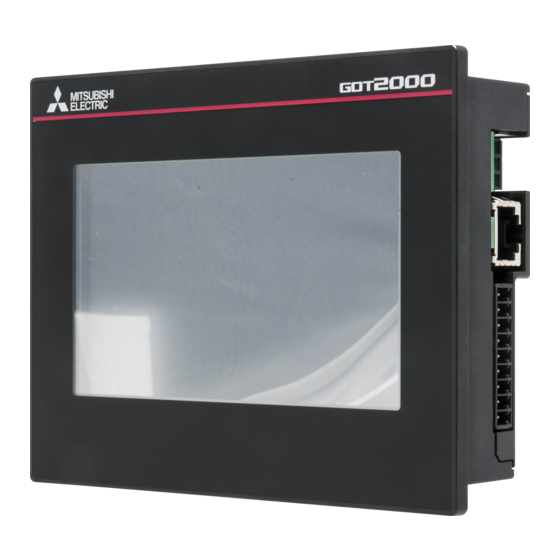

Mitsubishi GOT2000 Series Connection Manual

Graphic operation terminal

Hide thumbs

Also See for GOT2000 Series:

- User manual (520 pages) ,

- Supplementary description (2 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

GRAPHIC OPERATION TERMINAL

GOT2000

Connection Manual

(Mitsubishi Product)

For GT Works3 Version1

■ETHERNET CONNECTION

■DIRECT CONNECTION TO CPU

■COMPUTER LINK CONNECTION

■BUS CONNECTION

■MELSECNET/H CONNECTION,

MELSECNET/10 CONNECTION

■CC-Link IE CONNECTION

■CC-Link CONNECTION

■INVERTER CONNECTION

■SERVO AMPLIFIER CONNECTION

Series

■ROBOT CONTROLLER CONNECTION

■CNC CONNECTION

■INSTRUMENT CONNECTION

■GOT MULTI-DROP CONNECTION

■MULTI-CHANNEL FUNCTION

■FA TRANSPARENT FUNCTION

Advertisement

Chapters

Table of Contents

Summary of Contents for Mitsubishi GOT2000 Series

- Page 1 GRAPHIC OPERATION TERMINAL GOT2000 Series Connection Manual (Mitsubishi Product) For GT Works3 Version1 ■ETHERNET CONNECTION ■ROBOT CONTROLLER CONNECTION ■DIRECT CONNECTION TO CPU ■CNC CONNECTION ■COMPUTER LINK CONNECTION ■INSTRUMENT CONNECTION ■BUS CONNECTION ■GOT MULTI-DROP CONNECTION ■MELSECNET/H CONNECTION, ■MULTI-CHANNEL FUNCTION MELSECNET/10 CONNECTION ■FA TRANSPARENT FUNCTION...

-

Page 3: Safety Precautions

SAFETY PRECAUTIONS (Always read these precautions before using this equipment.) Before using this product, please read this manual and the relevant manuals introduced in this manual carefully and pay full attention to safety to handle the product correctly. The precautions given in this manual are concerned with this product. In this manual, the safety precautions are ranked as "WARNING"... - Page 4 [DESIGN PRECAUTIONS] WARNING If a communication fault (including cable disconnection) occurs during monitoring on the GOT, communication between the GOT and PLC CPU is suspended and the GOT becomes inoperative. For bus connection (GT27 Only) : The CPU becomes faulty and the GOT becomes inoperative. For other than bus connection : The GOT becomes inoperative.

- Page 5 [MOUNTING PRECAUTIONS] CAUTION Use the GOT in the environment that satisfies the general specifications described in this manual. Not doing so can cause an electric shock, fire, malfunction or product damage or deterioration. When mounting the GOT to the control panel, tighten the mounting screws in the specified torque range (0.36 N m to 0.48 N m) with a Phillips-head screwdriver No.2.

- Page 6 [WIRING PRECAUTIONS] CAUTION Use applicable solderless terminals and tighten them with the specified torque. If any solderless spade terminal is used, it may be disconnected when the terminal screw comes loose, resulting in failure. Correctly wire the GOT power supply section after confirming the rated voltage and terminal arrangement of the product.

- Page 7 Before touching the unit, always touch grounded metals, etc. to discharge static electricity from human body, etc. Not doing so can cause the unit to fail or malfunction. Use the battery manufactured by Mitsubishi Electric Corporation. Use of other batteries may cause a risk of fire or explosion. Dispose of used battery promptly.

- Page 8 [TOUCH PANEL PRECAUTIONS] CAUTION For the analog-resistive film type touch panels, normally the adjustment is not required. However, the difference between a touched position and the object position may occur as the period of use elapses. When any difference between a touched position and the object position occurs, execute the touch panel calibration.

- Page 9 When disposing of this product, treat it as industrial waste. When disposing of batteries, separate them from other wastes according to the local regulations. (Refer to the GOT2000 Series User’s Manual (Hardware) for details of the battery directive in the EU member states.)

-

Page 10: Table Of Contents

INTRODUCTION Thank you for choosing Mitsubishi Graphic Operation Terminal (Mitsubishi GOT). Read this manual and make sure you understand the functions and performance of the GOT thoroughly in advance to ensure correct use. CONTENTS SAFETY PRECAUTIONS .........................A - 1 INTRODUCTION ............................A - 8 CONTENTS ..............................A - 8... - Page 11 MELSEC-L............................. 2 - 10 MELSEC-A ............................ 2 - 11 MELSEC-FX ..........................2 - 12 MELSEC-WS ..........................2 - 13 3. ACCESS RANGE FOR MONITORING Access Range for Monitoring Stations on Network Systems............3 - 2 3.1.1 MELSECNET/H, MELSECNET/10, CC-Link IE Controller Network, CC-Link IE Field Network .....................

- Page 12 5. ETHERNET CONNECTION Connectable Model List ........................5 - 2 5.1.1 PLC/Motion controller CPU....................5 - 2 5.1.2 Ethernet module ........................5 - 6 System Configuration ........................5 - 7 5.2.1 Connection to Ethernet module .................... 5 - 7 5.2.2 Connection to Built-in Ethernet port CPU or C Controller module ........

- Page 13 7. COMPUTER LINK CONNECTION Connectable Model List ........................7 - 2 7.1.1 PLC/Motion controller CPU ....................7 - 2 7.1.2 Serial communication module/Computer link module ............7 - 6 System Configuration ........................7 - 7 7.2.1 Connecting to QCPU (Q mode) .................... 7 - 7 7.2.2 Connecting to LCPU ......................

- Page 14 8.4.12 When connecting multiple GOTs ..................8 - 40 8.4.13 When using a PLC CPU in the direct mode................ 8 - 40 8.4.14 When connecting to a Q4ARCPU redundant system ............8 - 41 8.4.15 When monitoring the Q170MCPU, Q170MSCPU(-S1) ............8 - 41 8.4.16 Troubleshooting ........................

- Page 15 11.2.1 Connecting to CC-Link IE Field Network communication unit ..........11 - 8 11.3 GOT side settings .......................... 11 - 9 11.3.1 Setting communication interface (Communication settings)..........11 - 9 11.3.2 Communication detail settings.................... 11 - 9 11.3.3 Routing parameter setting ....................11 - 10 11.4 PLC Side Setting .........................

- Page 16 13.6 Precautions ..........................13 - 18 MITSUBISHI FA DEVICE CONNECTIONS 14. INVERTER CONNECTION 14.1 Connectable Model List ......................... 14 - 2 14.2 System Configuration ........................14 - 3 14.2.1 Connecting to FREQROL-A500/A500L/F500/F500L/V500/V500L ........14 - 3 14.2.2 Connecting to FREQROL-E500/S500/S500E/F500J/D700/F700PJ ........14 - 6 14.2.3...

- Page 17 15.5.1 Connecting to the MELSERVO-J2-Super Series ............. 15 - 14 15.5.2 Connecting to the MELSERVO-J2M Series ..............15 - 15 15.5.3 Connecting to the MELSERVO-J4,J3, JE Series ............. 15 - 16 15.5.4 Station number setting...................... 15 - 16 15.6 Device Range that Can Be Set....................15 - 17 15.7 Precautions..........................

- Page 18 MULTIPLE GOT CONNECTIONS 18. GOT MULTI-DROP CONNECTION 18.1 CPU that can be Monitored ......................18 - 2 18.2 Connectable Model List ......................... 18 - 3 18.3 System Configuration ........................18 - 13 18.4 Connection Diagram ........................18 - 14 18.4.1 RS-485 cable ........................

- Page 19 20.4.6 FX Configurator-FP, FX3U-ENET-L Configuration tool ............ 20 - 29 20.4.7 RT ToolBox2........................20 - 29 20.4.8 NC Configurator........................ 20 - 30 20.5 GOT Side Settings........................20 - 31 20.5.1 Setting communication interface ..................20 - 31 20.6 Personal Computer Side Setting ....................20 - 34 20.6.1 Accessing the PLC by the PX Developer, GX Configurator ..........

-

Page 20: List Of Manuals For Gt Works3

List of Manuals for GT Works3 For the manuals related to this product, install the manuals with the drawing software. If you need a printed manual, consult your local Mitsubishi representative or branch office. ■ . List of Manuals for GT Designer3(GOT2000) -

Page 21: Abbreviations And Generic Terms

Abbreviations and generic terms Description GT2712-S GT2712-STBA, GT2712-STWA, GT2712-STBD, GT2712-STWD GT2710-S GT2710-STBA, GT2710-STBD GT27 GT2710-V GT2710-VTBA, GT2710-VTWA, GT2710-VTBD, GT2710-VTWD GT2708-S GT2708-STBA, GT2708-STBD GOT2000 Series GT2708-V GT2708-VTBA, GT2708-VTBD GT2310-V GT2310-VTBA, GT2310-VTBD GT23 GT2308-V GT2308-VTBA, GT2308-VTBD GT SoftGOT2000 GT SoftGOT2000 Version1 GOT1000 Series... - Page 22 SW1DND-GTW3-C GT Designer3 Version1 Screen drawing software GT Designer3 for GOT2000/GOT1000 series GT Designer3 Screen drawing software for GOT2000 series included in GT Works3 GT Designer3 (GOT2000) GT Designer3 (GOT1000) Screen drawing software for GOT1000 series included in GT Works3...

- Page 23 (3) Other software Abbreviations and generic terms Description SW□DNC-GXW2-J (-JA, -JAZ) type programmable controller engineering GX Works2 software (□ indicates a version.) GX Simulator2 GX Works2 with the simulation function SW□D5C-LLT-J (-JV) type ladder logic test tool function software package GX Simulator (SW5D5C-LLT (-V) or later versions) (□...

- Page 24 ■ . Others Abbreviations and generic terms Description IAI Corporation AZBIL Azbil Corporation OMRON OMRON Corporation KEYENCE KEYENCE CORPORATION KOYO EI KOYO ELECTRONICS INDUSTRIES CO., LTD. JTEKT JTEKT Corporation SHARP Sharp Manufacturing Systems Corporation SHINKO Shinko Technos Co., Ltd. CHINO CHINO CORPORATION TOSHIBA TOSHIBA CORPORATION...

-

Page 25: Preparatory Procedures For Monitoring

PREPARATORY PROCEDURES FOR MONITORING 1.1 Setting the Communication Interface ....1 - 3 1.2 Writing the Package Data onto the GOT ....1 - 13 1.3 Option Devices for the Respective Connection . - Page 26 PREPARATORY PROCEDURES FOR MONITORING The following shows the procedures to be taken before monitoring and corresponding reference sections. Setting the communication interface 1.1Setting the Communication Interface Determine the connection type and channel No. to be used, and Each chapter GOT Side Settings perform the communication setting.

-

Page 27: Setting The Communication Interface

1.1 Setting the Communication Interface Set the communication interface of GOT and the connected equipment. When using the GOT at the first time, make sure to set the channel of communication interface and the communication driver before writing to GOT. Set the communication interface of the GOT at [Controller Setting] and [I/F Communication Setting] in GT Designer3. -

Page 28: Setting Connected Equipment (Channel Setting)

Channel No.2 to No.4 Use the channel No.2 to No.4 when using the Multi-channel function. For details of the Multi-channel function, refer to the following. Mitsubishi Products 19. MULTI-CHANNEL FUNCTION 1 - 4 1. PREPARATORY PROCEDURES FOR MONITORING 1.1 Setting the Communication Interface... - Page 29 Setting item This section describes the setting items of the Manufacturer, Controller Type, Driver and I/F. When using the channel No.2 to No.4, put a check mark at [Use CH*]. Item Description Use CH* Select this item when setting the channel No.2 to No.4. Manufacturer Select the manufacturer of the equipment to be connected to the GOT.

- Page 30 (2) Setting [Controller Type] The types for the selection differs depending on the PLC to be used. For the settings, refer to the following. Type Model name Type Model name CNC C70 Q00CPU (Q173NCCPU) Q01CPU CRnQ-700 Q02CPU (Q172DRCPU) Q02HCPU CR750-Q Q06HCPU MELSEC-Q/QS, Q17nD/M/NC/DR, CRnD-700 (Q172DRCPU)

- Page 31 Type Model name Type Model name A1FXCPU A2UCPU A273UCPU A2UCPU-S1 A273UHCPU A3UCPU A273UHCPU-S3 A4UCPU A373UCPU A2ACPU A373UCPU-S3 A2ACPUP21 A171SCPU A2ACPUR21 MELSEC-A A171SCPU-S3 A2ACPU-S1 A171SCPU-S3N A2ACPUP21-S1 A171SHCPU A2ACPUR21-S1 A171SHCPUN A3ACPU A172SHCPU A3ACPUP21 A172SHCPUN A3ACPUR21 A173UHCPU A1NCPU A173UHCPU-S1 A1NCPUP21 A1NCPUR21 A2NCPU A2NCPUP21 A2NCPUR21 A2NCPU-S1 A2NCPUP21-S1...

- Page 32 Type Model name FREQROL-S500 FREQROL-S500E FREQROL-E500 FREQROL-F500 FREQROL-F500L FREQROL-F500J FREQROL-A500 FREQROL-A500L FREQROL-V500 FREQROL 500/700/800, FREQROL-V500L SENSORLESS SERVO FREQROL-D700 FREQROL-E700 FREQROL-F700 FREQROL-F700P FREQROL-F700PJ FREQROL-A700 FREQROL-A800 FREQROL-F800 FREQROL-E700EX FREQROL-A800 FREQROL 800 (Automatic Negotiation) FREQROL-F800 1 - 8 1. PREPARATORY PROCEDURES FOR MONITORING 1.1 Setting the Communication Interface...

- Page 33 (3) Setting [I/F] The interface differs depending on the GOT to be used. Set the I/F according to the connection and the position of communication unit to be mounted onto the GOT. Extension interface 3rd stage Standard interface 4 (Ethernet interface built in the GOT) Standard interface 1 (RS-232 interface built in the GOT) 2nd stage...

-

Page 34: I/F Communication Setting

1.1.2 I/F communication setting This function displays the list of the GOT communication interfaces. Set the channel and the communication driver to the interface to be used. Setting Select [Common] [I/F Communication Setting] from the menu. The I/F Communication Setting dialog box appears. Make the settings with reference to the following explanation. POINT POINT POINT... - Page 35 Setting item The following describes the setting items for the standard I/F setting and extension I/F setting. Item Description Standard I/F setting Set channel No. and drivers to the GOT standard interfaces. Set the CH No. according to the intended purpose. 0: Not used 1 to 4: Used for connecting a controller of channel No.

-

Page 36: Precautions

Use the channel No.2 to No.4 when using the Multi-channel function. For details of the Multi-channel function, refer to the following. Mitsubishi Products 19. MULTI-CHANNEL FUNCTION (2) Drivers The displayed items for a driver differ according to the settings [Manufacturer], [Controller Type] and [I/F]. -

Page 37: Writing The Package Data Onto The Got

1.2 Writing the Package Data onto the GOT Write the package data onto the GOT. For details on writing to GOT, refer to the following help. GT Designer3 (GOT2000) Help 1.2.1 Writing the Package Data onto the GOT Select [Communication] [Write to GOT…] from the menu. -

Page 38: Checking The Package Data Writing On Got

1.2.2 Checking the package data writing on GOT Confirm if the package data is properly written onto the GOT by reading from GOT using GT Designer3. For reading from the GOT, refer to the following help. GT Designer3 (GOT2000) Help Select [Communication] [Read from GOT…] from the menu. -

Page 39: Option Devices For The Respective Connection

1.3 Option Devices for the Respective Connection The following shows the option devices to connect in the respective connection type. For the specifications, usage and connecting procedure on option devices, refer to the respective device manual. 1.3.1 Communication module Product name Model Specifications For QCPU (Q mode), motion controller CPU (Q series) -

Page 40: Option Unit

Supplied connection cable dedicated for the conversion unit FA-LTBGT2R4CBL20 1.3.4 Serial Multi-Drop Connection Unit Product name Model Specifications GOT multi-drop connection module Serial multi-drop GT01-RS4-M connection unit Mitsubishi Products17. CNC CONNECTION 1 - 16 1. PREPARATORY PROCEDURES FOR MONITORING 1.3 Option Devices for the Respective Connection... -

Page 41: Installing A Unit On Another Unit (Checking The Unit Installation Position)

For the installation method of each unit, refer to the User's Manual for the communication unit and option unit you are using. For the method for installing a unit on another unit, refer to the following. GOT2000 Series User's Manual (Hardware) When using a bus connection unit The installation position varies depending on the bus connection unit to be used. - Page 42 When using a MELSECNET/H communication unit, CC-Link IE Controller Network communication unit, CC-Link IE Field Network communication unit, or CC-Link communication unit (GT15-J61BT13) Install a MELSECNET/H communication unit, CC-Link IE Controller Network communication unit, CC-Link IE Field Network communication unit, or CC-Link communication unit in the 1st stage of an extension interface. If a bus connection unit is installed in the 2nd stage or above, the unit cannot be used.

- Page 43 When using the video input unit, RGB input unit, video/RGB input unit, RGB output unit, or multimedia unit Install the video input unit, RGB input unit, video/RGB input unit, RGB output unit, or multimedia unit at the 1st stage of the extension interface.

-

Page 44: Connection Cables For The Respective Connection

1.4 Connection Cables for the Respective Connection To connect the GOT to a device in the respective connection type, connection cables between the GOT and a device are necessary. For cables needed for each connection, refer to each chapter for connection. 1.4.1 GOT connector specifications The following shows the connector specifications on the GOT side. -

Page 45: Coaxial Cableconnector Connection Method

1.4.2 Coaxial cableconnector connection method The following describes the method for connecting the BNC connector (connector plug for coaxial cable) and the cable. CAUTION Solder the coaxial cable connectors properly. Insufficient soldering may result in malfunctions. Components of the BNC connector Structure of the coaxial cable External conductor Outer sheath... -

Page 46: Terminating Resistors Of Got

1.4.3 Terminating resistors of GOT The following shows the terminating resistor specifications on the GOT side. When setting the terminating resistor in each connection type, refer to the following. RS-422/485 communication unit GT27 Set the terminating resistor using the terminating Set the terminating resistor using the terminating resistor setting switch. -

Page 47: Verifying Got Recognizes Connected Equipment

• Channel number of communication interface, communication drivers allocation status • Communication unit installation status For details on the Utility, refer to the following manual. GOT2000 Series User's Manual (Utility) After powering up the GOT, touch [GOT basic set] [Controller] from the Utility. - Page 48 When setting [Pressing time] to other than 0 second on the setting screen of the utility call key, press and hold the utility call key until the buzzer sounds. For the setting of the utility call key, refer to the following. GOT2000 Series User's Manual (Utility) (3) Communication interface setting by the Utility The communication interface setting can be changed on the Utility's [Communication setting] after writing [Communication Settings] of project data.

-

Page 49: Checking For Normal Monitoring

Presetting the system alarm to project data allows you to identify errors occurred on the GOT, PLC CPU, servo amplifier and communications. For details on the operation method of the GOT Utility screen, refer to the following manual. GOT2000 Series User's Manual (Utility) Error code Communication Channel No. - Page 50 • Display the I/O check screen by [Maintenance] [I/O check]. For details on the I/O check, refer to the following manual: GOT2000 Series User's Manual (Utility) Touch [CPU] on the I/O check screen. Touching [CPU] executes the communication check with the connected PLC.

- Page 51 Utility screen of the GOT. For details on the operation method of the GOT Utility screen, refer to the following manual. GOT2000 Series User's Manual (Utility) (2) For CC-Link IE Controller Network system The communication status between the GOT and CC-Link IE Controller Network can be confirmed by the utility screen of the GOT.

- Page 52 GOT. For details on the operation method of the GOT Utility screen, refer to the following manual. GOT2000 Series User's Manual (Utility) (4) For CC-Link system The communication status between the GOT and the CC-Link System can be confirmed by the Utility screen of the GOT.

-

Page 53: Confirming The Communication State On The Got Side (For Ethernet Connection)

1.6.2 Confirming the communication state on the GOT side (For Ethernet connection) ® Confirming the communication state on Windows , GT Designer3 ® (1) When using the Command Prompt of Windows ® Execute a Ping command at the Command Prompt of Windows (a) When normal communication C:\>Ping 192.168.3.18 Reply from 192.168.3.18: bytes=32 time<1ms TTL=64... - Page 54 [PING Test] can be confirmed by the Utility screen of the GOT. For details on the operation method of the GOT Utility screen, refer to the following manual. GOT2000 Series User's Manual (Utility) 1 - 30 1. PREPARATORY PROCEDURES FOR MONITORING...

-

Page 55: Confirming The Communication State To Each Station (Station Monitoring Function)

1.6.3 Confirming the communication state to each station (Station monitoring function) The station monitoring function detects the faults (communication timeout) of the stations monitored by the GOT. When detecting the abnormal state, it allocates the data for the faulty station to the GOT special register (GS). (1) No. - Page 56 (2) Faulty station information The bit corresponding to the faulty station is set. (0: Normal, 1: Abnormal) The bit is reset after the fault is recovered. (a) Ethernet connection (Except for Ethernet multiple connection) GS231 bit 0 GS231 bit 1 GS231 bit 2 GS231 bit 3 Station number...

-

Page 57: Check On Gx Developer

1.6.4 Check on GX Developer Check if the PLC CPU recognizes the GOT (For bus connection) (QCPU (Q mode) only) Using the [System monitor] of GX Developer, check if the PLC CPU recognizes the GOT or not. For the GX Developer operation method, refer to the following manual. GX Developer Version Operating Manual (1) Check the Module Name, I/O Address and Implementation Position. - Page 58 Checking the wiring state (For optical loop system only) Check if the optical fiber cable is connected correctly in [Loop test] of GX Developer. For the GX Developer operation method, refer to the following manual. Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network) (1) Check the [Receive direction error station] (The display example on GX Developer Version 8) Startup procedure GX Developer...

- Page 59 Checking if the GOT is performed the data link correctly (1) For MELSECNET/H, MELSECNET/10 network system Check if the GOT is performed the data link correctly in [Other station information]. For the GX Developer operation method, refer to the following manual. Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network) (a) Check [Communication status of each station] and [Data-Link status of each station] (The display example on GX Developer Version 8)

- Page 60 (2) For CC-Link IE Controller Network system Use [CC IE Control diagnostics…] of GX Developer to check if the GOT is correctly performed the data link. For the GX Developer operation method, refer to the following manual. CC-Link IE Controller Network Reference Manual (a) Check the [Select station network device status display] (The display example on GX Developer Version 8) Startup procedure GX Developer...

-

Page 61: Check On Gx Works2

1.6.5 Check on GX Works2 For CC-Link IE Controller Network system Use [CC IE Field diagnostics] of GX Works2 to check if the GOT is correctly performed the data link. For the GX Works2 operation method, refer to the following manual. MELSEC-Q CC-Link IE Field Network Master/Local Module User's Manual Startup procedure GX Works2... - Page 62 1 - 38 1. PREPARATORY PROCEDURES FOR MONITORING 1.6 Checking for Normal Monitoring...

-

Page 63: Mitsubishi Plc Connections

MITSUBISHI PLC CONNECTIONS DEVICE RANGE THAT CAN BE SET ....2 - 1 ACCESS RANGE FOR MONITORING ....3 - 1 HOW TO MONITOR REDUNTANT SYSTEM . -

Page 65: Device Range That Can Be Set

DEVICE RANGE THAT CAN BE SET MELSEC-Q/QS, Q17nD/M/NC/DR, CRnD-700 ..2 - 8 MELSEC-QnA, MELDAS C6 * ..... . 2 - 9 MELSEC-L . -

Page 66: Device Range That Can Be Set

DEVICE RANGE THAT CAN BE SET The device ranges that can be set for the Mitsubishi PLCs are as follows. Note that the device ranges in the following tables are the maximum values that can be set in GT Designer3. - Page 67 Setting item When selecting buffer memory (G) with the following controllers MELSEC-QnU/DC, Q17nD/M/NC/DR, CRnD-700 MELSEC-L MELSEC-QnA/Q/QS, MELDAS C6 * MELSEC-Q(MULTI)/Q MOTION (For MELSEC-Q/QS, Q17nD/M/NC/DR, CRnD-700) (For MELSEC-FX) Item Description Set the device name, device number, and bit number. The bit number can be set only by specifying the bit of word device. When setting buffer memory (BM) and (G), set the buffer memory address in the space for the device number.

- Page 68 (For device BM and CPU No. 1 to 4) (1) Setting of the CPU No. (a) When monitoring a single CPU system Set to 0. (b) When monitoring a multiple CPU system Set the CPU No. (0 to 4) in [CPU No.] when Device number monitoring a multiple CPU system.

- Page 69 (c) Mask type 2 (4) Setting of the mask type (MELSEC-FX) • (For 16 bits) Set the item for monitoring or writing only the specified Monitor and write only b4 to b7 of the buffer bits of the buffer memory. memory.

- Page 70 • (For 32 bits) (f) Mask type 5 Monitor and write only b8 to b11 and b28 to 31 of • (For 16 bits) the buffer memory. Monitor and write only b0 to b7 of the buffer Example: memory. The monitor value is 00070003 when monitoring Example: BM0=87654321...

- Page 71 • (For 32 bits) Monitor and write only b8 to b15 and b24 to 31 of the buffer memory. Example: The monitor value is 00870043 when monitoring BM0=87654321 as mask type 6. Monitor value BM0=65002100 when writing input value 87654321 to BM0=00000000 as mask type 6.

- Page 72 2.1 MELSEC-Q/QS, Q17nD/M/NC/DR, CRnD-700 The table below shows the device ranges in [MELSEC-Q/ Do not set a file register by GT Designer3 when executing QS, Q17nD/M/NC/DR, CRnD-700] as the controller type. multiple programs with the file of the file register set at [Use the same file name as the program] by the PLC parameter of Device No.

- Page 73 2.2 MELSEC-QnA, MELDAS C6 * The device ranges that can be set when selecting Do not set a file register by GT Designer3 when executing [MELSEC-QnA/, MELDAS C6*] as the controller type are multiple programs with the file of the file register set at [Use as follows.

-

Page 74: Melsec-L

2.3 MELSEC-L The device ranges that can be set when selecting Do not set a file register by GT Designer3 when executing [MELSEC-L] as the controller type are as follows. multiple programs with the file of the file register set at [Use the same file name as the program] by the PLC parameter of Device No. -

Page 75: Melsec-A

2.4 MELSEC-A The device ranges that can be set when selecting [MELSEC-A] as the controller type are as follows. (2) For GOT MULTI-DROP CONNECTION (1) For GT27 Device No. Device name Setting range representation Device No. Device name Setting range Input (X) X1FFF representation... -

Page 76: Melsec-Fx

2.5 MELSEC-FX The device ranges that can be set when selecting If using the 16 bit specification for a buffer memory of 32 bit data, monitoring and writing [MELSEC-FX] as the controller type are as follows. may not be executed normally. Device No. -

Page 77: Melsec-Ws

2.6 MELSEC-WS The device ranges that can be set when selecting • EFI output(EQ) [MELSEC-WS] as the controller type are as follows. Device No. Device Setting range representation Input (I) I1.1 I12.8 Device Byte number(0 to 2) name Output (Q) Q1.1 Q12.8 Decimal... - Page 78 Engineering software for Device GT Designer3 MELSEC-WS (0-1): Word number GOT independent device Word virtualization of LD (Not available) device LW0= (LD1(Upper bits), LD0(Lower bits)) When the mapping position is changed by the MELSEC-WS engineering software, a mismatch occurs between virtual devices on GOT and MELSEC-WS mapping devices.

- Page 79 (f) EFI output(EQ) (4) When using offset specification Offset +3 to +15 When setting devices using the offset function, the EQ10 EQ11 EQ12 device values are as follows. Fixed to 0 (a) Input(I) Fixed to 0 +240 Offset +8 to +15 +256 EQ20 EQ21...

- Page 80 2 - 16 2. DEVICE RANGE THAT CAN BE SET 2.6 MELSEC-WS...

-

Page 81: Access Range For Monitoring

ACCESS RANGE FOR MONITORING 3.1 Access Range for Monitoring Stations on Network Systems ..........3 - 2 3.2 Access Range for Monitoring when Using Ethernet Connection . -

Page 82: Access Range For Monitoring Stations On Network Systems

ACCESS RANGE FOR MONITORING 3.1 Access Range for Monitoring Stations on Network Systems 3.1.1 MELSECNET/H, MELSECNET/10, CC-Link IE Controller Network, CC-Link IE Field Network Bus connection (1) When connecting to multiple CPU system • The GOT can monitor the control station and all the normal stations on the Control station network. - Page 83 (2) When connecting to QCPU (Q mode)/QnACPU/AnUCPU • The GOT can monitor the control station and all the normal stations on the Control network. station Normal Normal station station Normal station • The GOT can monitor the control station and all the normal Control Control stations on other networks.

- Page 84 Direct CPU connection/computer link connection (1) When connecting to multiple CPU system • Corresponding to the access range described in ■ Bus connection (1). (2) When connecting to QCPU (Q mode)/QnACPU • Corresponding to the access range described in ■ Bus connection (2). (3) When connecting to QCPU (A mode)/AnUCPU •...

- Page 85 MELSECNET/H connection, MELSECNET/10 connection, CC-Link IE Controller Network connection, CC-Link IE Field Network connection POINT POINT POINT Precautions for cyclic transmission When transmitting cyclic transmission with a GOT, even if link device X and/or Y are assigned to a GOT when setting the network parameter for the control station, the GOT cannot access the host station.

- Page 86 POINT POINT POINT Precautions when using the QCPU redundant system When monitoring other networks, do not set the QCPU redundant system as a relay station. If the QCPU redundant system is set as a relay station, the GOT cannot switch the monitoring target automatically when the system is switched.

- Page 87 Monitor accessible range of other stations and setting method of monitor devices Example 1: When using bus connection Control station Control station (1-1) (2-1) Network No.1 (1-4) Network No.2 (1-2) (2-4) (2-2) (1-3) (2-3) • Monitor accessible range of devices (other than B or W) of other stations or other networks Specify the accessing network No.

- Page 88 Example 2: When using bus connection Control station Control station (1-1) (2-1) Network No.1 Network No.2 (2-4) (1-3) (2-2) (2-3) (1-2) Data link system (L1) (L2) • Monitor accessible range of devices (other than B or W) of other stations or other networks Specify the accessing network No.

- Page 89 Example 3: When using CPU direct connection or computer link connection Control station Control station (1-1) (2-1) Q(Q mode) Network No.1 (1-4) Network No.2 (1-2) (2-4) (2-2) (1-3) (2-3) • Monitor accessible range of devices (other than B or W) of other stations or other networks Specify the accessing network No.

- Page 90 Example 4: When using CPU direct connection or computer link connection Control station Control station Q(Q mode) (1-1) (2-1) Network No.1 Network No.2 (2-4) (1-3) (2-2) (2-3) (1-2) Data link system (L1) (L2) • Monitor accessible range of devices (other than B or W) of other stations or other networks Specify the accessing network No.

- Page 91 Example 5: When using MELSECNET/10 connection Q (Q mode) (1-1) (2-1) Q (Q mode) Network No. 1 Network No. 2 (1-4) (1-2) (2-2) (2-4) (2-3) (1-3) • Monitor access range for other station devices (other than B and W) Station to be accessed Network No.1 Network No.2 Q (Q mode)

- Page 92 Example 6: When using CC-Link connection (intelligent device station) /CC-Link connection (via G4) Image of CC-Link Connection Network module CC-Link Master Q(Q mode ) (1-2) module (0 station) (1-2) CC-Link System A nA (1-3) (1-1) Network System (1-4) Station to be accessed Q (Q mode) Station (1-1)

-

Page 93: Access Range For Monitoring When Using Ethernet Connection

Connection Access range (1) MITSUBISHI PLC The PLC can be monitored via the Ethernet module set in the Ethernet setting on GT Designer3. The GOT can access CPUs on another Ethernet, MELSECNET/H, MELSECNET/10, CC-Link IE Controller Network, or CC-Link field network via the QCPU or QnACPU. -

Page 94: Cc-Link System Access Range For Monitoring

3.3 CC-Link System Access Range for Monitoring When using Bus connection/CPU direct connection/computer link connection Only connected stations can be monitored. When using CC-Link connection (intelligent device station) (1) Access range The master station and local station can be monitored. : Can be monitored, : Cannot be monitored Monitor target... - Page 95 (b) Monitoring PLC CPU devices of other stations Set the device name and device No. DEVICE RANGE THAT CAN BE SET (3) Setting NW No. and station number (a) When monitoring devices RX, RY, RWw and RWr that are allocated to the master station by CC-Link parameter setting NW No.: 0, PLC station number: Local (b) When monitoring PLC CPU devices of another station...

- Page 96 Monitoring overview The following two methods are available for monitoring by the GOT with CC-Link communication unit. Monitoring method Monitoring by transient transmission Monitoring by cyclic transmission All remote inputs/outputs and remote registers assigned to Devices of the PLC CPU on the CC-Link system master and Contents the Master station by CC-Link parameter setting are local station are specified and monitored.

-

Page 97: Data Link System (Melsecnet/B, (Ii)) Access Range For Monitoring

3.4 Data Link System (MELSECNET/B, (II)) Access Range for Monitoring Bus connection, CPU direct connection, Computer link connection (1) When connecting to the master station • Local stations can be monitored. When the PLC CPU of the local station is QnACPU, devices other than B and W that are allocated by the link parameter cannot be monitored. -

Page 98: Access Range For Monitoring When Connecting Fxcpu

Setting method of monitor device The following example describes the method of setting the network No. and the station numbers when setting monitor devices . (1) Monitoring the connected station (host station) and B and W allocated by the link parameter Specify the host station. -

Page 99: Connection To Remote I/O Station In Melsecnet/H Network System

3.6 Connection to Remote I/O Station in MELSECNET/ H Network System When connected to the remote I/O station of the MELSECNET/H network system, the GOT can monitor the PLC CPU of the master station. When connecting the GOT to the remote I/O station, use the following connection methods. POINT POINT POINT... -

Page 100: Direct Connection To Cpu

Direct CPU connection (1) The network units (QJ72LP25-25, QJ72LP25G, QP72BR15) of the remote I/O station are handled as PLC CPU. Connect the GOT to the RS-232 interface of the network unit. For cables required for connection with the network module and other details, refer to the following. 6. - Page 101 Ethernet connection (1) Connect the GOT to the Ethernet module (QJ71E71-100, QJ71E71-B5, QJ71E71-B2, QJ71E71) mounted on the remote I/O station. For details of cables and others required for connecting the GOT to the Ethernet module, refer to the following. 5.

-

Page 102: Connection To The Head Module Of Cc-Link Ie Field Network System

3.7 Connection to the Head Module of CC-Link IE Field Network System When connected to the head module of the CC-Link IE Field Network, the GOT can monitor the PLC CPUs of the master station and local stations. When connecting the GOT to the head module, use the following connection methods. ... -

Page 103: How To Monitor Reduntant System

HOW TO MONITOR REDUNTANT SYSTEM 4.1 Connection to Remote I/O Station in MELSECNET/H Network System ......... .4 - 8 4.2 Direct CPU Connection . - Page 104 HOW TO MONITOR REDUNTANT SYSTEM This section explains the restrictions on the connection methods and other information applicable when the QCPU redundant system is monitored by the GOT. Monitor target Station No. 0 Station No. 1 (Multiplexed remote master station) (Multiplexed remote sub master station) Standby Control...

- Page 105 The following connection methods are available for the QCPU redundant system. • Connection to remote I/O station in MELSECNET/H network system (1) Direct CPU connection (Remote I/O station of MELSECNET/H network system) 4.1.1 Direct CPU connection (Direct CPU connection to the remote I/O station) (2) Computer link connection (Serial communication module mounted on remote I/O station of MELSECNET/H network system) 4.1.2 Computer link connection (Connection to serial communication module mounted on remote...

- Page 106 The following table shows the features of each connection method. Connection type Before system switching After system switching • Direct CPU connection (Remote I/O station of Standby system Control system Standby system Control system MELSECNET/H network Multiplexed remote Multiplexed remote Multiplexed remote Multiplexed remote system)

- Page 107 Connection type Before system switching After system switching • CC-Link connection Intelligent device station (intelligent device station) GOT1 GOT1 • CC-Link connection (Via AJ65BT-G4-S3 CC-Link GOT2 CC-Link GOT2 Master station Standby master station Master station Standby master station Control Standby system system Control...

- Page 108 Connection type Before system switching After system switching • Computer link connection (Serial communication Control system Standby system Control system module mounted on the Station Station Station Station redundant type extension No. 1 No. 2 No. 1 No. 2 base unit) •...

- Page 109 POINT POINT POINT Precautions for monitoring the QCPU redundant system (1) A system alarm may be detected when the system is switched in a redundant system. When Q redundant setting is made : "450 Path has changed or timeout occurred in redundant system." When Q redundant setting is not made : "402 Communication timeout.

-

Page 110: Connection To Remote I/O Station In Melsecnet/H Network System

4.1 Connection to Remote I/O Station in MELSECNET/ H Network System 4.1.1 Direct CPU connection (Direct CPU connection to the remote I/O station) This section explains the direct CPU connection that connects the GOT to the remote I/O station of the MELSECNET/H network system. -

Page 111: Computer Link Connection (Connection To Serial Communication Module Mounted On Remote I/O Station)

4.1.2 Computer link connection (Connection to serial communication module mounted on remote I/O station) This section explains the computer link connection that connects the GOT to the serial communication module mounted on the remote I/O station of the MELSECNET/H network system. The following shows an example of connecting the GOT to the serial communication module mounted on the remote I/O station of the MELSECNET/H network system. -

Page 112: Ethernet Connection (Connection To Ethernet Module Mounted On Remote I/O Station)

4.1.3 Ethernet connection (Connection to Ethernet module mounted on remote I/O station) This section explains the Ethernet connection for connecting the GOT to the Ethernet module mounted on the remote I/ O station of the MELSECNET/H network system. The following shows an example of connecting the GOT to the Ethernet module mounted on the I/O station of the MELESCNET/H network system. -

Page 113: Direct Cpu Connection

4.2 Direct CPU Connection This section describes the direct CPU connection by which a GOT is connected to a PLC CPU in the redundant system. Two methods for the CPU direct connection, using one or two GOTs, are available. 4.2.1 When using one GOT CPU direct connection Network No. -

Page 114: When Using Two Gots

4.2.2 When using two GOTs Connect a GOT to each PLC CPU to respond to the system switching. CPU direct connection CPU direct connection GOT2 GOT1 Monitor Network No. 1, Station No. 0 Network No. 1, Station No. 1 target (Multiplexed remote master station) (Multiplexed remote sub master station) Control system... -

Page 115: Precautions When Connecting A Got Directly To A Plc Cpu In The Redundant System Without Making Q Redundant Setting

4.2.3 Precautions when connecting a GOT directly to a PLC CPU in the redundant system without making Q redundant setting (1) As the GOT monitors exclusively the PLC CPU that is directly connected to, the monitor target cannot be changed in response to the system switching of the redundant system. To change the target monitor in response to the system switching, change the target of the connection cable between the GOT and PLC CPU to the other PLC CPU, or configure the system using GOTs connected to each PLC CPU. - Page 116 The following diagram shows an example of screen setting using SM1515. System configuration example: when using one GOT Standby Control Station Q25PRH QJ71 Q25PRH QJ71 Station system system No. 1 BR11 BR11 No. 0 (System B) (System A) QJ72 Station BR15 No.

- Page 117 Set the screen switching device of the base screen. Choose [Common] [GOT Environmental Setting] [Screen Switching/Window], and set the internal device GD100 as the base screen switching device. (Do not use PLC CPU devices for the screen switching device. If used, the Trigger Action operation of the GOT may be disabled since the device data of the PLC CPU is overwritten by the device value transferred with the redundant system tracking function) Set the trigger action.

- Page 118 Set the comment display on the base screen 1. Set a comment to be displayed on the base screen 1 depending on the system status (ON/OFF of the SM1515) of the connected PLC CPU using the Comment Display (Bit). Select [Object] [Comment Display] [Bit Comment] and set Comment Display (Bit).

- Page 119 Set the touch switches on the base screen 1. By using the go to screen switch function, set a touch switch for shifting the screen to the next screen with a screen touch, when the connected PLC CPU is the control system (SM1515 is ON). Select [Object] [Switch] [Go To Screen Switch] and set the screen switching function.

-

Page 120: Cc-Link Connection (Intelligent Device Station)

4.3 CC-Link Connection (Intelligent Device Station) This section describes the CC-Link connection (intelligent device station) that connects the GOT set as the intelligent device station to the CC-Link network. The following shows an example of connecting the GOT set as the intelligent device station to the CC-Link network. CC-Link connection Network No. - Page 121 (3) Monitoring target change when system switching occurs in a redundant system (a) System switching due to an alarm occurred in the control system When system switching occurs, the CC-Link switches the station No. 0 of the master station and the station No.

-

Page 122: Cc-Link Connection (Via G4)

4.4 CC-Link Connection (Via G4) This section explains the CC-Link connection (via G4) that connects the GOT to the AJ65BT-G4-S3 of the CC-Link network. The following shows an example of connecting the GOT to the AJ65BT-G4-S3 of the CC-Link network. Network No. - Page 123 (3) Monitoring target change when system switching occurs in a redundant system (a) System switching due to an alarm occurred in the control system When system switching occurs, the CC-Link switches the station No. 0 of the master station and the station No.

-

Page 124: Melsecnet/H And Melsecnet/10 Connections (Network Systems)

4.5 MELSECNET/H and MELSECNET/10 Connections (Network Systems) This section explains the MELSECNET/H and MELSECNET/10 connections (network systems) that connect the GOT to the MELSECNET/H and MELSECNET/10 network system. The following provides an example of connecting the GOT set as a normal station to the MELSECNET/ H network system. -

Page 125: Cc-Link Ie Controller Network Connection (Network System)

4.6 CC-Link IE Controller Network Connection (Network System) This section explains the CC-Link IE Controller Network connection (network system) that connects the GOT to the CC- Link IE controller network. The following shows an example of connecting the GOT set as a normal station to the CC-Link IE Controller Network. Network No. -

Page 126: Ethernet Connection

4.7 Ethernet Connection This section explains the Ethernet connection that connects the GOT to the Ethernet network system. The following shows an example of connecting the GOT to the Ethernet network. Network No. 1, Station No. 3 Network No. 1, Station No. -

Page 127: Connection To The Redundant Type Extension Base Unit

4.8 Connection to the Redundant Type Extension Base Unit 4.8.1 Computer link connection (Connection to the Serial communication module mounted on the redundant type extension base unit) This section explains the computer link connection for connecting the GOT to the serial communication module mounted on the redundant type extension base unit. -

Page 128: Ethernet Connection (Connection To The Ethernet Module Mounted On Redundant Type Extension Base Unit)

4.8.2 Ethernet connection (Connection to the Ethernet module mounted on redundant type extension base unit) This section explains the Ethernet connection for connecting the GOT to the Ethernet module mounted on the redundant type extension base unit. The following shows an example of connecting the GOT to the Ethernet module mounted on the redundant type extension base unit. -

Page 129: Cc-Link Connection (Intelligent Device Station) (Connection To The Cc-Link Module Mounted On Redundant Type Extension Base Unit)

4.8.3 CC-Link connection (intelligent device station) (Connection to the CC-Link module mounted on redundant type extension base unit) This section explains the CC-Link connection for connecting the GOT to the CC-Link module mounted on the redundant type extension base unit. The following shows an example of connecting the GOT to the CC-Link module mounted on the redundant type extension base unit. -

Page 130: Cc-Link Connection (Via G4) (Connection To The Cc-Link Module Mounted On Redundant Type Extension Base Unit)

4.8.4 CC-Link connection (Via G4) (Connection to the CC-Link module mounted on redundant type extension base unit) This section explains the CC-Link connection (Via G4) for connecting the GOT to the CC-Link module mounted on the redundant type extension base unit via the AJ65BT-G4-S3. The following shows an example of connecting the GOT to the AJ65BT-G4-S3 of the CC-Link network. - Page 131 4.9 Q Redundant Setting The following explains the setting for automatically change the monitoring target of the GOT when monitoring a QCPU redundant system. POINT POINT POINT Before making the Q redundant setting In the Q redundant setting, do not set stations other than redundant CPUs. Select [Common] [Controller Setting] [Q Redundant] from the menu.

- Page 132 *1 Pair number Redundant CPU pair means the redundant CPUs (System A / System B) in the redundant system configuration. Pair number is the number assigned to each redundant CPU pair. Example: Ethernet connection (Pair No. 1 and Pair No. 2) Redundant CPU pair (No.1) Station Station...

-

Page 133: Switch The Monitor Target To The Control System Using The Script Function

4.10 Switch the Monitor Target to the Control System Using the Script Function The following explains how to create a script screen, to be used for the MELSECNET/H or MELSECNET/10 connection (network system), or Ethernet connection, that automatically changes the monitoring target (Station No.) at the occurrence of system switching even if the Q redundant setting is not made. - Page 134 Set the station number switching device. Select [Common] [Controller Setting] [Station No. Switching], and set the internal device GD100 as the station number switching device. Do not use a device of PLC CPU as a screen switching device. Since the device information is transferred by the tracking transfer function of the redundant system, the trigger action may be disabled.

- Page 135 Create a monitor screen. For MELSECNET/H connection, MELSECNET/10 connection or Ethernet connection: (Common) In the device setting (network setting) of each object, set Network No. 1 and Station No. 1 of the control system. Validate the station number switching function. On the Basic tab screen specified by selecting [Screen] [Screen Property], select the item [Switch Station No.] to validate the station number changing function.

- Page 136 HINT HINT HINT When the MELSECNET/H network is connected to the redundant system only, SW56 (current control station) can be set as the station number switching device. In this case, even if the system switching occurs, the GOT always monitors the station number that is currently the control station.

- Page 137 Set the trigger action. Make the setting so that the station number is switched when the faulty station information (GS231) from the station monitoring specified by selecting [Common] [trigger action] turns ON. (For Network No. 1 and Station No. 2, set "258"(0102H)) Condition 1 : GS231.b0 (while ON) When b0 is ON, Station No.

- Page 138 On the screen 1, set the switch for writing the station No. 1 to the station number switching device. After the GOT is started up, the station number switching device value of the GOT is "0". For Ethernet connection, the monitor becomes abnormal when the station number switching device value is "0". Therefore, set the switch for writing the station number to the station number switching device and the switch for shifting to the monitor screen on the screen 1.

- Page 139 Change the station number switching device value in the script. By selecting [Common] [Script] [Script], create a script for each monitor screen that checks the SM1515 status of the current monitor station, and if it is OFF (standby system), changes the station number switching device value.

-

Page 140: Method For Using The Screen Changing Function

4.10.2 Method for using the screen changing function • As a feature of this function, monitor screens are created for each station number. When the system switching occurs, the GOT can change the monitoring target to the control system PLC CPU on the other monitor screen. - Page 141 Set the trigger action. Set the trigger action so that the station number is switched when the faulty station information (SW70) of MELSECNET/H turns ON in the project specified by choosing [Common] [trigger action]. Condition 1 : SW70.b0 (while ON) When b0 is ON, Station No.

- Page 142 Set monitor screens. For MELSECNET/H connection, MELSECNET/10 connection or Ethernet connection: (Common) • Create a monitor screen with each object whose network setting is Station No. 1 on Screen No. 1 (1-1). • Create a monitor screen with each object whose network setting is Station No. 2 on Screen No. 2 (1-2). Change the screen switching device value in the script.

- Page 143 Setting method (Ethernet connection) System configuration example 2: Ethernet connection Ethernet Network No. 1 Station No. 3 QJ71 QJ71 Standby system Control system Q25PRH Q25PRH (System B) (System A) Station No. 1 Station No. 2 Connected module Network No. Station No.

- Page 144 Change the screen switching device value in the script. By selecting [Common] [Script] [Script], create a script for each monitor screen that checks the SM1515 status of the current monitor station, and if it is OFF (standby system), changes the station number switching device value.

- Page 145 ETHERNET CONNECTION 5.1 Connectable Model List ......5 - 2 5.2 System Configuration ......5 - 7 5.3 GOT Side Settings .

-

Page 146: Ethernet Connection

ETHERNET CONNECTION 5.1 Connectable Model List 5.1.1 PLC/Motion controller CPU The following table shows the connectable models. Series Model name Clock Communication type Connectable model Refer to Q00JCPU Q00CPU Q01CPU Q02CPU Ethernet 5.2.1 Q02HCPU Q06HCPU Q12HCPU Q25HCPU Q02PHCPU Q06PHCPU Q12PHCPU Q25PHCPU Q12PRHCPU (Main base) Ethernet... - Page 147 Series Model name Clock Communication type Connectable model Refer to MELSEC-QS QS001CPU Ethernet 5.2.1 L02CPU L06CPU L26CPU L26CPU-BT L02CPU-P 5.2.2 MELSEC-L Ethernet L06CPU-P 5.2.1 L26CPU-P L26CPU-PBT L02SCPU L02SCPU-P Q02CPU-A MELSEC-Q Ethernet Q02HCPU-A 5.2.1 (A mode) Q06HCPU-A Q2ACPU Q2ACPU-S1 MELSEC-QnA Ethernet Q3ACPU 5.2.1 (QnACPU)

- Page 148 Series Model name Clock Communication type Connectable model Refer to A2USCPU A2USCPU-S1 A2USHCPU-S1 A1SCPU A1SCPUC24-R2 A1SHCPU MELSEC-A A2SCPU Ethernet 5.2.1 (AnSCPU) A2SCPU-S1 A2SHCPU A2SHCPU-S1 A1SJCPU A1SJCPU-S3 A1SJHCPU A0J2HCPU A0J2HCPUP21 Ethernet 5.2.1 A0J2HCPUR21 A0J2HCPU-DC24 A2CCPU MELSEC-A A2CCPUP21 A2CCPUR21 A2CCPUC24 A2CCPUC24-PRF A2CJCPU-S3 A1FXCPU *1*2 Q172CPU...

- Page 149 Series Model name Clock Communication type Connectable model Refer to A273UCPU A273UHCPU A273UHCPU-S3 A373UCPU A373UCPU-S3 A171SCPU Motion A171SCPU-S3 controller Ethernet 5.2.1 A171SCPU-S3N (A Series) A171SHCPU A171SHCPUN A172SHCPU A172SHCPUN A173UHCPU A173UHCPU-S1 WS0-CPU0 MELSEC-WS WS0-CPU1 QJ72LP25-25 MELSECNET/H Remote I/O QJ72LP25G Ethernet 5.2.1 station QJ72BR15 CC-Link IE...

-

Page 150: Ethernet Module

5.1.2 Ethernet module CPU series Ethernet module MELSEC-Q (Q mode) MELSEC-QS Motion controller CPU (Q Series) QJ71E71-100 QJ71E71-B5 QJ71E71-B2 QJ71E71 CNC C70 Robot controller (CRnQ-700) AJ71QE71N3-T AJ71QE71N-B5 AJ71QE71N-B2 AJ71QE71N-T AJ71QE71N-B5T AJ71QE71 AJ71QE71-B5 A1SJ71QE71N3-T MELSEC-QnA A1SJ71QE71N-B5 A1SJ71QE71N-B2 A1SJ71QE71N-T A1SJ71QE71N-B5T A1SJ71QE71-B5 A1SJ71QE71-B2 AJ71E71N3-T AJ71E71N-B5 AJ71E71N-B2... -

Page 151: System Configuration

5.2 System Configuration 5.2.1 Connection to Ethernet module When connecting to MELSEC-Q, QS, QnA, A or motion controller Communication driver Ethernet PLC CPU module Ethernet(MELSEC),Q17nNC, CRnD-700,Gateway Connection cable Maximum Connection cable Number of segment connectable Communication Ethernet module Model name Cable model Option device Model... - Page 152 A length between a hub and a node. The maximum distance differs depending on the Ethernet device to be used. The following shows the number of the connectable nodes when a repeater hub is used. • 10BASE-T: Max. 4 nodes for a cascade connection (500m) •...

- Page 153 When connecting to MELSEC-FX Communication driver Ethernet PLC CPU module Ethernet (FX), Gateway Connection cable Maximum Connection cable Number of segment connectable Communication Ethernet module Model name Cable model Option device Model equipment length type *3*4 MELSEC-FX • 100BASE-TX -ENET-L Ethernet , FX...

-

Page 154: Connection To Built-In Ethernet Port Cpu Or C Controller Module

A straight cable is available. When connecting QnUDE(H) and GOT directly with Ethernet cable, connection by cross cable is available. GOT2000 Series User's Manual (Hardware) A length between a hub and a node. The maximum distance differs depending on the Ethernet device to be used. -

Page 155: Connecting To Display I/F

5.2.3 Connecting to Display I/F Communication driver PLC CPU Ethernet(MELSEC),Q17nNC, CRnD-700,Gateway Connection cable Maximum Number of segment connectable Connection cable Communication Model name Option device Model equipment length type • 100BASE-TX Shielded twisted pair cable (STP) or unshielded twisted pair cable (UTP) of CNC C70 category 5 or higher 16 GOTs for 1... -

Page 156: Connection To Cc-Link Ie Field Network Ethernet Adapter Module

5.2.4 Connection to CC-Link IE Field Network Ethernet Adapter Module Communication driver Ethernet(MELSEC),Q17nNC, CRnD-700,Gateway CC-Link IE CC-Link IE Field Field Network Network Master/ QCPU Ethernet adapter Local module module Connection cable 1) Connection cable 2) CC-Link IE Field Network Connection cable 1) Connection cable 2) Ethernet adapter module Number of... -

Page 157: Connecting To Peripheral I/F (Built-In Ethernet Port Motion Controller Cpu)

5.2.5 Connecting to PERIPHERAL I/F (Built-in Ethernet port Motion Controller CPU) Communication driver Q172DCPU-S1 Q173DCPU-S1 Q172DSCPU Ethernet(MELSEC),Q17nNC, CRnD-700,Gateway Q173DSCPU Connection cable Q170MCPU Q170MSCPU Q170MSCPU-S1 MR-MQ100 Maximum Number of Communi segment connectable Connection cable cation Option device Model Model name equipment length type Motion controller CPU... -

Page 158: Got Side Settings

(Default: 3times) Set the following items. Specify the time period from the GOT startup until GOT starts the • Manufacturer: Mitsubishi Startup Time 3 to 255sec communication with the PLC CPU. • Controller Type: Set according to the Controller (Default: 3sec) Type to be connected. -

Page 159: Got Ethernet Setting

[Communication Settings] of project data. For details on the Utility, refer to the following manual. GOT2000 Series User's Manual (Utility) (2) Precedence in communication settings When settings are made by GT Designer3 or the Utility, the latest setting is effective. -

Page 160: Routing Parameter Setting

(3) Changing the host on the GOT main unit The host can be changed by the utility function of the GOT main unit. For the detailed connection method, refer to the following manual. GOT2000 Series User's Manual (Utility) Item Range Transfer Network No. - Page 161 POINT POINT POINT (1) Routing parameter setting of relay station Routing parameter setting may also be necessary for the relay station. For the setting, refer to the following. 5.4 PLC Side Setting (2) Parameter reflection function of MELSOFT Navigator (a) The color of the cells for the items which are reflected to GT Designer3 from MELSOFT Navigator changes to green.

-

Page 162: Plc Side Setting

5.4 PLC Side Setting 5.4.1 Connecting to Built-in Model Reference Ethernet port CPU (one-to- Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q10UDEHCPU, one connection) Q13UDEHCPU, Q20UDEHCPU, Q26UDEHCPU, Q50UDEHCPU, Q100UDEHCPU, Q03UDVCPU, 5.4.1 Built-in Ethernet This section describes the settings of the GOT and Built-in Q04UDVCPU, Q06UDVCPU, 5.4.2 port QCPU Ethernet port CPU in the following case of system... - Page 163 (3) Ethernet setting [Controller Setting] and [Ethernet] of GT Designer3 Item Set value Host POINT POINT POINT N/W No. PLC No. (1) [Controller Setting] and [Ethernet] of GT Ethernet Designer3 Type QnUDE(H), LCPU setting No.1 For [Controller Setting] and [Ethernet] of GT IP address 192.168.3.39 Designer3, refer to the following.

-

Page 164: Connecting To Built-In Ethernet Port Cpu (Multiple Connection)

5.4.2 Connecting to Built-in [Q parameter setting] or [L parameter setting] Ethernet port CPU (multiple for GX Developer connection) (1) Built-in Ethernet port Example: [Q parameter setting] screen This section describes the settings of the GOT and Built-in Ethernet port CPU in the following case of system configuration. - Page 165 (2) Open settings [Controller Setting] and [Ethernet] of GT The setting is required for all the connected GOTs. Designer3 POINT POINT POINT (3) [Controller Setting] and [Ethernet] of GT Designer3 For [Controller Setting] and [Ethernet] of GT Designer3, refer to the following. 5.3.1 Setting communication interface (Communication settings) (4) Ethernet setting...

-

Page 166: Connecting To Ethernet Module (Q/L Series)

5.4.3 Connecting to Ethernet (3) Ethernet setting module (Q/L Series) Set value Item This section describes the settings of the GOT and Ethernet module (Q Series) in the following case of the Host system configuration. N/W No. PLC No. POINT POINT POINT Ethernet setting... - Page 167 (2) Operation setting [Network parameter] of GX Developer (1) Network parameter Setting necessity at Item Set value connection (Use default value) Communication data code Setting IP address 192.168.3.39 necessity at Item Set value Initial timing connection Send frame setting Network type Ethernet (fixed) (Use default value)

- Page 168 (3) Routing parameter setting [Controller Setting] and [Ethernet] of GT Up to 64 [Transfer Network No.]s can be set. Designer3 However, the same transfer network number cannot be set twice or more (multiple times). (1) Controller setting Therefore, the one that can access to other station from the request source host GOT is 64 kinds of [Transfer Item Set value (Use default value)

-

Page 169: Connecting To C Controller Module

5.4.4 Connecting to C Controller Confirming the communication state of module Ethernet module (1) When using the Command Prompt of Windows This section describes the settings of the GOT and C Execute a Ping command at the Command Prompt of Controller module in the following case of the system ... - Page 170 (c) Detail settings Utility setting for C Controller module (1) Q12DCCPU-V Use SW3PVC-CCPU-E Ver.3.05F or later for the C Controller setting utility. (a) Connection settings Setting necessity at Item Set value connection Setting necessity at 192.168.3.3 (Default) Target module Item Set value Write authority...

- Page 171 (d) System settings (2) Q24DHCCPU-V Use SW4PVC-CCPU-E for the C Controller setting utility. (a) Connection settings Setting necessity at Item Set value connection Points occupied by empty slot Remote reset Output mode at STOP to Intelligent function module Setting settings necessity at Item Set value...

- Page 172 (1) Controller setting Checking communication state of C Controller module Item Set value (Use default value) GOT Net No. (1) When using the Command Prompt of Windows Execute a Ping command at the Command Prompt of GOT Station ...

-

Page 173: Connecting To Ethernet Module (Qna Series)

5.4.5 Connecting to Ethernet Switch settings of Ethernet module module (QnA Series) Set the operation mode setting switch and exchange condition setting switch. This section describes the settings of the GOT and AJ71QE71N3-T, AJ71QE71N-B5, A1SJ71QE71N3-T, A1SJ71QE71N-B5, Ethernet module (QnA Series) in the following case of the AJ71QE71N-B2, AJ71QE71N-T, A1SJ71QE71N-B2, A1SJ71QE71N-T, system configuration. - Page 174 (2) Exchange condition setting switch [Network parameter] of GX Developer Setting (1) Network parameter Exchange Setting necessity at condition Description switch value setting switch connection Selection of line processing at TCP timeout error Data code (fixed) setting Self start mode setting (Must not to be used)

- Page 175 (2) Routing parameter setting (3) Communication confirmation Up to 64 [Transfer Network No.]s can be set. The RDY LED on the Ethernet module turn on when However, the same transfer network number cannot be the module is ready to communicate. set twice or more (multiple times).

- Page 176 5.4.6 Connecting to Ethernet POINT POINT POINT module (A Series) [Controller Setting] and [Ethernet] of GT Designer3 This section describes the settings of the GOT and [Controller Setting] [Ethernet] Ethernet module (A Series) in the following case of the Designer3, refer to the following. system configuration.

- Page 177 (1) Operation mode setting switch Switch settings of Ethernet module Set the operation mode setting switch and exchange Setting condition setting switch. Operation mode necessity at Description Set value setting switch AJ71E71N3-T, AJ71E71N-B5, A1SJ71E71N3-T, A1SJ71E71N-B5, connection AJ71E71N-B2, AJ71E71N-T, A1SJ71E71N-B2, A1SJ71E71N-T, AJ71E71N-B5T, AJ71E71-S3 A1SJ71E71N-B5T, A1SJ71E71-B5-S3, A1SJ71E71-B2-S3...

- Page 178 (c) Buffer memory settings used in the present Sequence program example The sequence program for initial processing and Buffer memory communication line opening processing are required. address Item Set value (1) Programming condition Dec (Hex) This program performs the initial processing of the C0A80013 Ethernet module and the opening processing of 0 to 1 (0 to 1...

- Page 179 (2) Example of sequence program * Initial processing IP address of Ethernet module(192.168.0.19) Turned on at first scan only while detection running Initial request Read the initial fault code. Initial WDT ERR fault detection detection COM. ERR turned off request COM.

- Page 180 (3) Communication confirmation [Controller Setting] and [Ethernet] of GT The RDY LED on the Ethernet module turn on when Designer3 the module is ready to communicate. For confirming the communication state, refer to the (1) Controller setting following. 5.4.3 ■Confirming the communication state of Item Set value (Use default value) Ethernet module...

-

Page 181: Connecting To Ethernet Module (A Series)

5.4.7 Connecting to Ethernet Ethernet parameter settings of FX3U- module (FX Series) ENET-L Configuration tool (1) Ethernet settings This section describes the settings of the GOT and Set the Ethernet parameter with FX -ENET-L Ethernet module (FX Series) in the following case of the Configuration tool. - Page 182 (2) Operational settings (3) Open settings Setting Item Setting (with GOT connected) Communication (Use default value.) date code Setting Item Setting (with GOT connected) IP address 192.168.3.19 Protocol Initial timing Open system MELSOFT connection Send frame setting (Use default value.) Fixed buffer TCP Existence confirmation setting...

- Page 183 (2) Open settings Ethernet parameter settings of FX -ENET- (1) Ethernet settings Set the Ethernet parameter at [FX Parameter] on GX Works2. To set FX -ENET-ADP, GX Works2 Ver.1.90U or later is required. For details on the setting of FX -ENET-ADP, refer to the following manual.

- Page 184 [Controller Setting] and [Ethernet] of GT Confirming the communication state of Designer3 Ethernet module (1) Controller setting (1) When using the Command Prompt of Windows Execute a Ping command at the Command Prompt of Item Setting (Use default value.) ...

-

Page 185: Connecting To Built-In Ethernet Port Fxcpu (Fx3Ge)

5.4.8 Connecting to Built-in Ethernet parameter settings of FX Ethernet port FXCPU (1) Ethernet settings Set the Ethernet parameter at [FX Parameter] on GX Works2. To set FX , GX Works2 Ver.1.91V or later is required. This section describes the settings of the GOT and For details on the setting of FX , refer to the following Ethernet module (FX Series) in the following case of the... - Page 186 (2) Open settings [Controller Setting] and [Ethernet] of GT Designer3 (1) Controller setting Item Setting (Use default value.) GOT Net No. GOT Station GOT Ethernet Setting 192.168.3.18 GOT Communication Port No. 5019 Retry 3times Setting Startup Time 3sec Item Setting (with GOT connected) Timeout Time...

-

Page 187: Connecting To Display I/F (Cnc C70)

5.4.9 Connecting to Display I/F Confirming the communication state of (CNC C70) Ethernet module (1) When using the Command Prompt of Windows This section describes the settings of the GOT and Display Execute a Ping command at the Command Prompt of I/F (CNC C70) in the following case of the system ... - Page 188 (3) Communication check IP address settings of CNC C70 The CNC C70 can communicate with the GOT when (1) Remote monitor tool INIT.LED of the CNC C70 is lit. For confirming the communication state, refer to the following. ■Checking communication state of CNC C70 ...

-

Page 189: Connecting To Cc-Link Ie Field Network Ethernet Adapter Module

5.4.10 Connecting to CC-Link IE Checking communication state of CNC C70 Field Network Ethernet (1) When using the Command Prompt of Windows Adapter Module Execute a Ping command at the Command Prompt of Windows This section describes the settings of the GOT, Ethernet (a) When normal communication adapter module and the PLC in the following system C:\>Ping 192.168.3.19... - Page 190 GX Works2 network parameter Ethernet Adapter Module setting Ethernet/CC IE/MELSECNET Set the parameter with the Ethernet adapter module setting tool. For details of the setting contents of PLC side, refer to the For details of the setting method, refer to the following following manual.

- Page 191 (4) Routing parameter setting [Controller Setting] and [Ethernet] of GT Designer3 Item Set value Transfer Network No. POINT POINT POINT Relay Network No. Relay Station No. [Controller Setting] and [Ethernet] of GT Designer3 Set the same value as the Ethernet adapter module network For [Controller Setting] and [Ethernet] of GT Designer3, refer to the following.

-

Page 192: Connecting To Peripheral I/F (Built-In Ethernet Port Motion Controller Cpu)

5.4.11 Connecting to System configuration PERIPHERAL I/F (Built-in Leave the Built-in Ethernet port Motion Controller CPU Ethernet port Motion settings as default in the following system configuration. Controller CPU) ■ [Controller Setting] and [Ethernet] of GT Designer3 This section describes the settings of the GOT and Built-in <GOT>... - Page 193 (6) Open settings Basic setting of MT Works2 The setting is required for all the connected GOTs. Use the default values of the basic setting for the system configuration above. (5) Built-in Ethernet port Item Set value Protocol UDP (fixed) Open system MELSOFT connection (fixed) Host station port No.

- Page 194 (1) Controller setting Checking communication state of Connecting to Built-in Ethernet port CPU Item Setting (Use default value.) GOT Net No. (4) When using the Command Prompt of Windows GOT Station Execute a Ping command at the Command Prompt of GOT Ethernet Setting 192.168.3.1 ...

-

Page 195: Precautions

5.5 Precautions Connection to QnA (S) CPU type Connection to LCPU Use B or a later function version of Ethernet module LCPU may diagnose (check file system, recovering (QnA Series) and PLC CPU (QnA/QnASCPU type). process, etc.) the SD memory card when turning on the ... - Page 196 When setting IP address Do not use "0" and "255" at the end of an IP address. (Numbers of *.*.*.0 and *.*.*.255 are used by the system) The GOT may not monitor the controller correctly with the above numbers. Consult with the administrator of the network before setting an IP address to the GOT and controller.

-

Page 197: Direct Connection To Cpu

DIRECT CONNECTION TO CPU 6.1 Connectable Model List ......6 - 2 6.2 System Configuration ......6 - 6 6.3 Connection Diagram . -

Page 198: Connectable Model List

DIRECT CONNECTION TO CPU 6.1 Connectable Model List The following table shows the connectable models. Communication Series Model name Clock Connectable model Refer to type Q00JCPU Q00CPU Q01CPU Q02CPU RS-232 6.2.1 RS-422 Q02HCPU Q06HCPU Q12HCPU Q25HCPU Q02PHCPU Q06PHCPU Q12PHCPU RS-232 6.2.1 Q25PHCPU RS-422... - Page 199 Communication Series Model name Clock Connectable model Refer to type L02CPU L06CPU L26CPU L26CPU-BT RS-232 L02CPU-P MELSEC-L 6.2.2 RS-422 L06CPU-P L26CPU-P L26CPU-PBT L02SCPU L02SCPU-P Q02CPU-A MELSEC-Q RS-232 Q02HCPU-A 6.2.1 (A mode) RS-422 Q06HCPU-A Q2ACPU Q2ACPU-S1 RS-422 MELSEC-QnA Q3ACPU 6.2.3 (QnACPU) Q4ACPU Q4ARCPU RS-422...

- Page 200 Communication Series Model name Clock Connectable model Refer to type A2USCPU-S1 A2USHCPU-S1 A1SCPU A1SCPUC24-R2 A1SHCPU A2SCPU MELSEC-A RS-422 6.2.4 (AnSCPU) A2SCPU-S1 A2SHCPU A2SHCPU-S1 A1SJCPU A1SJCPU-S3 A1SJHCPU A0J2HCPU A0J2HCPUP21 RS-422 6.2.4 A0J2HCPUR21 A0J2HCPU-DC24 A2CCPU MELSEC-A A2CCPUP21 A2CCPUR21 RS-422 A2CCPUC24 6.2.4 A2CCPUC24-PRF A2CJCPU-S3 A1FXCPU *2*3...

- Page 201 Communication Series Model name Clock Connectable model Refer to type A273UCPU A273UHCPU A273UHCPU-S3 A373UCPU A373UCPU-S3 A171SCPU Motion A171SCPU-S3 controller RS-422 6.2.4 A171SCPU-S3N CPU (A Series) A171SHCPU A171SHCPUN A172SHCPU A172SHCPUN A173UHCPU A173UHCPU-S1 WS0-CPU0 MELSEC-WS RS-232 6.2.6 WS0-CPU1 MELSECNET/ QJ72LP25-25 QJ72LP25G RS-232 6.2.1 Remote I/O QJ72BR15...

-

Page 202: System Configuration

System Configuration 6.2.1 Connecting to QCPU Communication driver RS-422 connector QCPU conversion cable Q/L/QnA/A CPU, QJ71C24, LJ71C24 Connection cable Connection cable Number of Communi connectable RS-422 connector Max. Model name cation Cable model Option device Model equipment conversion cable distance type - (Built into GOT) RS-232... -

Page 203: Connecting To Lcpu

6.2.2 Connecting to LCPU Communication driver Q/L/QnA/A CPU, QJ71C24, LJ71C24 RS-422 connector LCPU Adapter conversion cable Connection cable Connection cable Number of Communi connectable RS-422 connector Max. Model name Adapter cation Cable model Option device Model equipment conversion cable distance type - (Built into GOT) L6ADP-R2... -

Page 204: Connecting To Qnacpu

6.2.3 Connecting to QnACPU Communication driver QnACPU Q/L/QnA/A CPU, QJ71C24, LJ71C24 Connection cable Connection cable Number of connectable Communication Max. Model name Cable model Option device Model equipment type distance - (Built into GOT) GT01-C30R4-25P(3m) GT01-C100R4-25P(10m) MELSEC-QnA RS-422 1 GOT for 1 PLC GT01-C200R4-25P(20m) GT01-C300R4-25P(30m) GT15-RS4-9S... -

Page 205: Connecting To Acpu

6.2.4 Connecting to ACPU Communication driver ACPU Q/L/QnA/A CPU, QJ71C24, LJ71C24 Connection cable Connection cable Number of connectable Communication Max. Model name Cable model Option device Model equipment type distance - (Built into GOT) GT01-C30R4-25P(3m) GT01-C100R4-25P(10m) MELSEC-A RS-422 1 GOT for 1 PLC GT01-C200R4-25P(20m) GT01-C300R4-25P(30m) GT15-RS4-9S... -

Page 206: Connecting To Fxcpu

6.2.5 Connecting to FXCPU Communication driver Function Function FXCPU expansion adapter board MELSEC-FX Connection cable When connecting to FX , FX , FX , FX , FX or FX Connection cable Number of Function Communi Function connectable Model Max. expansion cation Cable model... - Page 207 When connecting to FX , FX , FX , FX , FX (RS-422 connection) Connection cable Number of Function Communi connectable Function Model Max. expansion cation Cable model Option device Model name distance equipment adapter *1*3 type board - (Built into GOT) GT01-C10R4-8P(1m) GT01-C30R4-8P(3m) 1 GOT for 1...

- Page 208 When connecting to FX , FX , FX , FX , FX (RS-232 connection) Connection cable Number of Function Communi Cable model connectable Function Model Max. expansion cation Connection diagram Option device Model equipment name distance adapter *1*3 type number board - (Built into GOT)

- Page 209 The function expansion board to be used differs according to the type of the FXCPU. Select the function expansion board from the following table. Function expansion board to be used Item When connecting to FX or FX Series When connecting to FX Series RS-232 communication -232-BD -232-BD...

- Page 210 When connecting to FX , FX (RS-422 connection) Connection cable Number of Function Communi connectable Function Model Max. expansion cation Cable model Option device Model equipment name distance adapter type board - (Built into GOT) GT01-C10R4-8P(1m) GT01-C30R4-8P(3m) 1 GOT for 1 RS-422 GT01-C100R4-8P(10m) PLC built-in...

- Page 211 When connecting to FX , FX (RS-232 connection) Connection cable Number of Function connectable Communi Cable model Function Model Max. expansion equipment cation Connection diagram Option device Model name distance adapter type number board - (Built into GOT) GT01-C30R2-9S(3m) 1 GOT for 1 function -232-BD...

- Page 212 When connecting to FX /D, FX /DSS) (RS-422 connection) Connection cable Number of connectable Communication Max. Model name Cable model Option device Model equipment type distance - (Built into GOT) GT01-C10R4-8P(1m) GT01-C30R4-8P(3m) 1 GOT for 1 PLC built- RS-422 GT01-C100R4-8P(10m) in port /DSS...

- Page 213 When connecting to FX or FX -LT(-2)) (RS-422 connection) Connection cable Number of Function Commu connectable Function Max. expansion Model name nication Cable model Option device Model equipment adapter distance type board - (Built into GOT) GT01-C10R4-8P(1m) GT01-C30R4-8P(3m) 1 GOT for 1 RS-422 GT01-C100R4-8P(10m) PLC built-in...

- Page 214 When connecting to FX or FX -LT(-2)) (RS-232 connection) Connection cable Number of Function connectable Commun Cable model Function Max. expansion equipment Model name ication Connection diagram Option device Model distance adapter type number board - (Built into GOT) GT01-C30R2-9S(3m) 1 GOT for 1 function...

- Page 215 When connecting to FX /D, FX /DS, FX /DSS) (RS-422 connection) Connection cable Number of connectable Commun Max. Model name ication Cable model Option device Model equipment distance type - (Built into GOT) GT01-C10R4-8P(1m) GT01-C30R4-8P(3m) 1 GOT for 1 PLC built-in RS-422 GT01-C100R4-8P(10m) port...

-

Page 216: Connecting To Wscpu

6.2.6 Connecting to WSCPU Communication driver WSCPU MELSEC-WS Connection cable Connection cable Number of connectable Communication Cable model Max. equipment Model name Option device Model type Connection diagram number distance - (Built into GOT) MELSEC-WS RS-232 WS0-C20R2(2m) 1 GOT for 1 PLC GT15-RS2-9P Use the RS-232 connection model. -

Page 217: Connection Diagram

6.3 Connection Diagram The following diagram shows the connection between the GOT and the PLC. 6.3.1 RS-232 cable Connection diagram (1) RS232 connection diagram 1) FX PLC side (D-sub 9-pin) GOT side RS232 connection diagram 2) FX PLC side (D-sub 25-pin) GOT side ... -

Page 218: Got Side Settings

Retry 0 to 5times timeout occurs. (Default: 0time) Set the following items. Set the time period for a • Manufacturer: Mitsubishi Timeout Time communication to time out. 1 to 30sec • Controller Type: Set according to the Controller (Default: 3sec) Type to be connected. - Page 219 Utility's [Communication Settings] after writing [Communication Settings] of project data. For details on the Utility, refer to the following manual. GOT2000 Series User's Manual (Utility) (2) Precedence in communication settings Item Description Range When settings are made by GT Designer3 or the Set this item when change the Utility, the latest setting is effective.

-

Page 220: Precautions

6.5 Precautions Connection to FXCPU • QCPU (Q mode), motion controller CPU (Q series): (1) When connecting to FX series 10 seconds or more When the keyword of FXCPU (FX series) has been • MELDAS C70: 18 seconds or more set, GOT may not be able to monitoring.Perform an I/O When the GOT starts before the PLC runs, a system check again. -

Page 221: Computer Link Connection

COMPUTER LINK CONNECTION 7.1 Connectable Model List ......7 - 2 7.2 System Configuration ......7 - 7 7.3 Connection Diagram . -

Page 222: Connectable Model List