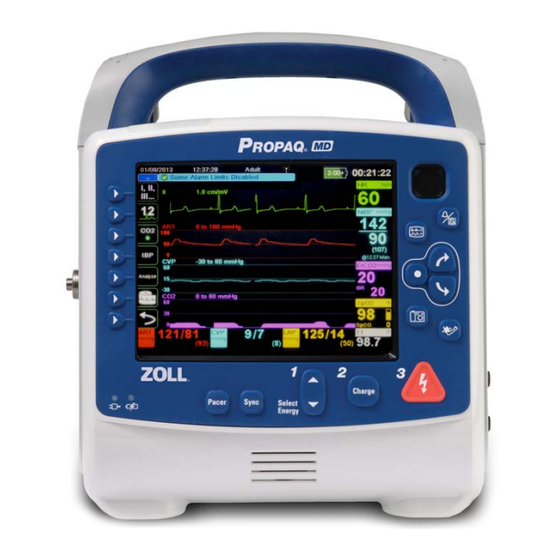

ZOLL Propaq MD Service Manual

Hide thumbs

Also See for Propaq MD:

- Operator's manual (326 pages) ,

- Service manual (142 pages) ,

- Quick reference manual (10 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for ZOLL Propaq MD

- Page 1 Propaq MD Service Manual ® April 2013 9650-0801-01 Rev. B...

- Page 2 The issue date for the Propaq MD Service Manual (REF 9650-0801-01 Rev. B) is April, 2013. If more than 3 years have elapsed since the issue date, contact ZOLL Medical Corporation to determine if additional product information updates are available.

-

Page 3: Table Of Contents

NIBP Calibration Check ...................... 36 NIBP Leak Test ........................39 Deflation Test ........................40 Inflation Test ........................41 NIBP Test ........................... 42 Temperature Test ....................... 43 Chapter 2 Troubleshooting Overview..........................45 Propaq MD Error Messages ....................45 9650-0801-01 Rev.B ZOLL Propaq MD Service Manual... - Page 4 Replacement Parts Overview..........................79 Replacement Parts ......................80 Chapter 6 Functional Description Overview..........................83 Appendix A Overview..........................89 Propaq MD Electrical Hardware Interconnect Diagram ............90 Propaq MD Signal and Power Interconnect Schematic ............91 Appendix B Overview..........................93 9650-0801-01 Rev.B...

-

Page 5: Preface

Propaq MD unit. Chapter 5—Replacement Parts List displays a complete list of ZOLL part numbers for field replaceable parts available for the Propaq MD unit, allowing the service person to identify and order replacement parts from ZOLL. -

Page 6: Safety Considerations

Do not discharge a battery pack except in a ZOLL SurePower Charging Station. Do not use the Propaq MD in the presence of flammable agents (such as gasoline), oxygen-rich atmospheres, or flammable anesthetics. Using the unit near the site of a gasoline spill may cause an explosion. -

Page 7: Conventions

Purchase Order for a unit with an expired warranty. • If the unit needs to be sent to ZOLL Medical Corporation, obtain a service request number (SR#) from the Technical Service representative. Return the unit in its original container to:... -

Page 8: Technical Service For International Customers

Technical Service for International Customers International customers should return the unit in its original container to the nearest authorized ZOLL Medical Corporation Service Center. To locate an authorized service center, contact the International Sales Department at ZOLL Medical at the above address. -

Page 9: Chapter 1 Maintenance Tests

It is necessary to perform maintenance tests after a module is repaired to ensure that the functions of the Propaq MD unit work properly. Use the checklist at the back of this document (ZOLL Propaq MD Maintenance Tests Checklist) to record your results of the maintenance tests. - Page 10 Before You Begin the Maintenance Tests Assemble the tools listed in following section, “Equipment You Need to Perform the • Maintenance Tests.” Keep an extra fully charged Propaq MD battery available. • Schedule an hour to conduct the entire maintenance test. •...

- Page 11 • Agilent E3633A Power Supply • Agilent 34401 Digital Multi-meter • Accessories You Need for the Propaq MD Options Maintenance Tests 3-lead, 5-lead and 12-lead ECG cables. (12-lead cable needed if 12-lead option is • installed.) Dual lumen NIBP hose •...

-

Page 12: Physical Inspection Of The Unit

1.12 Are all bend/strain reliefs undamaged and free of excessive cable wear? 1.13 Battery Is the Propaq MD battery fully charged? 1.14 Is the battery seated in the battery well correctly? 1.15 Is battery housing free of cracks and damage? 1.16 Are connectors free of damage and excessive wear? -

Page 13: Operational Tests

Propaq MD Overview 2.0 Operational Tests The Propaq MD unit comes equipped with routine operational tests that can be performed periodically. With the exception of the Physical Inspection of the Unit test, these tests contain instructions within them that provide guidance during the tests. - Page 14 HAPTER AINTENANCE ESTS Keypad Test This test checks all the front panel buttons on the unit to make sure they are working correctly. Follow the instructions and use the navigation keys to move around the display and make selections. LED Test This test checks all the Light Emitting Diodes in the unit to make sure they are working correctly.

- Page 15 Propaq MD Overview LCD Test This test checks the colors of the Liquid Crystal Display on the unit. Follow the instructions and use the navigation keys to move around the display and make selections. RFU Indicator Test This test checks the Ready For Use Indicator on the unit to make sure it is working correctly.

- Page 16 HAPTER AINTENANCE ESTS Audio Test This test checks the audio tones on the unit to make sure they are working correctly. Follow the instructions and use the navigation keys to move around the display and make selections. Printer Test This test checks the printer to make sure it is working correctly. Follow the instructions shown on the display.

- Page 17 Propaq MD Overview Battery Test This test checks the battery to make sure it is working correctly. Follow the instructions on the display. Fan Test This test checks the fan in the unit to make sure it is working correctly.

- Page 18 ESTS USB Test (Optional) Note: Before starting this test, contact the ZOLL Technical Service Department to obtain a test file, or create a file (see instructions below). Once you have obtained a copy, save it on a USB thumb drive.

-

Page 19: Leads Test

Test each cable separately. Connect the lead wires appropriate for each test to the Fluke Impulse 7000DP Analyzer Test Setup equivalent, then connect the ECG cable to the Propaq MD unit. Do this... Observe this... Pass/Fail 3.1 Turn on the Propaq MD unit. -

Page 20: Heart Rate Display Test

HAPTER AINTENANCE ESTS 4.0 Heart Rate Display Test Fluke Impulse 7000DP Analyzer Equipment ECG Cable (3-lead, 5-lead or 12-lead) Press Lead quick access key until II displays. Test Setup Connect the ECG leads to the ECG studs on Analyzer. Do this... Observe this... -

Page 21: Heart Rate Alarm Test

Press the Alarm quick • access key ( Press the Limits softkey. • On the Propaq MD unit, select HR/ PR Alarm in the Alarm Settings menu and use the navigation keys to do the following: Set the Upper Limit Enable •... - Page 22 Set simulator to 160 BPM or higher. Heart Rate Value is highlighted and the alarm tone sounds. The HR/PR HIGH ALARM message displays. 5.13 On the Propaq MD unit, press Alarm is suspended for 90 seconds. The alarm suspension timer appears Alarm Silence/Reset button in black.

-

Page 23: Power Supply Test

Pass/Fail Install the Battery Current Test Fixture into battery well and wait about five seconds. Make sure the Propaq MD unit is turned off. Press the “I Measure” switch on the Verify that the reading on the digital Battery Current Test Fixture. - Page 24 HAPTER AINTENANCE ESTS Do this... Observe this... Pass/Fail On the Propaq MD unit, do the following: Press the More ( ) then the • Setup ( ) quick access keys. Use the navigation keys to • select Supervisor>Display/ Configuration>Device Info and select Restore All Factory Defaults.

-

Page 25: Leakage Current Test

Propaq MD Overview 7.0 Leakage Current Test See the manufacturer’s instructions or supplied specifications for the leakage tester you use. Equipment See the manufacturer’s instructions or supplied specifications for the leakage tester you use. Setup Repeat leakage test with accessories: MFC, external paddles, internal paddles, and anterior/ posterior paddles. -

Page 26: Shock Test

15% based on the values in the table “Delivered Energy at 200J Defibrillator Setting into a Range of Loads” on page 25. 8.12 On the Propaq MD unit, set the energy level to 50J by pressing the Energy Select UP arrow. 9650-0801-01 Rev. B... - Page 27 “Delivered Energy at 200J Defibrillator Setting into a Range of Loads” on page 25. 8.16 On the Propaq MD unit, set energy level to 100J by pressing the Energy Select UP arrow. 8.17 On the Propaq MD unit, press the The unit charges to 100J, the CHARGE button.

- Page 28 HAPTER AINTENANCE ESTS Do This... Observe This... Pass/Fail 8.25 When the Propaq MD unit is charged, start Verify that after 50 seconds the the stop watch. tone changes and within 10 seconds the unit does an internal discharge and displays DISARMED TIMEOUT.

- Page 29 261 J 260 J ±15% Note: For a complete listing of Propaq MD Delivered Energy at Every Defibrillator Setting into a , see Appendix A in the Propaq MD Operator’s Guide. Range of Loads 9650-0801-01 Rev. B Propag MD Service Manual...

-

Page 30: Synchronized Cardioversion Test

Select Sync mode on analyzer. Input 1mV ECG signal at 60 BPM. Do this... Observe this... Pass/Fail 9.1 Verify that the Propaq MD unit is turned on and the lead is PADS selected. 9.2 Press the SYNC softkey on the Sync appears on display. -

Page 31: Pacer Test

JACKS, then press F5 (Done) to measure pulse. 10.3 Connect the MFC connector to the Analyzer. 10.4 On the Propaq MD unit, apply power to the unit using a battery or an AC adapter. 10.5 On the Propaq MD unit, press the PACER button. -

Page 32: Printer Test

ESTS 11.0 Printer Test Verify paper is installed Equipment Do this... Observe this... Pass/Fail 11.1 On the Propaq MD unit, verify that paper is installed. 11.2 Print quick access key ( Press the to start the recorder. Note: If the printer fails to start, check setup for printer=yes. -

Page 33: Treatment Report Test

Do this... Observe this... Pass/Fail 12.1 Connect the multifunction cable (MFC) to the Analyzer, and turn on the Analyzer. 12.2 Turn on the Propaq MD unit, and press the The Clear Log window following quick access keys: displays. 12.3 Select Yes. -

Page 34: Spo2 Test

13.0 SpO Test Fluke Index 2 SpO Simulator (or equivalent), Nellcor™ SPO2 Finger Probe Equipment Disconnect any ECG cable or IBP probes from the Propaq MD unit. Test Setup Do This... Observe This... Pass/Fail 13.1 Power on the Propaq MD unit without the... -

Page 35: Etco2 Calibration (Required For Annual Calibration)

On the Propaq MD unit, select Supervisor>Service>Diagnostic>CO > Calibration to enter the CO Calibration control panel. 14.3 Connect the Propaq MD unit to the 5% calibration gas cylinder using the sample line included with the calibration kit. 14.4 From the CO Calibration Menu, select Calibration. -

Page 36: Etco2 Calibration Check

On the Propaq MD unit, select Supervisor>Service>Diagnostic>CO > Calibration to enter the CO Calibration control panel. 15.2 Connect the Propaq MD unit to the 5% calibration gas cylinder using the sample line included with the calibration kit. 15.3 From the CO Calibration control panel, select Verify Calibration. -

Page 37: Etco2 Test

Equipment Do this... Observe this... Pass/Fail 16.1 On the Propaq MD unit, install the airway adapter set and sampling line in the connector at the side of the unit. 16.2 The CO trace is on the display. -

Page 38: Ibp Test

17.8 Set the IBP patient simulator to 0 mmHg. 17.9 On the Propaq MD unit, press > IBP. 17. 1 0 On the Propaq MD unit, Press > P2->0<-. Display of 0/0(+/-2) in the P2 box at the bottom of the display (P1 is zeroed). - Page 39 Propaq MD Overview Do This... Observe This... Pass/Fail 17. 1 6 On the Propaq MD unit, Press > P2->0<-. Display of 0/0(+/-2) in the P3 box at the bottom of the display (P1 is zeroed). The waveform for channel 3 is present.

-

Page 40: Nibp Calibration Check

18.2 Connect a dual lumen hose from the NIBP simulator to the NIBP port of the Propaq 18.3 On the Propaq MD unit, do the following to enter the NIBP Test control panel: Press the More ( ) then the Setup •... - Page 41 Propaq MD Overview Do This... Observe This... Pass/Fail 18.11 From the Propaq MD NIBP Test control panel, use the navigation keys to select: Close Valve • Turn Pump On • 18.12 Monitor the pressure reported by the external pressure standard.

- Page 42 HAPTER AINTENANCE ESTS Do This... Observe This... Pass/Fail 18.26 Press twice and select Diagnostic>NIBP>Calibration Info. Verify that the last NIBP Cal date is today’s date. 18.27 Exit out of the Supervisor menu. 9650-0801-01 Rev. B...

-

Page 43: Nibp Leak Test

19.2 Connect a dual lumen hose from the NIBP simulator to the NIBP port of the Propaq 19.3 On the Propaq MD unit, do the following to enter the NIBP Test control panel: Press the More ( ) then the Setup •... -

Page 44: Deflation Test

20.0 Deflation Test Dual lumen NIBP hose, stop watch, NIBP simulator Equipment Do This... Observe This... Pass/Fail 20.1 From the Propaq MD NIBP Test control panel, use the navigation keys to select: Close Valve • Turn Pump On • 20.2 Monitor the pressure reported by the... -

Page 45: Inflation Test

Propaq MD Overview 21.0 Inflation Test Dual lumen NIBP hose, stop watch, NIBP simulator Equipment Do This... Observe This... Pass/Fail 21.1 Verify that the pressure reported by the NIBP Test control panel or the external pressure standard system is less than 5 mmHg. -

Page 46: Nibp Test

Dual lumen NIBP hose, NIBP simulator Equipment Do This... Observe This... Pass/Fail 22.1 On the Propaq MD unit, ensure the patient mode is set to Adult. 22.2 Set the simulator to the 80/50 simulator preset. 22.3 Take a manual reading. -

Page 47: Temperature Test

Do this... Observe This... Pass/Fail 23.1 Connect the temperature simulator to the Propaq MD T1 channel. 23.2 On the IBP Temp Simulator, Select 98.6 The displayed temperature value is Degree F (36 Degree C) or a setting as close within 0.2 F or 0.1 C of the as possible as your simulator allows. - Page 48 HAPTER AINTENANCE ESTS 9650-0801-01 Rev. B...

-

Page 49: Chapter 2 Troubleshooting

Propaq MD Error Messages The following is a list of the Propaq MD error messages that may appear on your display. The “Technical Action” column describes what you as a technician can do to correct the situation. Error Message... - Page 50 HAPTER ROUBLESHOOTING Error Message Explanation Technical Action QUICK ACCESS SW 1 Quick access key 1 is stuck. Replace the front panel. SHORT QUICK ACCESS SW 2 Quick access key 2 is stuck. Replace the front panel. SHORT QUICK ACCESS SW 3 Quick access key 3 is stuck.

- Page 51 Remove probe, power out-of-range A/D converter. cycle. If problem persists, replace main board. TEMP2 CIRCUIT FAILURE The software detected an Remove probe, power out-of-range A/D converter. cycle. If problem persists, replace main board. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 52 HAPTER ROUBLESHOOTING Error Message Explanation Technical Action IBP DEVICE FAILURE IBP software detected a Replace the main board. problem with the IBP data that is most likely a hardware issue. IBP PROBE1 SHORTED An A/D value was detected Replace the IBP probe. If that indicated the probe was problem persists, replace shorted.

- Page 53 Chapter 1, "Calibration and Calibration Checks". Check the routing of the • NIBP tubing inside the device for kinks or obstructions. If the NIBP module is out of calibration, replace the NIBP module. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 54 HAPTER ROUBLESHOOTING Error Message Explanation Technical Action NIBP AIR LEAK Major air leak or could not Attempt to identify reach target pressure. problems with the hose and/or cuff by doing the following: Check the hose • connection to the device. Make sure that the hose is tightly screwed onto the NIBP connector.

- Page 55 Calibrate the CO module soon. CO2 CAL REQUIRED Calibration due. Calibrate the CO module. CO2 CHECK FLOW Exhaust port blocked. Check for exhaust port occlusion. If problem persists, replace the CO module. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 56 HAPTER ROUBLESHOOTING Error Message Explanation Technical Action CO2 GAS INPUT inlet blocked. ® Replace FilterLine . If OCCLUSION problem persists, check for inlet occlusion. If still persists, replace the CO module. CO2 MAINTENANCE Periodic maintenance Replace CO module soon. REMINDER reminder.

- Page 57 If still persists, replace the defib board module. PACER DEVICE FAILURE Generation of pacer pulse Replace the defib board failed. module. PACER CURRENT FAULT Lack of pacer current. Replace the defib board module. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 58 HAPTER ROUBLESHOOTING 9650-0801-01 Rev B...

-

Page 59: Chapter 3 Disassembly Procedures

Chapter 3 Disassembly Procedures Overview This chapter provides instructions on how to disassemble and reassemble the Propaq MD unit, and includes the following sections: Required Equipment • Safety Precautions • Modules • Handle Disassembly • Printer Disassembly • Main Unit Disassembly •... -

Page 60: Safety Precautions

You must remove the wrist strap when you discharge high voltage or when you are working on energized equipment. Modules The Propaq MD unit contains the following nine (9) modules or assemblies: Printer •... -

Page 61: Removing The Handle

Using an orange stick, lift the screw covers off the handle in two locations. screw covers Remove four (4) screws (2 on each handle) and remove the handle. Note: During reassembly, torque screws to 8 in-lbs. screws 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... -

Page 62: Removing The Printer Module

Removing the Printer Module Tools Required #1 Phillips screwdriver with torque capability • Orange (wooden) stick • Setup This procedure should be conducted on a static mat. • Wear a wrist strap to ground during the procedure. • To reinstall the printer module, reverse the steps. Printer Disassembly Place the unit screen down on the mat in a horizontal position. - Page 63 Removing the Printer Module Disconnect the two (2) cable connectors from the printer module. connectors 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

-

Page 64: Disassembling The Main Unit

Disassembling the Main Unit Tool Required # 1 Phillips screwdriver with torque capability • orange (wooden) stick • Setup This procedure should be conducted on a static mat. • Wear a wrist strap to ground during the procedure. • Complete these procedures in the following order before performing this procedure: •... - Page 65 Use an orange stick to release the tabs on either side of silver ZIF connector between the dock connector and the monitor board. Note: Release one side at a time. NIBP hoses 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 66 Separate the two parts of the unit. 9650-0801-01 Rev B...

-

Page 67: Removing The Front Enclosure Module

Pivot top up with cables still connected. Remove grounding screw as shown in the illustration. grounding Note: During reassembly, torque screw to 6 screw in-lbs. Disconnect the front panel multi-wire cable in the area illustrated. multi-wire cable 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 68 Remove the ZIF (Zero Insertion Force) flex cable using an orange stick. 9650-0801-01 Rev B...

-

Page 69: Removing The Display Module

Flip the unit over and remove the screw in the area illustrated. Remove the hex standoff located underneath the screw you just removed. Note: During reassembly, torque to 6 in-lbs. hex standoff 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 70 Flip the unit back over so the display screen is facing up. Lift the casting up while pushing down on the rubber boot that runs around the edge of the LCD screen. boot Remove the copper tape from the casting. Note: During reassembly, apply new copper tape for grounding.

-

Page 71: Removing The Etco2 And Nibp Modules

(4) screws from inside the unit. Note: During reassembly, torque screws to 6 in-lbs. Remove three (3) screws from underneath and outside the unit. Note: During reassembly, torque screws to 6 in-lbs. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 72 Disconnect multi-wire IBP cable with ferrite multi-wire IBP cable in the area illustrated. Cut the tie wrap to the IBP cable in the area shown with the orange stick. Note: During reassembly, secure a new tie wrap to the IBP cable. Disconnect the USB flex cable from ZIF connector in the area illustrated.

- Page 73 Remove multi-wire EtCO cable with ferrite. Disconnect the brown SpO flex cable as shown. Disconnect the NIBP tubing from the side panel in the area illustrated. Remove the NIBP module from the unit. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 74 Tilt side panel to access the EtCO EtCo connector connector and use an orange stick release EtCO2 connector after removal the tabs and remove the EtCO connector. after removal EtCo connector before removal Remove the EtCO2 module from the unit. Remove three (3) screws from the outside of the left side panel in the areas illustrated.

-

Page 75: Removing The Monitor Board And Spo2 Modules

Remove the EtCO2 anti-conductive shield that lies on top of the unit. shield Remove six (6) screws to release the monitor board in the areas illustrated. Note: During reassembly, torque screws to 6 in-lbs. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 76 Lift the monitor board to expose the multi-wire LCD cable on the back side of monitor board and disconnect it. Remove three (3) screws and washers from the NIBP unit. Note: During reassembly, torque screws to 6 in-lbs. Lift the SpO2 unit straight up to disconnect it from the monitor board and remove it from the unit.

-

Page 77: Removing The Defibrillator Board And Capacitor Bank Modules

Remove interface board and disconnect the black cable by pulling the black snap rivet straight out. Remove the multi-color cable from the defibrillator board. multi-color cable Pull out small interconnect board. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 78 Remove screw in the middle of the plastic isolator (located on top of the processor board) in the area illustrated. Note: During reassembly, torque screw to 6 in-lbs. Remove the plastic isolator shield. Remove the four (4) screws in the areas illustrated.

- Page 79 6 in-lbs. Remove red and white multi-function cable connector from the ECG board in the area illustrated. Remove two (2) screws in the areas illustrated to release the capacitor from the unit. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 80 9650-0801-01 Rev B...

-

Page 81: Chapter 4 Life Cycle Counters

Life Cycle Counters Overview This chapter contains instructions for setting life cycle counters on the Propaq MD. The Propaq MD tracks various life cycle counters for specific modules installed in the device. When replacing modules in the unit, it is important to reset the life cycle counters. Once you have reset the appropriate life cycle counter(s), see “Functional Verification Tests”... - Page 82 HAPTER YCLE OUNTERS On the Propaq MD, do the following: 1. Press the Setup quick access key ( Use the navigation keys to select Supervisor>Service>Diagnostic>CO2>Service Codes. Select Reset CRC Counter. Select Yes when prompted to confirm the reset. See “Functional Verification Tests” on page 1-21 to perform the functional verification tests.

-

Page 83: Chapter 5 Replacement Parts

Chapter 5 Replacement Parts Overview This section contains a listing of the replacement parts available for the ZOLL Propaq MD devices. Replacement parts may be ordered through an authorized ZOLL distributor or directly from ZOLL Medical Corporation. The prices for parts are available from ZOLL Medical Corporation’s Technical Service Department. -

Page 84: Replacement Parts

HAPTER EPLACEMENT ARTS Replacement Parts PART NUMBER QUANTITY DESCRIPTION 705519 Handle Top 705517 Handle Bottom 705510 Screw 0162-0263 Screw Mount 705523 Left Cap, Handle 705524 Right Cap, Handle 1017-0005-01 Front Panel Assembly 403889 Panel I/O Left 402359 Panel I/O Right 705099-99 Back Housing 708494-99... - Page 85 PART NUMBER QUANTITY DESCRIPTION 7772-0001-01 Printer Assembly 7772-0002-01 Front Enclosure Assembly 7772-0003-01 Display Assembly 7772-0004-01 NIBP Assembly 7772-0005-01 Oridion Assembly 7772-0006-01 Monitor Board Assembly 7772-0007-01 CapBank Assembly 7772-0008-01 Defib Board Assembly 7772-0009-01 Assembly 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 86 HAPTER EPLACEMENT ARTS 9650-0801-01 Rev B...

-

Page 87: Chapter 6 Functional Description

The Propaq MD system relies on a centralized dual processor engine for its computing needs. The Main... - Page 88 ECG CPLD. Blood Pressure NIBP The Propaq MD NIBP circuitry resided on module that connects to the Monitor board through J32. The PP communicates to the NIBP module via a bi-directional, serial bus. The NIBP module supports both dual lumen and single lumen cuffs. The NIBP pump and valve hoses are connected to the cuff connector on the left side panel and to the filter on the rear enclosure.

- Page 89 Monitor board through J31. USB Host Port Propaq MD Monitor Board incorporates one USB Host ver 1.1 port. The port uses the USB controller built into the PXA270 Main processor. Full speed of 12 Mbps and Low speed 1.5Mbps are supported.

- Page 90 Monitor Board. Paddle Interface Paddle interface circuitry detects analog voltage levels to decode switches and ID resistors of the standard ZOLL paddles and internal paddles. The paddle set interface is connected to J115 of the Processor-Bridge-Pace PCB. 9650-0801-01 Rev B...

- Page 91 Overview Printer Propaq MD uses an internal thermal printer of 50 mm paper size that is built into the Defib section of the enclosure. Communications with the printer is bi-directional, serial, (Main CPU to/from printer) and complies with the software/hardware interface of the internal printer.

- Page 92 HAPTER UNCTIONAL ESCRIPTION 9650-0801-01 Rev B...

-

Page 93: Appendix A Overview

Appendix A Overview This appendix includes the following diagrams: Propaq MD Electrical Hardware Interconnect Diagram • Propaq MD Signal and Power Interconnect Schematic • 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... -

Page 94: Propaq Md Electrical Hardware Interconnect Diagram

PPENDIX Propaq MD Electrical Hardware Interconnect Diagram 9650-0801-01 Rev B... -

Page 95: Propaq Md Signal And Power Interconnect Schematic

Propaq MD Signal and Power Interconnect Schematic Propaq MD Signal and Power Interconnect Schematic 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 96 PPENDIX 9650-0801-01 Rev B...

-

Page 97: Appendix B Overview

A dual lumen hose is required for FastBP.When you use FastBP, the reading is obtained during cuff inflation. StepBP StepBP is compatible with both single and dual lumen hoses.When you use StepBP, the reading is obtained during step deflation. 9650-0801-01 Rev B ZOLL Propaq MD Service Manual... - Page 98 PPENDIX Bio-Tek Instruments BP Pump Adult/Pediatric Mode FastBP StepBP Simulator Expected Expected Expected Expected Setting Systolic Diastolic Systolic Diastolic 200/150 120/80 80/50 Neonate Mode NeoBP Simulator Expected Expected Setting Systolic Diastolic 60/30 35/15 Bio-Tek Instruments BP Pump2 Adult/Pediatric Mode FastBP StepBP Simulator Expected...

- Page 99 Clinical Dynamics Smart Arm Adult/Pediatric Mode FastBP StepBP Simulator Expected Expected Expected Expected Setting Systolic Diastolic Systolic Diastolic 200/150 120/80 80/50 Neonate Mode NeoBP Simulator Expected Expected Setting Systolic Diastolic 80/50 60/30 35/15 9650-0801-01 Rev B ZOLL Propaq MD Service Manual...

- Page 100 PPENDIX 9650-0801-01 Rev B...

Need help?

Do you have a question about the Propaq MD and is the answer not in the manual?

Questions and answers

Why won't the machine take any readings for vital signs