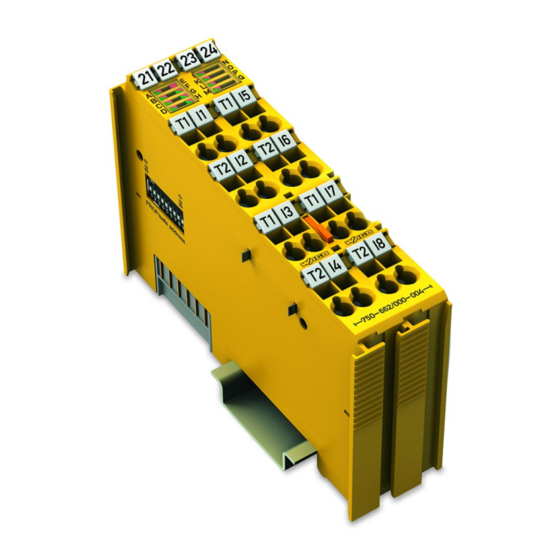

WAGO 8FDI 24V PROFIsafe 750-662/000-004 Manuals

Manuals and User Guides for WAGO 8FDI 24V PROFIsafe 750-662/000-004. We have 2 WAGO 8FDI 24V PROFIsafe 750-662/000-004 manuals available for free PDF download: Manual

WAGO 8FDI 24V PROFIsafe 750-662/000-004 Manual (138 pages)

8FDI 24V PROFIsafe Safe 8-Channel Digital Input; 24 VDC; PROFIsafe

Brand: WAGO

|

Category: I/O Systems

|

Size: 4 MB

Table of Contents

-

-

Symbols8

-

Legal Bases10

-

View18

-

Connectors19

-

Power Supply28

-

Device Data28

-

Approvals36

-

Applications37

-

Mounting43

-

ONLINE Mode57

-

OFFLINE Mode58

-

Diagnostics88

-

Procedure103

-

Service103

-

Firmware Update106

-

Appendix119

-

Profisafe119

-

Glossary126

-

List of Figures

134-

List of Tables136

-

Advertisement

WAGO 8FDI 24V PROFIsafe 750-662/000-004 Manual (128 pages)

Brand: WAGO

|

Category: I/O Systems

|

Size: 4 MB

Table of Contents

-

Symbols8

-

Legal Bases10

-

View18

-

Connectors19

-

Device Data28

-

Power Supply28

-

Approvals36

-

Applications37

-

Mounting42

-

ONLINE Mode52

-

OFFLINE Mode54

-

Diagnostics80

-

Service94

-

Procedure94

-

Appendix110

-

Profisafe110

-

Glossary117

-

List of Figures125

-

List of Tables126

Advertisement