Kemppi FastMig MXP 37 Pipe Steel Operating Manual

Hide thumbs

Also See for FastMig MXP 37 Pipe Steel:

- Operating manual (28 pages) ,

- Operating manual (30 pages)

Table of Contents

Advertisement

FastMig

MXP 37 Pipe Steel

MXP 37 Pipe Stainless

MXP 38

Operating manual

Brugsanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d'utilisation

Manuale d'uso

Gebruiksaanwijzing

Bruksanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

Advertisement

Table of Contents

Summary of Contents for Kemppi FastMig MXP 37 Pipe Steel

- Page 1 FastMig MXP 37 Pipe Steel MXP 37 Pipe Stainless MXP 38 Operating manual Brugsanvisning Gebrauchsanweisung Manual de instrucciones Käyttöohje Manuel d’utilisation Manuale d’uso Gebruiksaanwijzing Bruksanvisning Instrukcja obsługi Manual de utilização Инструкции по эксплуатации Bruksanvisning 操作手册...

- Page 3 OPERATING MANUAL English...

-

Page 4: Table Of Contents

CONTENTS Introduction ....................General . -

Page 5: Introduction

This operating manual contains important information on the use, maintenance and safety of your Kemppi product. The technical specifications of the equipment can be found at the end of the manual. Please read the operating manual and the safety instructions booklet carefully before using the equipment for the first time. -

Page 6: Installation

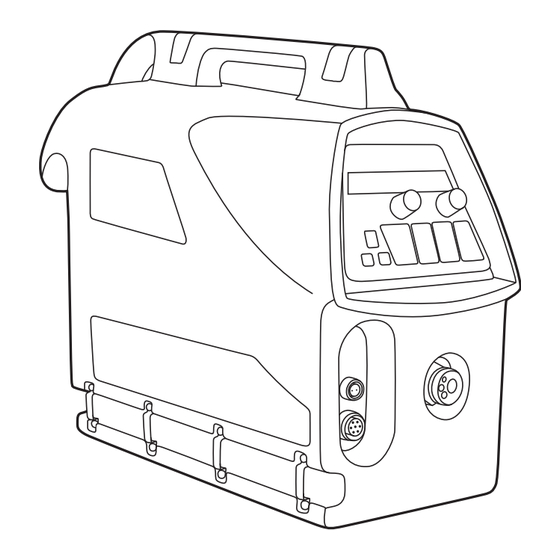

INSTALLATION Machine introduction: MXP 37 Pipe and MXP 38 MXP 37 Pipe MXP 38 1. Control panel XF 37 1. Control panel XF 38 2. ON/OFF button 2. ON/OFF button 3. Euro gun connection 3. Euro gun connection 4. Voltage sensing cable connection 4. -

Page 7: Connecting Cables

11. Voltage sensing cable (from wire feeder to work piece) MXP wire feeders can also be used with FastMig Pulse power source, but in that case NOTE! measurement cable and voltage sensing cable will not be used. © Kemppi Oy / 1515... -

Page 8: Assembly Of Mig/Mag System

2.2.2 Air-cooled system: FastMig X 450 + MXP Wire feed unit FastMig X 450 power source Gas supply MMA electrode holder Remote control device Air-cooled welding gun Power cable Earth return cable and clamp Measurement cable (from power source to wire feeder) 10. -

Page 9: Accessories Corresponding To Wire Diameter

For FastMig X 450 and MXP 37 Pipe setup Kemppi offers the PMT MN welding gun model, which is specially designed for welding root and fill passes on pipe. The neck is replaceable, so you can select just the right bending angle for different work stages. -

Page 10: Loading The Filler Wire And Automatic Feed

Loading the filler wire and automatic feed Automatic wire feed makes wire spool changes faster. When changing the wire spool, the pressure of feed rolls need not be released. Simply ensure that the groove of the feed roll matches the diameter of filler wire used. Release the wire end from the spool and cut off any deformed section. - Page 11 W006085 W006086 W006087 Fc, Mc, Ss, Fe W006088 W006089 U-groove W006090 W006091 W006092 W006093 Mount the lower feed roll, ensuring that the pin on the shaft fits in the cut on the feed roll. NOTE! © Kemppi Oy / 1515...

-

Page 12: Duratorque™ 400, 4-Wheel Wire Feed Mechanism In Mxp

DuraTorque™ 400, 4-wheel wire feed mechanism in MXP 38 Wire guide tubes ø mm outlet tube middle tube inlet tube Ss, Al, W007437 W007429 W007293 (Fe, Mc, Fc) 0.8 – 0.9 W007438 W007430 W007294 plastic W007439 W007431 W007295 W007440 W007432 W007296 W007441 W007433... - Page 13 W006086 W006087 Al, (Fc, Mc, Ss, Fe) W006088 W006089 U-groove W006090 W006091 W006092 W006093 Mount the lower feed roll, ensuring that the pin on the shaft fits in the cut on the feed roll. NOTE! © Kemppi Oy / 1515...

-

Page 14: Adjustment Of Pressure Arms

2.10 Adjustment of pressure arms Adjust the drive pressure to the filler wire with the thumb screws mounted over the pressure arms. Notice the graduated scales indicating load. The load applied should be sufficient to overcome a light braking force applied by hand to the filler wire, as it exits the welding gun contact tip. -

Page 15: Shielding Gas

Remember to close gas bottle valve after welding. Parts of gas flow regulator Gas bottle valve Flow regulation screw Connecting nut Hose tail Hose tail nut Gas bottle pressure gauge Shielding gas flow meter © Kemppi Oy / 1515... -

Page 16: Main Switch I/O

2.15 Main switch I/O When you turn the main switch of the FastMig power source into I-position, the pilot lamp closest to this switch will illuminate, indicating the power source is ready for welding. The equipment will return to the same operation state where it was before the last shutdown. Always start and switch off the machine with the main switch, never use the mains plug as a switch. -

Page 17: Layout

Voltage display will show arc voltage if selected from the setup panel. Voltage display's last dot indicates that arc voltage display is selected (for example 23.5. V). If arc voltage feature is not used, pole voltage of the power source is shown. © Kemppi Oy / 1515... -

Page 18: Button Functions

Button functions 3.3.1 ON/OFF button (1) Short press: XF 37 / X 38 panel returns to initial display. Long press: XF 37 / X 38 panel is turned ON or OFF. When wire feeder XF 37 / XF 38 control panel is turned ON, also the power source control NOTE! panel X 37 turns on and links automatically to this wire feeder. - Page 19 • selected parameter values. 3.3.11 Arc length and voltage control knob (11) XF 37 CH REMOTE This control knob adjusts the arc length, voltage or selected parameter values before or CHANNEL during welding. PANEL © Kemppi Oy / 1515 XF 37...

-

Page 20: Welding Software

If your welding needs change and you wish to update your system in the future, you can order additional welding programs or other welding software and load them to your system with Kemppi DataGun field programming device. Optional features can be purchased through Kemppi DataStore. - Page 21 More welding programs are available by purchasing MatchCurve and MatchCustom products. STEEL PACK FOR WISETHIN+ Group Material Wire ø (mm) Shielding gas Process Number Ar+15–25%CO₂ WiseThin+ Ar+15–25%CO₂ WiseThin+ Ar+15–25%CO₂ WiseThin+ Ar+15–25%CO₂ WiseThin+ CO₂ WiseThin+ CO₂ WiseThin+ CO₂ WiseThin+ CO₂ WiseThin+ © Kemppi Oy / 1515...

-

Page 22: Arc Voltage Display

WORK PACK Group Material Wire ø (mm) Shielding gas Process Number AlMg5 Pulse/Double Pulse AlSi5 Pulse/Double Pulse Ar+15–25%CO₂ Pulse/Double Pulse Ar+15–25%CO₂ Pulse/Double Pulse CrNiMo 19 12 Ar+2%CO₂ Pulse/Double Pulse CrNiMo 19 12 Ar+2%CO₂ Pulse/Double Pulse AlMg5 1-MIG AlSi5 1-MIG Ar+15–25%CO₂ 1-MIG Ar+15–25%CO₂... -

Page 23: Basic Troubleshooting

Err1 Power source is not calibrated or calibration data cannot be read • Restart power source • if the problem continues after multiple startups contact Kemppi service representative Err 3 Overvoltage in the mains supply • Check the mains voltage... - Page 24 • Check the shielding gas, gas guard and all connections. Err 50 The function is not activated in this machine • if you need this function, order a licence for it from a Kemppi representative. Err 51 Rear feed roll may be loose • Check that the feed rolls are properly tightened.

-

Page 25: Maintenance

Do not use compressed air, there is a risk that the dirt will compact even more tightly into gaps of cooling profiles. Do not use pressure washing devices. Only an authorized trained electrician should carry out repairs to Kemppi machines. Service Workshop maintenance Kemppi Service Workshops complete maintenance according to their Kemppi service agreement. -

Page 26: Disposal Of The Machine

The owner of the equipment is obliged to deliver a decommissioned unit to a regional collection centre, as per the instructions of local authorities or a Kemppi representative. By applying this European Directive you will improve the environment and human health. - Page 27 WiseFusion™ Included with MXP 37 wire feeder 9991014 WisePenetration™ function 9991000 Pipe Steel welding program package Inlcuded with FastMig MXP 37 Pipe Steel wire 99904274 feeder Pipe Stainless welding program package Inlcuded with FastMig MXP 37 Pipe Stainless wire 99904275...

- Page 28 WS 42 W Ss 1.2 mm 6254206S12 WS 42 W Ss 1.0 mm 6254208S10 WS 42 W Ss 1.2 mm 6254208S12 For a complete list of welding guns, please visit Kemppi web site at www.kemppi.com. FastMig MXP 37 Pipe, MXP 38...

-

Page 29: Technical Data

-40 ... +60 °C EMC class Degree of protection IP23S IP23S External dimensions L x W x H 590 x 240 x 445 mm 625 x 243 x 476 mm Weight 13.1 kg 12.5 kg © Kemppi Oy / 1515... - Page 30 KEMPPI OY KEMPPI, TRADING (BEIJING) COMPANY LTD Telefax +44 (0)845 6444202 Kempinkatu 1 sales.uk@kemppi.com Unit 105, 1/F, Building #1, PL 13 No. 26 Xihuan South Rd., KEMPPI FRANCE S.A.S. FIN-15801 LAHTI Beijing Economic-Technological Development 65 Avenue de la Couronne des Prés...

Need help?

Do you have a question about the FastMig MXP 37 Pipe Steel and is the answer not in the manual?

Questions and answers