Summary of Contents for Kemppi M 420MV FastMig

- Page 1 FastMig M 420MV Operating manual Brugsanvisning Manual de instrucciones Manual de utilização...

- Page 3 OPERATING MANUAL English...

-

Page 4: Table Of Contents

CONTENTS Introduction ......................... General . -

Page 5: Introduction

This operating manual contains important information on the use, maintenance and safety of your Kemppi product. The technical specifications of the equipment can be found at the end of the manual. Please read the manual carefully before using the equipment for the first time. For your own safety and that of your working environment, pay particular attention to the safety instructions in the manual. -

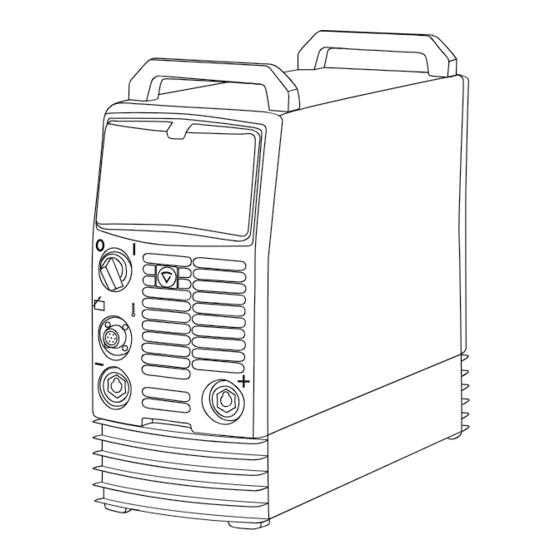

Page 6: About Fastmig M 420Mv

About FastMig M 420MV FastMig M 420MV is multi-operator power source designed for demanding professional use. It is suitable for MMA and MIG welding in DC. 1.2.1 Operation control and connectors 6,3A Fuse (delayed 6.3 A) Signal lamp Warning lamp for thermal protection Main switch Welding connection Earth connection... -

Page 7: Cables

MXF wire feed unit FastMig power source FastCool water cooler and power connection Gas supply MMA electrode holder Remote control device Liquid cooled welding Gun Power cable Earth return cable and clamp 10. Control cable © Kemppi Oy / 1515... -

Page 8: Installation

Air-cooled system: FastMig power source + MXF MXF wire feed unit FastMig power source Gas supply MMA electrode holder Remote control device Air cooled welding Gun Power cable Earth return cable and clamp Control cable INSTALLATION Positioning of the machine Place the machine on a firm, dry and level surface. -

Page 9: Connection To The Mains Supply

! Always check the serviceability of the earth return cable and clamp. Ensure the metal NOTE surface to which the cable is connected is clean from metal oxide or paint. Check the connector to the power source is fastened correctly. © Kemppi Oy / 1515... -

Page 10: Operation Controls

OPERATION CONTROLS Main switch I/O When you turn the switch into I-position, pilot lamp H11 on the front face is illuminated and the machine is ready for use. Always turn the machine on and off with the mains switch, never use the mains plugs as a NOTE! switch. -

Page 11: Maintenance

• Operation and performance values of the machine are checked, and when necessary adjusted by means of software and test equipment. Software loading • Kemppi Service Workshops can also test and load firmware and welding software. © Kemppi Oy / 1515... -

Page 12: Operation Disturbances

Should you experience a malfunction from your machine, please consult the basic troubleshooting text above first, and complete some basic checks. If the machine malfunction cannot be corrected with these measures, contact your Kemppi maintenance service workshop. Operation of the overload protection Yellow thermal protection lamp is lit when the thermostat is operating due to loading beyond the stated duty cycle. -

Page 13: Ordering Numbers

Cable for MMA welding 5 m, 70 mm² 6184701 6185409 AS KIT 6264263 Remote controlled interconnecting cable 10 m 6185481 Cooling unit FastCool 10 6068100 Transport unit PM 500 6185291 Gun holder GH 30 6256030 © Kemppi Oy / 1515... -

Page 14: Technical Data

TECHNICAL DATA FastMig™ M 420MV 230 V range 400 V range Connection voltage 3~, 50/60 Hz 220 V -10 %...230 V +10 % 380 V -10 %...440 V +10 % Rated power 60% ED 21 kVA 22 kVA 100% ED 18 kVA 19 kVA Connection cable... - Page 16 KEMPPI OY KEMPPI, TRADING (BEIJING) COMPANY LTD Telefax +44 (0)845 6444202 Kempinkatu 1 sales.uk@kemppi.com Unit 105, 1/F, Building #1, PL 13 No. 26 Xihuan South Rd., KEMPPI FRANCE S.A.S. FIN-15801 LAHTI Beijing Economic-Technological Development 65 Avenue de la Couronne des Prés...