Table of Contents

Advertisement

Quick Links

Service Manual

EN

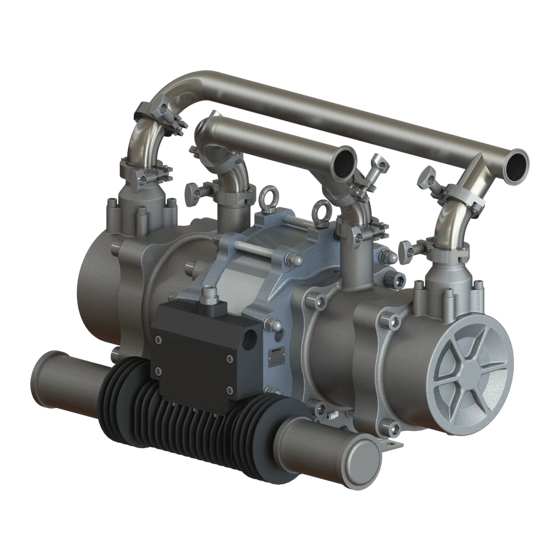

Maple 120/3 Pump

• Models 104265-HE & 104265-PE

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and understand this

manual.

Contact your local Carlisle Fluid Technologies representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS PRODUCT

77-3340 R1.0 (06/2021)

1/28

www.carlisleft.com

Advertisement

Table of Contents

Summary of Contents for Carlisle Binks Maple 120/3

- Page 1 It is the Customer's responsibility to have all operators and service personnel read and understand this manual. Contact your local Carlisle Fluid Technologies representative for additional copies of this manual. READ ALL INSTRUCTIONS BEFORE OPERATING THIS PRODUCT 77-3340 R1.0 (06/2021) 1/28 www.carlisleft.com...

-

Page 2: Eu Declaration Of Conformity

Notified body details and role: Element Materials Technology (0891) Lodging of Technical file This Declaration of conformity / incorporation is issued Carlisle Fluid Technologies UK Ltd, under the sole responsibility of the manufacturer: Ringwood Road, Bournemouth, BH11 9LH. UK Representative authorised to compile the technical file Sales and Marketing Director. - Page 3 Ex h IIB T4 Gb X Notified body details and role: Element Materials Technology (0891) Lodging of Technical file This Declaration of conformity/incorporation Carlisle Fluid Technologies UK Ltd, is issued under the sole responsibility of the Ringwood Road, manufacturer: Bournemouth, BH11 9LH. UK UKCA Declaration of Conformity ...

- Page 4 In this part sheet, the words WARNING, CAUTION and NOTE are used to emphasize important safety information as follows: WARNING CAUTION NOTE Hazards or unsafe practices which could result in Hazards or unsafe practices which could result in Important installation, operation or maintenance minor personal injury, product or property severe personal injury, death or substantial property information.

-

Page 5: Specification

Specification Ratio: Maximum air inlet pressure: 7 bar [101.5 psi] Maximum fluid pressure: 21 bar [304.5 psi] Nominal flow volume / cycle: 3.0 l/m [0.8 US gal/m] Output @ 60 cycles / min: 180 l/m [48 US gal/m] Maximum recommended continous cycle rate: See Graph - Page 6 Cycles/min Maximum recommended intermittent cycle rate:Cycles/min... - Page 6 Specification MAPLE 120/3 - PERFORMANCE CHART CYCLES/MIN CONTINUOUS INTERMITTENT FLUID FLOW [l/m] AIR CONSUMPTION AIR CONSUMPTION AIR CONSUMPTION RECOMMENDED OPERATING ENVELOPE - MAPLE 120/3 CONTINUOUS INTERMITTENT SPEED (Cycles / min) 77-3340 R1.0 6/28 www.carlisleft.com...

-

Page 7: Mounting Locations

Specification 2" SANITARY OUTLET 2" SANITARY INLET ** DETAIL VIEWS OF 104625-PE (PIPED EXHAUST) 3/4" BSPP AIR INLET EARTHING POINT PIPE CONNECTION 1.5'' NB PIPE MOUNTING LOCATIONS SECTION A-A 77-3340 R1.0 7/28 www.carlisleft.com... -

Page 8: Installation

Installation Mount the pump securely and position the pump at a convenient height (below the lid height of the paint container), to allow for maintenance, visual observation, and periodic inspection. The foot mount bracket is included with all pumps. The foot Mounting bracket must be connected to a suitable earth ground to ensure that there is no possibility of static build up. - Page 9 Installation This product should be flushed with a suitable compatible solvent prior to use. Check all inlet & outlet fittings for tightness. Set the pump speed to a slow cycle rate and prime the pump to remove any air before increasing pressure.

- Page 10 NOTES This product should be flushed with a suitable compatible solvent prior to use. Check all inlet & outlet fittings for tightness. Set the pump speed to a slow cycle rate and prime the pump to remove any air before increasing pressure.

-

Page 11: Pump Assembly

Pump Assembly ITEM PART NO. DESCRIPTION REMARKS MAPLE 120/3 PUMP ASSEMBLY 104265-PE, HE 192803 1" PLUG 104265-PE 192820 1 1/4" NB EXHAUST HOSE ADPATOR 104265-PE 195850 HEAT EXCHANGER EXTENSION 104265-PE 192821 HEAVY DUTY MUFFLERS 104265-HE 195849 HEAT EXCHANGER EXTENSION 104265-HE 104265-HE 104265-PE 77-3340 R1.0... - Page 12 Parts list - Pump Assembly ITEM PART NO. DESCRIPTION REMARKS 160513 SPRING ❶ ❷ 162897 O-RING ❶ ❷ 162913 PISTON SEAL ASSEMBLY ❶ ❷ ❻ RIVET ❽ 165123 SPRING WASHER 165947 ❽ SOCKET HEAD CAP SCREW 171784 ❷ BALL 177144 ❽...

- Page 13 Pump Assembly = GREASE (AGMD-010) = LOCTITE = TORQUE = GREASE INTERNAL (AGMD-010) Two small drops 77-3340 R1.0 13/28 www.carlisleft.com...

- Page 14 Parts list - 195816-K - Air Motor Assembly ITEM PART NO. DESCRIPTION REMARKS 0115-010037 POPPET ASSEMBLY ❿ 161994 O-RING ❸ ❹ 162738 O-RING ❸ ❹ 162896 O-RING ❸ ❹ ❺⓮ 165100 SPRING WASHER 165123 SPRING WASHER ❺ 165981 DOME NUT ❺...

- Page 15 77-3340 R1.0 15/28 www.carlisleft.com...

- Page 16 195823-K - Air Motor Piston Assembly ITEM PART NO. DESCRIPTION REMARKS 161451 O-RING ❸ ❹ 162739 AIR MOTOR PISTON SEAL ❸ ❹ PISTON WASHER PISTON SHAFT PISTON SHAFT PLEASE NOTE, ALL COMPONENTS WITH A KIT NUMBER ARE ONLY AVAILABLE FOR PURCHASE AS PART OF A KIT. SEE KITS / CONTENTS, PAGES 21 - 25 = GREASE (AGMD-010)

-

Page 17: Valve Block

195817-K - Air Valve Assembly ITEM PART NO. DESCRIPTION REMARKS 0115-010424 SPOOL AND SLEEVE ASSEMBLY ❾ 0115-010425 ❾ VALVE BLOCK END CAP 0115-010427 ❸❾ BUMPER 0115-010428 MAGNET ❾ ❸ 0115-010431 SPACER 0115-010463 ❸❾⓫ QEV PISTON 162719 ❸❹❾ O-RING 162767 O-RING ❸❹❾... - Page 18 195824 - Fluid Piston Assembly ITEM PART NO. DESCRIPTION REMARKS 162854 ❶ ❷ O-RING 162904 ❶ ❷ O-RING 162905 ❶ ❷ O-RING 162906 ❶ ❷ O-RING 171789 ❷ BALL ❶ ❷ 192629 INLET SPRING KEEP 192938 ❷ SEAT FLUID PISTON 195802 ❷...

-

Page 19: Fault Finding

Fault Finding Symptom Possible Cause Remedy Air getting into the suction hose/manifold Check seals and hose connections. Pump will not ‘Prime’ Worn piston seal. Replace piston seals. Inspect, clean and/or replace balls Ball checks not seating correctly. and seats. Check air and fluid supply ball valves No Air or Fluid supply and supply hoses. - Page 20 Fault Finding Symptom Possible Cause Remedy Worn air motor piston seals. Replace air motor piston seal. Disassemble pump as required to Worn/failed air motor shaft seals. replace air motor shaft seals. Pump runs but has excessive pulsation. Worn fluid piston seal. Replace fluid piston seal.

- Page 21 Spares Kits for Maple 120/3 Pump ❶ 250846 - FLUID SECTION SEAL KIT PART NO. DESCRIPTION REMARKS 192029 SANITARY GASKET 192505 O-RING - PTFE 160513 SPRING 192629 INLET SPRING KEEP 162897 O-RING - PTFE 192646 O-RING - PTFE 162854 O-RING 162904 O-RING 162905...

- Page 22 Spares Kits for Maple 120/3 Pump ❸ 250843 - Ø320 AIR MOTOR SEAL KIT PART NO. DESCRIPTION REMARKS 0115-010427 BUMPER 0115-010463 QEV PISTON 193244 GASKET 0115-010431 SPACER 162767 O-RING 163951 CAP HEAD SCREW 162719 O-RING 161994 O-RING 162896 O-RING 162738 O-RING 195772 BEARING...

- Page 23 Spares Kits for Maple 120/3 Pump ❺ 250852 - Ø320 AIR MOTOR FIXINGS KIT PART NO. DESCRIPTION REMARKS 165100 SPRING WASHER 165123 SPRING WASHER 165981 DOME NUT 165982 SPRING WASHER 177142 CAP HEAD SCREW 177143 CAP HEAD SCREW 163951 CAP HEAD SCREW 195790 EYE BOLT ❻...

- Page 24 Spares Kits for Maple 120/3 Pump ❿ 0115-010037-K2 - POPPET KIT - 1 PUMP PART NO. DESCRIPTION REMARKS 0115-010037 POPPET ASSEMBLY ❿ 0115-010037-K10 - POPPET KIT - 5 PUMP PART NO. DESCRIPTION REMARKS 0115-010037 POPPET ASSEMBLY ⓫ 0115-010463-K2 -QEV PISTON - 1 PUMP PART NO.

- Page 25 Spares Kits for Maple 120/3 Pump ⓯ 250863 INLET MANIFOLD KIT PART NO. DESCRIPTION REMARKS 195799 INLET MANIFOLD 192029 SANITARY GASKET 192544 SANITARY CLAMP 195801 ELBOW ⓰ 250864 OUTLET MANIFOLD KIT PART NO. DESCRIPTION REMARKS 195800 OUTLET MANIFOLD 192029 SANITARY GASKET 192544 SANITARY CLAMP 195801...

-

Page 26: Bellows Replacement

Bellows Replacement ITEM PART NO. DESCRIPTION REMARKS 502957 BELLOWS ASSEMBLY SPIGOT 502958 BELLOWS POSITIONING TOOL Screw Item No. 1 (assembly spigot) onto the piston shaft Using Item No. 2, push bellows over spigot until located in groove. Thread nut onto bellows ensuring the thread starts squarely. - Page 27 Accessories ITEM PART NO. REMARKS 2" Sanitary - 193275 3/4" NPT (f) Adapter Heavy duty 192028 2" Sanitary Clamp 502959 Seal Insertion Tool For Shaft seal (27) 502957 Seal Insertion Tool 502958 Bellows assembly spigot AGMD-010 Kluber Isoflex Topas NB 52 Grease 50ml Tube 77-3340 R1.0 27/28...

-

Page 28: Warranty Policy

WARRANTY POLICY This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty. The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties. Failure to reasonably follow any maintenance guidance provided, may invalidate any warranty.

Need help?

Do you have a question about the Binks Maple 120/3 and is the answer not in the manual?

Questions and answers