Table of Contents

Advertisement

Quick Links

Service Manual

EN

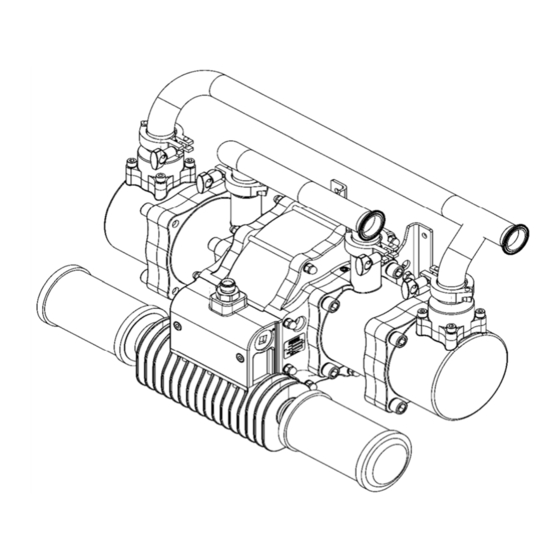

Maple 60/3 Pump

• Model 104020-M2

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and

understand this manual.

Contact your local Carlisle Fluid Technologies representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS PRODUCT

77-3236 R4.1

www.carlisleft.com

Advertisement

Table of Contents

Summary of Contents for Carlisle Maple 60/3

- Page 1 IMPORTANT! DO NOT DESTROY It is the Customer's responsibility to have all operators and service personnel read and understand this manual. Contact your local Carlisle Fluid Technologies representative for additional copies of this manual. READ ALL INSTRUCTIONS BEFORE OPERATING THIS PRODUCT 77-3236 R4.1...

-

Page 2: Eu Declaration Of Conformity

Providing all conditions of safe use / installation stated within the product manuals have been complied with and also installed in accordance with any applicable local codes of practice. D Smith Director of Sales (EMEA) Signed for and on behalf of Carlisle Fluid Technologies UK Ltd: 27/6/18 Bournemouth,BH11 9LH,UK 77-3236 R4.1... - Page 3 In this part sheet, the words WARNING, CAUTION and NOTE are used to emphasize important safety information as follows: WARNING CAUTION NOTE Hazards or unsafe practices which could result Hazards or unsafe practices which could result in Important installation, operation or severe personal injury, death or substantial in minor personal injury, product or property maintenance information.

-

Page 4: Specification

Specification Ratio: Maximum air inlet pressure 7 bar [101.5 psi] Maximum fluid pressure: 21 bar [304.5 psi] Nominal Flow Volume / Cycle: 1.5 l/m [0.4 US gal/m] Fluid Output @ 60 cycles/min 90 l/m [24 US gal/m] Maximum Recommended Continous Cycle Rate: 20 Cycles / min Maximum Recommended Intermittent Cycle Rate: 40 Cycles / min... -

Page 5: Dimensions And Mounting Details

Dimensions and Mounting Details 1 ½" Sanitary outlet 1 ½" Sanitary inlet MOUNTING LOCATIONS SECTION A-A 77-3236 R4.1 www.carlisleft.com 5/24... -

Page 6: Installation

Installation This product should be flushed with a suitable compatible solvent prior to use. Mount the pump securely and position the pump at a convenient height (below the lid height of the paint container), to allow for maintenance, visual observation, and periodic inspection. The wall mount bracket is included with all pumps. - Page 7 Installation Set the pump speed to a slow cycle rate and prime the pump to remove any air before increasing pressure. Inspect for any system leaks. Set the pump cycle rate to achieve the required paint volume and then adjust the system back pressure regulator and pump air pressure to achieve the desired system fluid pressure.

- Page 8 Parts list - Pump Assembly ITEM PART NO. DESCRIPTION REMARKS 160513 SPRING 164472 M8 x 25 SOCKET HEAD CAP SCREW 164838 No.2 x 4.75 RIVET 165077 M14 SPRING WASHER 165108 M8 SPRING WASHER 165978 M14 x 40 SOCKET HEAD CAP SCREW ...

- Page 9 Parts list - Pump Assembly GREASE LOCTITE TORQUE MAINTENANCE ORDER (Reverse for assembly) GREASE INTERNAL (AGMD-010) 77-3236 R4.1 www.carlisleft.com 9/24...

- Page 10 Parts list - Air Motor Assembly ITEM PART NO. DESCRIPTION REMARKS 0115-010037 POPPET ASSEMBLY 161993 Ø23.5 x 1.78 O-RING 161994 Ø4.47 x 1.78 O-RING 162729 SHAFT SEAL 162730 SHAFT BEARING 162731 Ø230 x 4 O-RING 165108 SPRING WASHER 165135 PLAIN WASHER 165963...

- Page 11 77-3236 R4.1 www.carlisleft.com 11/24...

- Page 12 Parts list - Air Motor Piston Assembly ITEM PART NO. DESCRIPTION REMARKS 162728 AIR MOTOR PISTON SEAL 165975 M16 x 61 GRUB SCREW 192882 PISTON SHAFT 192886 PISTON GREASE LOCTITE TORQUE MAINTENANCE ORDER (Reverse for assembly) GREASE INTERNAL (AGMD-010) 77-3236 R4.1 www.carlisleft.com 12/24...

-

Page 13: Air Valve Assembly

Air Valve Assembly ITEM PART NO. DESCRIPTION REMARKS 0115-010425 SPOOL AND SLEEVE O-RING 0115-010427 BUMPER 0115-010428 MAGNET 0115-010431 SPACER 0115-010463 QEV PISTON 162719 Ø47.29 x 2.62 O-RING 162767 Ø30 x 2 O-RING 163951 M16 x 16 SOCKET HEAD CAP SCREW 192651 1/'' BSPP PLUG 0115-010424... - Page 14 Air Valve Assembly GREASE LOCTITE TORQUE MAINTENANCE ORDER (Reverse for assembly) GREASE INTERNAL (AGMD-010) MAGNET HAZARD 77-3236 R4.1 www.carlisleft.com 14/24...

- Page 15 Parts list - Piston Assembly ITEM PART NO. DESCRIPTION REMARKS 160513 PISTON BALL CHECK SPRING 162805 Ø63.17 x 2.62 O-RING 162806 Ø107.62 x 2.63 O-RING 162807 Ø50.52 x 1.78 O-RING 171784 BALL 192629 INLET SPRING KEEP ...

- Page 16 Use a 36mm Single Hex Socket when tightening or removing ball cage from Piston. GREASE LOCTITE TORQUE MAINTENANCE ORDER (Reverse for assembly) GREASE INTERNAL (AGMD-010) 77-3236 R4.1 www.carlisleft.com 16/24...

-

Page 17: Fault Finding

Fault Finding Symptom Possible Cause Remedy Air getting into the suction hose/manifold Check seals and hose connections. Pump will not Worn piston seal. Replace piston seals. ‘Prime’ Inspect, clean and/or replace balls Ball checks not seating correctly. and seats. Check air and fluid supply ball No air or fluid supply valves and supply hoses. - Page 18 Fault Finding Symptom Possible Cause Remedy Check seals and hose connections. Air getting into fluid line, air supply restricted. Check air supply Remove, clean, and inspect seat, ball, and ball cage. Obstructed fluid ball checks. Replace if suspect or worn. Worn air motor piston seals.

- Page 19 Spares Kits for Maple 60/3 Pump KIT No. PART No. DESCRIPTION QTY. REMARKS 250632 Fluid section seal kit Check main parts list 250687 Fluid overhaul kit for details of individual kit contents 250656 Air Motor Seal Kit...

-

Page 20: Maintenance Schedule

Maintenance schedule Inspection Operation Daily Check for any general fluid or air leakage. Inspect Pump for Correct operation Check for any excessive mechanical noise Weekly Check for excessive fluid pressure pulsation Perform a pump stall test to ensure correct operation. If pump does not stall, check fluid piston seals and ball checks, replace as required. -

Page 21: Bellows Replacement

Bellows Replacement ITEM PART NO. DESCRIPTION REMARKS 502682 Bellows positioning tool 502681 Bellows assembly spigot Screw Item No. 2 (assembly spigot) onto the piston shaft Using Item No. 1, push bellows over spigot until located in groove. Smear loctite 572 over nose of bellows, thread nut onto bellows ensuring the thread starts squarely. - Page 22 Accessories PART NO. DESCRIPTION REMARKS 192008 1 ½'' Sanitary Gasket 192009 1 ½'' Sanitary Clamp 502680 Seal Insertion Tool For Shaft seal (162729) 502681 Bellows Assembly Spigot 502682 Bellows Positioning Tool AGMD-010 Kluber Isoflex Topas NB 52 Grease 50ml Tube 192779 Exhaust Tube Adapter (1”...

- Page 23 NOTES 77-3236 R4.1 www.carlisleft.com 23/24...

- Page 24 WARRANTY POLICY This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty. The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties. Failure to reasonably follow any maintenance guidance provided, may invalidate any warranty.

Need help?

Do you have a question about the Maple 60/3 and is the answer not in the manual?

Questions and answers