Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Noblelift PT 27R

- Page 1 重诺力行 物动随心 Service Manual PT27-36R PT27-36RM 1/2021 物料搬运· 系统集成...

-

Page 2: Table Of Contents

重诺力行 物动随心 Content GENERAL ............................... 5 INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS ..........5 MEASUREMENT CONVERSIONS ..................... 8 Sepcification ............................14 Overview of the main components .................... 14 Specification table ........................15 Electrical system ........................... 18 Electrical circuit diagram PT27R ..................... 18 Battery Using ............................ - Page 3 重诺力行 物动随心 Replace oil seal of lifting cylinder ....................60 Replace the sealing ring of the lifting cylinder ................61 Hydraulic motor fault ........................63 Hydraulic pump fault ........................64 Tiller ............................... 65 10.1 tiller operate ..........................65 CURTIS ............................68 Maintenance list ..........................

- Page 4 重诺力行 物动随心 Foreword This specification briefly introduces the technical parameters of our pallet, the structure of the main components, working principle and operation, maintenance, maintenance and other requirements and contents. Please read this manual carefully before operation in order to ensure safe and effective material handling through proper driving and maintenance.

-

Page 5: General

重诺力行 物动随心 1. GENERAL 1.1 INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS Maintenance work may cause injuries. Always take care to perform work safe, at least observing the following. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves, others or damage to the equipment. - Page 6 Battery should always be disconnected during replacement of electrical components. Always use the grades of grease and oil recommended by NOBLELIFT choose the viscosity specified for the ambient temperature. Exhaust gas is dangerous provide ventilation when working in a closed space.

- Page 7 When changing the oil or fitter, check the drained oil and filter for any signs of excessive metal particles or other foreign materials. Always use NOBLELIFT genuine parts for replacement. ENSURE REPLACEMENT PARTS OR COMPONENTS ARE IDENTICAL OR EQUIVALENT TO ORIGINAL PARTS OR COMPONENTS.

-

Page 8: Measurement Conversions

重诺力行 物动随心 1.2 MEASUREMENT CONVERSIONS Length Unit mile 0.00000 0.01 0.00001 0.3937 0.03281 0.01094 0.001 39.37 3.2808 1.0936 0.00062 100000 1000 39370.7 3280.8 1093.6 0.62137 0.00001 2.54 0.0254 0.000025 0.08333 0.02777 0.00018 30.48 0.3048 0.000304 0.3333 0.00056 91.44 0.9144 0.000914 mile 160930 1609.3... - Page 9 重诺力行 物动随心 Unit 0.001 0.000001 0.03527 0.0022 1000 0.001 35.273 2.20459 1000000 1000 35273 2204.59 28.3495 0.02835 0.000028 0.0625 453.592 0.45359 0.000454 1 tone (metric)= 1.1023 ton(US)=0.9842 ton(UK) Pressure Unit kgf/cm2 Pa=N/m2 lbf/in2 lbf/ft2 kgf/cm2 0.98067 98066.5 98.0665 14.2233 2048.16 1.01972 100000 14.5037...

- Page 10 重诺力行 物动随心 18.6 ± 1.9 52.2 ± 5.2 24.7 ± 2.5 69.4 ± 6.9 32.1 ± 3.2 90.2 ± 9.0 62.6 ± 6.3 176.1 ± 17.6 108.2 ± 10.8 304.3 ± 30.4 171.8 ± 17.2 483.2 ± 48.3 211.3 ± 21.1 594.3 ±...

- Page 11 重诺力行 物动随心 standardized ones. H Newton meter : 1 Nm = 0.1kgfm TIGHTENING TORQUE OF SPLIT FLANGE BOLTS The following torque shall be applied to the split flange bolts. PF THREAD Thread Torque (kgf· m) 1.1 ± 0.1 2.6 ± 0.2 4.6 ±...

- Page 12 重诺力行 物动随心 物料搬运· 系统集成...

- Page 13 重诺力行 物动随心 Replacement tool for electrical plug-in connection Application Remove pin Install pin Loose lock Two-hole lock Four-hole lock Remove pin 物料搬运· 系统集成...

-

Page 14: Sepcification

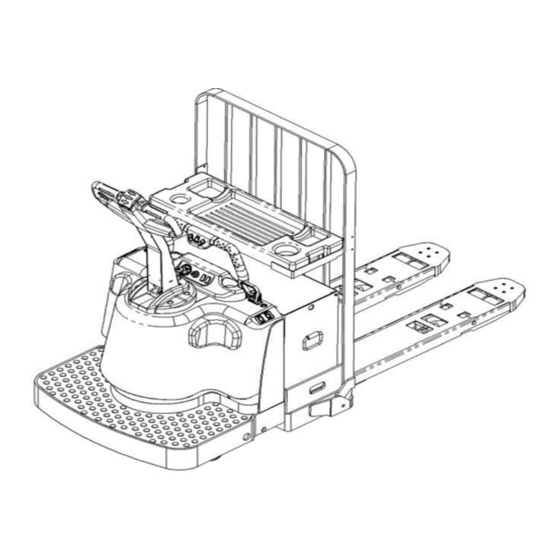

重诺力行 物动随心 2. Sepcification 2.1 Overview of the main components Foot plate Shelves Cover Pallet fork Left knee pad Wheel bearing Key switch Battery Electricity meter Battery plug Handle Switch seat Bulley button Electric meter cover Bulley button Right knee pad Accelerator fuel tank Handrest cover... -

Page 15: Specification Table

重诺力行 物动随心 Specification table PT 27R 货叉尺寸 PT 36R 货叉尺寸 Fork length mm 915 1067 1220 1372 1525 2440 2135 2362 2440 Actual fork length mm 908 1060 1213 1365 1518 2433 2128 2355 2433 Overall length mm 2025 2177... - Page 16 2297 2450 3365 2660 2660 2660 Fork width Type sheet for industrial truck acc. to VDI 2198 General Manufacturer`s type designation PT 27R PT 36R data Power (battery, diesel, petrol, Battery Battery gas, manual) Operator type Pedestrian Pedestrian Load Capacity / rated load...

- Page 17 重诺力行 物动随心 4.32 Ground clearance, centre of m2 (mm) 25 wheelbase 4.34 Aisle width for pallets 800X1200 Ast (mm) 2700 3900 lengthways 4.35 Turning radius Wa (mm) 2145 2660 Travel speed, laden/ unladen km/h 11/14 9.5/12 Lift speed, laden/ unladen mm/s 38/49 30/40...

-

Page 18: Electrical System

重诺力行 物动随心 3. Electrical system 3.1 Electrical circuit diagram PT27R 物料搬运· 系统集成... - Page 19 重诺力行 物动随心 PT36R Electrical assembly 物料搬运· 系统集成...

- Page 20 重诺力行 物动随心 New Code Art No. Description 506333010002 Cable-U-50-8-10-900 9000010237 506333010003 Cable-V-50-8-10-800 506333010004 Cable-W-50-8-10-700 506233010006 Cable-FP-25-6-8-1150 9000010160 506233010007 Cable-E1-25-8-8-150 506233010008 Cable-E2-25-8-8-1050 9000010161 506233010009 Power supply cable 物料搬运· 系统集成...

-

Page 21: Battery Using

重诺力行 物动随心 4. Battery Using Charging of the battery The storage battery shall be charged with the original charger, and the operation shall be carried out strictly in accordance with the maintenance instruction. A) The battery electrolyte shall not be kept too low. The battery electrolyte shall be kept to the specified level, otherwise the battery will overheat or burn out. -

Page 22: Battery Replacement

重诺力行 物动随心 The reference value of battery measurement is as follows: when the battery is full, the specific gravity is p = 1.28-1.30g/cm; when the monomer voltage is ≥ 2.1 V, the specific gravity is p = 1.16-1.17g/cm; the single voltage is less than 1.7 V, and the monomer voltage is less than 1.7 V. -

Page 23: Maintenance Of Batteries (Lead-Acid Batteries)

重诺力行 物动随心 No storage cover Park the vehicle safely, turn off the key switch (7), and unplug the battery connector (16). Then use a lifting tool to lift out the battery. Installation is the opposite procedure of removal. Please connect the positive terminal first, otherwise the vehicle is vulnerable to damage 4.2 Maintenance of batteries (lead-acid batteries) 1. - Page 24 重诺力行 物动随心 3. Distill-Water-adding materials and tools (1) Water requirements: it is recommended to use battery special supplementary liquid or distilled water. In case of emergency, pure water for drinking water on the market can also be used, but remember not to use tap water, mineral water and other water containing impurities.

- Page 25 重诺力行 物动随心 Max lever Standard lever 5.Use a plastic funnel to add water. 6. add-water lever Checking Maintenance Tool Daily Weekly Monthly Every three Half a year (8hrs) (50h) (200h) (1200h) Items requirements months (600h) √ √ √ √ √ Battery electrolyte level √...

-

Page 26: Test Of The Battery

重诺力行 物动随心 4.3 Test of the battery A. Battery status check the weak battery may cause or cause problems with the controller and the power circuit. Make sure the battery is in good condition before troubleshooting other areas. The preliminary step confirms whether the polarity of the battery connector and the control panel is correct. - Page 27 重诺力行 物动随心 The resistance between the pallet wiring and any point in the pallet body shall be at least 10,000 Ω or higher. The short-circuit of the battery case results in a number of faults. A short circuit in the chassis in the pallet wiring may cause a problem as the battery may have a chassis leak.

-

Page 28: Charger

重诺力行 物动随心 5. Charger 5.1 Notes Battery polarity cannot be reversed, otherwise it will damage the smart charger and battery. The intelligent charger should be installed in a special place with good ventilation, dry, no serious dust, no corrosive gas and no strong electromagnetic field interference. -

Page 29: Common Faults Of Charger

重诺力行 物动随心 temperature is reduced. Battery battery damage battery voltage UOL-L beyond retrieve mismatch with charger model too low Battery battery mismatch with charger voltage UOL-H beyond retrieve model too high The AC power is not on, or the open circuit ACOFF socket is out of power P-end... -

Page 30: Controller

重诺力行 物动随心 6. Controller 6.1 Controller function The model is equipped with a drive motor and a pump motor, which is controlled by a controller. It offers powers to controller by turning on the key switch. once the controller is energized, the magnetic coil built in the line contactor receives power from the driven motor controller. -

Page 31: Controller Test

重诺力行 物动随心 6.3 Controller test Measure the diode voltage inside the controller and check if there is burnout and damage. Test according to the following table, each test item must be repeatedly tested more than 3 times. Item Multimeter range terminal data Black... -

Page 32: Contactor And Fuse

重诺力行 物动随心 6.4 Contactor and fuse For contactor and fuse, using ohm scale to check if the value is the same. 6.5 controller of driving motor disassemble / assemble 1.cut off battery 物料搬运· 系统集成... - Page 33 重诺力行 物动随心 2.keep the key on and discharge the power module twice for 30 seconds. 3.Turn off the key 4.Remove the cover and find controller of driving motor Notes: Controller contains ESD (Electrostatic discharge) sensitive components. Appropriate precautions should be taken when connecting, disconnecting and handling. 5.Disconnect the control harness from the controller.

- Page 34 重诺力行 物动随心 9.Install the drive motor controller in reverse order 物料搬运· 系统集成...

-

Page 35: Contactor And Relay Common Malfunctions

重诺力行 物动随心 6.6 Contactor and relay Common malfunctions Fault Checking items reasons • Circuit breaker or fuse drops Whether the input voltage meets • Wiring error, mission the rated voltage of the device • Screw terminal mounting not tighten Whether Relay specification Relays of DC 48v specification were used on... -

Page 36: Error Code List

重诺力行 物动随心 6.7 Error code list Error code Description code Possible cause Cause/solution of deep fault failure Controller Overcurrent 1, the motor external Cause: phase current exceeds Motor stops working U,V or W connection limit current Main connector short circuit Solution: reset the key switch disconnected 2. - Page 37 重诺力行 物动随心 Controller Severe 1. Controllers work in Reason: Radiator temperature is Overtemp harsh environments higher than 95℃ Motor stops working 2. Vehicle overload Solution: Reduce temperature to Main connector Controller below 95 ° C and restart key disconnected installation error switch or interlock switch Electromagnetic brake disconnection...

- Page 38 重诺力行 物动随心 Controller Overtemp 2,2 1. The controller works Cause: radiator temperature over Cutback in a harsh environment 85℃ Overheating 2. Vehicle overload controller results 3. The controller is not Solution: Reduce performance installed correctly temperature degradation Reduced drive regenerative braking torque Undervoltage Cutback...

- Page 39 重诺力行 物动随心 Digital Out 6 Failure External load Cause: Output current of drive 6 Driver output impedance is too low exceeds 15mA overcurrent Solution: Adjust the load and Driver 6 output cannot then restart the driver with VCL be turned on setting "set_digout ()"...

- Page 40 重诺力行 物动随心 Coil Driver 1, connect the load Reason: drive 1 output (6 pin) Open/Short open circuit or short open circuit or short circuit. This Coil Driver circuit fault is only set on "Main Enable" Open/Short Contamination Only happen when it's OFF Coil 1 Driver is off connecting pin Resolution: Correct open/short...

- Page 41 重诺力行 物动随心 PD Open/Short 1, connect the load Cause: proportional drive (2 pin) PD Open/Short open circuit or short open circuit or short circuit PD off circuit Resolution: Correct open/short Contamination circuit errors and restart output connecting pin 3. Wrong wiring Encoder Fault Motor encoder...

- Page 42 重诺力行 物动随心 The brake disconnected Pump down Throttle Wiper High Throttle Wiper High Causes: Accelerator Throttle Wiper High potentiometer (16 pin) output Accelerator failure voltage is above the output voltage limit (VCL can be used to change limit, setup_pot_faults()) Solution: reduce output voltage...

- Page 43 重诺力行 物动随心 Pot Low Overcurrent Potentiometer Reason: Potentiometer low-end Pot Low Overcurrent impedance is too low pin) current exceeds Accelerator failure 10mASolution: lower low-end Complete the brake current, restart key switch EEPROM Failure Failed write Cause: The controller operating EEPROM Failure EEPROM storage.

- Page 44 重诺力行 物动随心 Accelerator failure The brake Pump down OEM Faults 51-67 Users can define their According to the user-defined. OEM failure (custom own faults for some failure) phenomena, which are represented by VCL code VCL RunTime Error The VCL code timed Cause: runtime VCL code error VCL RunTime Error out on the run time...

- Page 45 重诺力行 物动随心 OS General Internal controller Cause: Internal controller failure Operating system failure Solution: Restart the key switch failure The motor stopped main contactor stops Electromagnetic brake stop Accelerator stop Interlock stop 1-4 output stops Proportional drive stop The brake Pump stop PDO Timeout CAN PDO message...

- Page 46 重诺力行 物动随心 reaction failure 5= Low temperature reaction failure motor voltage reaction failure High pressure reaction failure controller cannot detect encoder signal and the channel signal disappears 9= Motor parameter setting out of range Motor Type Fault Motor type parameter Reason: MOTOR_TYPE value out of range...

- Page 47 重诺力行 物动随心 Encoder LOS (Limited restricted Cause: Restricted operation Operating Strategy) operation state condition is activated due to activated due to motor motor jam or encoder failure blocking or encoder Solution: Restart the key switch, failure if Motor is blocked, make sure 2.

-

Page 48: Meter

重诺力行 物动随心 7. Meter 7.1 Coulombmeter The discharge condition is represented by 10 display segments. Low battery power The battery is full of electricity The power of the battery is represented by 10 led display segments, and each grid represents 10% of the electricity. -

Page 49: Meter Disassemble/Assemble

重诺力行 物动随心 Common malfunction of electricity meter. A electricity meter wire harness B+, and B- ,there is a 12 v voltage, the meter does not show. Replace the power meter with the above fault. Battery switch common fault When the battery switch is closed, but it is open-circuit or emergency switch without 24V (meter doesn’t show). -

Page 50: Coded Lock

重诺力行 物动随心 7.5 Coded lock A. Product introduction Password ignition switch (password lock) like an electronic alarm electronic system, the machine will not be allowed to start until an authorized password is entered, the main function is to prevent unauthorized people from operating the machine. -

Page 51: Driving Motor

重诺力行 物动随心 8. Driving motor On the electric side, the drive motors rotate their drive wheels, allowing pallet to move forward/backward Controlled by the controller The drive motor is connected to the controller via U, V and W lines. The controller runs the drive motor according to the input from multiple switches and sensors and the internal parameter settings. - Page 52 重诺力行 物动随心 Notes: Contaminants in the stator may cause damage to the coil and therefore to the stator itself. Measurement of resistance per phase (uv,vw,wu) using multimeter Rated resistance:0.4Ω Test insulation at 1000 vac and min.10 MΩ using insulation tester. If there is insulation problem, please replace the new stator.

-

Page 53: Drive Motor Disassemble And Assemble

重诺力行 物动随心 8.4 Drive motor disassemble and assemble 1. Remove motor U/V/W connection 2. Remove motor speed sensor, temperature sensor and electromagnetic brake connection 3. Remove drive assembly fixing bolt. 4.Remove drive assembly by lifting equipment. 5. Do above steps in reverse order to assemble drive motor. 物料搬运·... -

Page 54: Drive Motor Common Fault

重诺力行 物动随心 8.5 Drive motor common fault Problem Reason Drive motor doesn’t work Switch is not off (battery connector, key switch, Drive motor doesn’t work proximity switch): Turn off switch. If still not running, use a voltmeter to test the power of the control panel and the current of each switch. - Page 55 重诺力行 物动随心 Due to the failure of the drive system, the drive system consumes too much battery power. Check the brake adjustment. Check the wheel bearings, axles and other mechanical parts for correction to eliminate the failure. Replace the smaller friction tire.

-

Page 56: Gearbox Remove/Assemble

重诺力行 物动随心 8.6 gearbox remove/assemble 1.Loosen the gearbox retaining bolts 2. Lift the body to make the body empty 3 can be removed from the gearbox 物料搬运· 系统集成... -

Page 57: Hydraulic System

重诺力行 物动随心 9. Hydraulic System The hydraulic system operates other hydraulic parts through hydraulic force from pump. The main hydraulic pump is driven by the pump motor controlled by the controller. The main hydraulic pump uses the rotating force output from the motor to pressure the oil in the hydraulic tank and conveys the oil to the lifting cylinder. -

Page 58: Disassembly Of Pump Motor

重诺力行 物动随心 9.2 Disassembly of pump motor 1. Disconnect pump motor B+ /B- terminal cable. 2. Disconnect hose from hydraulic pump. 3. Remove fixing bolt between pump motor and pump, then remove motor. 4. Install pump motor in reverse order. 5. -

Page 59: Replace Pump Motor Carbon Brush

重诺力行 物动随心 9.3 Replace pump motor carbon brush 1. Unscrew the bolt with a 10mm open wrench 2. Remove the cover 3.Unscrew the screw with a cross screwdriver and take out the carbon brush and replace it. Installation process and the inverse process of the above process. 物料搬运·... -

Page 60: Replace Oil Seal Of Lifting Cylinder

重诺力行 物动随心 9.4 Replace oil seal of lifting cylinder 1. Remove the top retaining bolt 2 Remove the cylinder retaining Seat 3 Remove the oil cylinder by lifting the cargo fork frame 物料搬运· 系统集成... -

Page 61: Replace The Sealing Ring Of The Lifting Cylinder

重诺力行 物动随心 9.5 Replace the sealing ring of the lifting cylinder 1. Remove the cylinder head with a crescent wrench 2.Remove piston, then remove retaining ring 物料搬运· 系统集成... - Page 62 重诺力行 物动随心 3.Remove dustproof seal and shield ring and Y-type seal 4. Remove o-seal and shield ring, then repair hose . Installation way is in reverse sequence 物料搬运· 系统集成...

-

Page 63: Hydraulic Motor Fault

重诺力行 物动随心 9.6 Hydraulic motor fault Breakdown Reason Bad connection or fuse burning. Check the battery connection. Check the key fuse. Check if hydraulic pump motor is likely to cause fuse burning. The key switch or pump station contactor is not turned off. -

Page 64: Hydraulic Pump Fault

重诺力行 物动随心 cells. Battery units are connected in series. A bad battery causes high resistance in series with other batteries. This reduces the speed of the motor. This may occur when other batteries are almost fully charged. The hydraulic pump motor is overheated. 9.7 Hydraulic pump fault Breakdown Reason... -

Page 65: Tiller

重诺力行 物动随心 The main safety valve pressure has been adjusted before leaving the factory, and the user is not allowed to adjust and disassemble at will. Tiller 10.1 tiller operate 1. Unscrew the two bolts to remove the proximity switch and replace it 物料搬运·... - Page 66 重诺力行 物动随心 2.Loose bolt , then remove gas spring 3 Remove the back bolt, open the handle and remove the retaining bolt to replace the handle 物料搬运· 系统集成...

- Page 67 重诺力行 物动随心 物料搬运· 系统集成...

-

Page 68: Curtis

重诺力行 物动随心 CURTIS 1 Precautions for Operation: Handheld unit attention function is for the convenience of vehicle inspection and maintenance, without the approval of the vehicle manufacturer, the controller parameters are not allowed to adjust, in order to avoid vehicle and personal safety accidents. After modifying the parameters of the handheld unit, it will be saved automatically. - Page 69 重诺力行 物动随心 Power up the programmer Connect to the controller by inserting the cable of the handheld programmer into the programming port of the controller. After connecting to the controller, the handheld programmer will automatically power on and display the control information on the programmer 物料搬运·...

- Page 70 重诺力行 物动随心 The function keys Because the function of the three keys is determined by the specified content, the three keys are blank. At any given time, the function of the button is displayed on the upper LCD screen. Direction arrow key The information displayed can be selected up, down, left and right through four directional buttons.

- Page 71 重诺力行 物动随心 a hierarchical menu, the name of the submenu or the path you are in is displayed at the top of the screen. NINE MENU Troubleshooting menu In the main menu, Select the "Diagnostics" icon and press the function key corresponding to Select to enter the Fault diagnosis menu, which contains two folders: "Present Errors"...

- Page 72 重诺力行 物动随心 recording. Programming menu In the main menu, Select the "Programming" icon and press the function key corresponding to "Select" to enter the menu. You can store and restore parameter Settings files (.cpf files) through the programming Save.cpf File(Save.cpf File) Use the save in the programming menu.

- Page 73 重诺力行 物动随心 following figure The other is to enter the parameter editing page, as shown in the following figure Periodic maintenance Only qualified and trained personnel are allowed to carry out maintenance work Before maintenance, remove the goods from the fork and put down fork.to minimum position For lifting the vehicle, use the specified binding or lifting equipment in accordance with Chapter IV.

-

Page 74: Maintenance List

重诺力行 物动随心 Pay attention to the maintenance of the handle lever. By compression, the gas pressure spring has been pre-installed. Carelessness may cause injury Use approved and dealer-issued original spare parts Please consider possible machine failures and accidents caused by leakage of hydraulic oil Allow only trained maintenance technician to adjust the pressure valve If you need to replace the wheel •... -

Page 75: Lubrication

重诺力行 物动随心 Brake system • Check brake function, replace brake shoe or adjust if necessary Battery • Check battery volatge • Check if wiring end is corrosion and damage, lubricate the wiring end • Check if battery cover is damaged Charger •... -

Page 76: Check Fuse

Add oil to the filling point if necessary. 12.2 Check fuse Remove the main cover and leave the fuse in position as shown in figure 19 and 20 Pic.19: Fuse positon PT 27R 物料搬运· 系统集成... -

Page 77: Error Analysis

重诺力行 物动随心 Pic.20: Fuse positon PT 36R Table 4: Fuse positon PT 27R Table 5: Fuse positon PT 36R Rate Rate 10 A 10 A FU01 300 A FU01 350 A FU02 150A FU02 150A 12.3 Error analysis • If the vehicle still has the faults mentioned in Chapter 6... - Page 78 重诺力行 物动随心 Fuse failure Check and replace the fuse Low battery Charge the battery Insert the key and pull the knob to The combined emergency switch is disable the combined emergency activated switch First move the handle to the brake The handle is in the operating area area If the vehicle fails and cannot be operated outside the work area, lift the vehicle and place a load handling...

Need help?

Do you have a question about the PT 27R and is the answer not in the manual?

Questions and answers