Canon LASER CLASS 810 Service Manual

Hide thumbs

Also See for LASER CLASS 810:

- User manual (8 pages) ,

- Basic operation manual (412 pages) ,

- Starter manual (39 pages)

Summary of Contents for Canon LASER CLASS 810

- Page 1 LASER CLASS 810/830i SERVICE MANUAL March 26, 2010 Rev. 1 CANON Laser Class 810/830i Rev.1. PRINTED IN U.S.A. COPYRIGHT © 2010 CANON INC.

- Page 3 Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

- Page 4 Introduction Symbols Used This documentation uses the following symbols to indicate special information: Symbol Description Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning. Indicates an item requiring care to avoid electric shocks. Indicates an item requiring care to avoid combustion (fire). Indicates an item prohibiting disassembly to avoid electric shocks or problems.

- Page 5 Introduction The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with refer- ence to the timing of operation. In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the direction of the electric signal.

-

Page 7: Table Of Contents

Contents Contents Chapter 1 Introduction 1.1 System Construction ..........................1- 1 1.1.1 System Configuration .............................. 1- 1 1.1.2 System Configuration .............................. 1- 3 1.2 Product Specifications ..........................1- 5 1.2.1 Names of Parts................................ 1- 5 1.2.1.1 External View (Front) ................................1- 5 1.2.1.2 External View (Rear)................................ - Page 8 Contents 2.2 Unpacking and Installation ......................... 2- 5 2.2.1 Unpacking and Removing the Packaging Materials ....................2- 5 2.2.2 Installing the Toner Cartridge...........................2- 5 2.2.3 Setting the Paper ..............................2- 6 2.2.4 Changing the Cassette Paper Size..........................2- 7 2.2.5 Connecting the Cable ..............................2- 8 2.2.6 Connecting the Cable ..............................2- 8 2.2.7 Checking the Image Quality.............................2- 9 2.2.8 Setting the Date and Time ............................2- 9...

- Page 9 Contents 4.4.2.1 Removing the Reader Controller PCB ............................. 4- 8 4.4.3 Contact Sensor................................ 4- 9 4.4.3.1 Removing the Contact Image Sensor ............................4- 9 4.4.3.2 Removing the Contact Image Sensor ............................ 4- 10 4.4.3.3 Action after Replacing the Contact Image Sensor ......................... 4- 10 4.4.4 Contact Sensor HP Sensor ...........................

- Page 10 Contents 6.1 Overview/Configuration ..........................6- 1 6.1.1 Specifications and Control Mechanism........................6- 1 6.1.2 Main Components..............................6- 2 6.2 Parts Replacement Procedure ........................6- 3 6.2.1 Laser/Scanner Unit ..............................6- 3 6.2.1.1 Removing the Laser Scanner Unit ............................6- 3 Chapter 7 Image Formation 7.1 Overview/Configuration ..........................

- Page 11 Contents 8.6.11 Registration Sensor ............................. 8- 11 8.6.11.1 Removing the Registration Sensor ............................8- 11 8.6.12 Duplex Pick-up Solenoid............................8- 12 8.6.12.1 Removing the Duplex Pickup Solenoid ..........................8- 12 8.6.13 Registration Clutch .............................. 8- 12 8.6.13.1 Removing the Registration Clutch............................8- 12 8.6.14 Main Motor................................

- Page 12 Contents 10.4.1.9 Removing the Document Feeder Tray ..........................10- 8 10.4.1.10 Removing the Document Delivery Tray..........................10- 8 10.4.1.11 Removing the Delivery Tray ............................... 10- 9 10.4.2 Main Drive Unit..............................10- 9 10.4.2.1 Removing the Main Drive Unit ............................. 10- 9 10.4.3 Pick-up Drive Unit ..............................10- 9 10.4.3.1 Removing the Pickup Drive Unit ............................

- Page 13 Contents 11.1.13 CA Certificate..............................11- 5 11.1.14 Settings of Network Connection (Installation/Maintenance) ................11- 5 11.1.15 Settings of e-RDS (Installation/Maintenance) ....................11- 5 11.1.16 Troubleshooting ..............................11- 6 11.1.17 Error Message list ............................. 11- 6 Chapter 12 Maintenance and Inspection 12.1 Periodically Replaced Parts ........................12- 1 12.1.1 Periodically Replaced Parts..........................

- Page 14 Contents 15.2 Jam Code ............................... 15- 2 15.2.1 Jam Codes (Main body) ............................15- 2 15.2.2 Jam Codes (ADF) ..............................15- 2 15.3 Fax Error Codes ............................. 15- 4 15.3.1 Outline..................................15- 4 15.3.1.1 Error Code Outline ................................15- 4 15.3.2 User Error Code ..............................15- 4 15.3.2.1 User Error Code ...................................

- Page 15 Contents 16.3.10.6 Detailed Discussions of Bit 4............................16- 15 16.3.10.7 Detailed Discussions of Bit 5............................16- 15 16.3.11 SSSW-SW30 ..............................16- 15 16.3.11.1 List of Functions ................................16- 15 16.3.11.2 Detailed Discussions of Bit 5............................16- 16 16.3.12 SSSW-SW33 ..............................16- 16 16.3.12.1 List of Functions ................................

- Page 16 Contents 16.6.18 <215: XYZ correction value (Z) of standard white plate> (if equipped with SEND functions) ......16- 25 16.7 Printer Function Settings (PRINTER) ....................16- 25 16.7.1 Service Soft Switch Settings (SSSW) ........................16- 25 16.7.1.1 SSSW-SW05..................................16- 25 16.7.1.2 SSSW-SW14..................................16- 26 16.7.1.3 SSSW-SW15..................................

- Page 17 Contents 16.16.4.1 Print Test ((3) PRINT TEST) ............................16- 43 16.16.5 Modem Test ..............................16- 44 16.16.5.1 MODEM Test ((4) MODEM TEST)........................... 16- 44 16.16.6 Faculty Test ..............................16- 46 16.16.6.1 FUNCTION TEST <(6) FUNCTION TEST> ........................16- 46 16.16.7 Cleaning Mode..............................16- 49 16.16.7.1 Roller cleaning mode ((0) ROLLER CLEAN) ........................

- Page 18 Contents...

-

Page 19: Chapter 1 Introduction

Chapter 1 Introduction... - Page 21 Contents Contents 1.1 System Construction ..............................1-1 1.1.1 System Configuration .................................. 1-1 1.1.2 System Configuration .................................. 1-3 1.2 Product Specifications..............................1-5 1.2.1 Names of Parts ..................................... 1-5 1.2.1.1 External View (Front) .....................................1-5 1.2.1.2 External View (Rear) ......................................1-6 1.2.1.3 Cross-Section ........................................1-7 1.2.2 Using the Machine ..................................1-8 1.2.2.1 Turning On the Power Switch..................................1-8 1.2.2.2 When Turning Off the Main Power Switch ..............................1-9 1.2.2.3 Control Panel.........................................1-11...

-

Page 23: System Construction

Chapter 1 1.1 System Construction 1.1.1 System Configuration 0017-7471 - Pickup/ Other Accessories F-1-1 Host machine FXL-Cassette Feeder 8 option Handset Kit 10 (for US) option HANDSET REST FP + TEL 6 KIT LONG CORD (except for US, HK and SPL) HANDSET REST FP + TEL 3 KIT LONG CORD (for HK and SPL) Stamp Unit-C1 option... - Page 24 Chapter 1 - Boards F-1-2 Color Send Kit-M1 option (standard for LASER CLASS 830i) - Function table Function IMAGE CLASS 830i FAX-L3000IP i-SENSYS FAX-L3000IP Copy Std. Std. Std. Std. Std. Std. Std. Std. Std. Print Std. Std. Std. PC-Fax RemoteUI Network SEND Std.

-

Page 25: System Configuration

Chapter 1 1.1.2 System Configuration 0017-7558 - Pickup/ Other Accessories F-1-3 Host machine FXL-Cassette Feeder 8 option Handset Kit 10 (for US) option HANDSET REST FP + TEL 6 KIT LONG CORD (except for US, HK and SPL) HANDSET REST FP + TEL 3 KIT LONG CORD (for HK and SPL) Stamp Unit-C1 option... - Page 26 Chapter 1 - Boards F-1-4 UFR II LT Printer kit-X1 option - Function table Function IMAGE CLASS 810/ FAX-L3000/ i-SENSYS FAX-L3000 Copy Std. Std. Std. Print Option UFRII LT Printer kit-X1 PC-Fax RemoteUI Network SEND None Soft-counter None E-RDS None...

-

Page 27: Product Specifications

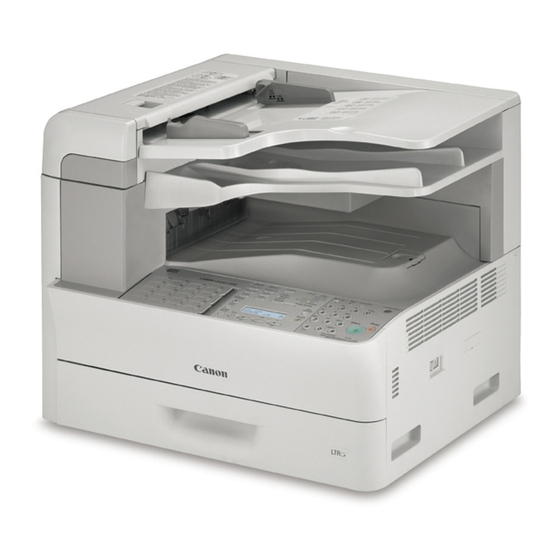

Chapter 1 1.2 Product Specifications 1.2.1 Names of Parts 1.2.1.1 External View (Front) 0016-8042 [10] [11] [14] [13] [12] F-1-5 Paper cassette Slide guides Stack support Document feeder tray [10] Left cover Document delivery tray [11] ADF scanning area Delivery tray [12] Multi-purpose tray Paper stopper... -

Page 28: External View (Rear)

Chapter 1 1.2.1.2 External View (Rear) 0017-8460 F-1-6 USB port Handset jack Ethernet port Power socket Telephone line jack Main power switch External device jack... -

Page 29: Cross-Section

Chapter 1 1.2.1.3 Cross-Section 0016-8044 [21] [20] [19] [18] [17] [16] [15] [14] [13] [12] [11] [10] F-1-7 Contact image sensor unit [12] Vertical path roller ADF feed roller [13] Registration roller ADF pickup roller [14] Developing cylinder ADF delivery roller [15] Transfer charging roller Laser scanner unit... -

Page 30: Using The Machine

Chapter 1 1.2.2 Using the Machine 1.2.2.1 Turning On the Power Switch 0016-7895 The machine possesses the main power switch. Normally (i.e., unless the machine is in a sleep state), the machine will be supplied with power when you turn on its main power switch. -

Page 31: When Turning Off The Main Power Switch

Chapter 1 1.2.2.2 When Turning Off the Main Power Switch 0016-7896 <During printing or fax data transmission/reception> Be sure to operate the main power switch while the Processing/Data lamp on the control panel is not lit. (Turning off the main switch during printing or fax data transmission/reception can erase the data being processed.) F-1-9... - Page 32 Chapter 1 <During downloading> Do not turn off the power switch or ON/OFF switch on the control panel. (Turning off the main power switch during downloading can make this machine inoperative.) F-1-10 1-10...

-

Page 33: Control Panel

Chapter 1 1.2.2.3 Control Panel 0018-2210 [1] [2] [10] [11] [12] [17] [15] [14] [13] [27] [26][25] [24] [23] [21] [19] [22] [20] [18] [16] F-1-11 [Additional Functions] key [15] [Start] key [Paper Select] key [16] Processing/Data indicator [Density] key [17] [SYMBOLS] key [2-Sided] key... - Page 34 Chapter 1 1.2.2.4 Control Panel 0016-7897 [1] [2] [10] [11] [12] [17] [15] [14] [13] [29] [28][27] [26] [25] [23] [21] [19] [24] [22] [20] [18] [16] F-1-13 [Additional Functions] key [16] Processing/Data indicator [Paper Select] key [17] [SYMBOLS] key [Density] key [18] Numeric keys...

- Page 35 Chapter 1 [2] [3] [4] [5] [6] 02 M3 03 M4 [10] F-1-14 One-Touch keys [Direct TX] key One-Touch Key Panels [Hook] key [Address Book] key [Pause] key [Stamp] key [Recall] key [Delayed TX] key [10] [Coded Dial] key 1-13...

-

Page 36: User Mode Items

Chapter 1 1.2.3 User Mode Items 1.2.3.1 PAPER SETTINGS 0017-7593 MEMO: User modes of the USA model are described. Menus and defaults may vary depending on the destination. For details, refer to the User's Guide. T-1-1 Additional Functions Available Settings *: indicates factory settings. CASSETTE1 PAPER SIZE (A4, LGL, LTR*, OFICIO, FLSP, B-OFICIO, M-OFICIO) PAPER TYPE (PLAIN PAPER*, COLOR, RECYCLED, HEAVY1, BOND, 3HOLE PUNCH PAPER) -

Page 37: Tx/Rx Settings

Chapter 1 Additional Functions Available Settings *: indicates factory settings. NDARD SETTINGS IMAGE QUALITY: TEXT/PHOTO*, TEXT, PHOTO DENSITY: STANDARD*, DARK, LIGHT COPIES: 1*-99 2-SIDED: OFF*, 1>2-SIDED, 2>2-SIDED, 2>1-SIDED PAPER SELECT: CASSETTE 1*, CASSETTE 2*1 SHARPNESS 1-5*-9 PAPER SIZE GROUP INCHES*, A, AB INIT. -

Page 38: Address Book Set

Chapter 1 Additional Functions Available Settings *: indicates factory settings. RX RESTRICTION ON, OFF* *1: if the optional Send kit is installed. *2: A3 type only (A3 type: IMAGE CLASS 830i/FAX-L3000IP/I-SENSYS FAX-L3000IP) 1.2.3.6 ADDRESS BOOK SET. 0017-7635 T-1-6 Additional Functions Available Settings *: indicates factory settings. -

Page 39: Printer Settings (If An Network Printer Kit Is Attached.)

Chapter 1 Additional Functions Available Settings *: indicates factory settings. FTP*1 HOST NAME max. 120 digits NAME max. 16 characters, including spaces FILE PATH max. 120 digits LOGIN NAME max. 24 characters PASSWORD max. 24 characters SMB*1 HOST NAME max. 120 digits NAME max. -

Page 40: Timer Settings

Chapter 1 Additional Functions Available Settings *: indicates factory settings. PAPER SAVE ON, OFF* ORIENTATION PORTRAIT, LANDSCAPE FONT NUMBER 0-91 POINT SIZE 4.00-12.00*-999.75 PITCH 0.44-10.00*-99.99 FORM LINES 5-60*-128 SYMBOL SET CUSTOM PAPER OFF*, ON (UNIT OF MEASURE: INCHES*, MILLIMETERS, X DIMENSION: 127-356 mm, Y DIMENSION: 76-216 mm) APPEND CR TO LF YES, NO*... -

Page 41: System Settings

Chapter 1 Additional Functions Available Settings *: indicates factory settings. ACTIVITY REPORT AUTO PRINT OUTPUT YES, OUTPUT NO* TX/RX SEPARATE OFF*, ON LIST PRINT ACTIVITY REPORT max. last 40 transactions SPEED DIAL LIST 1-TOUCH LIST, CODED DIAL LIST, GROUP DIAL LIST ADD BOOK DETAILS 1-TOUCH(DETAILS), CODED (DETAILS) USER DATA LIST... - Page 42 Chapter 1 Additional Functions Available Settings *: indicates factory settings. PROXY SETTINGS*2 USE PROXY OFF, ON(SERVER ADDRESS, PORT. NO, USE SAME DOMAIN: ON, OFF*, AUTH SETTINGS: ON, OFF) PORT NO. 0-515*-65535 0-9100*-65535 HTTP 0-80*-65535 SMTP RX*2 0-25*-65535 POP3 RX*2 0-25*-65535 FTP SENDING*2 0-21*-65535 SMTP TX*2...

- Page 43 Chapter 1 Additional Functions Available Settings *: indicates factory settings. E-MAIL/I-FAX SETTINGS*2 MAX TX DATA SIZE 0MB* - 99MB DIVIDED OVER MAX ON, OFF* FAX SETTINGS TX START SPEED 33600bps*, 2400bps, 4800bps, 7200bps, 9600bps, 14400bps RX START SPEED 33600bps*, 2400bps, 4800bps, 7200bps, 9600bps, 14400bps R-KEY SETTING TX DOC.

-

Page 44: Maintenance By The User

Chapter 1 1.2.4 Maintenance by the User 1.2.4.1 User Maintenance Items 0016-7921 T-1-11 Item Maintenance cycle Platen guide (white plate) cleaning As required Stream reading glass cleaning As required Fixing pressure roller cleaning As required Transfer charging roller cleaning As required ADF roller cleaning As required Exterior cleaning... - Page 45 Chapter 1 5) Open the manual feed tray. 6) Place an A4 or LTR sheet of plain paper in the manual feed tray. F-1-17 7) Press the OK key. The machine will start cleaning the fixing pressure roller. 4.Cleaning the Transfer roller If the reverse side of the printed paper is stained, the transfer roller can be dirty.

-

Page 46: Safety

These regulations apply to laser products manufactured on and after August 1, 1976, and the sale of laser products not certified under the regulations is banned within the Untied States. The label shown here indicates compliance with the CDRH regulations, and its attachment is required on all laser products that are sold in the United States. CANON 30-2, SHIMOMARUKO, 3-CHOME, OHTAKU, TOKYO, 146, JAPAN. -

Page 47: Handling The Laser Unit

Chapter 1 1.2.5.4 Handling the Laser Unit 0016-7901 The laser scanner unit emits invisible laser light inside it. If exposed to laser light, the human eye can irreparably be damaged. Never attempt to disassemble the laser scanner unit. (It is not designed for servicing in the field.) Warning labels are affixed to the top cover of the laser scanner unit. -

Page 48: Storing Or Handling The Cartridge After Unpacking

Chapter 1 Normal (9/10 of total storage period) 0 to 35 deg C Severe (1/10 of total storage time) High 35 to 40 deg C -20 to 0 deg C Change in temperature (within about 3 min) 40 to 15 deg C -20 to 25 deg C Humidity Normal (9/10 of total storage period) -

Page 49: Product Specifications

Chapter 1 1.2.6 Product Specifications 1.2.6.1 Product Specifications 0017-7256 Copyboard stream reading Body desktop (ADF standard type) Light source type Image reading method CCD (CIS) Photosensitive medium OPC drum (24-mm dia.) Reproduction method indirect electrostatic Exposure method by laser light Charging method by roller contact Development method... -

Page 50: Product Specifications

Chapter 1 Hard disk Image margin (leading edge) 5.0 -/+2.0 mm Image margin (trailing edge) 5.0 -/+2.0 mm Image margin (left/right) left: 2.5 -/+2.0 mm right: 0.5mm or more Image mode Yes (text, text/photo, photo) Energy save mode yes (manually ON/OFF; auto OFF after specific time, auto ON after fax reception/print data reception) Operating environment 15 to 30 deg C... - Page 51 Power supply rating 120V/230V (50/60Hz) Power consumption (maximum) 120V: Approx. 1020 kW (max.) 230V: Approx. 1011 kW (max.) Power consumption Continuous printing LASER CLASS 810: approx.476W i-SENSYS FAX-L3000/FAX-L3000: approx.335W Energy save stanby LASER CLASS 810: approx.1.7W i-SENSYS FAX-L3000/FAX-L3000: approx.2.6W (reference only) Ozone 0.01ppm or less (initial)

-

Page 52: Adf Specifications

Chapter 1 Option FXL-Cassette Feeder 8 UFR II LT Printer kit-X1 Handset Kit Stamp Unit-C1 1.2.6.3 ADF Specifications 0016-7890 Original orientation Face-up Original position Center reference Original processing mode - Single-sided document processing - Double-sided document processing Original reading Stream reading Stack small size *1: 50 sheets or less large size*2: 25 sheets or less... -

Page 53: Function List

Chapter 1 Printing resolution 600 dpi x 600 dpi Reduction for reception Fixed reduction (75%, 90%, 95%, 97%) Auto reduction (75 to 100%) FAX/TEL switching Yes (no voice response, no pseudo CI transmission) Answering machine connection Remote reception ID input method ID: 2 characters (default: 25) Auto dialing One-touch dialing: FAX80, TEL80... - Page 54 Chapter 1 T-1-14 Cassette Manual feed tray Duplex Size (W X L) A4 (For JP/KOR/EU/ASIA/OCE) 76 x 127 to 216 x 356 mm A4, LTR, LGL LGL/LTR/OFICIO/BOFI/M-OFI/ FOOLSCAP (for USA/CA/LA) 16K/A4(for CHN) Weight 64 to 90 g/m2 56 to 128 g/m2 64 to 90 g/m2 Quantity Max.

- Page 55 Chapter 1 1-33...

-

Page 57: Chapter 2 Installation

Chapter 2 Installation... - Page 59 Contents Contents 2.1 Making Pre-Checks................................2-1 2.1.1 Selecting the Site of Installation ..............................2-1 2.1.2 Before Starting the Work ................................2-3 2.1.3 Checking the Contents ................................. 2-4 2.2 Unpacking and Installation ............................2-5 2.2.1 Unpacking and Removing the Packaging Materials ........................2-5 2.2.2 Installing the Toner Cartridge ..............................

-

Page 61: Making Pre-Checks

Chapter 2 2.1 Making Pre-Checks 2.1.1 Selecting the Site of Installation 0016-7375 Select the site of installation against the following requirements; if possible, visit the user's before delivery of the machine: 1) There must be a power outlet properly grounded and rated as indicated (-/+10%) for exclusive use by the machine. 2) The environment of the room must be as indicated in the following diagram, and the machine must not be installed near a water faucet, water boiler, humidifier, or refrigerator: (%RH) - Page 62 Chapter 2 7) The machine must be placed in a well ventilated area. It is important to make sure, however, that the machine is not near the air vent (for suction) of the room.

-

Page 63: Before Starting The Work

Chapter 2 2.1.2 Before Starting the Work 0016-7377 Be sure to go through the following before starting the work: 1) If you are installing the machine after moving it from a cold to warm location, be sure to leave the machine unpacked for at least 2 hours so that the machine is fully used to the site temperature, thus avoiding image faults caused by condensation. -

Page 64: Checking The Contents

Chapter 2 2.1.3 Checking the Contents 0016-9612 Check to be sure that none of the following contents is missing: F-2-3 Host machine 1pc. Toner cartridge 1pc. Power cable 1pc. Mojular jack cord 1pc. Ferrite core*1 1pc. Destination Label 1pc. Registration Card 1pc. -

Page 65: Unpacking And Installation

Chapter 2 2)Gently rock the toner cartridge 5 or 6 times to distribute toner evenly. 2.2 Unpacking and Installation 2.2.1 Unpacking and Removing the Packaging Materials 0016-7378 1)Unpack the machine and remove vinyl, cushioning materials, and tape. 2)Hold the hand grips of the machine [1] together with one or more persons and take it out. -

Page 66: Setting The Paper

Chapter 2 2.2.3 Setting the Paper 6)Open the left cover [1]. 0016-9963 1)Holding the knob [1] at the center of the cassette, draw out the cassette [2] until it stops. F-2-10 7)Hold the toner cartridge by its handle. Insert the toner cartridge into the machine with the arrows [1] on the toner cartridge pointing toward the machine. -

Page 67: Changing The Cassette Paper Size

Chapter 2 4)Gently insert the paper cassette as far as it will go. 3) Detach the paper limiting plate (front) [1]. - Screw [2] 2pcs 4) Set the projection [3] of the paper limiting plate (front) to desired size po- When the size of the paper has been changed, follow the procedure below to sition [4]. -

Page 68: Connecting The Cable

Chapter 2 7) Attach the cassette lifting plate [1]. 1)Connect the power cord [1] into the AC inlet. When attaching the lifting plate, set the below-mentioned spring [2] (3 pcs) to each guide sleeve [3] on the back side of the cassette lifting plate. F-2-22 2.2.6 Connecting the Cable 0017-1065... -

Page 69: Checking The Image Quality

Chapter 2 2)Connect the power cord [1] into the AC inlet. 2) Select "# REPORT" using the left and right cursor keys, and then press the OK key. 3) Select "REPORT OUTPUT" using the left and right cursor keys , and then press the OK. -

Page 70: Installing The Hand Set

Chapter 2 2.3 Installing the Hand Set 2.3.1 Checking the Contents 0016-7441 F-2-27 Handset 1pc. Handset Cradle 1pc. Bracket 1pc. Knurled screw 2pcs. B tight screw (M3X12) 2pcs. 2-10... -

Page 71: Installing The Hand Set

Chapter 2 6)Place the handset [1] on the handset cradle. 2.3.2 Installing the Hand Set 0016-7444 1)Remove the cover [1] on the right side of the machine using the screwdriv- F-2-32 7)Connect the curl code jack to the module jack [1] on the backside. F-2-28 2)Attach one TP screw (M3X6)[1], which is packed with the host machine. -

Page 72: Installing The Stamp Unit

Chapter 2 2.4 Installing the Stamp Unit 2.4.1 Checking the Contents 0016-7447 F-2-34 Stamp solenoid 1 pc. Stamp 1 pc. Binding screw (M3X6) 1 pc. 2-12... -

Page 73: Installing To The Host Machine

Chapter 2 2.4.2 Installing to the Host Machine 0016-7449 1)Open the feeder cover. 2)Remove the open/close lever [1], and close the feeder guide [2]. F-2-35 3)Remove the stamp cover [1]. - Screw [2] 1pc. F-2-36 4)Connect the connector [1]. 2-13... - Page 74 Chapter 2 5)Attach the stamp solenoid [2]. - Binding screw (M3X6)[3] 1pc. F-2-37 6)Attach the stamp cover [1]. - Screw [2] 1pc. F-2-38 7)Install the stamp [1] using tweezers or the like. A loosely installed stamp will cause a paper jam. Push the stamp all the way in until it clicks.

-

Page 75: Checking The Operation

Chapter 2 2.4.3 Checking the Operation 0016-7451 1)Turn on the main power switch. 2)Enter in service mode. > 2 > 8 > 3) Enter #1 SSSW06 > bit03, and change the setting from 0 to 1. 4)Press the reset key to exit the service mode. 5)Turn off the main power switch. -

Page 77: Chapter 3 Basic Operation

Chapter 3 Basic Operation... - Page 79 Contents Contents 3.1 Construction ...................................3-1 3.1.1 Functional Construction................................3-1 3.1.2 Functional Block Diagram ................................3-2 3.1.3 Image Processor PCB .................................. 3-3 3.1.4 DC Controller PCB ..................................3-3 3.1.5 Reader Controller PCB ................................3-4 3.1.6 Power Supply PCB ..................................3-4 3.1.7 NCU PCB..................................... 3-4 3.1.8 Modular Jack PCB ..................................

-

Page 81: Construction

Chapter 3 3.1 Construction 3.1.1 Functional Construction 0016-7906 The machine may be divided into the following 7 functional blocks. Printer communication Fax communication system system Modem PCB Network PCB Mojular jack PCB Image reading/ NCU PCB processing system Original Image processor PCB CIS unit DC controller Control... - Page 82 Chapter 3 3.1.2 Functional Block Diagram 0016-7907 Contact SL2003 CL2001*3 M2001 SR2008*3 SR2010*3 CL2002 SL2004 M2002 SR2007*3 SR2009*3 image snsor J2006 J2003 J2005 J2001 J2010 J2011 J2012 J2013 J2016 J2002 J460 Capacitor J411 J406 J405 J403 J407 Speaker Reader controller PCB J01204 J401/ LAN I/F...

- Page 83 Chapter 3 3.1.3 Image Processor PCB 0016-7908 1.function The image processor PCB has the following functions. Control Panel Control Block The control panel control block receives the state of control keys while sending/receiving data in serial communication with the control IC of the control panel PCB. Also, it sends LED and LCD signals to the control panel PCB.

-

Page 84: Reader Controller Pcb

Chapter 3 High-Voltage Control Block The high-voltage control block controls the high voltage for the primary charging roller, developing cylinder of the cartridge, transfer charging roller, and fixing film. Drive Control Block The drive control block controls the main motor, pickup solenoid, and fan. Sensor Detection It detects the state of the sensors in the pickup assemblies and the printer block, thereby monitoring the drive assembly. - Page 85 Chapter 3 Modem PCB Image processor PCB PATCH (IC40) MODEM IC DX336 CU PCB (IC1) Speaker driver (IC70) DC/DC Super Speaker capacitor SDRAM 32bit (IC1) F-3-4 MPU (IC1) Processes JBIG coding/decoding, controls combinations over lines, and controls SDRAM. PATCH (IC40) controls the various boards (NCU, speaker).

-

Page 86: Basic Sequence

Chapter 3 3.2 Basic Sequence 3.2.1 Basic Sequence 0016-7920 The machine's sequence of operation is controlled by the CPU on the image processor PCB and the CPU on the DC controller PCB. The following figure shows the sequential flow, and table provides descriptions of the periods involved. Power ON The left cover is closed End of printing... - Page 87 Chapter 3...

- Page 89 Chapter 4 Original Exposure System...

- Page 91 Contents Contents 4.1 Basic Construction .................................4-1 4.1.1 Specifications, Control Methods, and Functions ......................... 4-1 4.1.2 Specifications, Control Methods, and Functions ......................... 4-2 4.1.3 Major Components..................................4-3 4.1.4 Major Components..................................4-4 4.2 Basic Sequence ................................4-5 4.2.1 Basic Sequence at Power-on ................................ 4-5 4.2.2 Basic Sequence after Depression of Start Key (One Sheet of Original)..................

-

Page 93: Basic Construction

Chapter 4 4.1 Basic Construction 4.1.1 Specifications, Control Methods, and Functions 0016-7813 T-4-1 Item Function/Method Exposure light source Original scan Original stream reading is performed with the contact sensor (CS) fixed. Scanning document size A5/B5/A4, STMT/LTR/LGL length :148.5mm to 356mm width : 105mm to 216mm (Transmitting fax only on one side 216mm X 630 mm) Scan resolution... - Page 94 Chapter 4 4.1.2 Specifications, Control Methods, and Functions 0017-1509 T-4-2 Item Function/Method Exposure light source Original scan Original stream reading is performed with the contact image sensor (CIS) fixed. Scanning document size A5/B5/A4/B4/A3, STMT/LTR/LGL/11X17 length :148.5mm to 432mm width : 105mm to 297mm (Transmitting fax only on one side 297mm X 630 mm) Scan resolution 600 dpi (vertical scan) x 600 dpi (horizontal scan)

-

Page 95: Major Components

Chapter 4 4.1.3 Major Components 0016-7814 Major components of the image read/processing system are as follows: - Contact sensor is used to read the document - Reader controller PCB that is used to convert the analog image read by the contact sensor to the digital image data Based on the drive signal from the image processor PCB, the image read system feeds the document using the ADF to read the document on the stream reading glass. - Page 96 Chapter 4 4.1.4 Major Components 0017-1510 Major components of the image read/processing system are as follows: - Contact image sensor that is used to read the document - Read motor, shading clutch, carriage, and carriage rail that are used to move the contact sensor - Reader controller PCB that is used to convert the analog image read by the contact sensor to the digital image data Based on the drive signal from the image processor PCB, the image read control system drives the motor to move the contact image sensor to the document read position and feeds the document using the ADF to read the document image.

-

Page 97: Basic Sequence

Chapter 4 4.2 Basic Sequence 4.2.1 Basic Sequence at Power-on 0016-7815 Main power switch SREADY STBY Read motor (M2002) Shading clutch (CL2001) CIS HP sensor (SR2006) Shading Shading position position : Foward : Backward F-4-3 CIS HP sensor Shading position 1.CIS position check F-4-4 4.2.2 Basic Sequence after Depression of Start Key (One Sheet of Original) -

Page 98: Various Control

Chapter 4 CIS HP sensor Stream reading Shading start position position 1.black shading/ white shading/ Original scan F-4-6 4.3 Various Control 4.3.1 Enlargement/Reduction 4.3.1.1 Magnification Change in Vertical Scan Direction 0016-7818 In the main scan direction, the image is read at 100%. Magnification is changed by processing data on the image processor PCB. 4.3.1.2 Magnification Change in Horizontal Scan Direction 0016-7819 In the horizontal scan direction, the document feed speed is changed depending on the magnification rate whether or not the image is enlarged or reduced. - Page 99 Chapter 4 0.5mm 0.5mm A B C Platen guide Steram reading glass Contact image sensor lens F-4-8 T-4-3 Position Description Read reference position About 0.5 mm from the reference position toward the roller inside About 1.0mm from the reference position toward the roller inside...

-

Page 100: Parts Replacement Procedure

Chapter 4 4.4 Parts Replacement Procedure 4.4.1 Copyboard Glass 4.4.1.1 Removing the Stream Reading Glass 0017-3081 1) Remove the left middle cover. 2) Open the feeder cover. 3) Remove the glass retainer [1]. - Screw [2] 3pcs. 4) Remove the stream reading glass [3]. F-4-11 - When removing the stream reading glass, take care not to touch the glass surface. -

Page 101: Contact Sensor

Chapter 4 reader controller PCB. Accordingly, it is not necessary to enter adjustment values after replacing the reader controller PCB. 1) Open the feeder cover. 2) Remove the tray stopper and open the document feed tray. 3) Remove the document delivery tray. 4) Remove the PCB cover [1]. -

Page 102: Action After Replacing The Contact Image Sensor

Chapter 4 F-4-18 4.4.3.2 Removing the Contact Image Sensor 0017-8892 1) Remove the left middle cover. 2) Remove the feeder cover. F-4-20 3) Remove the glass retainer and the stream reading glass. 4) Remove the jump mount [1]. - Screw [2] 2pcs. 1. -

Page 103: Contact Sensor Hp Sensor

Chapter 4 Sequentially press the User Mode key, 2 key, 8 key, and User Mode key on the operation panel. 2) Using the arrow keys on the operation panel, display "TEST MODE". 3) Press the "OK" key. 4) Press the 2 key. "SCAN TEST" appears. 5) Press the 1 key. - Page 105 Chapter 5 Original Feeding System...

- Page 107 Contents Contents 5.1 Basic Construction .................................5-1 5.1.1 Overview...................................... 5-1 5.1.2 Drive Mechanism..................................5-1 5.2 Basic Operation................................5-2 5.2.1 Outline of Operation Mode ................................5-2 5.2.2 Document Size Detection ................................5-4 5.2.3 Document Size Detection ................................5-4 5.2.4 Paper Pickup Operation ................................5-6 5.2.5 Reversal Operation..................................

-

Page 109: Basic Construction

Chapter 5 5.1 Basic Construction 5.1.1 Overview 0017-1766 The ADF of this machine is a document feeder designed only for stream reading. It performs document pickup, transport, and delivery operations sequentially with the aid of the ADF pickup motor (M2001) and read motor (M2002). Feed of the document supplied from the document setting (placement) section is controlled by the ADF registration roller so that the document is ready at the same time for image reading by the contact image sensor in the main unit. -

Page 110: Basic Operation

Chapter 5 5.2 Basic Operation 5.2.1 Outline of Operation Mode 0017-1768 This machine has 2 operation modes. This machine operates in the operation mode specified by the host machine to perform printing. Operation mode names, brief outline of operations, and associated print modes are given in the following table: T-5-2 Operation mode name Outline of operation... - Page 111 Chapter 5 [2] Forward Pickup/Reversal Delivery Operation The document flow is shown below. Document Pickup Reversal Formation of loop Feed Reading Reverse side reading Feed Feed Next F-5-4...

-

Page 112: Document Size Detection

Chapter 5 Delivery Reversal End of job Feed Idle feed F-5-5 5.2.2 Document Size Detection 0017-1769 This machine detects only the paper length during transport. (The paper length in the banner mode is included.) The document pickup tray has no sensor for paper size detection. T-5-3 Function Description... - Page 113 Chapter 5 Function Description Sensor used (Symbol) - Widthwise direction Detects the width of the document set on the document pickup Document width sensor 1/2 tray. (SR2007/SR2008) b. Method used in the banner mode In the banner mode, the following two document detection functions are used. T-5-5 Function Description...

-

Page 114: Paper Pickup Operation

Chapter 5 SR2010 SR2009 SR2007 SR2008 F-5-7 The relationship between length detection sensor signals, document widths, and initially detected document sizes are as follows: a. AB type T-5-6 Sensor name Document width sensor 1 Document width sensor 2 Document length sensor 1 Document length sensor 2 Size b. -

Page 115: Reversal Operation

Chapter 5 ADF pickup motor (M2001) Pickup clutch (CL2001) Shutter Pickup roller Paper Feed roller Separation pad Shutter F-5-8 5.2.5 Reversal Operation 0017-2121 There are two types of reversal operations, reversal from the top side to the back side and reversal from the back side to the top side. However, since their operating principles are the same, only reversal from the top side to the back side is described below. -

Page 116: Delivery Operation

Chapter 5 b. Reversal/Feed 1 After lapse of the specified time since the trailing edge of the transported document passed through the delivery sensor (SR2004), the read motor (M2002) stops. Immediately after this, the read motor turns in the reverse direction to turn over the document, feed the document to the registration roller, and stops, thus turning on the roller release solenoid (SL2003) to release the delivery roller. -

Page 117: Detection Jams

Chapter 5 5.3 Detection Jams 5.3.1 Overview 0017-2307 This machine detects a document jam using the sensors shown in the figure below. The check timing for document jam detection is memorized in the ROM on the image processor PCB. Occurrence of a jam is judged according to whether document is present at the relevant sensor. When a jam occurs, the host machine stores details of the jam with a jam code. -

Page 118: Adf/Dadf

Chapter 5 5.4.2 Pick-up Roller 5.4 ADF/DADF 5.4.2.1 Removing the Pickup Roller 0017-7106 5.4.1 Pick-up/Feed Roller Unit 1) Remove the pickup/feed roller unit. 5.4.1.1 Pickup/Feed Roller Unit 2) Remove the roller receiver [1]. - Screw [2] 1pc. 0017-7105 3) Remove the pickup roller [3]. 1) Open the feeder cover halfway. -

Page 119: Read Motor

Chapter 5 - Connector [2] 1pc. - Screw [3] 2pcs. - Timing belt [4] 1pc. F-5-21 5.4.6 Document Set Sensor 5.4.6.1 Removing the Document Set Sensor F-5-19 0017-7068 5.4.5 Read Motor 1) Remove the rear cover. 5.4.5.1 Removing the Read Motor 2) Remove the left middle cover and the left rear cover. -

Page 120: Document Length Sensor

Chapter 5 5.4.8 Document width sensor 5.4.8.1 Document Width Sensor 0017-7101 1) Remove the tray stopper and open the document pickup tray. 2) Remove the delivery pickup tray lower cover [1]. - Screw [2] 3pcs. F-5-24 5.4.7 Document Length Sensor 5.4.7.1 Removing the Document Length Sensor 1/2 0017-7099 1) Remove the tray stopper and open the document pickup tray. -

Page 121: Registration Sensor

Chapter 5 6) Remove the screw [2]. F-5-30 7) Open the feeder cover guide. 8) Remove the white plate [1]. F-5-32 - Tab [2] 2pcs. 10) Remove the document edge sensor [1]. - Connector [2] 1pc. F-5-33 5.4.10 Registration Sensor 5.4.10.1 Removing the Registration Sensor 0017-7075 1) Remove the rear cover. -

Page 122: Separation Sensor

Chapter 5 F-5-38 F-5-35 5.4.12 Delivery Sensor 5.4.11 Separation Sensor 5.4.12.1 Removing the Delivery Sensor 5.4.11.1 Removing the Separation Rear Sensor 0017-7078 0017-7088 1) Remove the rear cover and the left middle cover. 1) Remove the rear cover. 2) Remove the document feeder tray. 2) Remove the left middle cover and the left rear cover. -

Page 123: Release Solenoid

Chapter 5 F-5-43 5.4.13 Release Solenoid 5.4.13.1 Removing the Roller Release Solenoid 0017-7057 1) Remove the rear cover. 2) Remove the left middle cover and the left rear cover. 3) Remove the roller release solenoid [1]. - Connector [2] 1pc. - Screw [3] 1pc. -

Page 124: Pick-Up Clutch

Chapter 5 2) Remove the support base [1]. 5) Remove the pickup clutch support plate [1]. - E-ring [2] 1 pc. - E-ring [2] 1pc. - Bearing [3] 1 pc. - Bearing [3] 1pc. - Screw [4] 1 pc. - Screw [4] 5pcs. - Edge saddle [5] 2pcs. - Page 125 Chapter 5 3) Remove the ring arm [1] from the arm shaft [3]. 4) Remove the separation pad [1]. - Claw [2] 2pcs. F-5-52 When reinstalling the separation pad, insert spring [2] in the hole [1]. F-5-51 F-5-53 5-17...

- Page 126 Chapter 5 5-18...

- Page 127 Chapter 6 Laser Exposure...

- Page 129 Contents Contents 6.1 Overview/Configuration ..............................6-1 6.1.1 Specifications and Control Mechanism ............................6-1 6.1.2 Main Components ..................................6-2 6.2 Parts Replacement Procedure............................6-3 6.2.1 Laser/Scanner Unit..................................6-3 6.2.1.1 Removing the Laser Scanner Unit ..................................6-3...

-

Page 131: Overview/Configuration

Chapter 6 6.1 Overview/Configuration 6.1.1 Specifications and Control Mechanism 0016-7777 T-6-1 Item Description Laser beam Number of laser beams 2 beams Scanner Motor Type of motor DC brushless motor Rotation control Constant speed rotaion control Polygon Mirror Number of facets 4 facets (20-mm dia.) Control Mechanism Synchronous control... -

Page 132: Main Components

Chapter 6 6.1.2 Main Components 0016-7779 The laser scanner unit consists of the following major components: - laser unit, which serves as the source of laser beam. - laser scanner motor, equipped with a 4-face mirror for laser scanning. - laser driver/BD PCB used to detect laser beam or to control emission of laser beam. The laser beam generated by the laser unit based on the signals from the DC controller PCB moves through the collimator lens (inside the laser unit) and the cylin- drical lens to reach a 4-face polygon mirror rotating at a constant speed. -

Page 133: Parts Replacement Procedure

Chapter 6 6.2 Parts Replacement Procedure 6.2.1 Laser/Scanner Unit 6.2.1.1 Removing the Laser Scanner Unit 0017-3122 The laser scanner was-factory adjusted. Never disassemble it. 1) Remove the rear cover and front cover. 2) Remove the right cover and tray lower cover. 3) Remove the control panel and delivery tray. - Page 135 Chapter 7 Image Formation...

- Page 137 Contents Contents 7.1 Overview/Configuration ..............................7-1 7.1.1 Specifications and Control Mechanism ............................7-1 7.1.2 Outline......................................7-2 7.2 Image Formation Process...............................7-3 7.2.1 Cross-Section (Main body) ................................7-3 7.3 Parts Replacement Procedure............................7-5 7.3.1 Transfer Charging Roller ................................7-5 7.3.1.1 Removing the Transfer Charging Roller.................................7-5...

-

Page 139: Overview/Configuration

Chapter 7 7.1 Overview/Configuration 7.1.1 Specifications and Control Mechanism 0016-7781 T-7-1 Items Description Photosensitive drum Drum type OPC drum Drum diameter 24mm Cleaning mechanism Cleaning blade Processing speed 132.9mm/sec Primary charging Charging method Roller charging (AC + DC) ng roller diameter 12mm Transfer charging Charging method... -

Page 140: Outline

Chapter 7 7.1.2 Outline 0016-7782 The following is below the construction of the image formation system. The machine is a cartridge type, in which the core of its image formation components are constructed as a signal entity: photosensitive drum, primary charging roller, developing cylinder, cleaning blade, and toner housing. -

Page 141: Image Formation Process

Chapter 7 7.2 Image Formation Process 7.2.1 Cross-Section (Main body) 0017-2340 The machine uses an indirect electrostatic method, and is constructed as shown below Reading glass Contact image sensor Image processing block Fixing unit Primary charging Cleaning blade roller Laser scanner unit Drum Cartridge Static... - Page 142 Chapter 7 The machine is designed as a cartridge model, in which its drum, toner, primary charging assembly, developing assembly, and drum cleaner assembly are all con- structed as a single entity. The machine's image formation processes can be divided into the following 5 blocks (7steps): 4.

-

Page 143: Parts Replacement Procedure

Chapter 7 7.3 Parts Replacement Procedure 7.3.1 Transfer Charging Roller 7.3.1.1 Removing the Transfer Charging Roller 0017-3124 1) Remove the cartridge. 2) Remove the transfer charging roller [1]. - Claw [2] 2pcs. F-7-4 1. Do not touch the sponges of the transfer charging roller. If touched, it may cause stains on the back of paper or blank areas of images. - Page 145 Chapter 8 Pickup and Feed System...

- Page 147 Contents Contents 8.1 Overview/Configuration ..............................8-1 8.1.1 Outline......................................8-1 8.2 Detection Jams ................................8-2 8.2.1 Jam Detection Outline.................................. 8-2 8.2.1.1 Outline..........................................8-2 8.2.1.2 Types of Jams........................................8-2 8.3 Cassette Pickup Unit ..............................8-4 8.3.1 Outline......................................8-4 8.3.2 Retry Pickup....................................8-4 8.3.3 Detecting the Size of Paper................................8-4 8.4 Duplex Unit..................................8-5 8.4.1 Outline......................................

-

Page 149: Overview/Configuration

Chapter 8 8.1 Overview/Configuration 8.1.1 Outline 0016-7799 The machine is not equipped with a paper width detection mechanism. It uses center reference, in which paper moves centered through the pickup/feeding/delivery path. The source of paper may be from any of two: cassette and manual feed tray. The paper is controlled so that its leading edge matches the leading edge of the image on the photosensitive drum by means of the registration sensor (SR11);... -

Page 150: Detection Jams

Chapter 8 8.2 Detection Jams 8.2.1 Jam Detection Outline 8.2.1.1 Outline 0016-7800 The machine is equipped with 3 jam sensors and 1 jam switch used to motor the movement of paper. The presence/absence of paper or of a jam is checked at such times as programmed in advance in the CPU of the DC controller PCB and in relation to the presence/ absence of paper over a specific sensor at a given time. - Page 151 Chapter 8 The delivery sensor (SR5) has detected absence of paper within the prescribed time after it detected presence of paper. Initial Jam - When presence of paper is detected by the registration sensor (SR11) or delivery sensor (SR5) at the start of waiting. - When presence of paper is detected by the delivery sensor (SR5) during waiting.

-

Page 152: Cassette Pickup Unit

Chapter 8 8.3 Cassette Pickup Unit 8.3.1 Outline 0016-7803 Paper is picked up from the cassette under the control of the CPU on the DC controller PCB and using the drive of the main motor (M1). When the cassette pickup solenoid (SL2) goes ON, the drive of the main motor (M1) is transmitted to the cassette pickup roller assembly to rotate the cassette pickup roller. -

Page 153: Duplex Unit

Chapter 8 8.4 Duplex Unit 8.4.1 Outline 0016-7806 The duplex pickup operation of this machine is performed by driving the main motor (M1) under the control of the CPU installed on the DC controller PCB. When the trailing edge of the paper finished with printing on its top surface reaches the point 10 mm away from the delivery sensor (SR5), the duplex drive solenoid (SL1) turns on and the drive power of the main motor is transmitted to the delivery roller and duplex drive roller. -

Page 154: Manual Feed Pickup Unit

Chapter 8 8.5 Manual Feed Pickup Unit 8.5.1 Outline 0016-7807 Paper is picked up from the manual feed tray under the control of the CPU on the DC controller PCB and using the drive of the main motor (M1). When the manual feed pickup solenoid (SL5) goes ON, the drive of the main motor (M1) is transmitted as far as the manual feed pickup roller assembly to rotate the manual feed pickup roller. -

Page 155: Parts Replacement Procedure

Chapter 8 8.6 Parts Replacement Procedure 8.6.1 Cassette Pickup Roller 8.6.1.1 Removing the Cassette Pickup Roller 0017-3126 1) Remove the cassette. 2) Place the machine with the rear panel down. However, since the exhaust duct projects about 18 mm from other area of the rear panel, insert stacks of paper or the like under the rear panel so that the machine stands stably. -

Page 156: Cassette Pickup Solenoid

Chapter 8 - Screw [3] 1pc. F-8-14 8.6.5 Paper Feed Roller 8.6.5.1 Removing the Cassete Feed Roller 0017-3130 1) Remove the cassette. 2) Place the machine with the rear panel down. However, since the exhaust duct projects about 18 mm from other area of the rear panel, insert stacks of paper or the like under the rear panel so that the machine stands stably. -

Page 157: Manual Feed Tray Paper Sensor

Chapter 8 F-8-19 8.6.8 Manual Pickup Solenoid 8.6.8.1 Removing the Manual Pickup Solenoid 0017-3143 1) Remove the rear cover, left middle cover, and left rear cover. 2) Remove the manual tray pickup solenoid [1]. - Connector [2] 1pc. - Screw [3] 1pc. F-8-17 F-8-20 3) While holding the manual separation pad [1], release the right hook [2]... -

Page 158: Registration Roller

Chapter 8 F-8-22 8.6.10 Registration Roller F-8-24 8.6.10.1 Removing the Registration Roller 6) Remove the registration sensor unit [1]. - Connector [2] 1pc. 0017-3147 - Boss [3] 2pcs. 1) Remove the front cover and rear cover. 2) Remove the left middle cover and left rear cover. 3) Remove the registration clutch. -

Page 159: Registration Sensor

Chapter 8 - Shaft support [4] 1pc. F-8-27 When reinstalling the right registration roller, the grounding spring [2] must be in touch with the end [1] of this roller. It is recommended to use tweezers when reinstalling the E-ring [3]. F-8-29 2) Remove the registration sensor cover [1]. -

Page 160: Duplex Pick-Up Solenoid

Chapter 8 F-8-32 8.6.12 Duplex Pick-up Solenoid 8.6.12.1 Removing the Duplex Pickup Solenoid F-8-35 0017-3150 8.6.14 Main Motor 1) Remove the rear cover, left middle cover, and left rear cover. 2) Remove the fan duct and main motor. 8.6.14.1 Removing the Main Motor 3) Remove the relay PCB and registration clutch. - Page 161 Chapter 9 Fixing System...

- Page 163 Contents Contents 9.1 Overview/Configuration ..............................9-1 9.1.1 Specifications, Control Mechanisms, and Functions ........................9-1 9.1.2 Outline......................................9-1 9.2 Various Control Mechanisms............................9-3 9.2.1 Controlling the Temperature of the Fixing Unit .......................... 9-3 9.2.1.1 Outline..........................................9-3 9.2.2 Controlling the Fixing Film Temperature............................ 9-3 9.2.2.1 Controlling the Fixing Film Temperature ...............................9-3 9.2.2.2 Target Temperatures by Mode ..................................9-4 9.3 Protection Function ................................9-4 9.3.1 Outline......................................

-

Page 165: Overview/Configuration

Chapter 9 9.1 Overview/Configuration 9.1.1 Specifications, Control Mechanisms, and Functions 0016-7785 T-9-1 Item Function/Method Fixing method by fixing film + pressure roller Fixing heater Unitary flat heater incorporating both main heater and sub heater Fixing temperature detection [1] Main thermistor (TH1): Temperature control and fault detection [2] Sub thermistor (TH2): Fault detection [3] Temperature-switch (TP): Fault detection Fixing temperature control... - Page 166 Chapter 9 Fixing heater (H1) Temperature fuse (TP) Sub thermistor (TH2) Fixing pressure roller Main thermistor (TH1) Fixing film F-9-2...

-

Page 167: Various Control Mechanisms

Chapter 9 9.2 Various Control Mechanisms 9.2.1 Controlling the Temperature of the Fixing Unit 9.2.1.1 Outline 0016-7788 The fixing film unit has a plate-shaped fixing heater built into it for heating the fixing film. The fixing heater is equipped with 2 thermistor: a main thermistor in the middle and a sub thermistor at the end. The main thermistor is used to control the temper- ature of the fixing heater and to detect its overheating, while the sub thermistor is used to detect an error temperature on the end of the fixing heater. -

Page 168: Target Temperatures By Mode

Chapter 9 9.2.2.2 Target Temperatures by Mode 0016-7790 This machine controls the fixing temperature according to the "media type" selected in the user mode and the "target temperature" set in the "special mode." The correspondence between each mode and target temperature is as follows: T-9-3 Paper type Cassette... -

Page 169: Failure Detection

Chapter 9 Power supply PCB DC controller PCB Low-voltage power +3.3V, +5V, +24V supply circuit J103 ZEROX Zerocross circuit Heater drive circuit J103 ASIC RLYD Relay FSRDRV circuit J113 Heater trigger SUBTH circuit Fixing heater high temperature MAINTH error detection Fixing unit F-9-3 9.3.2 Failure Detection... -

Page 170: Parts Replacement Procedure

Chapter 9 9.4 Parts Replacement Procedure 9.4.1 Fixing Unit 9.4.1.1 Removing the Fixing Unit 0017-3153 The fixing assembly is in a very high temperature just after operation. Firstly turn off the power switch and remove the assembly when it is fully cooled. The height of the fixing unit is adjusted at 2 mounting points at the front (left door + front cover) prior to shipment. - Page 171 Chapter 9 - Screw [5] 1pc. F-9-8 8) Slide the guide (rear) [1] backward to remove it. - Boss [2] 1pc. F-9-10 10) Apply marking [1]. 11) Remove the positioning pin [2]. - Screw [3] 1pc. F-9-11 12) Apply marking [1]. 13) Remove the fixing unit [2].

-

Page 172: Installing The Fixing Unit

Chapter 9 F-9-12 F-9-14 5) Perform the following procedure by reversing the installation procedure. To install the fixing unit, follow "Installing the fixing unit". 9.4.2 Fixing Film Unit 9.4.1.2 Installing the fixing unit 9.4.2.1 Removing the Fixing Film Unit 0017-3154 0017-3155 Follow the procedure described below when installing the fixing unit. -

Page 173: Fixing Pressure Roller

Chapter 9 F-9-19 7) Remove the fixing film unit [1]. F-9-16 F-9-20 9.4.3 Fixing Pressure Roller See the illustration below when reinstalling the pressure springs [1] and plates [2]. 9.4.3.1 Removing the Pressure Roller 0017-3156 1) Remove the fixing film unit. 2) Slide the fixing unit inlet guide [1] sideways to release it. -

Page 174: Fixing Delivery Paper Sensor

Chapter 9 9.4.5 Delivery Full Sensor 9.4.5.1 Removing the Delivery Full Sensor 0017-3158 1) Remove the fixing unit. 2) Remove the delivery full sensor [1]. - Connector [2] 1pc. F-9-23 9.4.4 Fixing Delivery Paper Sensor 9.4.4.1 Removing the Delivery Sensor F-9-26 0017-3157 1) Remove the front cover, left front cover, and front left cover. - Page 175 Chapter 10 External and Controls...

- Page 177 Contents Contents 10.1 Control Panel................................10-1 10.1.1 Outline...................................... 10-1 10.2 Fan....................................10-1 10.2.1 Outline...................................... 10-1 10.3 Power Supply ................................10-3 10.3.1 Power Supply ................................... 10-3 10.3.1.1 Outline.........................................10-3 10.3.1.2 Rated Output of the Power Supply PCB ..............................10-3 10.3.2 Protection Function .................................. 10-4 10.3.2.1 Protective Functions....................................10-4 10.4 Parts Replacement Procedure.............................10-5 10.4.1 External Cover ..................................

- Page 178 Contents 10.4.16 Capacitor PCB ..................................10-17 10.4.16.1 Removing the capacitor PCB.................................. 10-17 10.4.17 Interlock Switch ................................... 10-17 10.4.17.1 Removing the Interlock Switch ................................10-17 10.4.18 Fan......................................10-17 10.4.18.1 Removing the Heat Discharge Fan ................................. 10-17 10.4.18.2 Removing the Reader Fan..................................10-18 10.4.19 Speaker....................................

-

Page 179: Control Panel

Chapter 10 10.1 Control Panel 10.1.1 Outline 0016-7794 The machine's control panel consists of the following PCBs, and is controlled by the ASIC of the image processor PCB. Image processor Power supply Key SW ASIC F-10-1 10.2 Fan 10.2.1 Outline 0016-7795 This machine has two fans on the rear side. - Page 180 Chapter 10 FM2000 F-10-2 10-2...

-

Page 181: Power Supply

Chapter 10 10.3 Power Supply 10.3.1 Power Supply 10.3.1.1 Outline 0016-7796 When the main power switch (SW1) is turned on, AC power is supplied to the low-voltage power supply circuit in the power supply PCB. The low-voltage power supply circuit supplies +3.3 V, +5 V, and +24 V to operate the machine. +24 V is supplied to the motors, fan, electromagnetic clutch, solenoid, etc. -

Page 182: Protection Function

Chapter 10 T-10-2 Output 24VR 3.3V 3.3VR Rated output voltage 5.1V 5.1V 3.4V 3.4V Output voltage tolerance +10%, -5% +3%, -4% +3%, -4% +3%, -3% +3%, -3% Rated output current 4.5A 0.3A 0.7A 2.4A 0.8A Overcurrent protection 7.0A 4.0A 2.0A 3.7A 2.0A trigger current... -

Page 183: Parts Replacement Procedure

Chapter 10 10.4 Parts Replacement Procedure 10.4.1 External Cover 10.4.1.1 Exteranal Covers 0018-2078 [10] [13] [12] [11] F-10-4 Feeder cover Document feeder tray Front cover Delivery tray Left front cover Left cover Left middle cover Multi-purpose tray Left rear cover [10] Document delivery tray [11]... -

Page 184: Removing The Rear Cover

Chapter 10 10.4.1.2 Removing the Rear Cover 0017-1904 1) Remove the rear cover [1]. - Screw [2] 4pcs. F-10-5 10.4.1.3 Removing the Left Middle Cover F-10-7 0017-1906 10.4.1.5 Removing the Left Rear Cover 1) Remove the left cover. 0017-1908 2) Slide the left middle cover [1] in the direction of the rear side to detach it. - Screw [2] 2pcs. -

Page 185: Removing The

Chapter 10 1) Remove the cassette. 2) Remove the front cover. 3) Remove the rear cover. 4) Release the two claws [1] at the rear back of the right cover. 5) Using a flathead screwdriver, release the three claws [2] at the top of the right cover. -

Page 186: Removing The Document Feeder Tray

Chapter 10 F-10-13 10.4.1.9 Removing the Document Feeder Tray 0017-1913 F-10-15 1) Remove the rear cover. 10.4.1.10 Removing the Document Delivery Tray 2) Open the feeder cover. 0017-1914 3) Remove the gear cover [1]. - Screw [2] 1pc. 1) Reamove the rear cover. 2) Remove the tray lower cover. -

Page 187: Removing The Delivery Tray

Chapter 10 - Screw [2] 2pcs. F-10-19 10.4.3 Pick-up Drive Unit F-10-17 10.4.1.11 Removing the Delivery Tray 10.4.3.1 Removing the Pickup Drive Unit 0017-1912 0017-3606 1) Remove the front cover and rear cover. 1) Remove the rear cover. 2) Remove the right cover and tray lower cover. 2) Remove the left middle cover and left rear cover, 3) Remove the operation panel. -

Page 188: Operation Panel Unit

Chapter 10 F-10-21 10.4.5 Operation Panel Unit 10.4.5.1 Removing the Operation Panel Unit 0017-3061 1) Remove the front cover and rear cover. 2) Remove the left middle cover and left rear cover. 3) Remove the right cover and tray lower cover. 4) Remove the front left cover [1]. -

Page 189: Removing The Image Processor Pcb

Chapter 10 10) Close the window on the Desktop. MEMO: 11) Turn off the main power switch of this machine. The modem PCB [1] is connected to the IP PCB with the connector [5]. 12) Disconnect the USB cable from this machine. 6) Disconnect the connector [6] on the network PCB. -

Page 190: Procedure After Replacing The Image Processor Pcb

Chapter 10 piece or two pieces) "additional functions key" > "01 of the one-touch speed dial key" > "20 of 12) Remove the SEND memory [6]. (if equipped with SEND functions) the one-touch speed dial key" > "view settings key" 12) Disconnect all connectors and flexible cables from the image processor 9) Display "TURN POWER OFF->ON". -

Page 191: Dc Controller Pcb

Chapter 10 Caution on attaching the jumper plug 1. Put back the jumper plug (JP100) on the modem PCB to where it was. 2. If the jumper plug were not at the proper location, the backup would not function at the main switch 'OFF' status and at the power breakdown. And also it will lose the image data, which is stocked in the SDRAM. -

Page 192: Relay Pcb

Chapter 10 10.4.12 Modem PCB 10.4.12.1 Removing the Modem PCB 0017-3629 1) Remove the rear cover. 2) Remove the LAN cover [1]. - Connector [2] 1pc. - Clamp [3] 1pc. (remove the cable.) - Screw [4] 6pcs. F-10-35 10.4.10 Relay PCB 10.4.10.1 Removing the Relay PCB 0017-3625 F-10-38... -

Page 193: Modular Jack Pcb

Chapter 10 F-10-40 F-10-42 3) Remove the network PCB [1]. - Connector [2] 1pc. Caution on attaching the jumper plug - Screw [3] 4pcs. 1. Put back the jumper plug (JP100) on the modem PCB to where it was 2. If the jumper plug were not at the proper location, the backup would not function at the main switch 'OFF' status and at the power breakdown. - Page 194 Chapter 10 F-10-44 3) Remove the SEND PCB [1]. - Connector [2] 1pc. - Screw [3] 4pcs. F-10-46 MEMO: The jumper plug is small. A needlenose pliers or tweezers may be useful in this operation. Be sure not to short-circuit the jumper pin and its neighboring metal. 5) Remove the modem PCB [1].

-

Page 195: Capacitor Pcb

Chapter 10 F-10-48 7) Remove the SEND PCB [1]. - Screw [2] 1pc. F-10-51 10.4.17 Interlock Switch 10.4.17.1 Removing the Interlock Switch 0017-5549 1) Remove the rear cover and front cover. 2) Remove the right cover and tray lower cover. 3) Remove the control panel and delivery tray. -

Page 196: Removing The Reader Fan

Chapter 10 1) Remove the rear cover, front cover, and right cover. 2) Disconnect the connector [1]. (remove the cable from the cable guide.) F-10-55 3) Remove the speaker [1]. F-10-53 - Screw [2] 2pcs. 10.4.18.2 Removing the Reader Fan 0017-7064 1) Remove the rear cover. - Page 197 Chapter 11 e-Maintenance/imageWARE Remote...

- Page 199 Contents Contents 11.1 e-Maintenance/imageWARE Remote........................11-1 11.1.1 Overview....................................11-1 11.1.2 Application Operation Mode ..............................11-1 11.1.3 Communication Test ................................11-1 11.1.4 Communication Log ................................11-1 11.1.5 Detail of Communication Log ..............................11-1 11.1.6 Initialization of e-RDS ................................11-1 11.1.7 SOAP Communication Function ............................. 11-2 11.1.8 Retransmission at the time of SOAP Transmission Error .......................

-

Page 201: E-Maintenance/Imageware Remote

Chapter 11 11.1 e-Maintenance/imageWARE Remote 11.1.1 Overview 0017-9788 Product Overview Embedded RDS (henceforth: e-RDS) is the front-end module of e-Maintenance embedded with a network module of a device controller. Product Package Configuration Embedded with a network module of a device. Features e-RDS is embedded with a network module of a device controller, which works as a front-end module of e-Maintenance without any hardware other than device. -

Page 202: Soap Communication Function

Chapter 11 (As for deletion of certificate, see 'CA certificate'.) 11.1.7 SOAP Communication Function 0017-9795 Following processings are enabled by use of SOAP communication (SSL client communication). Server authentication is performed by use of CA*1 certificate issued by VeriSign. In case the server certificate or CA certificate is expired, the device is not connected to UGW. *1: CA stands for Certificate Authority, which are the institutions which issue electronic certificate used in e-commerce etc. -

Page 203: Retransmission At The Time Of Soap Transmission Error

Chapter 11 Transmission Detail / Process Detail Transmission Timing Remarks Environment log (Device condition log) transmission Once every 12 hours. The environment information inside the device postEnvironmentLog such as temperature and humidity. Alert filtering Upon a request from UGW When requested from UGW with getAlertCodeNotificationList 'getOperationList' - The timing of transmission to UGW varies according to the device. -

Page 204: Report Output Of Communication Error Log

Chapter 11 An example for the transition of the menu related to the e-RDS in the service mode. arrow key #E-RDS #E-RDS #E-RDS E-RDS SWITCH RGW-ADDRESS RGW-PORT OK key #E-RDS SWITCH #RGW-ADDRESS #RGW-PORT https://xxxxxxxxxxxxxx #E-RDS #E-RDS COM-TEST COM-LOG #E-RDS No:1 Ecode:870F2052 COM-TEST OK 2006 03/24 11:56 F-11-1... -

Page 205: Alarm Filtering, Alert Filtering

Chapter 11 11.1.12 Alarm Filtering, Alert Filtering 0017-9800 With the instruction from UGW (getOperationList), change the alarm level for the specified alarm code, and transmit only the specified alert code. 11.1.13 CA Certificate 0017-9801 (1). Overview of functions CA certificate (CA-KEY) is included in the system software System (Default CA certificate. For UGW). The CA certificate other than the default is installable with SST. -

Page 206: Troubleshooting

Chapter 11 #CLEAR > ERDS-DAT If necessary, install or delete CA Certificate and turn off/on the power. (1)-3. Display the menu screen of e-RDS Press the arrow key to move to the menu (#E-RDS) of e-RDS. (2). Set E-RDS SWITCH to 1 in order to enable e-RDS. (3). - Page 207 Chapter 11 Error Character Strings Error Description Cause Measures Proxy connection error Proxy connection error Cannot connect to the Proxy server. Check the server IP address and port number and correct the settings accordingly. The device needs rebooting when network- related settings such as Proxy settings are modified.

- Page 208 Chapter 11 Error Character Strings Error Description Cause Measures Server response time out Server response time out Due to network congestion etc., response In case this occurred when implementing the from server does not return within a communication test, retry after a certain period specified period of time.

- Page 209 Chapter 11 [Detail of server error]: Display detailed error information from error in case there is an error response from UGW. However, in case the character number exceeds 128, character strings after 128th are omitted. In case of the other error, nothing is displayed here. Below is the example of the actual characters displayed: Example) Unexpected error: postGlobalClickCount() 11-9...

- Page 211 Chapter 12 Maintenance and Inspection...

- Page 213 Contents Contents 12.1 Periodically Replaced Parts ............................12-1 12.1.1 Periodically Replaced Parts ..............................12-1 12.2 Consumables ................................12-1 12.2.1 Durables ....................................12-1 12.3 Periodical Service ..............................12-1 12.3.1 Periodeical Service Items................................. 12-1...

- Page 215 Chapter 12 12.1 Periodically Replaced Parts 12.1.1 Periodically Replaced Parts 0011-5784 The machine does not have parts that require periodical replacement. 12.2 Consumables 12.2.1 Durables 0011-5785 The machine does not have durables. 12.3 Periodical Service 12.3.1 Periodeical Service Items 0011-5787 The machine does not have periodecal service items.

- Page 217 Chapter 13 Measurement and Adjustments...

- Page 219 Contents Contents 13.1 Image Adjustments ..............................13-1 13.1.1 Image parallelism adjustment ..............................13-1 13.2 Scanning System ................................13-2 13.2.1 Action after Replacing the Contact Image Sensor ........................13-2 13.3 Electrical Adjustments ...............................13-2 13.3.1 Procedure after Replacing the Image Processor PCB......................13-2 13.3.2 Actions to Take before All Clearing (Backing up the User Data) ................... 13-2 13.4 ADF....................................13-4 13.4.1 Outline......................................

-

Page 221: Image Adjustments

Chapter 13 13.1 Image Adjustments 13.1.1 Image parallelism adjustment 0017-5659 1) Create a test chart, load it in the ADF, and make a copy of it. Test Sheet 10mm 10mm (feeding direction) Rear 10mm F-13-1 2) Compare the lines at the end of the test chart with those on the copy for parallelism. -

Page 222: Scanning System

Chapter 13 13.2 Scanning System 4. Reading related adjustment 13.2.1 Action after Replacing the Contact Image Sensor - Correction of output between CIS channels 1) Enter the service mode. 0017-5660 Sequentially press the Additional functions key, 2 key, 8 key, and Additional functions key on the operation panel. - Page 223 Chapter 13 the one-touch speed dial key" > "view settings key" 9) Display "TURN POWER OFF->ON". 10) Close the window on the Desktop. 11) Turn off the main power switch of this machine. 12) Disconnect the USB cable from this machine. 13-3...

-

Page 224: Adf

Chapter 13 9) Using the numeric keys, change the value to determine the optimum value. Next, press the OK key. (Default: 32) 13.4 ADF Do not change the adjustment value excessively. 13.4.1 Outline 13.4.1.1 Outline 13.4.2.2 Adjusting the Horizontal Registration 0017-5663 0017-5952 This machine has the following adjustment items. -

Page 225: Leading Edge Registration Adjustment

Chapter 13 required, make an adjustment. The image is shifted to the right. -> Increase the value. The specified horizontal registration is 10mm +/-2mm. Unit of adjustment 1 = 0.1 mm 3) Enter the service mode. Sequentially press the Additional functions key, 2 key, 8 key, and Additional functions key on the operation panel of the host machine. - Page 227 Chapter 14 Correcting Faulty Images...

- Page 229 Contents Contents 14.1 Initial Checkup................................14-1 14.1.1 Site Environment ..................................14-1 14.1.2 Checking the Paper .................................. 14-1 14.1.3 Checking the Placement of Paper ............................14-1 14.1.4 Checking the Durables ................................14-1 14.1.5 Checking the Units and Functional Systems ........................... 14-1 14.1.6 Others ....................................... 14-2 14.2 Outline of Electrical Components..........................14-3 14.2.1 Clutch/Solenoid/Motor/Fan ..............................

-

Page 231: Initial Checkup

14.1.2 Checking the Paper 0016-7931 a. Be sure the paper being used is of a type recommended by Canon. b. Be sure that the paper is not moist. Try using paper fresh out of package. 14.1.3 Checking the Placement of Paper 0016-7932 a. -

Page 232: Others

Chapter 14 14.1.6 Others 0016-7936 If a machine is brought from a cold to warm room, its inside can start to develop condensation, leading to various problems. a. condensation on the BD sensor is likely to cause problems associated with E100 b. -

Page 233: Outline Of Electrical Components

J206 (Relay PCB) E805 FM2000 Reader fan Cools reader controller PCB. FK2-5776 J412 (Reader controller PCB) *1:A3 model only A4 model: LASER CLASS 810/i-SENSYS FAX-L3000/FAX L-3000 A3 model: LASER CLASS 830i/i-SENSYS FAX-L3000IP/FAX L-3000IP/Canofax L-1000 FM2000 M2002 SL2003 CL2001 M2001 CL2002... -

Page 234: Sensor

J411 (Reader controller PCB) Interlock switch Detects opening/closing of the WC4-5236 J112 (DC controller PCB) 1118 left cover. *1:A3 model only A4 model: LASER CLASS 810/i-SENSYS FAX-L3000/FAX L-3000 A3 model: LASER CLASS 830i/i-SENSYS FAX-L3000IP/FAX L-3000IP/Canofax L-1000 SR2010 SR2001 SR2005 SR2009 SR2007 SR2002... -

Page 235: Pcbs

Noise filter FM3-3840 (230V only) [15] SEND PCB SEND functuion expansion FM3-3378(standard for LASER CLASS 830i only) [16] SDRAM Image memory storage 64MB:FM3-3373 128MB:FM3-3324 A4 model: LASER CLASS 810/i-SENSYS FAX-L3000/FAX L-3000 A3 model: LASER CLASS 810i/i-SENSYS FAX-L3000IP/FAX L-3000IP/Canofax L-1000 14-5... - Page 236 Chapter 14 [10] [15] [14] [13] [16] [12] [11] F-14-3 14-6...

-

Page 237: Others

Chapter 14 14.2.4 Others 14.2.4.1 List of Lamps, Heaters, and Others 0017-2296 T-14-4 Symbol Name Function Parts No. Connection Jack No. Error Fixing heater Used as the heater for fixing. Fixing unit (100V:FM2-5297, J15(power supply PCB) E000, E001, E002, 120V:FM2-5278, 230V:FM2- E003 5298) Fixing main thermistor... - Page 238 Chapter 14 14-8...

- Page 239 Chapter 15 Error Code...

- Page 241 Contents Contents 15.1 Error Code..................................15-1 15.1.1 List of Error Codes................................... 15-1 15.2 Jam Code..................................15-2 15.2.1 Jam Codes (Main body) ................................15-2 15.2.2 Jam Codes (ADF) ..................................15-2 15.3 Fax Error Codes .................................15-4 15.3.1 Outline...................................... 15-4 15.3.1.1 Error Code Outline ......................................15-4 15.3.2 User Error Code ..................................

-

Page 243: Error Code

Chapter 15 15.1 Error Code 15.1.1 List of Error Codes 0016-7821 T-15-1 Display Detail Code Main Cause/Symptom Countermeasure Code E000 0000 Startup error The temperature detected by the main or sub thermistor does - Check the fixing film connector. not rise to the specified value during startup control. - Replace the fixing film unit. -

Page 244: Jam Code

Chapter 15 Display Detail Code Main Cause/Symptom Countermeasure Code E733 0000 Erroneous communication between controller and printer Cannot communicate with the printer at startup. - Check the connectors of the DC controller PCB and image processor PCB for normal connection. - Check the power supply of the printer (Check whether initialization is performed at startup). - Page 245 Chapter 15 T-15-3 Code Name Sensor No. Description 0000 Unknown jam Some other error 0007 Initial stationary SR2002, SR2003, SR2004, Paper has been detected in the transport path before ADF initialization. SR2005 0008 Document edge sensor SR2002 The document edge sensor cannot detect the document even when the document has delay been transported by the specified distance after reception of the pickup request.

-

Page 246: Fax Error Codes

Chapter 15 15.3 Fax Error Codes 15.3.1 Outline 15.3.1.1 Error Code Outline 0016-7822 An error code is used to indicate a fault in a machine, and is indicated in the machine's LCD or reports, showing the nature (symptoms) of the fault. Using the error code, the user or the service man can readily find out how to correct the fault by simply referring to the User's Manual or service manual. - Page 247 Chapter 15 Tx/Rx Description ##0282 [Tx] at time of transmission, the procedural signal has been transmitted more than specified. ##0283 [Tx] at time of transmission, the procedural signal has been transmitted more than specified. ##0284 [Tx] at time of transmission, DCN is received after transmission of TCF. ##0285 [Tx] at time of transmission, DCN is received after transmission of EOP.

- Page 248 Chapter 15 Tx/Rx Description ##0791 [Tx/Rx] while ECM mode procedure is under way, a signal other than a meaningful signal is received. ##0792 [Rx] at time of ECM reception, PPS-NULL cannot be detected over partial page processing. ##0793 [Rx] at time of ECM reception, no effective frame is received while high-speed signal reception is under way, thus causing time- out.

- Page 249 Chapter 16 Service Mode...

- Page 251 Contents Contents 16.1 Outline..................................16-1 16.1.1 Outline of Service Mode ................................16-1 16.1.2 Using the Mode..................................16-3 16.1.3 Import/export of the user information by the USB storage ..................... 16-3 16.2 Default Settings................................16-4 16.2.1 Service Mode Menus ................................16-4 16.3 Service Soft Switch Settings (SSSW) ........................16-10 16.3.1 Outline....................................

- Page 252 Contents 16.3.12.2 Detailed Discussions of Bit 0.................................. 16-16 16.3.12.3 Detailed Discussions of Bit 1.................................. 16-16 16.3.12.4 Detailed Discussions of Bit 2.................................. 16-16 16.4 Menu Switch Settings (MENU) ..........................16-16 16.4.1 Menu Switch Composition ..............................16-16 16.4.2 <No.005 NL equalizer> ................................. 16-17 16.4.3 <No.006 telephone line monitor>............................

- Page 253 Contents 16.7.1.2.1 List of Functions ....................................16-26 16.7.1.2.2 Detailed Discussions of Bit 0 ................................16-26 16.7.1.2.3 Detailed Discussions of Bit 2 ................................16-26 16.7.1.2.4 Detailed Discussions of Bit 4 ................................16-26 16.7.1.2.5 Detailed Discussions of Bit 5 ................................16-26 16.7.1.2.6 Detailed Discussions of Bit 7 ................................16-26 16.7.1.3 SSSW-SW15 ......................................16-27 16.7.1.3.1 List of Function ....................................16-27 16.7.1.3.2 Detailed Discussions of Bit 3 ................................16-27...

- Page 254 Contents 16.16.3.1 Scan Test ((2) SCAN TEST) .................................. 16-43 16.16.4 Print Test....................................16-43 16.16.4.1 Print Test ((3) PRINT TEST) ................................. 16-43 16.16.5 Modem Test ..................................16-44 16.16.5.1 MODEM Test ((4) MODEM TEST) ..............................16-44 16.16.6 Faculty Test..................................16-46 16.16.6.1 FUNCTION TEST <(6) FUNCTION TEST>............................16-46 16.16.7 Cleaning Mode..................................

- Page 255 Chapter 16 16.1 Outline 16.1.1 Outline of Service Mode 0016-7859 The items that follow may be checked/set using the machine's service mode, which is designed the way the service mode used in fax machines is designed in terms of contents and operation. #SSSW Use it to register/set basic fax functions (e.g., error control, echo remedy, communication error correction).

- Page 256 Chapter 16 16-2...

- Page 257 Chapter 16 16.1.2 Using the Mode 0016-7861 <Operation at the time of Bit SW> <Operation at the time of Parameter> 1) Selecting Service Mode 1) Selecting Service Mode Press the Additionalfunctions Press the Additionalfunctions key, 2key, 8key, Additional functions key, 2key, 8key, Additional functions key sequentially.

- Page 258 Chapter 16 16.2 Default Settings 16.2.1 Service Mode Menus 0016-7862 #SSSW Initial setting Function SW01 00100000 error/copy control SW02 not used SW03 00000000 echo remedy setting SW04 10000000 communication fault remedy setting SW05 00000000 standard function (DIS signal) setting SW06 - SW11 not used SW12 00000010...

- Page 259 Chapter 16 #NUMERIC Param. Initial setting Range of setting Function 001: not used 002: 10 (10%) (1 - 99) RTN signal transmission condition (1) setting 003: 15 (15lines) (2 - 9) RTN signal transmission condition (2) setting 004: 12 (12times) (1 - 99) RTN signal transmission condition (3) setting 005:...

- Page 260 Chapter 16 #SCAN Initial setting Range setting Explanation #SCAN SW SW1 - SW50 Not used #SCAN 001: - 025: Not used NUMERIC 026: 6 to 48, one unit=0.1mm Distance from the standby position of CIS to the shading start point. (CIS shift type only) 027: - 040: Not used 041:...