Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pitney Bowes F601

- Page 1 Operating Guide F601 Booklet Feeder...

-

Page 2: Table Of Contents

Contents 1. Introduction page 1.1 Safety 2. Getting to know the Model F601 2.1 Main components 2.2 The menus, flow chart 2.3 How to read the display 2.4 Explanation of the menus 3. Operation 3.1 Setting up the Model F601 3.2 Adjusting the separation... -

Page 3: Introduction

Introduction 1. INTRODUCTION This operator manual describes how to operate the Model F601 Booklet feeder. 1.1 Safety General • Know your equipment, especially how to stop it in the event of an emergency. • Never reach into the machine while it is on; always wait until the machine has come to a full stop. -

Page 4: Getting To Know The Model F601

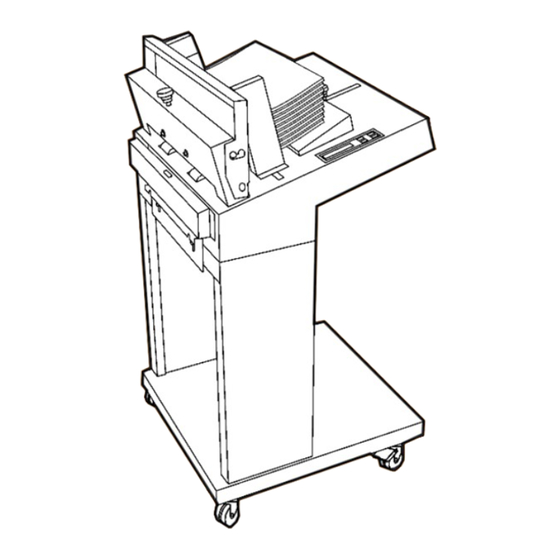

The Model F601 is a microprocessor controlled booklet feeder designed to be used in a system together with the Model F610 inserter and Model F612/F615 collator or as a stand-alone unit. Take a few minutes to become familiar with components of the Model F601. 2.1 Main components front... -

Page 5: Diagnostics

The Feeder 2.2 The menus, flow chart Run Mode Menus STOP 00075 START PAUSE MODE On-line Pause Mode Menus Main Menu STOP 00075 STOP 00075 PAUSE CONTINUE PAUSE CONTINUE Option ADJUST ADJUST Menus On-Line START SETS PER HOUR Off-Line MODE CLEAR COUNTER On-line SETS PER HOUR... - Page 6 00075 your selection and the Model F601 will start. If the PAUSE F601 is installed in a system with a Model F610 Inserter Run Mode Menu and a Model F612/F615 Collator, the complete system can be started from any unit’s start button. The “Main Menu”...

- Page 7 2.4 Explanation of the menus (continued) The “Run Mode Menu” is displayed when the Model STOP 00075 F601 is started. In the “Run Mode Menu” there are PAUSE three options: “STOP”, “PAUSE” and “ADJUST”. Scroll/ PAUSE select an option with the arrow buttons and confirm ADJUST with the OK button.

- Page 8 OK button to confirm changes or the ESC button to cancel. In either case you will be returned to the “Option Menus”. Decide whether the Model F601 should be on-line or START 00075 off-line with the system or function as a stand alone...

- Page 9 The range is 60 to 100%. Default value is 80%. If the belt speed is too slow the inserts might have problems to “leaving” the Model F601. If the belt speed is too high, single sheets might turn over when they are fed and booklets might bounce back.

-

Page 10: Setting Up The Model F601

Model F601 Lift the Model F601 docking plate and position the Model F601 up to the Model F610. Ensure that the docking plate locks the Model F601 to the Model F610. If a Model F612/F615 Collator is present in the system, it should be positioned in the docking plate on Model F610. -

Page 11: Adjusting The Separation

Operation 3.2 Adjusting the separation The illustration to the left shows schematically how separator adjustment knob the separation works and the name of the different parts. Tightening the separator adjustment knob moves separator pads the bearing rollers and the separator pads closer to the feed belt. - Page 12 Operation The adjustment of the rear guide affects the friction between the inserts and the feed belt. Adjustment therefore depends on paper weight, structure and printing method as well as what type of inserts are being fed. Proper adjustment is more significant when running single sheets.

-

Page 13: Programming The Model F601

Switch on the power. Select “Mode” and press the OK button. Choose “On-line” if the Model F601 is used together with a Model F612/F615 collator and/or a Model F610 inserter. Choose “Stand Alone” to use the Model F601 as a stand alone booklet feeder. -

Page 14: The Diagnostics Function

If cleaning does not correct the problem, or if any other of the parts checked fails the test, have the Model F601 checked by a qualified technician. The self test is indicated with a flashing “TEST” until MEMORY: PASSED the test is completed. -

Page 15: General Problems

"Diagnostics" to verify status of sensor. If the set. self test verifies that the sensor is defective, 5. Outfeed sensor have the Model F601 checked by a qualified defective or dirty. technician. Press the up arrow button to reset the insert/s. - Page 16 (see section 3.3). 3. Run "Diagnostics" to verify status of sensor. If the self test verifies that the sensor is defective, have the Model F601 checked by a qualified technician. 1. Interlock switch at unit See section 2.4 to identify which unit is System ERROR with ID number "X"...

-

Page 17: Model F601 Specifications

Specifications 7. SPECIFICATIONS 7.1 Model F601 Specifications Model F601 Paper size 140 x 210 mm 310 x 310 mm Paper weight 60 gsm Up to 600g total weight of insert Speed Up to 3600 sets per hour Max insert thickness... - Page 18 FOR SERVICE AND SUPPLIES: 3001 Summer Street, Stamford, Connecticut 06926 www.pitneybowes.com Form No. SDC490 RevB (9-22) © Pitney Bowes Limited, 2022 Printed in England...

Need help?

Do you have a question about the F601 and is the answer not in the manual?

Questions and answers