Table of Contents

Advertisement

Quick Links

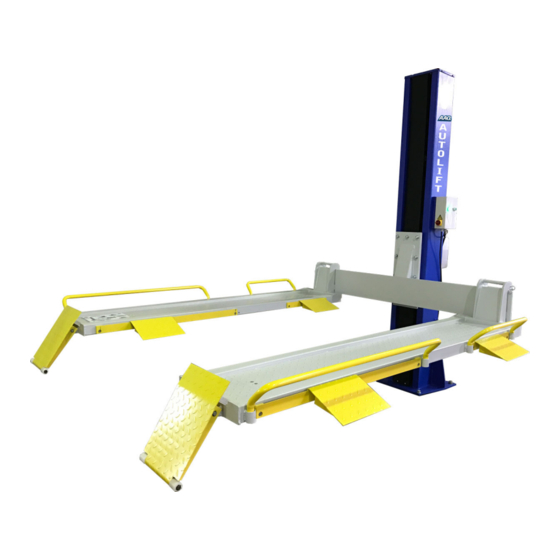

SINGLE POST HOIST

AutoLift AL-167262

Single Post Lawnmower & Service Vehicle Hoist

1000Kg Maximum Lifting Capacity

Design Registration Approval Number: WAH22390

Design Code: AS1418.9-1996

Note: While all due care and attention has been taken in the preparation of this document, Advance AutoQuip shall not be liable for any inaccuracies or omissions

Ph: 08 9279 1663 | Fax: 08 9279 1667 | E: sales@aaq.net.au | W: www.aaq.net.au

INSTALLATION MANUAL & OPERATION

INSTRUCTIONS

- READ THE ENTIRE CONTENTS OF THIS MANUAL BEFORE

INSTALLATION AND OPERATION. BY PROCEEDING YOU AGREE THAT

YOU FULLY UNDERSTAND AND COMPREHEND THE FULL CONTENTS

OF THIS MANUAL. FORWARD THIS MANUAL TO ALL OPERATORS.

FAILURE TO OPERATE THIS EQUIPMENT AS DIRECTED MAY CAUSE

Specifications subject to change without notice.

which may occur therein

Advance AutoQuip

2 McDonald Crescent | Bassendean WA 6054

INJURY OR DEATH.

READ FIRST

DO NOT use the

machine until you read

and understand all the

dangers, warnings and

cautions in this manual.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for AAQ AutoLift AL-167262

- Page 1 Note: While all due care and attention has been taken in the preparation of this document, Advance AutoQuip shall not be liable for any inaccuracies or omissions which may occur therein Advance AutoQuip 2 McDonald Crescent | Bassendean WA 6054 Ph: 08 9279 1663 | Fax: 08 9279 1667 | E: sales@aaq.net.au | W: www.aaq.net.au...

-

Page 2: Table Of Contents

CONTENT Safety 1.1 Note, Caution and Warning 1.2 Important Information 1.3 Safety Instructions Technical Manual 2.1 Product Description 2.2 Technical Data 2.3 Hydraulic Scheme 2.4 Circuit Diagram Before Using 3.1 Site Selection 3.2 Surface Condition 3.3 Installation Instruction 3.4 Preparation for Starting up 4. -

Page 3: Safety

The operation of the hoist is permitted by authorized person only. If any confusion, please contact the service provider or contact the manufacturer: Advance AutoQuip 2 McDonald Crescent Bassendean, Western Australia, 6054 +61 8 9279 1663 sales@aaq.net.au... -

Page 4: Safety Instructions

1.3 Safety Instructions 1. Do not raise a vehicle on the hoist until the initialization is completed as described in this manual. Technicians should be trained to use and care for the hoist by familiarizing themselves with the publications listed above. The hoist should never be operated by an untrained person. 3. - Page 5 18. Unusual vehicles, such as limousines, RV’s, and long wheelbase vehicles, may not be suitable for lifting on this equipment. If necessary, consult with the manufacturer or the manufacturer’s agent. 19. The maintenance procedures described in this manual can be done by the hoist's owner/employer.

-

Page 6: Technical Manual

2. Technical Manual 2.1 Product Description The AutoLift 167262 hydraulic single post hoist is a frame contact hoist incorporating the latest safety technologies. Designed and manufactured for lifting vehicles with a capacity of 1,000kg, it is also fully capable for lifting small tractors, ride on mowers, quads bikes and small vehicles under 1000Kg and safely holding them in an elevated position. - Page 7 Fig.01...

-

Page 8: Hydraulic Scheme

2.3 Hydraulic Scheme 1. Oil tank 2. Mesh 3. Gear pump 4. Motor 5. One-way valve 6. Mesh 7. Release valve 8. Overflow valve 9. Restrictor valve 10. Cylinder 11. Oil tube... -

Page 9: Circuit Diagram

2.4 Circuit Diagram... -

Page 11: Before Using

3. Before Using 3.1. Site Selection The hydraulic single post hoist is designed only for indoor use. Application in a room with explosion hazard is not permitted. Setting in a wet place, a car wash center for instance, is forbidden. 3.2. - Page 12 B. Fix the lifting frame Put the lifting frame in front of the column by using a fork lift or engine crane. Then bolt the lifting frame on the carriage with the bolt supplied. Fig. 2-B-1 Fig. 2-B-2 3. Mount the hydraulic power unit A.

- Page 13 4. Mount the control box A & B. Mount the control box on the back or side of the column. Fig. 4-A Fig. 4-B Connecting A. According to the connecting diagram, connect the cables to the appropriate position. B. Connect the 240V/50Hz, 1 phase power supply cable to the control box. Fig.

-

Page 15: Preparation For Starting Up

7. Install platforms & accessories A. H ook on the platforms on the lifting frame. B. Install all the ramps. Fig. 7-A Fig. 7-B-1 Fig. 7-B-2 3.4. Preparation for Starting up The locks are automatic and will engage when in operation. 3.4.1 3.4.2 The hydraulic oil should be ISO-32.or 46... -

Page 16: Operating Instructions

4. Operating Instructions Be sure to read and familiarize yourself with the Safety Instructions at the beginning of this manual. Failure to follow Safety Instructions may result in property damage, personal injury or death. Be sure to read and familiarize yourself with the Safety Instructions at the beginning of this manual. -

Page 17: To Lower Hoist

Vehicle is stable on hoist 4.3 To Lower Hoist a. Check all danger points of the hoist and be sure that there are no objects or people in the working area (danger area) around the hoist or on the hoist. b. -

Page 18: Maintenance Instructions

5. Maintenance Instructions Contact your service provider for instruction before starting up if you are not completely familiar with automotive hoist maintenance procedures. Only qualified personnel can perform maintenance on this equipment. Any failure in operation may cause personal injury or death. Always keep bolts tight. - Page 19 6. Parts Drawing...

- Page 22 Parts List ITEM CODE DESCRIPTION NOTE DJ05-10000-000 anchor 3/4-10 TC02-01000-000 column 5105-06025-000 screw M6*25 DJ01-00005-M00 upper cover 5101-08030-000 bolt M8*30 DJ01-24000-A00 upper curtain bar TC02-00012-000 curtain TC02-00005-000 down curtain plate DJ01-00031-A00 down curtain bar 5110-06012-000 screw M6*12 DJ02-00027-000 fixing plate 5603-00016-000 combined washer 5309-00010-000...

- Page 23 ITEM CODE DESCRIPTION NOTE 5203-00020-000 thin nut M20*1.5 5201-00006-000 TC02-00008-000 upper chain block 5201-00016-000 5206-00016-000 lock nut TC02-00010-000 chain 5105-16060-000 screw TC01-00002-000 chain pin TC02-00007-000 down chain block 5206-00030-000 thin lock nut M30*1.5 DJ01-13001-M00 lock board SJ01-07007-000 spring DJ01-13002-M00 lock tongue 5206-00010-000 thin lock nut DJ01-13003-M00...

- Page 24 ITEM CODE DESCRIPTION NOTE TC02-07000-000 ramp TC02-15001-000 roller board TC02-09000-000 inside ramp frame TC02-05300-000 SJ03-00013-000 handle TC02-05003-000 chain TC02-00006-000 hook board 5105-06015-000 bolt M6*15 5101-10025-000 bolt M10*25 TC02-04000-000 lifting frame 5201-00010-000 5105-16040-000 bolt M16*40 5303-00016-000 spring washer Φ16 5301-00016-000 flat washer Φ16 5105-16030-000 bolt...

-

Page 25: Troubleshooting Guide

7. Troubleshooting Guide Problem Cause Solution 1. Blown fuse or circuit breaker Replace blown fuse or reset circuit Motor does not run. 2. Incorrect voltage to motor breaker. 3. Bad wiring connections. Supply correct voltage to motor. 4. Motor up switch burned out. Repair and insulate all connections. - Page 26 SAFETY OPERATING PROCEDURES Vehicle Hoist DO NOT use this machine unless you have been instructed in its safe use and operation and have been given permission PERSONAL PROTECTIVE EQUIPMENT Safety glasses must be worn at Long and loose hair must be Do not stand on hoist whilst all times in work areas.

- Page 27 THIS WARRANTY SUPERSEDES ALL OTHER WARRANTY POLICIES PREVIOUSLY STATED AND IN ALL OTHER ADVANCE AUTOQUIP’s PRODUCT SPECIFIC LITERATURE. Advance AutoQuip 2 McDonald Crescent | Bassendean WA 6054 Ph: 08 9279 1663 | Fax: 08 9279 1667 | E: sales@aaq.net.au | W: www.aaq.net.au...

- Page 28 Model No: AutoLift 167262 2 McDonald Crescent Hoist Type: Single Post Hoist Bassendean WA 6054 Installation Date: P: 08 9279 1663 | E: sales@aaq.net.au 3. Commissioning Report Comments Safety Devices Safety devices incorporated into the design of the vehicle to AS/NZS 1418.9...

- Page 29 COMMISSIONING REPORT Location of Vehicle Hoist & Vehicle Clearances Vehicle hoist or any part of the load is positioned no less than 600mm away from any fixed structure Provisions have been made for effective clearances above the vehicle when the hoist is in its fully raised position.

Need help?

Do you have a question about the AutoLift AL-167262 and is the answer not in the manual?

Questions and answers