Summary of Contents for Landoll Brillion SS108

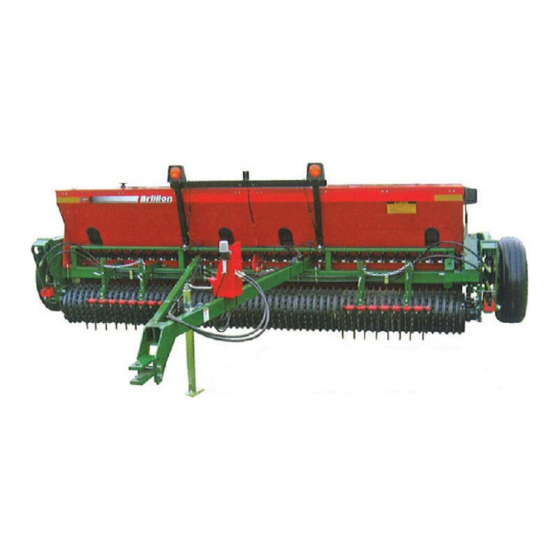

- Page 1 ‘ Mid-Size Sure Stand Seeder Models SS108/SS110/SS112 SSP108/SSP110/SSP112 Operator’s Manual LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM 9K713-0522...

- Page 2 Manuals for Mid-Size Sure Stand Seeder, Models SS108/SS110/SS112 and SSP108/SSP110/SSP112 Manual Number Manual Type 9K713 Operator’s Manual 9K712 Parts Manual...

- Page 3 Table of Contents Safety Information Introduction ........... . 1-1 Description of Unit .

- Page 4 TABLE OF CONTENTS Operation Tractor Preparation..........3-2 Tractor Preparation/ Attaching of 3-PT Seeder .

- Page 5 TABLE OF CONTENTS Settings Menu - GPS Settings ........4-7 GPS Status .

- Page 6 TABLE OF CONTENTS 9K713-0522...

-

Page 7: Warranty Registration

10 days of retail purchase, using the Landoll injury or death, damage to the machine or its Company, LLC Ag Products on-line registration process. -

Page 8: Safety Information

TABLE OF CONTENTS SAFETY INFORMATION Safety • When applying decals to the machine, be sure to clean the surface to remove any dirt or residue. Where possible, sign placement should protect the NOTE sign from abrasion, damage, or obstruction from mud, dirt, oil etc. - Page 9 TABLE OF CONTENTS SAFETY INFORMATION Transporting Safety Attaching, Detaching and Storage IMPORTANT • Do not stand between the tractor and machine when It is the responsibility of the owner/operator to attaching or detaching machine unless both are not comply with all state and local laws. moving.

-

Page 10: Tire Safety

TABLE OF CONTENTS SAFETY INFORMATION Tire Safety NOTE Tire changing can be dangerous and should be performed Relieve hydraulic pressure by shifting the control valve by trained personnel using correct tools and equipment. lever to float. • When inflating tires, use a clip-on chuck and Wear protective gloves and safety glasses or goggles extension hose long enough to allow you to stand to when working with hydraulic systems. - Page 11 250 REVOLUTIONS FOR 8 FOOT SEEDER. 200 REVOLUTIONS FOR 10 FOOT SEEDER. 167 REVOLUTIONS FOR 12 FOOT SEEDER. 5. WEIGH SEED FOR APPROXIMATE PLANTING RATE IN POUNDS PER ACRE. Landoll Company, LLC #40 CHAIN Marysville, Kansas MOVING PART HAZARD TIGHTENER...

- Page 12 TABLE OF CONTENTS SAFETY INFORMATION Figure 1-4: Decal Placement - Hitch Decals 9K713-0522...

- Page 13 TABLE OF CONTENTS SAFETY INFORMATION Figure 1-5: Decal Placement - 8FT Models 9K713-0522...

- Page 14 TABLE OF CONTENTS SAFETY INFORMATION Figure 1-6: Decal Placement - 10FT Models 9K713-0522...

- Page 15 TABLE OF CONTENTS SAFETY INFORMATION Figure 1-7: Decal Placement - 12FT Models 9K713-0522...

- Page 16 TABLE OF CONTENTS SAFETY INFORMATION Table provided for general use. NOTES: 1-10 9K713-0522...

- Page 17 Chapter 2 TABLE OF CONTENTS Assembly IMPORTANT CAUTION All harnesses must be firmly attached to machine Do not work on or under this machine unless frame members, so they don’t sag or become torn securely blocked and supported by a hoist or loose by field debris.

- Page 18 TABLE OF CONTENTS ASSEMBLY 3-PT Seeder Assembly CAUTION When shipped, seeder comes assembled except for Do not disengage pin unless seeder is fully Lights and 3-PT Hitch. attached to a tractor. Seeder may be rear-heavy 1. Support Seeder Assembly with a hoist or by similar and tip backward on frame.

- Page 19 TABLE OF CONTENTS ASSEMBLY Frame Nut,5/8-11 Lock Washer,5/8 Hose Clamp Manual Holder Op3PtHitch U-Bolt,5/8-11 3-PT Hitch Figure 2-5: Attach 3-PT Hitch 9K713-0522...

- Page 20 TABLE OF CONTENTS ASSEMBLY Pull Type Seeder Assembly 4. Install Manual Holder to Drawbar with Hose Clamps. 5. 8FT Seeders: Install SMV Mount to Seed Box Frame When shipped, Seeder comes assembled except for with 1/2-13 U-Bolt, Lock Washers and Nuts. See Lights, Hub and Spindle Assemblies, Tire and Wheels Figure 2-1.

- Page 21 TABLE OF CONTENTS ASSEMBLY Tire and Wheel Installation WARNING Use a torque wrench to assure proper torque. Insufficient torque can cause stud breakage and damage the wheel pilots. Over torque can stress the Bolts and strip the threads. NOTE The tire/wheel assembly is mounted with the valve stem facing outward from Hub and Spindle.

-

Page 22: Hydraulic Installation

TABLE OF CONTENTS ASSEMBLY Hydraulic Installation Hydraulic Assembly 1. Restrictors installed in Cylinder Ports, connect 45 Degree Fitting so they are free to swivel. Connect top WARNING Hydraulic Hose to the Cylinder Base and bottom Hydraulic Hose to the Cylinder Rod End. Position the Escaping fluid under pressure can be nearly Hydraulic Hoses so that the Cylinder Base End points invisible and have enough force to penetrate the... - Page 23 TABLE OF CONTENTS ASSEMBLY Frame Hose Assembly Bolt,1/4-20 x 1-1/2 Top Plate Drawbar Top Plate SeederHydLayout10Ft Figure 2-11: Drawbar Hydraulic Hoses 9K713-0522...

- Page 24 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 9K713-0522...

- Page 25 TABLE OF CONTENTS ASSEMBLY Purge the Hydraulic Lift System Bolt,5/8-11 Flat Washer,5/8 The Hydraulic system is not filled with oil and should be Locknut,5/8-11 purged of air before transporting and field operations. Lift Circuit approximate oil requirement: 0.4 gallons. 1. Carefully Hitch the Seeder to the Tractor and connect the Hydraulic Lift Hoses.

- Page 26 TABLE OF CONTENTS ASSEMBLY Warning Lamp Installation, NOTE 8FT and 10FT If equipped with optional Electrical Clutch, install, route and secure Electric Clutch Harness with the Warning Lamp Harness. NOTE 8FT 3-PT Model is shown, 8FT Drawbar, 10FT 3-PT and IMPORTANT 10FT Drawbar models similar.

- Page 27 TABLE OF CONTENTS ASSEMBLY Amber Lamp Locknut,1/4-20 Bolt,1/4-20 x 1 Bolt,1/4-20 x 1-1/4 Light Bracket Connector Holder Bolt,1/2-13 x 1-1/4 Red Lamp Lock Washer,1/2 Wrap Nut,1/2-13 Bolt,5/16-18 x 1 Locknut, 5/16 Flat Washer,1/4 Flat Washer,5/16 Locknut, 1/4-20 7-Pin Harness Mount Lamp Harness Longer...

- Page 28 TABLE OF CONTENTS ASSEMBLY Warning Lamp Installation, NOTE 12FT If equipped with optional Electrical Clutch, install, route and secure Electric Clutch Harness with the Warning Lamp Harness. NOTE IMPORTANT 12FT Drawbar model is shown, 3-PT models similar. 1. Place a Red Lamp at each end of the Light Bar and All wires must be firmly attached to Machine Frame members or Hydraulic Hoses so they do not sag or insert the Red Lamp Cord into the Light Bar cutout.

- Page 29 TABLE OF CONTENTS ASSEMBLY Amber Lamp Locknut,1/4-20 Bolt,1/4-20 x 1-1/4 Light Bracket Bolt,1/2-13 x 1-1/4 Lock Washer,1/2 Wrap Flat Washer,5/16 Nut,1/2-13 Bolt,5/16-18 x 1 Bolt,1/4-20 Locknut, x 1-1/4 5/16 Red Lamp Connector Light Bar Holder Bolt, 1/4-20 x 1 Locknut, 1/4-20 Locknut, Flat...

- Page 30 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 2-14 9K713-0522...

- Page 31 TABLE OF CONTENTS ASSEMBLY Electric Clutch Kit - Optional Mini Monitor, 3-Pin Power Plug to 12 Volt Tractor Convenience Outlet and 6-Pin Connector to the 240" Extension Harness. 4-Pin Connector is not used at IMPORTANT this time. Connect 240" Extension Harness to Seeder At no time use high pressure water or air to clean the Harness.

- Page 32 TABLE OF CONTENTS ASSEMBLY Brillion Elite Mini Monitor - Smart Shaft Pick-up Switch Optional Sensor Bracket Assembly instruction for models with Clutch. Transmission The Brillion Elite Mini Monitor System by Loup 1/8" utilizes a MUX communication line. Sensors must be learned into the Monitor.

- Page 33 TABLE OF CONTENTS ASSEMBLY 7. Connect the 240" Extensions Harness to the Seeder 10. Connect the Elite Mini Tractor Harness 14-Pin Harness. Route the 240" Extension Harness along Connector to Brillion Elite Mini Monitor, 3-Pin Power the Seeder Frame and down the Drawbar/3-PT Hitch Plug to 12 Volt Tractor Convenience Outlet and 6-Pin to the Tractor.

- Page 34 TABLE OF CONTENTS ASSEMBLY Brillion Elite Mini Monitor Electrical Schematic Monitor Mount Brillion Elite Mini Monitor 4-Pin Radar/GPS Plug Elite Mini Tractor Harness Bin Level Smart Shaft 3-Pin Sensor #2 Sensor #1 Power Plug Smart Clutch Relay 240" Extension Harness Cavity Plug 3-Pin...

- Page 35 TABLE OF CONTENTS ASSEMBLY Brillion Elite Mini Monitor - Front Seed Box Seed Shaft Sensor Screw,Rnd Hd 1/4-20 x 3/4 Seed Shaft,3/8 Square Sensor Mount Washer,Flat 1/4 Magnet 1-1/4 x 1/4 x 1/16 Washer,Lock 1/4 Magnet Collar Nut,1/4-20 3/8 Sq Shaft Locknut, Screw,Rnd Hd Flange #8-32...

- Page 36 TABLE OF CONTENTS ASSEMBLY Brillion Elite Mini Monitor 4. Attach the Monitor Mount to the Straight Bracket with #10-24 x 1 Machine Screws, Flat Washers, Lock Tractor Installation - Optional Washers, and Nuts, provided with Monitor Mount. 5. With the Brillion Elite Mini Tractor Harness, plug the 1.

- Page 37 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 9K713-0522 2-21...

- Page 38 TABLE OF CONTENTS ASSEMBLY Acre Meter Kit - Optional 3. Transmission w/o Clutch: Attach the Pick-Up Switch Bracket to the front of the Transmission with Not Used with Brillion Elite Mini Monitor 3/16 x 1-1/4 Bolts, Lock Washers and Nuts. Transmission w/ Clutch - Optional: Attach the P/N 5K745 - Transmission w/o Clutches Pick-Up Switch Mount to the Clutch Bracket with...

- Page 39 TABLE OF CONTENTS ASSEMBLY 7. Attach the Pick-Up Switch Ground Wire to the small Magnet Wheel Assembly hole in the Pick-Up Switch Mount with a #6-32 x 1/2 Screw, removing paint under the wire connector to Magnet assure a good electrical ground connection. 8.

- Page 40 TABLE OF CONTENTS ASSEMBLY Console w/Clutch Control 5. On left side connect plug labeled “Electric Clutch Power” to the Electric Clutch lead. If you do not have Installation - Optional an Electric Clutch seal the plug end using a 2-Pin Shroud and Cavity Plug to protect it from the Mount Console with Clutch Control on Tractor.

- Page 41 TABLE OF CONTENTS ASSEMBLY Console w/Clutch Control Shaft Sensor Seed Shaft Sensor - Optional Bracket 1. Remove the two 10 x 24 x 3/4 self tapping screws from the Magnet Wheel Assembly. Position the rounded half of the Magnet Wheel Assembly on the seed shaft.

- Page 42 TABLE OF CONTENTS ASSEMBLY Console w/Clutch Control 4. Plug Console 3-Pin Power Cord into the Tractor Convenience Outlet and 9-Pin Cord into the Seeder Tractor Installation - Optional Harness. 5. Check clutch operation: Clutch will disengage when 1. Mount Angle Bracket onto Tractor where convenient power is applied.

- Page 43 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 9K713-0522 2-27...

- Page 44 TABLE OF CONTENTS ASSEMBLY Scraper Kit - Optional 2. Attach the LH and RH Angle Brackets to the Brackets with 1/2-13 x 3-1/4 x 4-9/16 U-Bolts, Lock Washers and Nuts. Do not tighten at this time. IMPORTANT 3. Attach the Scraper Angle to the LH and RH Angle Cannot be used with the Coil Tine Track Remover Kit.

- Page 45 TABLE OF CONTENTS ASSEMBLY U-Bolt,1/2-13 x Lock Washer,1/2 7-1/2 x 4-1/2 Nut,1/2-13 Bracket U-Bolt,1/2-13 x Nut,3/8-16 Center 3-1/4 x 4-9/16 Scraper Lock Washer,3/8 Flat Washer,3/8 Seeder Frame Tube Scraper LH Angle Bracket Carriage Bolt, 3/8-16 x 1-1/4 Scraper Angle LH Angle Bracket SeederScraperKit Lock Washer,1/2...

- Page 46 TABLE OF CONTENTS ASSEMBLY S-Tine Tire Track Remover that long ends of brackets are downward. Brackets should be about 53" from center of machine. See Kit - Optional Figure 2-39. 2. Attach the Tooth Tube to the S-Tine Brackets approximately 5 inches from each end of the Tooth IMPORTANT Tube with Straps, 1/2-13 x 6 Bolts, Lock Washers and S-Tines should not be operated any deeper than...

- Page 47 TABLE OF CONTENTS ASSEMBLY Lock Washer,1/2 U-Bolt,1/2-13 x Nut,1/2-13 7-1/2 x 4-1/2 S-Tine Bracket Strap Clamp Nut,1/2-13 Carriage Bolt, Lock Washer,1/2 7/16-14 x 3-1/2 Bolt,1/2-13 x 6 Tooth Tube Locknut,7/16-14 S-Tine Reversible Point Flange Locknut, SeederS-TineTrackRemoverKit 3/8-16 Duck Foot Point Plow Bolt 3/8-16 X 1-3/4 Seeder Frame...

- Page 48 TABLE OF CONTENTS ASSEMBLY Coil Tine Track Remover - Optional IMPORTANT Cannot be used with the Scraper Kit. 1. Slide the Coil Tines onto the Round Bar so that the straight leg is frontward. See Figure 2-40. 2. Mount an Arm Weldment and a Coil Tine to the Round Bar second hole from the right end and the third hole from the left end with 3/8-16 x 3 Bolts, Flat Washers, Lock Washers and Nuts.

- Page 49 TABLE OF CONTENTS ASSEMBLY Bolt,3/8-16 x 1-1/4 Hair Pin Cotter Adjusting Angle Place Chain in Adjusting Angle Slot Clevis Pin, 1/2 x 1-1/4 Flat Washer,3/8 Lock Screw Nut,1/2-13 Chain Lock Washer,3/8 Lock Washer,1/2 Nut,3/8-16 Bracket Bolt, Seeder Frame 1/2-13 x 1-3/4 Tube Bolt, Bolt,...

- Page 50 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 2-34 9K713-0522...

- Page 51 Chapter 3 TABLE OF CONTENTS Operation DANGER DANGER DANGER DANGER Never allow anyone to ride on the seeder at any Always lock the tractor drawbar in the center time. Allowing a person to ride on the machine position when transporting the unit. Failure to do can inflict serious personal injury or death to that so can result in serious injury or death and cause person.

-

Page 52: Operation

TABLE OF CONTENTS OPERATION Tractor Preparation DANGER DANGER The Sure Stand Seeder is available as a Pull Type or Do not allow any bystanders to stand between 3-PT mounted version. the tractor and the machine while backing up to • A Pull Type seeder is equipped to be pulled by a the machine. - Page 53 TABLE OF CONTENTS OPERATION 1" Pin 24" 1-1/8" Pin Category 2 Free Link 1-1/4" Bushing 1" Pin 1-7/16" Bushing 15" 1-1/8" Pin Category 2 Quick Coupler Op LargeSeeder3PtHitch 1-1/4" Bushing 1" Pin 1-7/16" Bushing 19" 1-1/8" Pin Category 3 Narrow Quick Coupler Figure 3-1: 3-Point Hitch 9K713-0522...

- Page 54 TABLE OF CONTENTS OPERATION Attaching/Detaching 3-PT Hitch Seeder Klik Pin WARNING Disengaged To prevent the machine from tipping backward on the frame, disengage parking pin only when the seeder is fully attached to the tractor. Be sure to observe the following sequences. Parking Pin Klik Pin Figure 3-3: Parking Pin Disengaged...

- Page 55 TABLE OF CONTENTS OPERATION Tractor Preparation/ Frame Attaching of Pull Type Seeder Cylinder Engaged DANGER DANGER Transport Lock Do not allow any bystanders to stand between Hair Pin the tractor and the machine while backing up to Cotter the machine. 1.

-

Page 56: General Operation

TABLE OF CONTENTS OPERATION Attaching/Detaching Pull Frame Type Seeder Cylinder Attaching the Seeder for Field Operations: Seeder parked lowered Hair Pin 1. Attach Seeder to the Tractor. Cotter 2. Raise the Seeder fully to extend the Hydraulic Lift Cylinders and rotate the Transport Locks in the engaged position over the Cylinder Rod. -

Page 57: Hydraulic Lift System

TABLE OF CONTENTS OPERATION Hydraulic Lift System Transmission Electric Clutch - Optional The Drawbar Seeder is equipped with a Hydraulic Lift System to raise and lower the unit in the field. IMPORTANT WARNING At no time use high pressure water or air to clean the Electric Clutch as damage could occur. - Page 58 TABLE OF CONTENTS OPERATION Brillion Elite Mini Monitor - • Brillion Elite Mini Monitor is operated on a 12-Volt DC negative ground system. The monitor should be Optional connected using the existing convenience plug connection. Brillion Elite Mini Monitor provides information to the •...

- Page 59 TABLE OF CONTENTS OPERATION Seed Box Seed Rate IMPORTANT Adjustment If equipped, the Clutch must be disengaged when Seed Shafts are turned manually for Calibration. WARNING Seed Rate Charts specific to Seeder Model are located inside the Seed Box Cover and in this manual. See Tables 3-1, 3-2 and 3-3.

- Page 60 TABLE OF CONTENTS OPERATION POUNDS PER ACRE POUNDS PER 1000 SQ FT Indicator Settings Alfalfa (Uncoated) 1.06 1.25 Bahia Bermuda (Hulled) 1.28 Birdsfoot Trefoil (Broadleaf) 1.17 1.39 1.65 Bluegrass (Kentucky) Bluegrass (Park Kentucky) Bluegrass (Sherman Big) Canola 1.06 Centipede Chickory (Forage) Clover (Alsike,Ladino,Sweet,Red) 1.10 1.25...

- Page 61 Seed Shafts are turned manually for Calibration. Electrical Power is required to disengage the Clutch. Brillion/Landoll assumes no liability pertaining to Seeding Rates achieved with this Seeder. Rates listed are general in nature and should be used as starting points only. Seed varieties and blends listed represent those calibrated through in-house test meters.

- Page 62 TABLE OF CONTENTS OPERATION #40 CHAIN TIGHTENER #A550 CHAIN 12 TOOTH DRIVEN 15/16 HEX 13 TOOTH DRIVER 13 TOOTH (26 TOOTH - OPTIONAL) 37 TOOTH IDLER DRIVEN TIGHTENER 7 TOOTH DRIVER Figure 3-13: Transmission Drive 3-12 9K713-0522...

- Page 63 TABLE OF CONTENTS OPERATION Speed-Up Kit - Optional 4. Remove the Locking Collar from the left side of the Front Transmission Shaft. Seed rates can be doubled by using a 26 Tooth Sprocket 5. Move the shaft far enough to the right to remove the and following the procedure below: follows: See 13 Tooth Sprocket.

- Page 64 TABLE OF CONTENTS OPERATION Loup Acre Meter Kit - To clear the total acre count, press and hold the UP and DOWN buttons for two seconds. If a password has been Optional (After 05/15/2012) entered, you will not be able to clear the total acre count. Total acres will count from.1 to 99999 acres.

- Page 65 TABLE OF CONTENTS OPERATION If the display shows “Ent”: You must enter your 6. Press the function button to set the width. (If screen password using the UP and DOWN buttons. When your goes blank before you press the function button, password is displayed, press the /FUNC button to test repeat steps 4 and 5).

- Page 66 TABLE OF CONTENTS OPERATION PULSES WIDTH MODEL per 400 FT (Feet) SSP T604 SSP4 SSP5 SSP6 SSP8 SSP10 SS10 10.0 SSP12 SS12 12.0 SSP108 SS108 SSP110 SS110 10.0 SSP112 SS112 12.0 SSP208 SSP2081 SS208 SS2081 SSP210 SSP2101 SS210 SS2101 10.0 SSP212 SSP2121 SS212...

- Page 67 TABLE OF CONTENTS OPERATION MODEL PULSES WIDTH SSP T604 SSP4 SSP5 SSP6 SSP8 SSP10 SS10 SSP12 SS12 SSP108 SS108 SSP110 SS110 SSP112 SS112 SSP208 SSP2081 SS208 SS2081 SSP210 SSP2101 SS210 SS2101 SSP212 SSP2121 SS212 SS2121 SSP308 SS308 SSP310 SS310 SSP312 SS312 SLP8 4147...

- Page 68 TABLE OF CONTENTS OPERATION Transporting the Seeder 6. Before transporting: • Know the height and width of the implement being 1. Check and follow all federal, state, and local towed. Markers, tanks, attachments, etc. can requirements before transporting the Seeder. increase the height and width of the implement.

-

Page 69: Main Screen Layout

Chapter 4 TABLE OF CONTENTS Brillion Elite Mini Monitor Overview • Field Acres and Total Acres • Clutch Control The Brillion Elite Mini Monitor is a full featured display • (Up to 6) Six Seed Shaft Rotation Sensors designed to provide accurate information to the operator •... -

Page 70: Settings Menu

TABLE OF CONTENTS BRILLION ELITE MINI MONITOR 9:30AM SETTINGS BACK APP VER: 2.1.1 SPEED CLUTCH SCROLL UP SETTINGS SETTINGS INSTALL SHAFT SETUP SETTINGS DIAGNOSTICS SETTINGS DISPLAY SCROLL DOWN SETTINGS Figure 4-2: Settings Menu Display (Sure Stand Seeder) Settings Menu - Source: Shaft Sensor Speed SHAFT SHAFT... - Page 71 TABLE OF CONTENTS BRILLION ELITE MINI MONITOR Speed Source Displays Speed Source Icon Features Pulses Per Revolution SPEED SETTINGS BACK Pulses Per Revolution are the PULSES PER IMP. SWITCH: SOURCE: number of magnets the implement REV: SHAFT SPEED DISABLED mounted speed sensor sees in one revolution of the shaft being monitored.

- Page 72 TABLE OF CONTENTS BRILLION ELITE MINI MONITOR Speed Calibration Implement Switch Setup All new systems require a ground Implement Switch SPEED SWITCH speed calibration to ensure Setup tells the CALIBRATION SETTINGS accurate area totals and accurate monitor if the ground speed readings. To complete the calibration, Implement Switch IMP.

-

Page 73: Remove A Sensor

TABLE OF CONTENTS BRILLION ELITE MINI MONITOR Settings Menu - Remove A Sensor INSTALL Install Setup Select this option to remove a SETUP REMOVE A sensor from your existing system. RECEIVER SENSOR Select “Install Setup” icon to Learn New System, Add A Sensor, or Remove A Sensor to your machine. - Page 74 TABLE OF CONTENTS BRILLION ELITE MINI MONITOR Settings Menu - Settings Menu - SHAFT DIAGNOSTICS Shaft Settings Diagnostics RECEIVER SETTINGS The Diagnostics screen can help in identifying issues with Seed Shaft Settings sensors, harnessing or other items. Status reports for The Seeder can have up to six Smart Shaft Sensors that Battery Voltage, Sensors Learned, MUX Communication indicate shaft rotation.

- Page 75 TABLE OF CONTENTS BRILLION ELITE MINI MONITOR Settings Menu - Settings Menu - DISPLAY GPS Settings Display Settings RECEIVER SETTINGS SETTINGS “GPS Settings” defines any Baudrate, Speed Corrections or the current GPS Status. DISPLAY SETTINGS BACK UNITS GPS SETTINGS BACK VOLUME BRIGHTNESS GPS BAUDRATE...

-

Page 76: Service And Technical Support

TABLE OF CONTENTS BRILLION ELITE MINI MONITOR Service And Technical System Update Support The system update screen is used SYSTEM to update to newer versions of UPDATE Contact: Loup Electronics Inc. software or reset to factory default Address: 2960 N. 38th Street settings. -

Page 77: General Torque Specifications

Chapter 5 TABLE OF CONTENTS Maintenance General Torque Specifications (rev. 4/97) This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). They do not apply if special graphite moly-disulfide or other extreme pressure lubricants are used. -

Page 78: Maintenance

TABLE OF CONTENTS MAINTENANCE Hydraulic Fitting Torque Specifications 37 degree JIC, ORS, &ORB (REV. 10/97 This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). They do not apply if special graphite moly-disulfide or other extreme pressure lubricants are used. -

Page 79: Lubrication Maintenance

TABLE OF CONTENTS MAINTENANCE Tires 9. Tighten the Slotted Nut while rotating the Hub until there is a slight resistance to wheel rotation. Then, Recommended Tire Size: 9.5L-15 - 6 Ply Rating back the Slotted Nut off one notch, until the wheel rotates freely without end play. - Page 80 TABLE OF CONTENTS MAINTENANCE Pull Type Frame Wheel Arm Tire and Wheel Assembly Wheel Hub Repack Annually Rear Roller Bearing Rear Arm Rear Roller Bearing Pull Type Seeder Frame Front Roller Bearing SL2 OpGrease 3-PT Seeder Frame Front Roller Bearing Figure 5-2: Lubrication Intervals 9K713-0522...

-

Page 81: Hydraulic Maintenance

TABLE OF CONTENTS MAINTENANCE Hydraulic Maintenance NOTE Failure to position the Clamp Band Socket Head Bolt (Clamp Band open section) over the Roller Drum weld IMPORTANT seam will cause Clamp Band to loosen and slide. Lower the Drawbar Seeder to the ground, and relieve After an initial run of 5-10 hours, check the Front and hydraulic pressure before attempting to service any Rear Roller Assemblies to ensure that the Wheels are... -

Page 82: Chain Tension

TABLE OF CONTENTS MAINTENANCE Chain Tension Clevis Drawbolt Locknut To adjust the Transmission Chain, loosen the 5/8" Idler Sprocket Axle Bolt and then adjust the Clevis Drawbolt #40 Chain Locknut to obtain about 1/8"-1/4" sag. Re-tighten the Idler Sprocket Axle Bolt. Be careful not to over-tighten this chain. - Page 83 TABLE OF CONTENTS MAINTENANCE Seed Meter Adjustment IMPORTANT Ensure the Seed Shaft can turn freely without any binding when the Seed Meters are open or closed IMPORTANT after servicing. The Clutch must be disengaged when Seed Shafts 1. 1/2-13 Locknuts on both ends of the Adjusting Screw are turned manually for Calibration.

- Page 84 TABLE OF CONTENTS MAINTENANCE LED Warning Lamps When plugging in the Lamp 7-Pin Warning Lamp Connector: 1. Make sure the Tractor has a good clean Receptacle, free of dirt and corrosion. 2. Make sure the 7-Pin Connector is inserted ALL the way in.

- Page 85 TABLE OF CONTENTS MAINTENANCE Electric Clutch - Optional display harness connector. You should see the display increment +1 with each contact of the connector terminals. IMPORTANT 4. If step 3 works then wave a magnet in front of the If your machine is equipped with an Electric Clutch at Pick-Up Switch face with it re-connected to the no time use high pressure water or air to clean it, as display and see if the display increments up.

- Page 86 TABLE OF CONTENTS MAINTENANCE Table provided for general use. NOTES: 5-10 9K713-0522...

- Page 87 Chapter 6 TABLE OF CONTENTS Specifications Product Attributes SS 108 SSP 108 Approximate Weight 2,054 lbs. (924 kg) 1,734 lbs. (780 kg) Working Width 8 ft. 0 in. (2.4 m) 8 ft. 0 in. (2.4 m) Transport Width 11 ft. 1 in. (3.33 m) 9 ft.

-

Page 88: Specifications

TABLE OF CONTENTS SPECIFICATIONS Product Attributes SS 110 SSP 110 Approximate Weight 2,394 lbs. (1,077 kg) 2,074 lbs. (933 kg) Working Width 10 ft. 0 in. (3.0 m) 10 ft. 0 in. (3.0 m) Transport Width 12 ft. 11 in. (3.88 m) 11 ft. - Page 89 TABLE OF CONTENTS SPECIFICATIONS Product Attributes SS 112 SSP 112 Approximate Weight 2,842 lbs. (1,279 kg) 2,488 lbs. (1,120 kg) Working Width 12 ft. 0 in. (3.6 m) 12 ft. 0 in. (3.6 m) Transport Width 15 ft. 0 in. (4.5 m) 13 ft.

- Page 90 TABLE OF CONTENTS SPECIFICATIONS Table provided for general use. NOTES: 9K713-0522...

- Page 91 Document Control Revision Log: Date Form # Improvement(s): Description and Comments 07/07/2008 205rev7-7-08 Initial Release 09/2013 205rev0913 Added LED Warning Lights 12/2015 205rev1215 Added Seed Box Dividers, moved Decals 06/2021 9K713-0621 ECN 47093 - Hub & Spindle Asm Update to 6 Bolt 05/2022 9K713-0522 ECN 46900, 47187 - Add Brillion Elite Mini Monitor by Loup...

- Page 92 Equipment from Landoll Company, LLC is built to exacting standards ensured by ISO 9001 registration at all Landoll manufacturing facilities. Mid-Size Sure Stand Seeder Model SS108/SS110/SS112 SSP108/SSP110/SSP112 Operator’s Manual Re-Order Part Number 9K713 LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM...

Need help?

Do you have a question about the Brillion SS108 and is the answer not in the manual?

Questions and answers