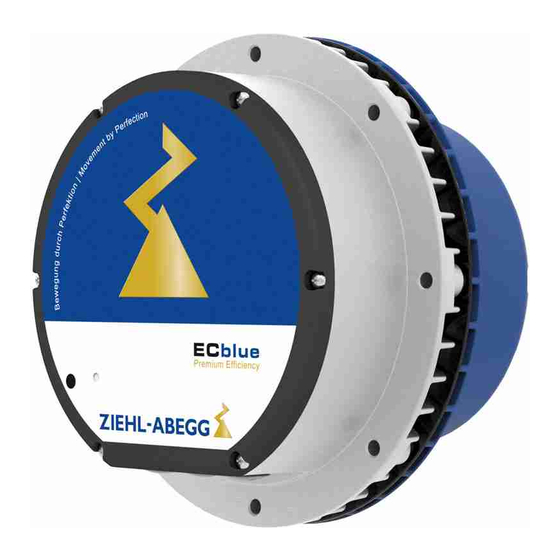

ZIEHL-ABEGG ECblue Assembly Instructions Manual

Ec-fans and motors with highest eficiency

Hide thumbs

Also See for ECblue:

- Assembly instructions manual (59 pages) ,

- Operating instructions manual (10 pages) ,

- Quick start manual (32 pages)

Summary of Contents for ZIEHL-ABEGG ECblue

- Page 1 ECblue EC-fans and motors with highest efciency Assembly instructions Motor size B (IP54) L-BAL-F055-GB 1344 Index 002 Part.-No. 00700561-GB...

-

Page 2: Table Of Contents

Assembly instructions ECblue Content General notes .......... - Page 3 Assembly instructions ECblue 4.4.4 Optimal installation distances according to for RH../ ER../ GR.. fans ........

- Page 4 Assembly instructions ECblue Connection diagram ........EC Declaration of Incorporation ......

-

Page 5: General Notes

We do not accept any liability for possible errors or omissions in the information con- tained in data, illustrations or drawings provided. ZIEHL-ABEGG SE is not liable for damage due to misuse, incorrect use, improper use or as a consequence of unauthorized repairs or modifications. -

Page 6: Intended Use

VDE-approved ZIEHL-ABEGG fans ( rating plate) may only be used as built-in fans for internalwiring. • Proper use of VDE-approved ZIEHL-ABEGG fans assumes indirect wiring in the terminal unit. • Reading these document and complying with all contained instructions -especially the safety notifications contained therein -are considered part of intended use. -

Page 7: Explanations Of Symbols

Assembly instructions ECblue Safety instructions 2.3 Explanations of symbols Safety instructions are highlighted with warning triangles and are depicted according to the degree of hazard as follows. Attention! General hazardous area. Death or severe injury or significant property damage can... -

Page 8: Working On Device / Hazards Through "Residual Voltage

Assembly instructions ECblue Safety instructions when it is faulty. • Fuses must always be only replaced; never repaired or bridged. The specifications Technical data). Only for the maximum series fuse must always be adhered to ( fuses cited in the electrical circuit diagram may be used. -

Page 9: Modifications / Interventions In The Device

ZIEHL-ABEGG.These parts were specifically designed for the device. There is no guarantee that parts from non-original sources are designed and manufactured in correspondence with load and safety requirements. Parts and optional equipment not supplied by ZIEHL-ABEGG are not approved by ZIEHL-ABEGG for use. 2.9 Operator’s obligation of diligence •... -

Page 10: Employment Of External Personnel

3.2 Functional description ECblue stands for EC fans and motors with maximum efficiency. Highly efficient, elec- tronically commutated motors with permanent magnets are used the speed of which is controlled by the integrated controller. -

Page 11: Note On The Erp Directive

Product overview 3.4 Note on the ErP directive ZIEHL-ABEGG SE wishes to point out that, based on the directive (EU) no. 327/2011 of the Commission of 30th of March 2011 for enforcing directive 2009/125/EC (hereinafter referred to as ErP directive), the operational area of certain fans within the EU is bound by certain prerequisites. -

Page 12: Storage

Assembly instructions ECblue Mounting 3.6 Storage • Store the fan / motor in the original packaging in a dry area protected from the weather and protect it from dirt and weather until final installation. • Do not stack pallets! •... -

Page 13: Connecting Lead, Position Terminal Compartment

Assembly instructions ECblue Mounting • If the fan is located in danger zone, then the manufacturer or operator shall ensure that hazards shall be prevented by appropriare protective constuctions which meet the requirements to EN ISO 13857. • Custom designs must suit the prevailing conditions. -

Page 14: Zaplus Fans

Assembly instructions ECblue Mounting Information • Pay attention to a sufficient screw-in length in the motor flange. • An excess screw length of max. 3 mm is permissible. • Every screwing case is different. The tightening torque adapted to it must be determined by the appropriate screw tests. -

Page 15: Mounting Of Centrifugal Fans

Assembly instructions ECblue Mounting 4.4 Mounting of centrifugal fans 4.4.1 Mounting of centrifugal fans design RE, RH, RZ For attachment to fixed motor flange use screws with property class 8.8 to EN ISO 4014 and provide with suitable screw locking. -

Page 16: Mounting Of Centrifugal Fans Design Rg

Assembly instructions ECblue Mounting 4.4.2 Mounting of centrifugal fans design RG.. / RD.. Fastening depending on housing design on flange or fastening brackets. Information An additional bracket is required for fastening to the flange. This is available as an accessory. -

Page 17: Optimal Installation Distances According To For Rh

• The max. permissible mass of the impeller ort he component to be driven must be inquired from and confirmed in writing by ZIEHL-ABEGG. Design K (with rotor flange) or D (with offset rotor flange) as a drive for fans: •... -

Page 18: Outdoor Fans In A Humid Atmosphere

Assembly instructions ECblue Mounting • Motors are not balanced as standard, a complete balancing with mounted fan impeller is necessary. The balancing must be done on the fan impeller. The pertinent regulations must be observed. Permissible tightening torques M Thread size Property class 8.8, friction coefcient µges = 0.12... -

Page 19: Electrical Installation

Assembly instructions ECblue Electrical installation 5 Electrical installation 5.1 Safety precautions Danger due to electric current • Work on electric components may only be carried out by trained electricians or by persons instructed in electricity under the supervision of an electrician in accordance with electrical engineering regulations. -

Page 20: Connection To Terminals In Terminal Compartment

Assembly instructions ECblue Electrical installation 5.2.1 Connection to terminals in terminal compartment 29.08.2013 v_anchluss_ecblue_B.vsd 1 Cover for terminal compartment 2 Cable glands (2 x M16) seal insert with two holes 5 mm for two cables applicable if necessary 3 Do not loosen the safety screws from the housing! - Page 21 Assembly instructions ECblue Electrical installation Connection data of terminals Line, relay Control Terminal Stripping length 10 mm 10 mm Conductor cross-section rigid min. 0.2 mm 0.2 mm Conductor cross-section rigid max. 4 mm 1.5 mm Conductor cross-section flexible min. 0.2 mm 0.2 mm...

-

Page 22: Version With Connection Cables

Assembly instructions ECblue Electrical installation Permissible tightening torques M Thread size Tightening Remark torque M Cable gland Sealing area: cable diameter 4…10 mm 2.5 Nm Cover for terminal com- 2.3 Nm partment 5.2.2 Version with connection cables In versions with connecting lead the connection is made to the colour coded wires. -

Page 23: Emc-Compatible Installation Of Control Lines

Assembly instructions ECblue Electrical installation For control: hose cable 7 x 0.34 mm (22 AWG) comparable LiYY-OB brown B (D-) MODBUS (RS-485) black A (D+) MODBUS (RS-485) white OC Out Status (Tacho) green Digital In 1 yellow Analog In 1 blue length approx. -

Page 24: Operating In It-System

Assembly instructions ECblue Electrical installation 5.4.3 Operating in IT-System Danger due to electric current • In the IT-System the neutral point of voltage supply is not grounded; in the case of a short-circuit between a phase (e.g. “L1”) and protective earth “PE” becomes the protective earth potential = phase. - Page 25 Assembly instructions ECblue Electrical installation Possibilities for speed setting • 0...10 V Control via external setting signal • 10...0 V Control by inverted setting signal (reprogramming necessary). • By external wiring with a resistor (499 Ω / 0,25 W) between the “E1”...

- Page 26 Assembly instructions ECblue Electrical installation Diagram setting signal and motor speed 100 % 50 % 4.5 % 0.5 V 5 % PWM 0 – 10 V 0 – 100 % PWM 06.06.2013 v_ecblue_nmotor@0_10v_pwm.vsd nM Motor speed 100 % Rated Speed 6 % Height of start speed 4.5 % Height of stop speed...

-

Page 27: Voltage Supply "10 V Dc

Assembly instructions ECblue Electrical installation 5.8 Voltage supply “10 V DC” Voltage supply for activation of the digital input and external components, e.g. for a potentiometer for speed setting (PELV current source according to DIN EN 60204-1). Connection: “10 V” - “GND” (max. load Technical data und connection diagram). -

Page 28: Open-Collector Output "A1" (Status / Tacho)

Assembly instructions ECblue Electrical installation The connection is made by a 4-wire cable at the terminals: A (D+), B (D-) and GND. E. g. telephone cable type: J-Y (St) Y 2x2x0.6 (or similar), maximum cable length approx. 250 The voltage supply of the terminal is made by the accumulators inserted there or the plug power supply unit. -

Page 29: Potential At Control Voltage Connections

Assembly instructions ECblue Electrical installation Tacho out Alternatively, via output “A1”, the current motor speed can be output. 200...300 The frequency (duty cycle 50 : 50) that can be measured by a pull-up resistor at the output “A1” corresponds to the motor speed. -

Page 30: Start-Up

Assembly instructions ECblue Start-up 6 Start-up 6.1 Prerequisites for commissioning During commissioning, unexpected and hazardous conditions can arise in the entire installation due to defective adjustments, defective components or incorrect electrical connections. Remove all persons and objects from the hazardous area. - Page 31 Assembly instructions ECblue Diagnostic Type of error Possible cause Remedial measures Thermal motor protection check for free air passages; remove foreign bodies if nec- has triggered (motor is over- essary heated) "Impeller blocked or dirty" Check temperature of supply air...

-

Page 32: Status Out With Flash Code

Assembly instructions ECblue Diagnostic Status LED in the lid of the terminal compartment. Output A1 Status Out OC Electrical installation. 23.04.2012 v_flash_explain_1_x.VSD LED Code Relays K1* Cause Reaction of Controller Explanation Adjustment Line voltage available? Unit switch OFF and automatically... - Page 33 Assembly instructions ECblue Diagnostic LED Code Relays K1* Cause Reaction of Controller Explanation Adjustment Motor blocked EC-Controller switches off, renewed attempt to start after about 2.5 sec. If after 8 seconds of commutation no speed is measured > 0, the fault...

-

Page 34: Behaviour In Rotation By Air Current In Reverse Direction

Assembly instructions ECblue Diagnostic LED Code Relays K1* Cause Reaction of Controller Explanation Adjustment line voltage too low If the line voltage rises above a specified limit within 75 seconds, If the DC-link voltage drops below a then the controller will attempt to specified limit the device will switch... -

Page 35: Service Work

Assembly instructions ECblue Service work 8 Service work 8.1 Repairs / maintenance Attention! • Allow maintenance work to be carried out by trained specialists only. • Wear safety shoes and gloves for handling! • Please observe the safety regulations and the worker´s protection rules by all maintenance and service work (EN 50 110, IEC 364). -

Page 36: Cleaning

Assembly instructions ECblue Enclosure 8.2 Cleaning Danger due to electric current Voltage supply for motor must be interrupted and secured against restoration! Attention! • Do not use any aggressive, paint solvent cleaning agents when cleaning. • Make sure that no water gets inside the motor and the electronics (e.g. by direct contact with seals or motor openings), observe protection class (IP). - Page 37 Assembly instructions ECblue Enclosure Permissible minimal and maxi- -25...60 °C ( rating plate) ** mal ambient temperature for op- Please see the technical documentation of the product for the minimum eration and maximum ambient temperature valid for the respective fan; These may deviate from the specified permissible ambient temperatures.

-

Page 38: Connection Diagram

Assembly instructions ECblue Enclosure 9.2 Connection diagram ECblue (_ _ _ _ _-_I_.B_._ _ _ _) (_ _ _ _ _-_I_.D_._ _ _ _) max. AC 250 V 2 A 10V GND E1 (D+) (D-) 10 k Signal 0...10 V... -

Page 39: Ec Declaration Of Incorporation

Assembly instructions ECblue EC Declaration of Incorporation EC Declaration of Incorporation ZA87-GB-12/13 Index 004 00296702-GB as defined by the EC Machinery Directive 2006/42/EC, Annex II B The design of the incomplete machine: • Axial fan FA.., FB.., FC.., FE.., FF.., FS.., FT.., FH.., FL.., FN.., VR.., VN.., ZC.., ZF.., ZN.. - Page 40 Assembly instructions ECblue EC Declaration of Incorporation It is prohibited to commission this incomplete machine until it has been secured that the machine into which it was incorporated complies with the stipulations of the EC Machinery Directive. Dr. W. Angelis - Technical Director Ventilation Division Künzelsau, 22.11.2013...

-

Page 41: Index

Assembly instructions ECblue 9.4 Index motor speed Motors Type air current 3, 33 Outdoor fans Bearing Relay output change the bearing relays condensation drain hole 13, 15 Residual-current-operated Conductor cross-section protective constructed rotor flange control cable S1 operated DC voltage... -

Page 42: Manufacturer Reference

Assembly instructions ECblue Index 9.5 Manufacturer reference Our products are manufactured in accordance with the relevant international regulations. If you have any questions concerning the use of our products or plan special uses, please contact: ZIEHL-ABEGG SE Heinz-Ziehl-Straße 74653 Künzelsau...

Need help?

Do you have a question about the ECblue and is the answer not in the manual?

Questions and answers