Summary of Contents for ZIEHL-ABEGG ECblue BASIC-MODBUS

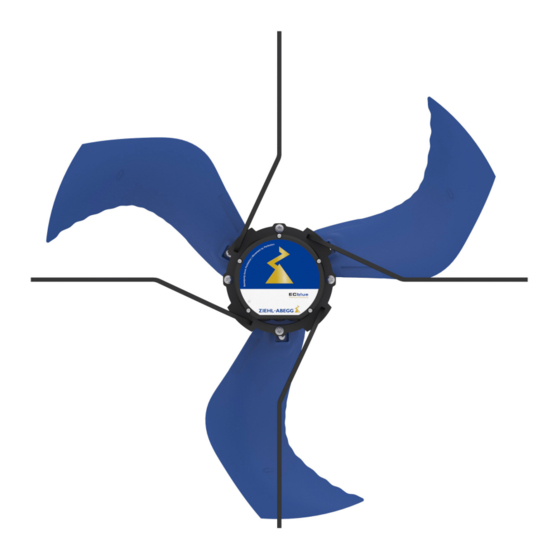

- Page 1 ECblue BASIC-MODBUS, ECblue BASIC Motor sizes: D (116), G (152) EC- fans and motors with and highest efciency for livestock houses Assembly instructions Keep for reference! L-BAL-F079D-GB 2044 Index 002 Part.-No.

-

Page 2: Table Of Contents

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Content General notes ............. - Page 3 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC EMC-compatible installation ..........

- Page 4 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Diagnostics / Faults ............

-

Page 5: General Notes

We do not accept any liability for possible errors or omissions in the information contained in data, illustrations or drawings provided. ZIEHL-ABEGG SE is not liable for damage due to misuse, improper use or as a consequence of unauthorized repairs or modifications. -

Page 6: Use Of Auxiliary Modules In Europe (Red)

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC General notes Use of auxiliary modules in Europe (RED) The AM-MODBUS-WB and AM-STICK-WB modules comply with the Radio Equipment Directive (RED) 2014/53/EU. • Article 3.1[a]: Protection of health and safety of persons and of domestic animals –... -

Page 7: Fcc Statements For Us @ Am-Modbus-Wb, Am-Stick-Wb

Caution The FCC requires the user to be notified that any changes or modifications made to this device that are not expressly approved by ZIEHL-ABEGG SE may void the user's authority to operate the equip- ment. Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment. -

Page 8: Industry Canada Certification @ Am-Modbus-Wb, Am-Stick-Wb

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC General notes • Reorient or relocate the receiving antenna. • Increase the separation between the equipment and receiver. • Connect the equipment into an outlet on a circuit different from that to which the receiver is connected. -

Page 9: Safety Instructions

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Safety instructions PAN1740 est garanti conforme aux dispositions règlementaires d’Industry Canada (IC), licences: IC: 216Q-1740 Il est recommandé aux fabricants d’appareils fixes, mobiles ou portables de consulter la réglementation en vigueur et de vérifier la conformité de leurs produits relativement aux limites d’exposition aux rayonnements radiofréquence ainsi qu’au débit d’absorption spécifique maximum... -

Page 10: Explanations Of Symbols

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Safety instructions • Unauthorised constructional modifications to the fan. • Operation of the fan as a safety component or for the performance of safety-relevant functions in the sense of EN ISO 13849-1. • Blocking or braking of the fan by inserting objects. -

Page 11: Work On The Device

Use only genuine spare parts / genuine wearing parts / genuine accessories from ZIEHL-ABEGG.Th- ese parts were specifically designed for the device. There is no guarantee that parts from non-original sources are designed and manufactured in correspondence with load and safety requirements. -

Page 12: Operator's Obligation Of Diligence

The fans may not be operated until they are installed in line with their intended use. The supplied and certified guard grille of ZIEHL-ABEGG SE fans is designed in accordance with DIN EN ISO 13857 Table 4 (from the age of 14 up). In the event of deviations, further structural protective measures must be taken for safe operation. - Page 13 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Product overview Example of rating plate on stator flange no. Explanation no. Explanation ZIEHL-ABEGG related data UL related data Datamatrix-Code Seriennummer UL file and insulation system Product standard Motor identification UL Electronic input values:...

-

Page 14: Temperature Management

- on the rating plate. Note on the ErP directive ZIEHL-ABEGG SE wishes to point out that, based on the directive (EU) no. 327/2011 of the Commis- sion of 30th of March 2011 for enforcing directive 2009/125/EC (hereinafter referred to as ErP directive), the operational area of certain fans within the EU is bound by certain prerequisites. -

Page 15: Mounting

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Mounting 4 Mounting General notes Attention! • Mounting is only to be undertaken by trained service personnel. The system manufacturer or the machine builder and/or the user is responsible that the inherent installation and security information are harmonized with the valid standard and guidelines (EN ISO12100 / 13857). -

Page 16: Version With Separate Junction Box

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Mounting Version with separate junction box For products supplied by ZIEHL-ABEGG with a separate junction box, note the following information. 1 Separate junction box made of plastic or metal Lid screws Tightening torque: Plastic box 1.3 Nm/12 Lb In, metal box 2.6 Nm/23 Lb In... -

Page 17: Connection According Ul And Csa In Different Applications

It must be used a connection technology suitable for the environmental type rating of the drive! If the connection of the conduits is not possible with the thread adapter due to a lack of installation space, ZIEHL-ABEGG recommends its customers use an UL514B approved flexible connection hose system. -

Page 18: Connection In Nfpa 79 Applications

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Mounting 4.6.2 Connection in NFPA 79 Applications In applications where the NFPA 79 (Electrical Standard for industrial machinery) applies the enclosed cable glands can be used. Attention! • Independent of the type and manner of the conduit / tube connection, correct connection of the supply line(s), the safety of people and objects must be provided at all times. -

Page 19: Installation In An Exhaust Air Stack, Design T

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Mounting Installation in an exhaust air stack, design T 4.8.1 Mounting with plastic brackets • Mark and bore position of the mounting brackets (2) in the chimney (3) by means of a stencil 4x90°. -

Page 20: Zaplus Fans

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Mounting 9/10 ai_kl_1905_1 figure 2 figure 3 Feed the fan (1) into the chimney in accordance with fig. 3, and center it in the mounting bracket (4). In addition, the support is to be secured in accordance with fig. 2 by using bolts (9/10). -

Page 21: Mounting The Motor

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 4.10 Mounting the motor Motors design MK Fastening to fixed motor flange, see assembly of axial fans / fans of design A, D .. and assembly of radial fans of design RH. -

Page 22: Version With Connection Cables

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation Version with connection cables Information • In versions with connecting leads the connection is made to the colour coded wires. Note the cable bands on the connecting leads and the respective connection diagram. -

Page 23: Version Without Connection Cables

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation Version without connection cables ECblue BASIC connection version example 1 Cover of controller housing 2 Version with cable glands 3 x M20x1.5 inserted: 1 x Black seal insert for cables with 8...12 mm outer diameter inserted: 2 x Blue seal insert for cables with 6...7.9 mm outer diameter... - Page 24 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation • Remants from installation and foreign object may not remain on the inside! Remants from installation, foreign objects and dirt has to be removed from the sealing area between cover and controller housing!

-

Page 25: Assembly Notes For Cable Glands

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.3.1 Assembly notes for cable glands Correct use of the cable glands is of crucial importance for high operational reliability; note the following instructions. Construction of a cable gland 1. O-ring 2. Collar with connecting thread 3. - Page 26 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation Cables and installation position " Depending on the installation position and load, run the connecting cables to the cable gland from below or fit a water draining pipe elbow. Notes Do not use any additional cable sheathing (e.g. with insulating tape or "...

-

Page 27: Connection Versions

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation Connection versions Each version can be supplied with an integrated AM-STICK-WB Bluetooth communication module, and this option is indicated by the addition of “WB” to the type designation (see rating plate), e.g. -

Page 28: Voltage Supply

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation Voltage supply 5.6.1 Line voltage Danger due to electric current • It must be strictly observed that the line voltage complies with specified on the rating plate and lies within the allowable tolerance specifications (see technical data). -

Page 29: Operation In Grounded Delta System

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation For 1 ~ fan types 1 ~ types can be used in IT-System in standard version. These may only be used in 3 ~ IT-Systems if no higher voltage to the “PE” can occur than the specified mains voltage of the device even in case of a fault to earth of a mains phase which is not used by the device (of none of the two power supplies). -

Page 30: Analog Input "E1" For Setting Speed

• Control via external setting signal PWM. f = 1...10 kHz 15...28 V • Connection to ZIEHL-ABEGG ventilation computer with PWM output CTE/AH(X)-L (A4) 5.10 Output voltage “10 V” Voltage supply e.g. for speed setting by external potentiometer (PELV current source according to EN 60204-1). -

Page 31: Digital Input "1D" For "100% Function

An external fault indicator is available over the potential-free contact of the built-in relay (max. contact rating see Technical data and connection diagram). The relay is energised during operation. I.e. on the ECblue BASIC-MODBUS contacts 11-14 are bridged, and on the ECblue BASIC contacts 13-14. In case of failure, the relay is de-energised (see Diagnostics/Faults). -

Page 32: Rs-485 Interface For Modbus

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.14 RS-485 interface for MODBUS RS-485 interface for networking via MODBUS, on ECblue BASIC in connection with AM-MODBUS auxiliary module. Connection to: “A (D+)”, “B (D-)” and “GND”. MODBUS MODBUS MODBUS MODBUS... - Page 33 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation Shielding The use of shielded cables is normally not needed but offers high protection against electromagnetic interferences, especially high frequencies. However, the effectiveness of the shield depends on care- ful installation of the line.

-

Page 34: Automatic Addressing

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.14.1 Automatic addressing Automatic addressing can be started when the connections “ID1” and “ID2” for “Addressing” are connected with each other additionally next to the bus connection. I.e. it is no longer necessary to address every user manually in the network. -

Page 35: Specification Signal/Speed Characteristic Curve

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.15 Specification signal/speed characteristic curve Depending on the fan type and agreement, different operating modes/characteristic curves are possible. 5.15.1 Specification signal/speed characteristic curve In “Constant speed” mode, the motor speed is proportional to the specification signal. -

Page 36: Specification Signal/Torque Characteristic Curve

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.15.2 Specification signal/torque characteristic curve In “Constant torque” mode, the max. motor torque is achieved at the maximum specification, accord- ing to the motor type (10 V / 100 % PWM). The fan reaches its maximum speed, from which the preset characteristic curve can be derived. -

Page 37: Potential At Control Voltage Connections

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.16 Potential at control voltage connections The connections for the control voltage (< 30 V) relate to the common GND potential (exception: relay contacts are potential-free). There is a potential isolation between the connections for the control voltage and the PE conductor. -

Page 38: Add-On Modules For Ecblue Basic

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Electrical installation 5.18 add-on modules for ECblue BASIC The ECblue BASIC connection version has an “add-on” module function. I.e. if necessary, you can retrofit an “AM-..” auxiliary module in the slot provided (see auxiliary module operating instructions for assembly). -

Page 39: Start-Up

3. If resonance vibrations occur, it is possible to hide certain speed ranges (see Motor Setup). 4. Fans from ZIEHL-ABEGG SE are delivered balanced in accordance with DIN ISO 21940-11 for the appropriate fan category in accordance with ISO 14694 Check the fan for mechanical vibrations after installation. -

Page 40: Communication Options For Programming

“ZAset Mobile” app. • The MODBUS interface in the ECblue BASIC-MODBUS connection version and ECblue BASIC with AM-MODBUS auxiliary module enables programming using the A-G-247NW hand held termi- nal or the ZAset PC software. -

Page 41: Bluetooth Communication Module Am-Stick-Wb

• Customers who sell or use these ZIEHL-ABEGG products for these applications do so at their own risk. They undertake to reimburse ZIEHL-ABEGG in full for any possible costs that may occur. •... -

Page 42: Label Datamatrix-Code Serial Number

50 %. Label Datamatrix-Code serial number Every ZIEHL-ABEGG product (fan/inverter), supplied with a built-in AM-STICK-WB or with a slot for it, comes with an additional sticker for addressing via Bluetooth®. This sticker is individualized for the final product. On the sticker is the serial number, which is unique to each product and matches the serial number on the product rating plate. -

Page 43: Establishing The Bluetooth Connection

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Bluetooth communication module AM-STICK- Establishing the Bluetooth connection Proceed as follows: 1. Depending on your device, download and install the "ZAset Mobile" app from Google Play Store or Apple App Store. 2. Start the app and, if necessary, open the Settings area with the gear wheel symbol. - Page 44 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Bluetooth communication module AM-STICK- 5. Tap the "Bluetooth" button to create a system with a Bluetooth LE data connection. ZAset checks whether Bluetooth is activated on your smartphone, and prompts you to activate it if necessary.

- Page 45 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Bluetooth communication module AM-STICK- 8. As soon as a connection to the device is established, a two-stage authentication process is initiated. – First stage: Binding (linking AM-STICK-WB with device serial number). The app checks whether the MAC address of the stick has already been assigned a serial number.

- Page 46 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Bluetooth communication module AM-STICK- – Set a new PIN to prevent unauthorised access. 9. If required, enter a name of your choice (alias) Example: 01_ECblue L-BAL-F079D-GB 2044 Index 002 Part.-No. 46/80...

- Page 47 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Bluetooth communication module AM-STICK- 10. Press the button on the device to establish the connection (the colour of the Bluetooth symbol changes from red to green). 11. Actual values on Dashboard when connection is established successfully.

- Page 48 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Bluetooth communication module AM-STICK- 12. Buttons for subsequent operation can be found on the dashboard. 1 Menu: Start, List my devices, Settings 2 Disconnecting the Bluetooth connection 3 Info: BLE vesion, MODBUS address, identification etc.

-

Page 49: Hand Held Terminal A-G-247Nw

Hand held terminal A-G-247NW 9 Hand held terminal A-G-247NW In the ECblue BASIC-MODBUS version, a direct connection is possible, with ECblue BASIC it is via the AM-MODBUS auxiliary module. The connection is made by a 4-wire cable at the terminals: A (D+), B (D-) and GND. E. g. telephone cable type: J-Y (St) Y 2x2x0.6 (or similar), maximum cable length approx. -

Page 50: Menu Group Start

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Max. Speed The speed limiting is active in every control mode. Setting range: 100 % (Rated speed)... “Min.Speed” Factory setting*: 100 % (Rated speed) * Specifications not binding, these values can differe depending on the software version and customer-specific pre-setting. -

Page 51: Menu Group Info

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Software version Parameter sets can be saved by the module in the terminal type A-G-247NW and transferred to other devices (see Operating Instructions Terminal Type A-G-247NW). Name parameterset with the keys ▼, ▲ + P and load in the terminal with the P-key. -

Page 52: Menu Group Controller Setup

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Menu group Controller Setup Controller Setup 9.4.1 Controlmode Type of device modulation. Factory setting Control by external signal (0 - 10 V / PWM) at the input “E1”. Switching to fixed speed “Default Internal2” or “Default Internal3” via digital input possible (see IO Setup). -

Page 53: Limit

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW 9.4.2 Limit After allocation of a digital input (see IO Setup) an adjustable limitation of the modu- lation can be activated via a digital input. Limit (idealized principle diagram) “Limit value” = max. possible modulation (e.g. -

Page 54: Message At Speed Deviation "Fan Bad

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW 9.4.5 Message at speed deviation “Fan Bad” Fanbad Speed Speed deviation Factory setting: 0 rpm Setting range: 0 - 255 rpm Fanbad Time Time delay Factory setting: 0 sec Setting range: 0 - 255 sec. -

Page 55: Networking Via Modbus

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Limit ON / OFF see Controller Setup / Limit Set Internal2 Fixed speed “Default Internal2” active. Function with selected “control mode”: 0, 1, 2 , 3 (see “Controller Setup”). With simultaneous activation of “Default Internal3” with function has prior- ity). -

Page 56: Input "E1

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW 9.5.3 Input “E1” E1 Function (factory setting) = speed setting by external signal (0 - 10 V / PWM). For settings via “E1” operates like “D1” as a digital input (see digital inputs / function). -

Page 57: Networking Via Modbus

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW 9.5.5 Networking via MODBUS It is possible to network several devices with each other. The device uses the MODBUS-RTU as the protocol for the RS-485 interface. Bus Address The device address is factory set to the highest available MODBUS address: 247. - Page 58 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Suppression2 Range2 min. Range2 max. Suppression3 Range3 max. Range3 max. L-BAL-F079D-GB 2044 Index 002 Part.-No. 58/80...

-

Page 59: Setting For Rampup Time And Rampdown Time

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW 9.6.1 Setting for Rampup time and Rampdown time By separate menus for Rampup time and Rampdown time an adjustment is possible to individual system conditions. This function is switched behind the actual controller function. -

Page 60: Diagnostics Menu

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Suppression active = “ON” Setting for “Range1 min.” Setting range: “0” - “Range 1 max.” Setting for “Range1 max.” Setting range: “Range 1 max.” - “Rated speed” Identical procedures for Suppression2 and Suppression3, as far as desired Diagnostics menu The diagnostics menu supplies information about the momentary operating condition of the device. -

Page 61: Display And Query Of Events And Malfunctions

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Hand held terminal A-G-247NW Display and query of events and malfunctions Events The event memory is read out after pressing the P key. Reading »»» Beispiel: keine vorliegenden Störungen Empty = no entry = no event in the memory... -

Page 62: 10 Diagnostics / Faults

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Diagnostics / Faults 10 Diagnostics / Faults 10.1 Trouble shooting Type of error Possible cause Adjustment Fan does not run No line voltage Check line voltage (anymore) Line failure Under - or overvoltage Earth fault... -

Page 63: Status Output With Flashing Code

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Diagnostics / Faults 10.2 Status output with flashing code Vision panel for status LED in the case of plastic cover design 22.06.2012 v_flash_expl_red_1_x.VSD LED Code Relays Cause Reaction of Controller Explanation Adjustment Unit switch off and automatically on when the voltage has been restored. - Page 64 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Diagnostics / Faults LED Code Relays Cause Reaction of Controller Explanation Adjustment Intermediate circuit overvoltage If the DC-link voltage drops below the limit within 75 seconds, then the cotroller will attempt to start. If the DC-link voltage increases above a specified limit, the motor will switch off.

-

Page 65: Brake Function And Behaviour In Rotation By Air Current

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Diagnostics / Faults LED Code Relays Cause Reaction of Controller Explanation Adjustment Internal communication error Fault indication ∞ Internal communication failure If error message persists, repair by the manufac- x – turer is necessary. -

Page 66: 11 Service Work

• Repair, e.g. by welding is prohibited! • Bolted-on impellers and/or wings may only be replaced by authorised ZIEHL-ABEGG SE staff. The manufacturer shall not be liable for damage caused through improper repair work. • Please consult our service department with regard to changing the bearing as for all other damage (e.g. -

Page 67: Cleaning

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Service work 11.2 Cleaning Danger due to electric current Voltage supply for motor must be interrupted and secured against restoration! Clean the fans`s flow area. Attention! • Do not use any aggressive, paint solvent cleaning agents when cleaning. -

Page 68: 12 Enclosure

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure 12 Enclosure 12.1 Technical data Line voltage* 1 ~ 200...277 V, 50/60 Hz (see rating plate) 3 ~ 200...240 V, 50/60 Hz 3 ~ 380...480 V, 50/60 Hz 3 ~ 200...480 V, 50/60 Hz... - Page 69 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure Ball-bearings service life The according to standard calculation methods determined bearing service life expect- ation of the motor-integrated ball bearings is mainly determined by the grease service life F10h and amounts for standard application to approx. 30.000 - 40.000 operating hours.

-

Page 70: Ul Specifications

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure 12.2 UL specifications 12.2.1 UL: Ratings RATINGS: Ambient Model Input at 50 / 60 Hz Output Tempera- ture [C°] MK116 MK 116-#I#.07.#A 3x 380–480 Vac, 2500W, 4.0-3.2A 2400 W / 16kHz 4.7 A, 460Vac (rms) MK 116-#I#.11.#A... -

Page 71: Ul: Overload Protection

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure Ambient Model Input at 50 / 60 Hz Output Tempera- ture [C°] MK 152-#I#.11.#E 3x 200–240 Vac,1900-2300W, 6.1A 1800-2175 W / 16kHz / 6.6 A 215Vac (rms) MK 152-#I#.17.#E MK 152-#I#.24.#E 3x 200–240 Vac, 1650-2000W, 5.4A 1550-1900 W / 16kHz / 5.7 A 215Vac... -

Page 72: Ul: Short Circuit Current Rating

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure 12.2.3 UL: Short Circuit Current Rating The integrated variable speed drives are suitable to be used on a circuit capable of delivering no more than 100 kA RMS symmetrical. Details can be found in the following table. -

Page 73: Connection Diagrams

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure 12.3 Connection diagrams Adhere to the further information under Mains connection. UL: Input (Line) Copper connecting leads with an insulation temperature of at least 80 °C must be used! ECblue BASIC-MODBUS 100%-function (_ _ _ _ _-_I_.D_._ _ _ _), (_ _ _ _ _-_I_.G_._ _ _ _) - Page 74 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure ECblue BASIC 100%-function (_ _ _ _ _-_I_.D_._ _ _ _), (_ _ _ _ _-_I_.G_._ _ _ _) Kontaktbelastung Contact rating max. AC 250 V 2 A AM-.. 24V 10V GND D1...

-

Page 75: Application Examples

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure 12.4 Application examples 12.4.1 Installation with ventilation computer CTE/AH-L and main switch Zenec Abzweigdose Distributor box CTE/AH(X)-L ECblue BASIC 100%-function Zenec Zenec i_abzwd_ecblue_basic_2nd_zenec_cte.eps 07.11.2019 1 7 x 1.5 mm : line voltage and "100 % function"... -

Page 76: Overvoltage Protection

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure 12.4.2 Overvoltage protection A sensible excess voltage protection is divided into coarse, medium, and device protection. The coarse protection is normally installed near the mains supply input, the medium protection in the subsidiary distribution. Device protection is integrated into all our devices, thus also in the ECblue fans. -

Page 77: Ec Declaration Of Incorporation

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure EC Declaration of Incorporation 12.5 - Translation - (english) ZA87-GB 2044 Index 009 as defined by the EC Machinery Directive 2006/42/EC, Annex II B The design of the incomplete machine: Axial fan DN.., FA.., FB.., FC.., FE.., FF.., FG.., FH.., FL.., FN.., FS.., FT.., FV.., VN.., VR.., ZC.., ZF.., ZG.., ZN..Centrifugal fan ER.., GR.., HR.., RA.., RD.., RE.., RF.., RG.., RH.., RK.., RM.., RR.., RZ..,... - Page 78 Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Enclosure It is prohibited to commission this incomplete machine until it has been secured that the machine into which it was incorporated complies with the stipulations of the EC Machinery Directive. Künzelsau, 28.10.2020 (location, date of issue)

-

Page 79: Index

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC 12.6 Index address air current pin code Android PIN input Assembly power electronics Baudrate Rampdown time Bearing Rampup time Binding rating plate Bluetooth addressing Bluetooth LE relay Relay output residual current protective device changing the bearing... -

Page 80: Manufacturer Reference

Assembly instructions ECblue BASIC-MODBUS, ECblue BASIC Index 12.7 Manufacturer reference Our products are manufactured in accordance with the relevant international regulations. If you have any questions concerning the use of our products or plan special uses, please contact: ZIEHL-ABEGG SE Heinz-Ziehl-Straße...

Need help?

Do you have a question about the ECblue BASIC-MODBUS and is the answer not in the manual?

Questions and answers