Graco HUSKY 715 Instructions-Parts List Manual

Double-diaphragm pump

Hide thumbs

Also See for HUSKY 715:

- Instructions and parts list (37 pages) ,

- Instructions-parts list manual (36 pages) ,

- Instructions manual (36 pages)

Table of Contents

Advertisement

Quick Links

INSTRUCTIONS-PARTS LIST

This manual contains IMPORTANT

INSTRUCTIONS and WARNINGS.

READ AND RETAIN FOR REFERENCE.

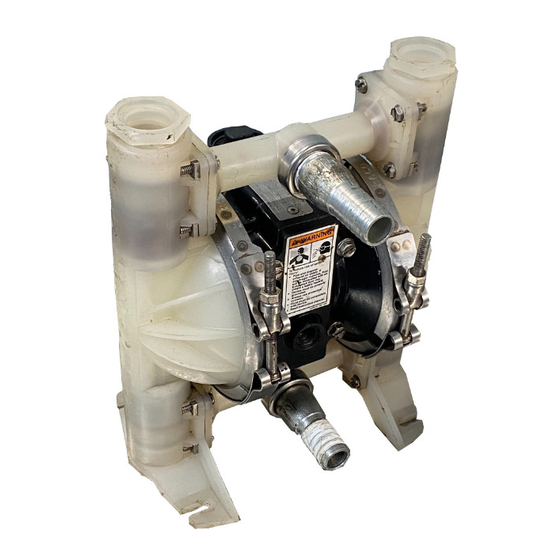

HUSKY 715 Double-Diaphragm Pump

100 psi (7 bar) MAXIMUM INCOMING AIR PRESSURE

100 psi (7 bar) MAXIMUM FLUID WORKING PRESSURE

U.S. PATENT NOS. 4,789,131 AND 4,867,653

OTHER U.S. AND FOREIGN PATENTS PENDING

ACETAL PUMPS (Black)

Model 220–617, Series F

PTFE

With

diaphragms and balls*

Model 220–618, Series F

With buna–N diaphragms and balls*

Model 223–747, Series A

With buna–N diaphragms and balls*

For Use In Graco Lube Evacuation Systems Only

(Also refer to Manual 308–035, supplied)

40–50 psi (2.8 to 3.5 bar) RECOMMENDED INLET

OPERA TING PRESSURE

POLYPROPYLENE PUMPS (Gray)

Model 223–154, Series B

PTFE

With

diaphragms and balls*

Model 223–155, Series B

With buna–N diaphragms and balls*

* See TECHNICAL DA TA on pages

31–35 for a complete list of materials

of pump construction. Also refer to

the Compatibility Charts on page 7 for

recommendations on pump usages

with various fluids.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 1987, GRACO INC.

307–855

Rev R

Supersedes L

and PCN M

0947

Advertisement

Table of Contents

Summary of Contents for Graco HUSKY 715

- Page 1 Model 220–618, Series F With buna–N diaphragms and balls* Model 223–747, Series A With buna–N diaphragms and balls* For Use In Graco Lube Evacuation Systems Only (Also refer to Manual 308–035, supplied) 40–50 psi (2.8 to 3.5 bar) RECOMMENDED INLET OPERA TING PRESSURE POLYPROPYLENE PUMPS (Gray) Model 223–154, Series B...

-

Page 2: Table Of Contents

Tightening Threaded Connections ... . . Graco Toll–Free Phone Numbers Tightening the Clamps ..... . . -

Page 3: Safety Warnings

SAFETY WARNINGS FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS. Read and understand all instruction manuals before operating equipment. EQUIPMENT MISUSE HAZARD General Safety ible with the “Wetted Parts” and “Non–wetted Parts” (refer to TECHNICAL DATA on pages 31–35). Always read the fluid and Any misuse of the equipment or accessories, such as overpres- solvent manufacturer ’s literature before using them in this surizing, modifying parts, using incompatible chemicals and flu-... -

Page 4: Above Ground Transfer

NOTE: For Lube Evacuation Systems using Model 223–747, refer to the Installation section in manual 308–035. ABOVE GROUND TRANSFER INSTALLATION Air Line Bleed–type Master Air Valve Air Filter Air Regulator and Gauge Husky 715 Pump G Drain Valve Fluid Regulator (optional) Fluid Outlet Hose Suction Hose Underground Storage Tank... -

Page 5: Venting Exhaust Air (Pump Shown Submerged)

TYPICAL INSTALLATIONS NOTE: For Lube Evacuation Systems using Model 223–747, refer to the Installation section in manual 308–035. VENTING EXHAUST AIR (Submerged Installation Shown) See Fig 2 for air line accessories In a submerged installation (as shown), all wetted and non–wetted pump parts must be compatible with the fluid being pumped. -

Page 6: Tray Fill

TYPICAL INSTALLATIONS NOTE: For Lube Evacuation Systems using Model 223–747, refer to the Installation section in manual 308–035. TRAY FILL INSTALLATION Uses dual inlet and dual outlet manifolds See Fig 2 for air line accessories P – OPEN TO ATMOSPHERE System Explanation In this installation, fluid is drawn from the RETURN... -

Page 7: Fluid Compatibility Charts

Read and follow all warnings re- limits, or contact Graco T echnical Assistance: garding fluid use and compatibility given in this manual. -

Page 8: Installation

T o reposition or change manifolds, see 2. See pages 28 and 29 for ACCESSORIES available page 10. from Graco. Always use Genuine Graco Parts and Accessories. 2. Be sure the mounting can support the weight of the pump, hoses, and accessories, as well as the stress 3. -

Page 9: Air Line

INSTALLATION Air Line 2. Install a fluid regulator (H) at the pump outlet to con- trol pump speed, if desired. See Air Line, Step 1.a., WARNING for another method of controlling pump speed. A bleed–type master air valve (B) is required in your system to relieve air trapped between this valve and 3. -

Page 10: Changing Manifolds

INSTALLATION Changing Manifolds 3. Install the dual manifold, with the ports facing the de- sired direction. Reassemble the pump. T orque the The inlet and outlet manifolds can be rotated to three po- bolts (36) to 20–25 in–lb (2.3–2.8 N.m). sitions to best suit your installation needs. -

Page 11: Operation

OPERATION Flushing the Pump Before First Use NOTE: If the inlet pressure to the pump is more than 25% of the outlet working pressure, the ball The pump was tested in water. If the solution could con- check valves will not close fast enough, resulting taminate the fluid you are pumping, flush it thoroughly in inefficient pump operation. -

Page 12: Troubleshooting Guide

TROUBLESHOOTING GUIDE WARNING Pressure Relief Procedure GRACO To reduce the risk of serious bodily injury, including splashing fluid or sol- TECHNICAL ASSISTANCE vent in the eyes or on the skin, always shut off the air to the pump, open Toll Free Phone Number: the dispensing valve, if used, and open the drain valve, to relieve all sys- 1–800–543–0339... -

Page 13: Service

SERVICE Ball Check Valves 3. Use a 1–1/2” socket wrench to remove the plug (26) from the top ball check. Remove the o–ring (58), NOTE: Repair kits are available for both the PTFE spacer (53), ball stop (4), and ball (17). See Fig 12. Buna–N ball check valves. -

Page 14: Director Valve

SERVICE Director Valve NOTE: Model 224–015 Director V alve, used on Pump Model 223–747 only , has a dif ferent cylinder NOTE: A complete air director valve assembly , part (120) on the top end, which includes a reset pin number 223–178 (224–015 for Model 223–747 (118). - Page 15 SERVICE NOTE: Fig 15 is an exploded view of the director valve. 10. Install the washer (105) in the housing. Repeat for Details A, B, and C are cutaway views of how the the other side. o–rings and u–cup seals fit onto the parts. Lubri- cate the o–rings and seals with a lightweight lith- 11.

-

Page 16: Diaphragm

SERVICE Diaphragm 4. Remove the nuts (37) and bolts (36) holding one cov- er (1) to the manifolds (2), and remove the cover. It NOTE: Diaphragm repair kits are available. See page 30 is not necessary to disassemble the other cover from for ordering. - Page 17 SERVICE 7. To remove the bearings (29), clamp the EZY–OUT in a vise, as shown in Fig 17. Turn the housing (5) in the direction shown by the arrows. 8. Pull the seal (30) out of the housing (5), us- ing a pick.

-

Page 18: Pilot Valve

SERVICE Pilot Valve 2. With the diaphragms removed (see Diaphragm on page 16) , use a screwdriver or tool 183–899 to un- NOTE: Repair kit 221–087 is available for the Pilot screw the valve nut (8). Remove the valve parts. Valve. -

Page 19: Director Valve

CYLINDER; acetal (black) Included in Repair Kit 221–090. See page 30. TORQUE TO 38–42 in–lb See page 20 for HOW TO ORDER REPLACEMENT PARTS . (4.3–4.8 N.m) Use only GENUINE GRACO PARTS AND ACCESSORIES. DETAIL A: FOR MODEL 224–015 ONLY 0823... - Page 20 2. Check the parts list to identify the correct part number; do not use the ref. no. when ordering. 3. Order all parts from your nearest Graco distributor. 6 digit Part Number Part Description...

- Page 21 PARTS DRAWING Model 220–617, Series F Includes items 1 to 58 TORQUE TO 38–42 in–lb (4.3–4.8 N.m) TORQUE TO 6–10 ft–lb (8–14 N.m) TORQUE TO 4–5 ft–lb (5.4–6.8 N.m) TORQUE TO 20–25 in–lb ***4 (2.3–2.8 N.m) ***17 ***3 ***58 **50 ***58 **22 **21...

- Page 22 2. Check the parts list to identify the correct part number; do not use the ref. no. when ordering. 3. Order all parts from your nearest Graco distributor. 6 digit Part Number Part Description...

- Page 23 PARTS DRAWING Model 220–618, Series F Includes items 1 to 58 Model 223–747, Series A TORQUE TO Includes items 1–61 38–42 in–lb (4.3–4.8 N.m) Model 220–618 only Model 223–747 only TORQUE TO 6–10 ft–lb (8–14 N.m) TORQUE TO 4–5 ft–lb (5.4–6.8 N.m) RESTART PIN ON MODEL 223–747...

- Page 24 2. Check the parts list to identify the correct part number; do not use the ref. no. when ordering. 3. Order all parts from your nearest Graco distributor. 6 digit Part Number Part Description...

- Page 25 PARTS DRAWING Model 223–154, Series B PTFE Polypropylene Pump with diaphragms and balls Includes items 1 to 58 TORQUE TO 38–42 in–lb (4.3–4.8 N.m) TORQUE TO 6–10 ft–lb (8–14 N.m) TORQUE TO 4–5 ft–lb (5.4–6.8 N.m) TORQUE TO 20–25 in–lb ***4 (2.3–2.8 N.m) ***17...

-

Page 26: Model 223-155

2. Check the parts list to identify the correct part number; do not use the ref. no. when ordering. 3. Order all parts from your nearest Graco distributor. 6 digit Part Number Part Description... - Page 27 PARTS DRAWING Model 223–155, Series B Polypropylene Pump with buna–N diaphragms and balls Includes items 1 to 58 TORQUE TO 38–42 in–lb (4.3–4.8 N.m) TORQUE TO 6–10 ft–lb (8–14 N.m) TORQUE TO 4–5 ft–lb (5.4–6.8 N.m) TORQUE TO ***4 20–25 in–lb (2.3–2.8 N.m) ***17 **50...

-

Page 28: Accessories

Makes removal of the pilot valve (8) easier. Grounding Clamp 103–538 Wall Mounting Bracket 221–167 Ground Wire 208–950 Mounts the Husky 715 Pump to a wall. See Fig 2 for appli- 25 ft (7.6 m) long, cation. See page 31 for mounting detail. 1.5 mm (12 ga.) 110–760 Accessory Muffler... - Page 29 ACCESSORIES (continued) Accessories must be purchased separately . Use only GENUINE GRACO PARTS AND ACCESSORIES. Air Regulator 110–318 Fluid Regulator 214–706 300 psi (21 bar) MAXIMUM WORKING PRESSURE 5–100 psi (0–7 bar) REGULA TED PRESSURE RANGE 0–180 psi (0–12 bar) Adjustment Range.

- Page 30 REPAIR KITS Repair Kits must be purchased separately . Use only GENUINE GRACO PARTS AND ACCESSORIES. PTFE Ball Repair Kit 224–216 The Ref. No. shown in the kits below correspond to the reference numbers used in the parts lists on pages For Model 220–617 Acetal Pump.

-

Page 31: Dimensional Drawing

SLOT (171.2 mm) 0654 TECHNICAL DATA Model 223–747 Acetal Pump, with Buna–N Diaphragm For use in Graco Lube Evacuation Systems Only Maximum Fluid Working Pressure ..100 psi (7 bar) Return Tube Outlet ..... - Page 32 TECHNICAL DATA PTFE Model 220–617 Acetal Pump, with Diaphragm Maximum Fluid Working Pressure ..100 psi (7 bar) Maximum Operating Temperature ..150 F (65 C) Air Pressure Operating Range 25–100 psi (1.75–7 bar) Air Inlet .

- Page 33 TECHNICAL DATA Model 220–618 Acetal Pump, with Buna–N Diaphragm Maximum Fluid Working Pressure ..100 psi (7 bar) Maximum Noise Level..... . 85 dBa Air Pressure Operating Range 25–100 psi (1.75–7 bar) Maximum Operating Temperature...

- Page 34 TECHNICAL DATA PTFE Model 223–154 Polypropylene Pump, with Diaphragm Maximum Fluid Working Pressure ..100 psi (7 bar) Maximum Noise Level ..... 85 dBa Air Pressure Operating Range 25–100 psi (1.75–7 bar) Maximum Operating Temperature...

- Page 35 TECHNICAL DATA Model 223–155 Polypropylene Pump, with Buna–N Diaphragm Maximum Fluid Working Pressure ..100 psi (7 bar) Maximum Noise Level..... . 85 dBa Air Pressure Operating Range 25–100 psi (1.75–7 bar) Maximum Operating Temperature...

-

Page 36: Model 220-617

WARRANTY Graco warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defective.

Need help?

Do you have a question about the HUSKY 715 and is the answer not in the manual?

Questions and answers