Table of Contents

Advertisement

Repair/Parts

®

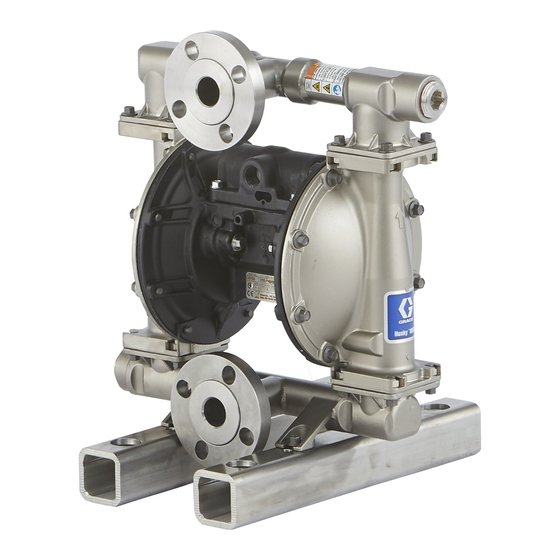

Husky

Diaphragm Pump

1-inch pump with modular air valve for fluid transfer applications.

For professional use only.

See page 4 for model information, including approvals.

125 psi (0.86 MPa, 8.6 bar) Maximum Fluid Working Pressure

125 psi (0.86 MPa, 8.6 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

1050A

Aluminum

ti13946a

1050 Air-Operated

1050S

Stainless Steel

1050H

Hastelloy

1050P

Polypropylene

1050C

Conductive

Polypropylene

1050F

PVDF

Center

Flange

End

Flange

ti14342a

313435ZAA

EN

ti13843a

ti13844a

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Graco Husky 1050

- Page 1 Repair/Parts ® Husky 1050 Air-Operated 313435ZAA Diaphragm Pump 1-inch pump with modular air valve for fluid transfer applications. For professional use only. See page 4 for model information, including approvals. 125 psi (0.86 MPa, 8.6 bar) Maximum Fluid Working Pressure 125 psi (0.86 MPa, 8.6 bar) Maximum Air Input Pressure 1050P Polypropylene...

-

Page 2: Table Of Contents

Check Valve Repair ..... 14 Graco Information ......36 Diaphragms and Center Section . -

Page 3: To Find Your Nearest Distributor

To find part numbers for new pumps or kits, use the Online Diaphragm Pump Selector Tool. To find part numbers for replacement parts: Use the configuration number from the ID plate on the pump. If you only have the Graco 6-digit part num- ber, use the selector tool to find the corresponding configuration number. -

Page 4: Pump Matrix

Pump Matrix Pump Matrix Check the identification plate (ID) for the Configuration Number of your pump. Use the following matrix to define the components of your pump. PART NO. CONFIGURATION NO. SERIAL NO. Sample Configuration Number: 1050A-PA01AA1SSBNBNPT DATE CODE SERIES MAX WPR PSI-bar MADE IN 1050 A... -

Page 5: Atex Certifications

ATEX Certifications ATEX Certifications DataTrak and Pulse Count are All 1050A (Aluminum) and ‡ 1050S (Stainless Steel) and 1050H certified: 1050C (Conductive Polypropylene) (Hastelloy) pumps with aluminum or pumps are certified: conductive polypropylene centers are II 1 G certified: 0359 II 2 GD c IIC T4... - Page 6 Warnings WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

- Page 7 Warnings WARNING TOXIC FLUID OR FUMES HAZARD Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed. • Read MSDS’s to know the specific hazards of the fluids you are using. •...

-

Page 8: Troubleshooting

Air valve damaged. Replace air valve. See page 10. Air valve gasket damaged. Replace air valve gasket. See page 10. Air supply erratic. Repair air supply. Exhaust muffler icing. Use drier air supply or use low ice muffler (Graco part 102656). 313435ZAA... - Page 9 Troubleshooting Problem Cause Solution Air bubbles in fluid. Suction line is loose. Tighten. Diaphragm (and backup) ruptured. Replace. See page 15. Loose manifolds, damaged seats or Tighten manifold bolts or replace manifold o-rings. seats or o-rings. See page 14. Diaphragm shaft bolt o-ring dam- Replace o-ring.

-

Page 10: Repair

Repair Repair WARNING WARNING WARNING WARNING SPECIAL CONDITIONS FOR SAFE USE Equipment must comply with the following conditions to avoid a hazardous condition which can cause fire or explosion. • All label and marking material must be cleaned with a damp cloth (or equiva- lent). - Page 11 Repair 8. For motors with DataTrak: Remember to reattach Reassemble the Air Valve the solenoid bracket and the solenoid. NOTE: Apply lithium-based grease whenever instructed to grease. 9. For motors with Pulse Count or DataTrak: Use screw to attach the reed switch assembly to the new 1.

- Page 12 Repair 209† 205 212 214 1 210 206† 213 207 211 203 204 210 inlet 206† 208† 217 219 DataTrak Models 202 218 with Runaway 208† Protection 207 206† Apply lithium-based grease. 210 U-cup lips must face piston. Apply lithium-based grease to contact surface.

-

Page 13: Datatrak

Follow all instruc- tions in your pump operation manual. Use only an approved replacement battery, and an approved fuse (see pump operation manual). Use of an unapproved battery or fuse will void Graco’s warranty and Intertek and Ex approvals. 313435ZAA... -

Page 14: Check Valve Repair

Repair Check Valve Repair Torque to 100 in-lb (11.3 N•m). See Torque Instructions, page 18. Arrow (A) must point toward outlet manifold. Not used on some models. NOTE: Kits are available for new check valve balls and seats in a range of materials. See page 28 to order kits Aluminum pump in the material(s) desired. -

Page 15: Diaphragms And Center Section

Repair Diaphragms and Center Section b. Plastic Pumps: Use a 1-1/4 socket or box end wrench on the hex of a fluid side diaphragm plate to remove. Then remove all parts of the diaphragm assembly. See F . 8. Metal Pumps: Remove the bolt (304) from one side of the diaphragm shaft, then remove all parts of that diaphragm assembly. - Page 16 Repair 104* 104* TP, SP, BN, FK, and GE PO and CO models models (Metal pumps) ti14037b (Plastic pumps) ti14022b Rounded side faces diaphragm. Apply lithium-based grease. Torque to 20-25 ft-lb (27-34 N•m) at 100 rpm maximum. AIR SIDE markings on diaphragm must face center housing.

- Page 17 Repair Reassembly All Other Diaphragms - Metal Pumps: Follow all notes in F . 8. These notes contain a. Install the o-ring (301) on the shaft bolt (304). important information. b. Assemble the fluid side plate (13), the dia- NOTE: Apply lithium-based grease whenever instructed phragm (15), the backup diaphragm (305, if to grease.

-

Page 18: Torque Instructions

Repair 7. To ensure proper seating and extend diaphragm Torque Instructions life, attach the second fluid cover with air pressure on the pump. NOTE: Fluid cover and manifold fasteners have a thread-locking adhesive patch applied to the threads. If a. See F . - Page 19 Repair ti18448a ti18449a . 10. Torque sequence 313435ZAA...

-

Page 20: Parts

Parts Parts see page 27 see page 27 see page 26 see page 28 see page 22 see page 28 see page 24 see page 26 see page 29 see page 30 see page 27 see page 32 see page 26 ti14023a 1 Not used on some models. -

Page 21: Parts/Kits Quick Reference

Parts Parts/Kits Quick Reference Use this table as a quick reference for parts/kits. See pages indicated in table for full description of kit contents. Ref. Part/Kit Description Qty. Ref. Part/Kit Description Qty. Seats; 4-pack, includes 8 o-rings where Center Section; see page 22 needed, see page 28 24X345 Aluminum... -

Page 22: Center Section

Parts Center Section Sample Configuration Number: 1050A-PA01AA1SSBNBNPT 1050 A01A BN BN Pump Size Wetted Section Drive Center Section Fluid Covers and Seats Balls Diaphragms Manifold O-Rings Material Identifier and Air Valve Manifolds air valve Aluminum Center Section detail, see (A01x, AC1x, AU1x, and AU3x) page 24 109*... - Page 23 Parts Center Section Rebuild Kits (*) Center Shaft Kits 24B621 24B656 A01A-A01D, AU1A, AU3A, AC1A, A01A-A01D, AU1A, AU3A, AC1A, C01A-C01D, C01A-C01D, P01A-P01D P01A-P01D 24D730 24D731 A01E A01E Kits include: Kit includes: All models • 1 center shaft (104) • 2 pilot valves (101) •...

-

Page 24: Air Valve And Data Monitoring

Parts Air Valve and Data Monitoring Standard (no reed switch) or 208† Pulse Count (with reed switch) 202 208† 207 210 206† 210 206† 207 (Compatible with DataTrak 219† with runaway protection) 204 206† 203 211 213 218 214 217 212 210... - Page 25 Parts Air Valve Repair Kits () Air Valve Upgrade Kit A01A-A01C, AU1A, 24B768 AUxA 24K224 AU3A, AC1A, Kit includes: C01A-C01C, P01A-P01C • 2 air valve end caps A01D, C01D, P01D 24D044 • 2 o-rings (206) A01E 24D699 • 2 o-rings Kits include: •...

-

Page 26: Fluid Covers And Manifolds

Parts Fluid Covers and Manifolds Sample Configuration Number: 1050A-PA01AA1SSBNBNPT 1050 A01A BN BN Pump Size Wetted Section Drive Center Section Fluid Covers and Seats Balls Diaphragms Manifold O-Rings Material Identifier and Air Valve Manifolds Fluid Cover Kits Hastelloy and Stainless Steel A1, A2 24B653 Outlet Manifold Kits... - Page 27 Parts Kit 24B910, Fluid Pressure Relief Valve Plastic Outlet Fuel Dispense Model only Manifold Kits Kit includes: 24C039 • 1 valve, 3/8 nptf (9) 24C042 24C038 NOTE: See page 32 for manifold o-rings (12). 24C041 ti14309a 24C040 24C043 Manifold Fasteners (Ref. 9) Kits include: Manifold Fastener Fastener...

-

Page 28: Seats And Check Ball

NOTE: Some kits may not be available for your model. NOTE: Some kits may not be available for your model. See the selector tool at www.graco.com or speak with See the selector tool at www.graco.com or speak with your distributor. -

Page 29: Diaphragms

Balls Diaphragms Manifold O-Rings Material Identifier and Air Valve Manifolds NOTE: Some kits may not be available for your model. See the selector tool at www.graco.com or speak with your distributor. Standard Diaphragm Kits Overmolded Diaphragm Kits 24B622 24B625 24B629... - Page 30 Parts Diaphragms (continued) Sample Configuration Number: 1050A-PA01AA1SSBNBNPT 1050 A01A Pump Size Wetted Section Drive Center Section Fluid Covers and Seats Balls Diaphragms Manifold O-Rings Material Identifier and Air Valve Manifolds Two-Piece Diaphragm Kits Air and Fluid Plate Kits 24B627 1050A 24C035 24F926 1050C...

-

Page 31: Seat, Check Ball, And Diaphragm Kits

Parts Seat, Check Ball, and Diaphragm Kits Sample Configuration Number: 1050A-PA01AA1SSBNBNPT 1050 A01A BN BN Pump Size Wetted Section Drive Center Section Fluid Covers and Seats Balls Diaphragms Manifold O-Rings Material Identifier and Air Valve Manifolds Parts Qty. Parts Qty. 25A860 BALL, PTFE 25A855... -

Page 32: Manifold O-Rings

Parts Manifold O-Rings Sample Configuration Number: 1050A-PA01AA1SSBNBNPT 1050 A01A BN BN Pump Size Wetted Section Drive Center Section Fluid Covers and Seats Balls Diaphragms Manifold O-Rings Material Identifier and Air Valve Manifolds O-Ring Kit Qty. 24B655 Model includes no o-rings Kit Includes: •... -

Page 33: Technical Data

Technical Data Technical Data Maximum fluid working pressure ....... . . 125 psi (0.86 MPa, 8.6 bar) Air pressure operating range . - Page 34 Technical Data Non-wetted external parts Aluminum (1050A) ......... . aluminum, coated carbon steel Hastelloy (1050H) .

- Page 35 Technical Data Fluid Temperature Range NOTICE Temperature limits are based on mechanical stress only. Certain chemicals will further limit the fluid operating tem- perature range. Stay within the temperature range of the most-restricted wetted component. Operating at a fluid temperature that is too high or too low for the components of your pump may cause equipment damage. Fluid Temperature Range Polypropylene or Aluminum, Hastelloy, or...

-

Page 36: Graco Standard Husky Pump Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Husky 1050 and is the answer not in the manual?

Questions and answers