Graco Husky 715 Instructions Manual

5 air-operated diaphragm pum

Hide thumbs

Also See for Husky 715:

- Instructions and parts list (37 pages) ,

- Instructions-parts list manual (36 pages) ,

- Instructions manual (20 pages)

Advertisement

Quick Links

INSTRUCTIONS–PARTS LIST

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

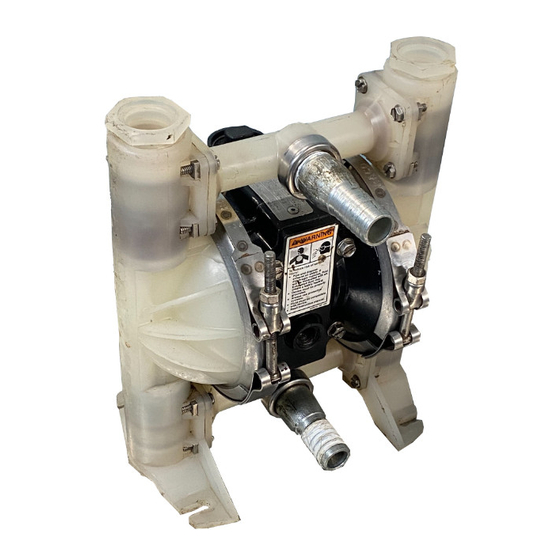

ACETAL AND POLYPROPYLENE

Husky

Diaphragm Pumps

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

*Model No. D61–_____ Acetal Pumps, Series E

*Model No. D62–_____ Polypropylene Pumps, Series E

*Model No. D6A–_____ Acetal BSPT Pumps, Series E

*Model No. D6B–_____ Polypropylene BSPT Pumps, Series E

*NOTE: Refer to the Pump Matrix on page 26 to

determine the Model No. of your pump.

US Patent Nos. 4,789,131 and 4,867,653

Other US and Foreign Patents Pending

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

715 Air-Operated

COPYRIGHT 1995, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

308–444

Supersedes Rev. P

First choice when

quality counts.

Rev. R

Advertisement

Summary of Contents for Graco Husky 715

- Page 1 Model No. of your pump. US Patent Nos. 4,789,131 and 4,867,653 Other US and Foreign Patents Pending GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 COPYRIGHT 1995, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001...

- Page 2 Read all instruction manuals, tags, and labels before operating the equipment. Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

- Page 3 WARNING TOXIC FLUID HAZARD Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed. Know the specific hazards of the fluid you are using. Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state and national guidelines.

- Page 4 Tightening Threaded Fasteners Before First Use The Husky 715 Pump can be used in a variety of installations. See Figs. 3 to 5 for some examples. After unpacking the pump, and before using it for the first time, check and retorque all external fasteners.

- Page 5 Installation Grounding Ground all of this equipment: WARNING Pump : Attach a ground wire (Y) to the grounding strip (107) with the screw (117), lockwasher (118) FIRE AND EXPLOSION HAZARD and nut (119), as shown in Fig. 1. Connect the This pump must be grounded.

- Page 6 Installation GROUNDING A PUMP Husky 715 pump Hose must be conductive. Fluid drain valve (required) Dispense valve Dispense valve nozzle must be in contact with container. Fluid drain line Air motor ground wire (required; see page 5 for installation instructions) Container ground wire (required) Fig.

- Page 7 Installation Air Line Fluid Suction Line If using a conductive (acetal) pump, use conductive WARNING hoses. If using a non-conductive (polypropylene) pump, ground the fluid system. See Grounding on A bleed-type master air valve (B) is required in your page 5. The pump fluid inlet is 3/4 npt(f). See system to relieve air trapped between this valve Fig.

- Page 8 Installation ABOVE-GROUND TRANSFER INSTALLATION Husky 715 pump Bleed-type master air valve (required for pump) Electrically conductive air supply line Air line quick disconnect Master air valve (for accessories) Air line filter G Pump air regulator Fluid drain valve (required) Fluid regulator (optional)

- Page 9 Installation AIR SPRAY INSTALLATION Husky 715 pump Electrically conductive air line to pump Gun air line shutoff valve Air line filter G Gun air regulator Fluid drain valve (required) Electrically conductive fluid supply hose Circulating valve Electrically conductive air line to gun...

- Page 10 Installation Changing the Orientation of the Fluid Inlet Fluid Pressure Relief Valve and Outlet Ports CAUTION You can rotate the fluid inlet and outlet manifolds (102) to three positions. As shipped, the fluid inlet manifold Some systems may require installation of a pressure points down and the fluid outlet manifold points toward relief valve at the pump outlet to prevent overpres- from the air valve (A).

- Page 11 Installation Air Exhaust Ventilation The air exhaust port is 3/8 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can cause erratic pump operation. WARNING To exhaust to a remote location: FIRE AND EXPLOSION HAZARD Be sure to read FIRE AND EXPLOSION HAZARD and TOXIC FLUID HAZARD 1.

- Page 12 Operation Pressure Relief Procedure 2. Check all fittings to be sure they are tight. Use a compatible liquid thread sealant on all male threads. Tighten the fluid inlet and outlet fittings WARNING snugly. Do not overtighten the fittings into the pump.

- Page 13 Maintenance Lubrication Tightening the Clamps The air valve is designed to operate unlubricated, When tightening the clamps (113), apply thread lubri- however if lubrication is desired, every 500 hours of cant to the bolts and be sure to torque the nuts (114) operation (or monthly) remove the hose from the pump to 75 to 85 in-lb (8.5 to 9.6 N-m).

- Page 14 Troubleshooting 1. Relieve the pressure before checking or servicing WARNING the equipment. To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the 2. Check all possible problems and causes before Pressure Relief Procedure on page 12. disassembling the pump.

- Page 15 Troubleshooting PROBLEM CAUSE SOLUTION Air bubbles in fluid. Suction line is loose. Tighten. Diaphragm (401 or 404) ruptured. Replace. See page 23. Loose manifolds (102) or damaged Tighten manifold bolts (104) or nuts o-rings (109). (105); replace o-rings (109). See page 23. Loose fluid side diaphragm plates Tighten.

- Page 16 Service Tools Required WARNING Torque wrench To reduce the risk of serious injury whenever you Phillips screwdriver are instructed to relieve pressure, always follow the O-ring pick Pressure Relief Procedure on page 12. 1/8” EZY-OUT bearing extractor Rubber mallet 1. Relieve the pressure. Replacing the Air Valve NOTE: Air Valve Kit 239–952 is available.

- Page 17 Service 3. See Fig. 11. Use an o-ring pick to remove the 10. Apply grease (25 ) to the bearings (9 and 24). bearings (9 and 24). Install the bearing (9 ) in the pump housing (1). Install the other bearing (24). 4.

- Page 18 Service 16. Install the six screws (10) and torque oppositely CAUTION and evenly to 20 to 25 in-lb (2.3 to 2.8 N-m). See Fig. 10. If you are replacing the diaphragms, you must rein- stall the air valve before installing the diaphragms, as the diaphragms will force the pilot pins into the air valve area.

- Page 19 Service Tools Required 2. Remove the air valve (A) from the pump (see page 16). Torque wrench 3. Remove the screw (15) and shift saddle (14). See Phillips screwdriver Fig. 14. O-ring pick 4. Disassemble the link assembly, consisting of the Rubber mallet actuator link (16), spacer (17), detent link (22), spring (3), stop (4), and valve cup (5).

- Page 20 Service Reassembly 1. If the detent collar (7) was removed, carefully 4. Grease the spring (3). Place the link stop (4) inside install a new collar in a new cover (2). Using a the spring. See Fig. 16. rubber mallet, carefully press fit the detent collar into the cover.

- Page 21 Service Tools Required Torque wrench 1. Relieve the pressure. 1–1/2” socket wrench 2. Use a 1–1/2” socket wrench to remove the plugs (106) from the top ball checks. Remove the o-ring 3/8” x 8” dowel (111), spacer (110), ball stop (202), and ball (301). O-ring pick See Fig.

- Page 22 Service *201 *111 *111 *202 Torque to 5 to 10 ft-lb *301 (6.8 to 13.6 N-m) *201 When tightened fully, there will be a small gap be- tween the hex of the plug (106) and the cover (101). DO NOT OVERTIGH- TEN.

- Page 23 Service Tools Required 3. Remove the screws (104) and nuts (105) holding the manifolds (102) to the covers (101). Remove Torque wrench the manifolds and o-rings (109). Pull the covers Socket wrenches (101) off the pump. See Fig. 22. O-ring pick 4.

- Page 24 Service Reassembly CAUTION CAUTION Do not over-torque the fluid side diaphragm plates If you have removed the air valve (A), you must (112). Doing so will damage the hex heads. reinstall it before reinstalling the diaphragms. See page 16. 4. Install the o-rings (109*) in the manifolds (102). Position the manifolds (102) as desired and install on one of the covers (101) with the screws (104) 1.

- Page 25 Service Grease. Apply medium-strength (blue) Loctite or equivalent to threads, and torque to 75 to 85 in-lb (8.5 to 9.6 N-m) at 100 Detail of Grounding rpm maximum. Do not over-torque. Strip and Clamps The words “AIR SIDE” on diaphragm (401, 404) must face into the pump housing (1).

- Page 26 Husky diaphragm pumps. The remaining five digits define the materials of construction. For example, a pump with a Husky 715 aluminum air motor, acetal fluid section, acetal seats, PTFE balls, and PTFE diaphragms is D 6 1 – 2 1 1.

- Page 27 Repair Kit Matrix For Husky 715 Acetal and Polypropylene Pumps, Series E Repair Kits may be ordered separately. To repair the air valve, order Part No. 239–952 (see page 28). Parts included in the Air Valve Repair Kit are marked with a symbol in the parts list, for example (2 ).

- Page 28 Parts Air Motor Parts List (Matrix Column 2) Ref. Ref. Digit Part No. Description Digit Part No. Description 189–531 HOUSING, center; 111–624 O-RING; buna-N aluminum; see page 29 111–625 O-RING; buna-N 187–706 COVER, air valve; 187–727 SHAFT, reset; sst polypropylene 192–526 LINK, detent;...

- Page 29 Parts Part of Diaphragm Shaft Kit 239–016. See page 28. 109* Part of Air Valve Kit 239–952. See page 28. Used only on models with PTFE diaphragms. 109* *111 *202 *301 *201 *111 401* 404* 109* Detail of Grounding Strip 109* *202 *301...

- Page 30 Parts Fluid Section Parts List (Matrix Column 3) Ref. Ref. Digit Part No. Description Digit Part No. Description 189–635 COVER, fluid; acetal 189–637 COVER, fluid; polypropylene 237–038 MANIFOLD; acetal 237–039 MANIFOLD; 108–630 SCREW; 10–24; polypropylene 5/8 in. (16 mm) long 108–630 SCREW;...

- Page 31 Parts Fluid Section Parts List (Matrix Column 3) (continued) Ref. Ref. Digit Part No. Description Digit Part No. Description 189–635 COVER, fluid; acetal 189–637 COVER, fluid; polypropylene 239–315 MANIFOLD; acetal; BSPT 2 239–316 MANIFOLD; 108–630 SCREW; 10–24; polypropylene; BSPT 5/8 in. (16 mm) long 108–630 SCREW;...

- Page 32 Parts Guide Parts List (Matrix Column 4) Diaphragm Parts List (Matrix Column 6) Ref. Ref. Digit Part No. Description Digit Part No. Description 201* 186–691 GUIDE; acetal 401* 183–542 DIAPHRAGM, backup; polyurethane 202* 186–692 STOP; acetal 404* 108–839 DIAPHRAGM; PTFE 201* 187–242 GUIDE;...

- Page 33 Dimensions FRONT VIEW SIDE VIEW 3/4 npt(f) 4.36 in. (110.5 mm) Fluid Outlet 1/4 npt(f) Air Inlet 3/8 npt(f) Air Exhaust (muffler included) 10.69 in. (271.5 mm) 7.21 in. (183 mm) 8.94 in. (227 mm) 6.44 in. (163.5 mm) 1.73 in. (44 mm) 3/4 npt(f) 7401A...

- Page 34 Technical Data Maximum fluid working pressure ....100 psi Maximum operating temperature ... 150 F (65.5 C) (0.7 MPa, 7 bar) Air inlet size...

- Page 35 Notes...

- Page 36 Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Husky 715 and is the answer not in the manual?

Questions and answers