Graco Husky 715 Instructions Manual

Texture pump series a 100 psi (0.7 mpa, 7 bar) maximum air and fluid working pressure

Hide thumbs

Also See for Husky 715:

- Instructions and parts list (37 pages) ,

- Instructions-parts list manual (36 pages) ,

- Instructions manual (36 pages)

Advertisement

Table of Contents

INSTRUCTIONS-PARTS LIST

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

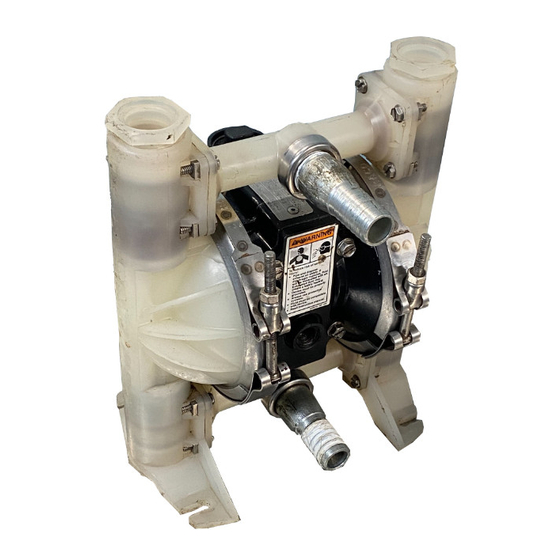

Husky 715 Texture Pump

100 psi (0.7 MPa, 7 bar) Maximum Air and Fluid Working Pressure

Model 239-421, Series A

U.S. Patent Nos. 4,789,131 and 4,867,653

Other U.S. and Foreign Patents Pending

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

. . . . . . . . . . . . . . . . . . . . . . .

COPYRIGHT 1997, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

First choice when

quality counts.

2

4

5

6

7

12

13

16

17

19

20

20

308-781

Rev. A

7323A

Advertisement

Table of Contents

Summary of Contents for Graco Husky 715

-

Page 1: Table Of Contents

......7323A GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 COPYRIGHT 1997, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Warnings

Read all instruction manuals, tags, and labels before operating the equipment. Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. Do not expose the system to rain. Always store the system indoors. - Page 3 WARNING TOXIC FLUID HAZARD Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed. Know the specific hazards of the fluid you are using. Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state and national guidelines.

-

Page 4: Operation

Operation See your system manual for operating instructions. -

Page 5: Maintenance

Maintenance Apply thread lubricant to WARNING bolts, and torque the nuts Air inlet (110) to 75 to 85 in-lb Clamp nuts PRESSURIZED EQUIPMENT HAZARD (8.5 to 9.6 N.m). Clamps The equipment stays pressurized until pressure is Torque to 3 to 6 ft-lb manually relieved. -

Page 6: Troubleshooting

Troubleshooting WARNING To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the Pressure Relief Procedure on page 5. See the Troubleshooting section of instruction manual 308–718 before you proceed with the table below. Check all possible problems and causes before you disassemble the pump. -

Page 7: Service - Air Valve

Pump Repair – Air Valve Replacing the Air Valve 4. Remove the two screws (23) holding the valve WARNING plate (13) to the pump. Use an o-ring pick to remove the valve plate and seal (12). Clean and To reduce the risk of serious injury whenever you inspect the parts. - Page 8 Pump Repair – Air Valve NOTE: If the pilot pin o-rings (28) and bearings (27) 11. Make certain the o-ring (201) is in good condition were not removed, go to step 8. and in place on the air valve cover (206). 7.

- Page 9 Pump Repair – Air Valve Disassembly 4. Remove the screw (219) and shift saddle (218). WARNING See Fig. 4. To reduce the risk of serious injury whenever you 5. Disassemble the link assembly, consisting of the are instructed to relieve pressure, always follow the actuator link (217), spacer (220), detent link (213), Pressure Relief Procedure on page 5.

- Page 10 Pump Repair – Air Valve Reassembly 1. If the detent collar (208) was removed, install a new collar in a new cover (206). Using a rubber mallet, carefully press fit the detent collar (208) into the cover (206). See Fig. 5. 2.

- Page 11 Pump Repair – Air Valve 7. Install the link assembly onto the air valve cover Apply grease. (206) so the pointed end of the reset shaft (214) fits through the holes in the links, and the square Torque to 8 to 14 in-lb part of the reset shaft engages the square hole in (0.9 to 1.6 N.m).

-

Page 12: Service - Duckbill Valves

Pump Repair – Duckbill Valves NOTE: Duckbill Valve Repair Kit 239–754 is available. Kit parts are shown with two asterisks (**) after the Ref. No. Use all the parts in the kit. Install Duckbill Valve Repair Kit 239–754 as follows. See Fig. 8: 1. -

Page 13: Service - Diaphragm

Pump Repair – Diaphragm Disassembly 5. Unscrew one outer plate (118) from the diaphragm WARNING shaft (29). Remove one diaphragm (60) and inner plate (116). Pull the opposite diaphragm assembly To reduce the risk of serious injury whenever you and the shaft out of the pump housing (2). See are instructed to relieve pressure, always follow the Fig. - Page 14 Pump Repair – Diaphragm Grease Apply medium-strength (blue) Loctite or equivalent. Torque to 75 to 85 in lb (8.5 to 9.6 N.m). Do not over-torque. Torque to 3 to 6 ft-lb (4 to 8 N-m). ‡ ‡ ‡ 116* 118* 7328A Fig.

- Page 15 Pump Repair – Diaphragm 3. Assemble the inner diaphragm plates (116), diaphragms (60), and outer diaphragm plates The words “AIR SIDE” on diaphragm (60) (118) exactly as shown in Fig. 11. Apply must face into the pump housing (2). medium-strength (blue) Loctite or equivalent to Flat side of plates (116) must face center of pump.

-

Page 16: Parts List

Parts List Model 239–421, Series A Ref. Ref. Part No. Description Part No. Description 189–531 HOUSING, center 118* 191–837 PLATE, diaphragm, outer; sst 112–545 SCREW, thread-forming; 111–881 MUFFLER M5 x 0.8; 16 mm long 187–726 BEARING, link; acetal 187–719 SEAL, plate, valve; buna-N 237–683 AIR VALVE 187–720... -

Page 17: Parts Drawing

Parts Drawing Model 239–421, Series A **53 See Detail **52 **51 **50 ‡ ‡ ‡ 116* 118* 7327A **52 Detail of Air Valve, Ref. No. 200 **51 **50 Part of Air Valve Kit 237–683. 05525 ‡ Part if Diaphragm Shaft Kit 239–016. * Part of Diaphragm Plate Kit 239–141. - Page 18 Notes...

-

Page 19: Technical Data

Technical Data Technical Data based on tests with water . Data varies with different materials and operating conditions. Maximum air and fluid working pressure ..........100 psi (0.7 MPa, 7 bar) Air pressure operating range . -

Page 20: Graco Warranty

Graco distributor to the original purchaser for use. With the exception of any special extended or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Husky 715 and is the answer not in the manual?

Questions and answers