Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Siemens SIMOTICS M-1PH3

- Page 3 Introduction Fundamental safety instructions SIMOTICS Motor description Mechanical properties SIMOTICS M-1PH3 1PH3 main motors Preparation for use Mounting the motor Equipment Manual Electrical connection Configuration Commissioning Operation Maintenance Decommissioning and disposal Technical data and characteristics Appendix 01/2021 A5E43087278-004...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Introduction

Introduction Standard version This documentation only describes the functionality of the standard version. The machine OEM documents any extensions or changes to the motor made by it. For reasons of clarity, this documentation cannot contain all of the detailed information on all of the product types. - Page 6 If you want to use this function, you must first register. Later, you can log on with your logon data. Training The following link provides information on SITRAIN - training from Siemens for products, systems and automation engineering solutions: SITRAIN (http://siemens.com/sitrain)

- Page 7 Siemens does not accept any warranty for the properties of third-party products. Compliance with the General Data Protection Regulation Siemens respects the principles of data protection, in particular the data minimization rules (privacy by design). For this product, this means: The product does not process neither store any person-related data, only technical function data (e.g.

- Page 8 Introduction 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 9: Table Of Contents

Table of contents Introduction ............................3 Fundamental safety instructions ......................11 General safety instructions ....................11 Equipment damage due to electric fields or electrostatic discharge ........16 Security information ......................17 Residual risks of power drive systems ................. 18 Motor description ..........................19 Highlights and benefits ...................... - Page 10 Table of contents 3.11.2 Natural frequency for mounting ..................48 3.11.3 Misalignment ........................49 3.11.4 Flywheels .......................... 50 3.11.5 Vibration stressing ......................51 3.12 Vibration severity ....................... 52 3.13 Noise emission ........................53 Preparation for use ..........................55 Shipment and packaging ....................55 Transportation and storage ....................

- Page 11 Decommissioning and disposal ......................121 11.1 Decommissioning ......................121 11.2 Disposal ........................... 122 Technical data and characteristics ....................123 12.1 SIMOTICS M-1PH3 main motors ..................123 12.1.1 General technical data ..................... 123 12.1.2 Dimension drawings ......................124 12.1.3 Specific technical data ..................... 125 12.1.3.1...

- Page 12 Table of contents 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 13: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions WARNING Electric shock and danger to life due to other energy sources Touching live components can result in death or severe injury. • Only work on electrical devices when you are qualified for this job. •... - Page 14 Fundamental safety instructions 1.1 General safety instructions WARNING Electric shock due to damaged motors or devices Improper handling of motors or devices can damage them. Hazardous voltages can be present at the enclosure or at exposed components on damaged motors or devices. •...

- Page 15 • Therefore, if you move closer than 20 cm to the components, be sure to switch off radio devices or mobile telephones. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off. WARNING Unrecognized dangers due to missing or illegible warning labels Dangers might not be recognized if warning labels are missing or illegible.

- Page 16 Fundamental safety instructions 1.1 General safety instructions WARNING Unexpected movement of machines caused by inactive safety functions Inactive or non-adapted safety functions can trigger unexpected machine movements that may result in serious injury or death. • Observe the information in the appropriate product documentation before commissioning.

- Page 17 Fundamental safety instructions 1.1 General safety instructions WARNING Injury caused by moving or ejected parts Contact with moving motor parts or drive output elements and the ejection of loose motor parts (e.g. feather keys) out of the motor enclosure can result in severe injury or death. •...

-

Page 18: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Fundamental safety instructions 1.2 Equipment damage due to electric fields or electrostatic discharge Equipment damage due to electric fields or electrostatic discharge Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge. NOTICE Equipment damage due to electric fields or electrostatic discharge Electric fields or electrostatic discharge can cause malfunctions through damaged individual... -

Page 19: Security Information

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure to... -

Page 20: Residual Risks Of Power Drive Systems

Fundamental safety instructions 1.4 Residual risks of power drive systems Residual risks of power drive systems When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system: 1. -

Page 21: Motor Description

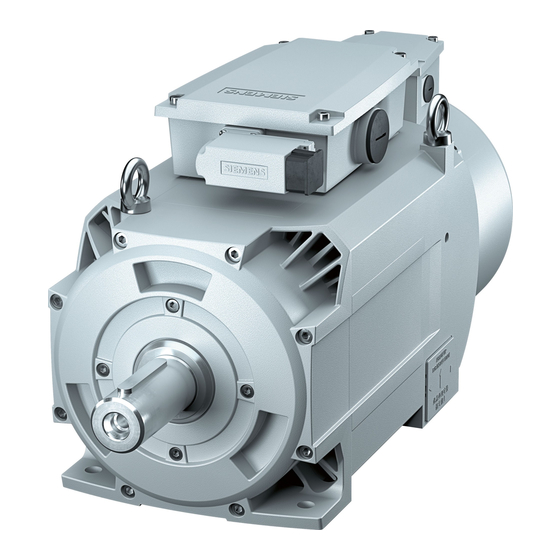

Motor description Highlights and benefits Overview The SIMOTICS M-1PH3 motors, referred to as 1PH3 motors in the following, is a motor generation developed for universal implementation in plants and machines with motion control applications. The motors are provided with the following mechanical properties: •... -

Page 22: Use For The Intended Purpose

When necessary, take into account deviations regarding approvals or country-specific regulations. • If you have any questions regarding the intended use, please contact your local Siemens office. • If you wish to use special versions and design variants whose specifications vary from the motors described in this document, then first contact your local Siemens office. -

Page 23: Scope Of Delivery

Motor description 2.3 Scope of delivery • High-load milling spindles • Counterspindles or power tools for turning machines • Main drives in presses and extruders, converting applications • Rotary axes in the paper and printing industry • For use in crane systems (power house) •... -

Page 24: Motor Rating Plate

Motor description 2.3 Scope of delivery 2.3.2 Motor rating plate ① Motor type ⑪ Thermal class ② Article number ⑫ Maximum torque ③ Serial number ⑬ Rated power ④ Mounting orientation ⑭ Motor power factor ⑤ Temperature sensor type ⑮ Weight ⑥... - Page 25 Article number explanation (example) For shaft height 100 mm only For shaft height 132 mm only According to Siemens/EN 60034-14 (IEC 60034-14) DE = Drive End (motor drive end), NDE = Non-Drive End (motor fan end) 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 26: Cables

4 × 10 ❑ 008-1BB51- ..Connecting SIMOTICS M-1PH3 motors to SINAMICS S120 Motor Modules in booksize format Power cable assemblies (for the S120 Motor Modules C/D-Type with the rated output current ≤ 30 A) 4 × 2.5 002-5CP17- .. - Page 27 Max. length (m) Article number DRIVE-CLiQ cable assem- 002-2DC10- ..blies 002-2DC10- ..MOTION-CONNECT 500 MOTION-CONNECT 800PLUS Siemens MOTION-CONNECT 800PLUS temperature sensor Pt1000 cable Cable type Illustration Length (m) Article number Raw cables 6FX8008-1BD00-1FA0 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 28 Motor description 2.3 Scope of delivery Length code Note MOTION-CONNECT power cable delivery type • For power cable assemblies, the maximum delivery length is 299 m. • For raw cables, the maximum delivery length is 500 m. – Cables with a cross-section of 2.5 mm are available in fixed lengths 50 m, 100 m, 200 m and 500 m.

-

Page 29: Device Combination

Motor description 2.3 Scope of delivery 2.3.4 Device combination The table below lists the 1PH3 motors and configurable cables. You can select the desired cable according to the motor: SIMOTICS M-1PH3 motors Power cable (cross-section, DRIVE- Tem- CLiQ pera- MOTION-... -

Page 30: Derating Factors

Motor description 2.4 Derating factors Derating factors 2.4.1 Overview Derating for ambient/coolant temperature Operation: T = -15 °C to +40 °C (without derating) Under conditions other than those specified above (ambient temperature > 40 °C or installation altitude > 1000 m above sea level), the permissible torque/power reduction must be considered. -

Page 31: Mechanical Properties

Mechanical properties Directives and standards Standards that are complied with The 1PH3 motors comply with the following standards: • IEC/EN 60034-1: Rotating electrical machines – Dimensioning and operating behavior • IEC/EN 60204-1: Safety of machinery – Electrical equipment of machines; general requirements •... - Page 32 Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Certificates for the 1PH3 motors can be downloaded from the Internet at the following link: Certificates for the 1PH3 motors (https://support.industry.siemens.com/cs/products?search=1PH3&dtp=Certificate&mfn=ps&o...

-

Page 33: Cooling

0.71 Note Higher ambient temperatures For ambient temperatures > 50 °C, contact your local Siemens office. The 1PH3 motors are not suitable for use in corrosive atmospheres or atmospheres with a high salt content, or in outdoor applications. 1PH3 main motors... -

Page 34: Degree Of Protection

Mechanical properties 3.3 Degree of protection Mounting a fan and minimum clearance to parts and components mounted by the customer Shaft height (mm) Fan mounting Minimum clearance S (mm) NDE axial Ventilation data Shaft height (mm) Air flow direction Degree of protec- Air discharge tion DE →... - Page 35 Mechanical properties 3.3 Degree of protection Note Liquid and/or oil jet Liquid and/or oil jet must be prevented from collecting on the motor shaft. Degree of protection The only one protection degree for the 1PH3 motors is described in detail in the following table: Degree of 1st code number...

-

Page 36: Construction Types

Mechanical properties 3.4 Construction types Construction types Mounting orientation The 1PH3 motors can be mounted in the following types of construction according to EN 60034-7 (IEC 60034-7): Mounting method Standard type of construction Rotated type of construction Foot mounting IM B3 IM V5 Flange mounting IM B5... -

Page 37: Motor Dimensions

Mechanical properties 3.5 Motor dimensions Motor dimensions Flange mounting (unit: mm) Specification 1PH310 1PH313 1PH310❑-1❑❑02 1PH313❑-1❑❑02 1PH313❑-1❑❑04 7th position of the article number Shaft height 51.5 51.5 M12×30 M16×40 M16x40 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004... -

Page 38: Bearing

Mechanical properties 3.6 Bearing Foot mounting (unit: mm) Specification 1PH3101 1PH3103 1PH3105 1PH3107 1PH3131 1PH3132 1PH3133 1PH3135 1PH3136 Shaft height 51.5 M12×30 M16×40 36.7 40.6 182.9 212.9 262.9 292.9 251.8 251.8 301.8 346.8 346.8 For more information about dimension drawings, see Section "Dimension drawings (Page 124)". -

Page 39: Bearing Lifetime

Mechanical properties 3.6 Bearing See the following table for the recommended bearing change intervals based on the bearing versions at the average operating speed: Shaft height Bearing version Average operating speed Recommended bearing (r/min) change interval (h) Standard ≤ 5000 20000 Performance ≤... -

Page 40: Shaft End

Mechanical properties 3.7 Shaft end Bearing change interval The recommended bearing change intervals are obtained from the interdependencies mentioned above in the following specific operating conditions: • Coupling output or belt coupling • Coolant temperature up to +40 °C • Complying with the permissible radial and axial forces (For more information, see Section "Radial and axial forces (Page 38)".) •... - Page 41 Mechanical properties 3.8 Radial and axial forces For force levels going beyond the upper and lower limits, contact your local Siemens office. NOTICE Premature damage to bearings and shaft breakage due to strong radial forces Bearings can be prematurely damaged and shafts may break if force transmission elements apply too much load to the shaft end as a result of radial forces.

-

Page 42: Axial Force

Mechanical properties 3.8 Radial and axial forces Calculating the total radial force F for belt couplings If the belt manufacturer has not provided precise radial force data, the radial force can be determined approximately via the following formula: = c x F = 2 x 10 x P / (n x D) Formula ab-... - Page 43 Mechanical properties 3.8 Radial and axial forces The permissible axial force F in operation depends on the motor mounting position and can be calculated as shown in the table below: Horizontal arrangement Shaft end facing downwards Shaft end facing upwards Permissible axial force in operation Permissible axial force as a function of the average operating speed nm in each case, ignoring the spring-loading force and the force due...

-

Page 44: Radial And Axial Force Diagrams

Mechanical properties 3.8 Radial and axial forces 3.8.3 Radial and axial force diagrams Permissible radial forces Shaft height 100, performance bearing version, 12000 h bearing lifetime Shaft height 100, standard bearing version, 20000 h bearing lifetime 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004... - Page 45 Mechanical properties 3.8 Radial and axial forces Shaft height 132, performance bearing version, 12000 h bearing lifetime Shaft height 132, standard bearing version, 20000 h bearing lifetime 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 46 Mechanical properties 3.8 Radial and axial forces Permissible axial forces Shaft height 100, performance bearing version, 12000 h bearing lifetime Shaft height 100, standard bearing version, 20000 h bearing lifetime 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 47 Mechanical properties 3.8 Radial and axial forces Shaft height 132, performance bearing version, 12000 h bearing lifetime Shaft height 132, standard bearing version, 20000 h bearing lifetime 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 48: Radial Eccentricity, Concentricity And Axial Eccentricity

Mechanical properties 3.9 Radial eccentricity, concentricity and axial eccentricity Radial eccentricity, concentricity and axial eccentricity The shaft and flange accuracies are always obtained in accordance with IEC 60072 and DIN 42955-1981 and defined as follows: • Radial eccentricity tolerance: tolerance of the motor shaft (cylindrical shaft extension) in relation to the frame axis •... -

Page 49: Balancing

Mechanical properties 3.10 Balancing 3.10 Balancing Requirements on the process of balancing mounted components - especially belt pulleys In addition to the balance quality of the motor, the vibration quality of the motor with mounted belt pulleys and coupling is essentially determined by the balance quality of the mounted components. -

Page 50: Vibration Response

Mechanical properties 3.11 Vibration response Balancing equipment/process step Motor with half-key balancing Motor with a plain shaft Positioning the mounted components • Mounted components attached in a posi- • No special requirements on the auxiliary shaft tion on the auxiliary shaft same as on the actual motor Balancing the mounted components •... -

Page 51: Misalignment

Mechanical properties 3.11 Vibration response The magnitude of the natural frequency occurring when the motor is mounted depends on the following factors: • Mechanical transmission elements (gearboxes, belts, couplings, pinions, and so on) • Stiffness of the machine onto which the motor is mounted •... -

Page 52: Flywheels

Mechanical properties 3.11 Vibration response Alignment accuracy Proceed through the following steps to align the motor: 1. Align the motor with coupling outputs in such a manner that the center lines of the shafts are parallel with no offset. This ensures that no additional force affects the bearings of the shafts during operation. -

Page 53: Vibration Stressing

Mechanical properties 3.11 Vibration response 3.11.5 Vibration stressing The on-site system vibration behavior depends on factors, such as the output components, mounting situation, alignment, installation, and external vibration, which can increase the vibration values of the motor. Under certain circumstances, the rotor may have to be balanced together with the output components. -

Page 54: Vibration Severity

Vibration must be analyzed and measured, for example, measuring points, according to ISO 10816-3. 3.12 Vibration severity The 1PH3 motors are provided with the following vibration qualities in accordance with Siemens/EN 60034-14 (IEC 60034-14): Vibration quality position of the article number G, L Note The vibration quality depending on the bearing is encoded in the article number. -

Page 55: Noise Emission

Mechanical properties 3.13 Noise emission The following figure provides vibration severity limit values over various speed ranges: 3.13 Noise emission The sound pressure level (1 m) of the 1PH3 motors is no higher than 73 dB (A) when the following conditions are satisfied: •... - Page 56 Mechanical properties 3.13 Noise emission 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 57: Preparation For Use

Checking the delivery for completeness Upon receipt of the delivery, check immediately whether the components delivered are in accordance with the accompanying documents. Siemens will not accept any claims relating to components missing from delivery and which are submitted at a later date. -

Page 58: Transporting

Preparation for use 4.2 Transportation and storage WARNING Danger to life as a result of incorrect transport and/or lifting of the motor Incorrectly transporting and/or lifting the motor can lead to severe injuries and/or material damage. For instance, the motor can fall. •... - Page 59 Preparation for use 4.2 Transportation and storage Lifting and transporting the motor with a crossbeam (example) Location of the lifting eyebolts on the motor ① Horizontal shaft extension (standard) ② Shaft extension pointing downwards Transporting a motor that has already been operated If you want to transport a motor that has already been operated, proceed as follows: 1.

-

Page 60: Storing

– No harmful gases in the air of the storage area • Protect the motor against shocks and humidity. • Make sure that the motor is covered properly. • Avoid contact corrosion. Siemens recommends you to rotate the shaft extension manually every three months. 1PH3 main motors... - Page 61 Preparation for use 4.2 Transportation and storage Long-term storage If you intend to place the motor in storage for longer than six months, you must check its condition every six months. • Check the motor for any damage. • Carry out any necessary maintenance work. •...

- Page 62 Preparation for use 4.2 Transportation and storage 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 63: Mounting The Motor

Mounting the motor Protection against the spread of fire The device may be operated only in closed housings or in control cabinets with protective covers that are closed, and when all of the protective devices are used. The installation of the device in a metal control cabinet or the protection with another equivalent measure must prevent the spread of fire and emissions outside the control cabinet. -

Page 64: Mounting Orientation And Outline Dimensions

For more mounting conditions, see Section "Technical data and characteristics (Page 123)". Mounting orientation and outline dimensions 5.2.1 Mounting orientation The SIMOTICS M-1PH3 motors support the following construction types: • IM B3 • IM V5 • IM B5 • IM V1 For more information, see Section "Construction types (Page 34)". -

Page 65: Outline Dimensions

Mounting the motor 5.3 Mounting the motor 5.2.2 Outline dimensions For more information about the motor dimensions, see Section "Motor dimensions (Page 35)". Mounting the motor To ensure smooth, vibration-free motor operation, a stable foundation design is required, the motor must be precisely aligned, and the components that are to be mounted on the shaft extension must be correctly balanced. - Page 66 Mounting the motor 5.3 Mounting the motor NOTICE Damage to the bearing and bearing grease due to liquid at the flange If liquid accumulates at the flange because of vertical or horizontal mounting, the bearing and bearing grease may be adversely affected. •...

-

Page 67: Attaching The Output Elements

Mounting the motor 5.4 Attaching the output elements Foot mounting Remove the plastic cover, fix the motor to the mounting plate with screws, and then reinstall the plastic cover. Motor variant Screw Tightening torque Foot mounting 1PH310❑-1❑❑00-❑❑A0 4 × M10 39 Nm 1PH313❑-1❑❑00-❑❑A0 4 ×... - Page 68 Mounting the motor 5.4 Attaching the output elements Attaching the output components Do as follows when attaching the output components: • Make sure that the balancing method of the output components is correct. The output components must be balanced to balance quality grade G2.5 according to ISO 1940. Rotary forces that exceed this are not permissible.

-

Page 69: Installation As A Direct Drive For Spindles

Mounting the motor 5.5 Installation as a direct drive for spindles Installation as a direct drive for spindles General procedure 1. Run in the bearings. The bearings are run in at the factory in order to ensure that the bearing grease is displaced before the motor is shipped. - Page 70 Mounting the motor 5.5 Installation as a direct drive for spindles 3. Balance the complete assembly (spindle with mounted coupling half). Balance the complete assembly, that is, spindle with the mounted coupling half, on a suitable fixture. Residual imbalance u = G1 g/mm 4.

- Page 71 Mounting the motor 5.5 Installation as a direct drive for spindles 5. Mount the coupling half on the motor shaft. 6. Balance complete assembly, that is, motor with the mounted coupling half. Balance the motor when it is completely assembled with the coupling half. The aim is to achieve the same vibration levels as the motor would exhibit without the coupling half.

- Page 72 Mounting the motor 5.5 Installation as a direct drive for spindles 8. Check the smooth running performance of the complete drive train. To ensure satisfactory smooth running and a long bearing service life, the specified vibration velocity values must not be exceeded at any point along the train. 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 73: Notes On Laying Cables In Drag Chains

Mounting the motor 5.6 Notes on laying cables in drag chains 9. Balance the complete drive train. The complete drive train will need to be balanced if the specified vibration velocity values cannot be achieved. ① 1PH3 motor ② Location flange for the motor ③... - Page 74 Mounting the motor 5.6 Notes on laying cables in drag chains To ensure a long service life of the drag chain and cable, lay cables made of different materials separately with separating webs in the drag chain. • Fill the webs evenly to ensure that the position of cables does not change during operation.

-

Page 75: Electrical Connection

Electrical connection Permissible line system configurations In combination with the drive system, the motors are generally approved for operation on TN and TT systems with grounded neutral and on IT systems. In operation on IT systems, the occurrence of the first fault between an active part and the ground must be signaled by a monitoring device. - Page 76 Electrical connection 6.3 Connecting the motor components The prewarning signal from the evaluation circuit in the SINAMICS converter can be externally evaluated. In the high short-term overload conditions, additional protective measures are required as a result of the thermal coupling time of the temperature sensor. NOTICE Destruction of the temperature sensor if the insulation resistance is tested improperly.

-

Page 77: Encoder System

Electrical connection 6.3 Connecting the motor components Wiring Motors without an encoder can be directly connected to the corresponding Motor Module/Power Module via the available MOTION-CONNECT temperature sensor Pt1000 cable. The temperature sensor data is transferred directly to the Control Unit. 6.3.2 Encoder system 6.3.2.1... -

Page 78: Encoder Connection

• Only use the Sensor Module and the electronic rating plate for the original motor. • Do not mount the Sensor Module onto other motors. • Do not replace the Sensor Module by a Sensor Module of another motor. • Only appropriately trained Siemens service personnel is allowed to replace the Sensor Module. NOTICE... - Page 79 Electrical connection 6.3 Connecting the motor components DRIVE-CLiQ interface With the DRIVE-CLiQ interface, the encoder system of the 1PH3 motors provides the following functions: • Angular measuring system for the commutation • Actual speed value sensing • Indirect incremental measuring system for the position control loop •...

-

Page 80: External Fan

Electrical connection 6.3 Connecting the motor components The table below provides the 10-pin RJ45 socket for being connected with the DRIVE-CLiQ MOTION-CONNECT cable. Pin No. Signal Illustration P_24V RJ_TXP RJ_TXN RJ_RXP Reserved Reserved RJ_RXN Reserved Reserved M 0V Wiring Motors with an encoder can be directly connected to the corresponding Motor Module/Power Module via the DRIVE-CLiQ MOTION-CONNECT cable in degree of protection IP65. - Page 81 Electrical connection 6.3 Connecting the motor components Connection The external fan is connected in the fan terminal box. Connect the power supply in the fan terminal box, as shown in the figure below. ① Terminal box of the external fan ②...

-

Page 82: System Integration

Electrical connection 6.4 System integration System integration 6.4.1 SINAMICS drive I/O The figures below give the SINAMICS S120 system overview. SINAMICS S120 Motor Modules in booksize format Terminal module Main motor with encoder Control Unit Main motor without encoder Option board MOTION-CONNECT power cable Smart Line Module/Basic Line DRIVE-CLiQ cable... - Page 83 Electrical connection 6.4 System integration SINAMICS S120 Combi Power Modules TTL spindle encoder Servo motor Power Module MOTION-CONNECT power cable Option line filter Sub D 15 cable Line reactor DRIVE-CLiQ MOTION-CONNECT cable Main motor without encoder MOTION-CONNECT temperature sensor Pt1000 cable Main motor with encoder Three-phase 380 ...

-

Page 84: Connecting-Up Information

Electrical connection 6.4 System integration 6.4.2 Connecting-up information Observe data on the motor rating plate data and circuit diagram in the motor terminal box. Use sufficiently dimensioned connection cables. Note System compatibility for connection System compatibility is guaranteed only if shielded power cables are used and the shield is conductively bonded over a large area to the metal motor terminal box (with a metal EMC cable gland). -

Page 85: Routing Cables

Electrical connection 6.4 System integration 6.4.3 Routing cables For more information about how to route cables, see Section "Degree of protection (Page 32)". 6.4.4 Terminal boxes WARNING Thermally damaged connecting cables If connection cables have a conductor cross section that is too small for the application, the connection cables can be thermally damaged. -

Page 86: Fan Terminal Box

Electrical connection 6.4 System integration Terminal box connection Current-carrying capacity for power cables and DRIVE-CLiQ MOTION-CONNECT cables See the table below for derating factors for power cables and DRIVE-CLiQ MOTION-CONNECT cables. Surrounding air temperature (°C) Derating factor according to EN 60204-1, Table D1 1.15 1.08 1.00... -

Page 87: Connecting The Terminal Boxes

Electrical connection 6.4 System integration Terminal box connection 6.4.5 Connecting the terminal boxes Note • The recommended sequence for cable connections is as follows: the DRIVE-CLiQ MOTION- CONNECT cable or temperature sensor Pt1000 cable first, the power cable next, and then the fan cable. - Page 88 Electrical connection 6.4 System integration For motors with an encoder 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 89 Electrical connection 6.4 System integration For motors without an encoder 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 90 Electrical connection 6.4 System integration Loosen the screws on the top of both the motor terminal box and the fan terminal box to remove the terminal box covers. Remove the two screw plugs in one side of the two terminal boxes. Then remove the cover of the Sensor Module (for motors with an encoder) or the screw plug in the front of the motor terminal box (for motors without an encoder).

- Page 91 Electrical connection 6.4 System integration WARNING Electric shock or short circuit due to improper connections Improper connections have high risks of electric shock and short circuit, which will jeopardize personal safety and equipment. • The converter must be directly connected with the motor. It is not permissible to connect a capacitor, inductor or filter between them.

- Page 92 Electrical connection 6.4 System integration 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 93: Configuration

• Installation information of the drive and drive components • Energy considerations of the configured drive systems You can find further information on the Internet at: SIZER (https://support.industry.siemens.com/cs/ww/en/view/54992004) Configuration tool Article number of the DVD SIZER for SIEMENS Drives 6SL3070-0AA00-0AG0 German/English 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004... -

Page 94: Procedure When Engineering

Configuration 7.2 Procedure when engineering Minimum system requirements • PG or PC, Pentium™ III min. 800 MHz (recommended > 1 GHz) 512 MB RAM (recommended > 1 GB) • At least 2 GB free hard disk space • Additional 100 MB free hard disk space on the Windows system drive •... - Page 95 Configuration 7.2 Procedure when engineering General configuring procedure The function description of the machine provides the basis for configuring the drive application. The components are selected according to physical interdependencies and the selection process is usually carried out in the following sequence of steps: Step Configuration activity description Remarks...

-

Page 96: Specifying The Duty Cycle

Configuration 7.2 Procedure when engineering Asynchronous motors can be used to increase maximum speeds in the field-weakening range. Asynchronous motors for higher power ratings are also available. The following factors are especially important when you configure a drive application: • The ambient temperature and installation altitude of the motors and drive components. •... - Page 97 Configuration 7.2 Procedure when engineering These drives typically operate at a specific operating point and are dimensioned for a base load. The base load torque must lie below the S1 characteristic curve. An overload rating is provided for transient overloads (for example, during acceleration). The overload current must be calculated relative to the required overload torque.

- Page 98 Configuration 7.2 Procedure when engineering Free duty cycle The figure below shows a load duty cycle that defines the characteristics of the speed and torque of the motor with respect to the time. A load torque is specified for each time period. In addition to the load torque, the average load moment of inertia and motor moment of inertia must be taken into account for acceleration.

-

Page 99: Selecting Motors

Configuration 7.2 Procedure when engineering The following criteria must be taken into account when you select the motor: • The dynamic limits must be adhered to, that is, all speed-torque points of a certain load event must lie below the relevant limiting characteristic curve. •... - Page 100 Configuration 7.2 Procedure when engineering The figure below shows the typical speed-power diagram: In order that safe, reliable operation is guaranteed even when the line supply voltage fluctuates and the motor parameters vary, a safety margin of at least 10% should always be maintained to the voltage limit at every operating point depending on the type of supply voltage of the Motor Module and Line Module.

- Page 101 Configuration 7.2 Procedure when engineering Example The following takes an SLM with a line voltage of 380 V and a converter output voltage of 355 V for example to show how to calculate the new voltage limiting characteristic for operation. 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 102 Configuration 7.2 Procedure when engineering Output voltages For correct configuration, the characteristics are relevant for the line voltage and the line infeed. Characteristics Converter Line voltage Line Module Remarks order system SINAMICS 380 V 3 AC Smart/Basic Line Module Infeed with a non-regulated SLM/BLM (SLM/BLM) (converter output voltage up to 355 V) SINAMICS...

-

Page 103: Commissioning

Commissioning Safety instructions for commissioning WARNING Danger to life due to touching a live part when the insulation is damaged as a result of the high-voltage test The motor insulation can be damaged when a motor high voltage test is carried out. You can get an electric shock when touching live components. -

Page 104: Checklists For Commissioning

Are all of the necessary components of the configured drive line-up available, cor- rectly dimensioned, installed and connected? Are the manufacturer's documentations for the system components and the SIMOTICS M-1PH3 main motors available? If the 1PH3 motors are operating in a SINAMICS S120 drive system, are the following documentation available? •... - Page 105 Commissioning 8.2 Checklists for commissioning Checking items If the 1PH3 motors are operating in a SINAMICS S120 drive system, are the checklists related to the commissioning in the SINAMICS S120 Commissioning Manual careful- ly observed? Do you know the type of the to-be-commissioned motor clearly? 1PH3 _ _ _ - _ _ _ _ _ - _ _ _ _ Are the environmental conditions in the permissible range? Checking the mechanical system...

- Page 106 Commissioning 8.2 Checklists for commissioning Checking the cooling system Checking items Have you checked all safety-related and function-relevant details? Examples: • Is the electrical installation of the fan, including accessories OK, for example, has the protective conductor been connected? • Are the mechanical installation and electrical installation of the safety-relevant components OK? These include the installation of a circuit breaker and attaching protective guards.

-

Page 107: Checking The Insulation Resistance

Commissioning 8.3 Checking the insulation resistance Checking the insulation resistance After long storage or shutdown periods, the insulation resistance of the windings must be measured to ground with direct voltage. WARNING Danger to life through electric shock During and immediately after the measurement, the terminals are in some cases at hazardous voltages, which can lead to death when touched. - Page 108 Commissioning 8.3 Checking the insulation resistance Note the following: • Dry, new windings have an insulation resistance of between 100 MΩ and 2000 MΩ (sometimes higher). If the insulation resistance is close to the minimum value, this could be due to humidity and/or an accumulation of dirt.

-

Page 109: Switching On And Switching Off

Commissioning 8.4 Switching on and switching off Switching on and switching off Note EMERGENCY OFF To avoid accidents, be familiar to the EMERGENCY OFF function before you switch on the system. The motor is switched on and off using the converter. Read about this topic in the converter operating instructions. - Page 110 Commissioning 8.4 Switching on and switching off 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 111: Operation

Operation Note EMERGENCY OFF To avoid accidents, be familiar to the EMERGENCY OFF function before you switch on the system. Switching on WARNING Danger to life caused by the machine movement and loose objects Machine movement and loose objects, which can fall or are flung out, can cause severe injury. -

Page 112: Faults

Operation 9.1 Faults Faults WARNING Injuries caused by the drive system as a result of ineffective protective devices Injuries can be caused if protective devices are deactivated while troubleshooting. • Only operate the drive system with functioning protective devices. Note Damage to the machine caused by faults •... - Page 113 Mechanical shocks from cou- Inspect coupled machine pled machine Uneven gearbox operation Repair the gearbox If the fault still cannot be resolved after applying the measures specified above, contact the manufacturer or Siemens Service Center. 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 114: Non-Operational Periods

Operation 9.2 Non-operational periods Non-operational periods NOTICE Damage due to improper storage The motor can be damaged if it is not stored properly. • If the motor is not operational for longer periods of time, preserve it by using anti- corrosion protection and ensure that it remains dry (for example, appropriate drying agents). -

Page 115: Maintenance

If you have any questions, please contact the manufacturer, informing them of the machine type and serial number. We recommend that a Siemens Service Center carries out inspection and maintenance work. The contact data is provided in Section "Technical support" in Chapter "Introduction (Page 3)". -

Page 116: Maintenance And Inspection Intervals

Maintenance 10.2 Maintenance and inspection intervals 10.2 Maintenance and inspection intervals General Inspect and maintain the motor at regular intervals to be able to identify faults at an early stage and remove them. NOTICE Damage to the machine due to unusual conditions or faults Unusual conditions or faults of the motor, for example, overload or short circuit can result in consequential damage to the machine. -

Page 117: Initial Inspection

Maintenance 10.3 Initial inspection 10.3 Initial inspection Initial inspection Carry out an initial inspection after one of the following conditions is satisfied: • Installation • 500 operating hours, at the latest after 6 months • Corrective maintenance of the motor Note Adapt the inspection to the plant-specific conditions. -

Page 118: Spare Parts - External Fans

Abnormalities identified during inspection that are subsequently ignored can result in machine damage. • Analyze and remove any abnormalities identified, taking into consideration Chapters "Faults (Page 110)" and "Maintenance (Page 113)". • Contact the Siemens Service Center if you require any support. 10.5 Spare parts - External fans Replacement fans... -

Page 119: Replacing The Motor Components

• External fan Note The external fan can be replaced by the customers themselves or by appropriately trained Siemens service personnel. For other components, the replacement can only be implemented by appropriately trained Siemens service personnel. Replacing the external fan Before replacing the fan, proceed as follows: 1. -

Page 120: Cleaning The Motor And The External Fan

Maintenance 10.7 Cleaning the motor and the external fan 1. Open the terminal box. 2. Disconnect all terminals. 3. Part the four screws and disassemble the fan. When you complete the replacing, proceed as follows: 1. After replacing, check the insulation resistance. 2. - Page 121 Maintenance 10.7 Cleaning the motor and the external fan Preparing for cleaning WARNING Death of severe injury as a result of rotating fan blades When carrying out repair and maintenance work on the fan, rotating fan blades can cause severe injury. •...

- Page 122 Maintenance 10.7 Cleaning the motor and the external fan NOTICE Damaged fan blades as a result of excessive force Fan blades can be damaged if subject to excessive force. • Avoid applying excessive force to the fan. Note Use a lint-free cloth or a soft brush to clean the fan blades; ensure that no moisture enters the inside of the motor.

-

Page 123: Decommissioning And Disposal

Decommissioning and disposal 11.1 Decommissioning Disassembly of the motor must be carried out and/or supervised by qualified personnel with appropriate expert knowledge. 1. Contact a certified waste disposal organization in your vicinity. Clarify what is expected in terms of the quality of dismantling the motor and provision of the components. 2. -

Page 124: Disposal

Decommissioning and disposal 11.2 Disposal 11.2 Disposal Recycling and disposal For environmentally-friendly recycling and disposal of your old device, please contact a company certified for the disposal of waste electrical and electronic equipment, and dispose of the old device as prescribed in the respective country of use. Components Sort the components for recycling according to whether they are: •... -

Page 125: Technical Data And Characteristics

Installation altitude ≤ 1000 m (without power derating) Noise level ≤ 73 dB Thermal class Vibration severity grade S/SR according to Siemens/EN 60034-14 (IEC 60034-14) Shock resistance 2.25 m/s (continuous in the axial direction); 10 m/s (continuous in the radial direction) -

Page 126: Dimension Drawings

Note Changing motor dimensions Siemens AG reserves the right to change the dimensions of the motors as part of mechanical design improvements without prior notice. This means that dimension drawings can become out of date. Up-to-date dimension drawings can be requested without any charge from your local SIEMENS office. -

Page 127: Specific Technical Data

Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 12.1.3 Specific technical data 12.1.3.1 Shaft height 100 Article number 1PH310... 1-1❑F 3-1❑F 3-1❑D 5-1❑G 5-1❑D 7-1❑G Insulation class Rated power (kW) Rated torque (Nm) Maximum torque (Nm) (speed (r/min)) (≤ 1500) (≤... -

Page 128: Overload Factors For Intermittent Duty Types (S6)

Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 12.1.3.3 Overload factors for intermittent duty types (S6) The table below specifies the overload factors for intermittent duty types (S6) based on the S1 (continuous operation) characteristics of the relevant motors:... - Page 129 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors Shaft height 100 Shaft height 100 1PH3101-1❑F❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1500 52.5 7000 12000 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 130 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3103-1❑F❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1500 16.9 53.3 5500 12000 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 131 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3103-1❑D❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1000 12.9 36.9 5400 6000 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 132 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3105-1❑G❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 2000 16.5 69.3 4500 12000 11.3 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 133 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3105-1❑D❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1000 17.8 36.4 4500 6000 11.0 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 134 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3107-1❑G❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 2000 69.3 5000 12000 14.3 16.5 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 135 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors Shaft height 132 Shaft height 132 1PH3131-1DF❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1500 51.6 4000 10000 14.3 16.5 1PH3 main motors...

- Page 136 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3131-1DE❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1200 21.7 41.5 6000 8000 11.3 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 137 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3132-1DE❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1200 41.7 5000 8000 11.7 13.5 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 138 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3133-1DG❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 2000 68.1 4000 10000 19.5 22.5 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 139 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3133-1DD❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1000 29.4 4000 6000 14.3 16.5 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 140 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3135-1DD❑: s6-40% s6-40% s6-25% s6-25% s6-15% s6-15% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1000 34.7 4000 8000 15.6 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

- Page 141 Technical data and characteristics 12.1 SIMOTICS M-1PH3 main motors 1PH3136-1DD❑: s6-40% s6-40% s6-25% s6-25% s6-10% s6-10% [r/min] [kW] [Nm] [Hz] [r/min] [r/min] [kW] [kW] [kW] 1000 42.8 3500 6000 19.5 22.5 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 142: Motion-Connect Cables

Technical data and characteristics 12.2 MOTION-CONNECT cables 12.2 MOTION-CONNECT cables Parameter Power cable DRIVE-CLiQ MOTION-CONNECT cable MOTION-CONNECT MOTION-CONNECT MOTION-CONNECT MOTION-CONNECT 800PLUS 800PLUS Certificate /RoHS of suitability conformity cURus or UL758-CSA-C22.2- UL758-CSA-C22.2- UL STYLE 2502/CSA- UL STYLE 2502/CSA- UR/CSA N.210.2-M90 N.210.2-M90 N.210.2-M90 N.210.2-M90 Rated volt-... -

Page 143: Address Of Ce-Authorized Manufacturer

12.3 Address of CE-authorized manufacturer 12.3 Address of CE-authorized manufacturer The CE Declaration of Conformity is held on file available to the competent authorities at the following address: Siemens AG Digital Industries Motion Control Industriestraße 1 DE-97615 Bad Neustadt a. d. Saale... - Page 144 Technical data and characteristics 12.3 Address of CE-authorized manufacturer 1PH3 main motors Equipment Manual, 01/2021, A5E43087278-004...

-

Page 145: Appendix

Appendix Description of terms Rated torque M This is the torque that is mechanically available at the shaft and can be thermally provided corresponding to the specified operating mode (duty type) according to IEC 60034-1. Rated speed n This is the speed for which the rated power and rated torque are defined corresponding to the specified operating mode (duty type) according to IEC 60034-1. - Page 146 Appendix A.1 Description of terms No-load current I μ This is the current (effective phase current) that is required for operating the motor under no- load conditions at the rated speed without load torque. The no-load current defines the motor magnetization in the base speed range (low speed at the start of field weakening). Maximum speed n This is the speed determined by mechanical factors.

-

Page 147: Environmental Compatibility

Appendix A.2 Environmental compatibility Environmental compatibility Environmental compatibility • Environmental compatibility during development – When selecting third-party products, environmental compatibility is an essential criterion. – Special emphasis is placed on reducing the volume, mass and type variety of metal and plastic parts. -

Page 148: Assembling The Temperature Sensor Cable Terminals On The Motor Side

Appendix A.3 Assembling the temperature sensor cable terminals on the motor side Assembling the temperature sensor cable terminals on the motor side 1. Remove the specified length (see illustration) of the outer sheath of the cable. 2. Strip the specified length (see illustration) of the insulation at the end of the wire. 3. -

Page 149: Index

Index DRIVE-CLiQ interface, 76 DT Configurator, 124 Applications, 20 Axial eccentricity, 46 Axial force, 40 Encoder, 75 Axial force diagrams, 44 Environmental compatibility, 145 Balancing instruction (general), 67 Fan mounting, 32 Balancing process, 47 Faults, 110 Bearing change interval, 38 Flywheels, 50 Bearing lifetime, 37 fN, 126... - Page 150 Output components, 66 PN, 126 Radial eccentricity, 46 Radial force, 38 Radial force diagrams, 42 Replacing, 117 Fan, 117 Siemens Service Center, 4 Spare part Fan, 116 Storage, 58 Technical data MOTION-CONNECT cables, 140 Technical Support, 4 Temperature sensor Pt1000, 73...

Need help?

Do you have a question about the SIMOTICS M-1PH3 and is the answer not in the manual?

Questions and answers