Summary of Contents for Huck Alcoa BobTail SF46

- Page 1 ® nstallatIon ysteM sF46 hydraulIc InstallatIon tools Makers of Huck , Marson , Recoil ® ® ® Brand Fasteners, Tools & Accessories April 15, 2015 HK1181...

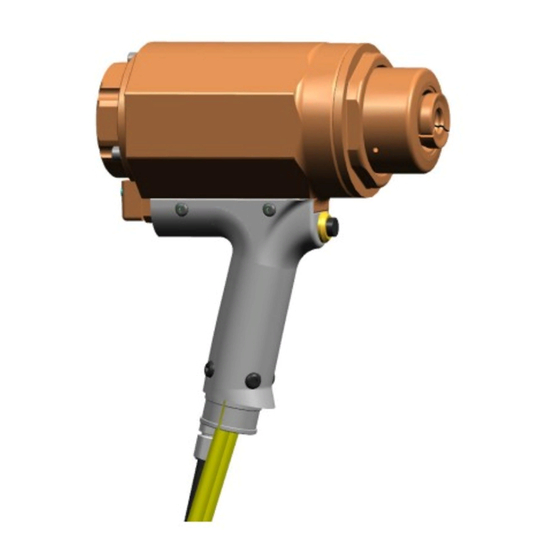

- Page 2 SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181)

-

Page 3: Table Of Contents

SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181) ontents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 afety . -

Page 4: S Afety

Huck representative. 7. Avoid unsuitable postures, as it is likely for these not 11. Only genuine Huck parts shall be used for replacements or to allow counteracting of normal or unexpected tool spares. Use of any other parts can result in tooling damage movement. - Page 5 SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181) afety nstruCtIons (continued) IV. REPETITIVE MOTION HAZARDS: VIII. VIBRATION HAZARDS: 1. When using assembly power tool, the operator can 1. Exposure to vibration can cause disabling damage to the experience discomfort in the hands, arms, shoulders, neck nerves and blood supply to the hands and arms.

-

Page 6: Pecifications

Alcoa Fastening Systems & Rings (HK1181) peCIfICatIons Power Source: Huck POWERIG Hydraulic Unit Max Operating Temp: 125 ° F (51.7 ° C) Hose Kits: Use only genuine HUCK Hose Kits rated at Max Flow Rate: gpm ( l/m) 7.57 10,000 psi working pressure . -

Page 7: P Rinciple Of O Peration

DANGEROUS. 5. Connect PULL pressure hose, with coupler nipple, into port “P” of tool . Use only with HUCK supplied hoses rated at 10,000 psi or greater . Check trigger assembly for apparent damage or wear . If required, adjust position of trigger assembly on hose . -

Page 8: T Ool To P Owerig S Et - Up

1 . Set Pull and Return pressures on Powerig using and install test fastener . Check to be sure that Huck Gage P/N: T-124833CE and Table 1 . the fastener is installed correctly . This can be checked by using the appropriate swage gauge . -

Page 9: Ssembly Of Nptf T Hreaded Omponents

SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181) nptf t ssembly of hreaded omponents AIR FITTINGS ALL FITTINGS: 1) Apply TEFLON stick to male threads which do 2) Tighten to finger-tight condition. ® not have pre-applied sealant per manufacturer’s 3) Wrench tighten to 2-3 turns past finger-tight condition. -

Page 10: Aintenance

Pipe threads may cause tape to shred resulting in tool malfunction. (Threadmate™ Nose Assembly Maintenance is available from Huck in a 4oz. tube as part Clean nose assembly often. Dip in mineral spirits or number 508517.) similar solvent to clean puller and wash away metal chips and debris . -

Page 11: Ydraulic Ouplings

SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181) ydraulIC ouplIngs Igure 504438 O-ring 501102 Back-up Ring Use a fine India stone to remove any nicks or burrs from diameter A and leading edge to prevent damage to O-ring. ptIonal quIpment TEFLON... -

Page 12: T Ool C Omponents D Rawing

SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181) omponents Figure 4... -

Page 13: T Ool D Isassembly

SF46 BobTail® Installation Tooling Alcoa Fastening Systems & Rings (HK1181) IsasseMBly WARNING: Disconnect tool electrical control 6 . a . For installation noses and 3/4” and 20 mm trigger system from Powerig® Hydraulic cutter puller: Unit BEFORE disconnecting tool hydraulic Push the puller through the rear of the tool and hoses from unit. -

Page 14: T Ool A Ssembly

WARNING: Do not omit any seals during and screw gland into cylinder . servicing, leaks will result and personal Note: Threadmate is available from Huck in a injury may occur. 4oz. tube as part number 508517. WARNING: Tool must be fully assembled 7 . - Page 15 Service Parts Kits, Service Tools Kits and Nose Assemblies. Please oolIng ther teMs not contact your Huck Representative or the nearest Huck office listed on the back cover for the ATSC in ManuFactured By HUCK MAKES NO WARRANTY WITH your area .

- Page 16 International. Huck provides technical assistance acknowledgments, and/or purchase orders. It For the Long Haul ™ regarding the use and application of Huck fasten- is recommended that the user secure specific, ers and tooling. up-to-date data and information regarding each application and/or use of such products.

Need help?

Do you have a question about the Alcoa BobTail SF46 and is the answer not in the manual?

Questions and answers