Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Siruba 700KST

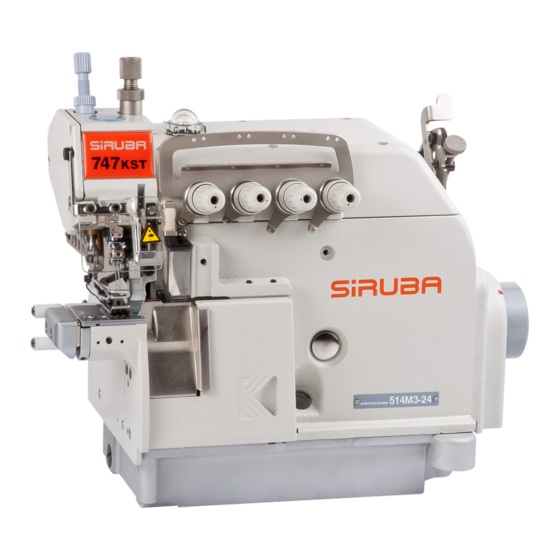

- Page 1 使用說明書與零件圖 INSTRUCTION BOOK & PARTS LIST 700KST...

- Page 3 誌...

- Page 5 Introduction 頁 /PAGE INDEX 索引 TO THE OPERATORS 致使用者 WARNING TAG 警告標籤 MOVING THE SEWING MACHINE 搬運縫紉機 THE INSTALLATION POSITION 縫紉機的安裝位置 SPECIFICATIONS 規格 NAMES OF MAJOR PARTS 各部件名稱 INSTALLATION 安裝 HOW TO OPERATE THE NEW MACHINE 新機器啟用規定 LUBRICATION AND DRAINAGE 潤滑油之注入與更換...

- Page 6 頁 /PAGE INDEX 索引 CONDITIONS OF ALL OPERATORS 操作者條件 MAINTENANCE 保養 DEMOLITION PROCEDURE 報廢流程 TABLE CUT-OUT 桌板圖 GAGE PARTS LIST 規格件表 PARTS LIST 零件圖...

-

Page 7: Warning Tag

Introduction TO THE OPERATORS 致使用者 • 我們非常感謝您使用本公司出品之超高轉 • Thank you very much for using our Ultra 速直驅式直針鎖邊縫紉機 ( 拷克車 )。 Hihg Speed Straight Needle Overlock/ • 請詳細閱讀此說明書,將使您更了解本機 Safety Stitch Machine. • Before operating his machine Please study 器獨特之性能及正確的使用方法,進而提 this bock carejully undwrstand the junction 高您縫製的效率及品質。 • 首先請您注意 : 請先注入潤滑油及確認馬達 and jeatures of the machine. • Then it will help you to crease your sewing 之轉向為順時鐘方向,才可以啟動本機器。 efficiency and quality. WARNING TAG 警告標籤 • 縫紉機上有警告標籤。 • The following warning tags will be attached • 當使用縫紉機時,請遵守標籤上的說明。 on the sewing machine. - Page 8 MOVING THE SEWING MACHINE 搬運縫紉機 • 應按圖適用左手托住前機殼本體,右手撐 • Follow the instruction figure, hole the front 扶住底盤進行搬運。( 圖 3) cover of the machine with the left hand, • 搬運時需穿著安全鞋。 and then hold the bottom machine with right hand to move it.(Fig.3) • Should wear safety boots while moving. 圖 3 / Fig. 3 THE INSTALLATION POSITION 縫紉機的安裝位置 • 勿將該縫紉機置於設備附近,如電視機收 • Do not put the sewing machine around the following devices, such as televisions, 音機或無線電話等,否則這些設備可能會 radios or wireless telephones etc. 對縫紉機的電子干擾所影響。 • 應將縫紉機直接插入 AC 電源插座,如果 Otherwise, the electricity from these 使用延長線,可能會造成操作故障。( 圖...

-

Page 9: Specifications

Introduction SPECIFICATIONS 規格 1. 外銷型號分類 : 1.Description: M 3 2 4 (2) (3) (7) (8) (1) 線數 : 737 為 3 線、747 為 4 線 (1)Thread Numbers: 3 for 737,4 for 747 (2) 表示車台機構及外觀改良之區分編碼 (2)Distinguishing code for machine 型式 型式 (3) ST:筒車... - Page 10 2. 規格說明 ( 表 1) 2. Specification(Table1) 機型 Model 700KST 最高縫速 6300rpm Max Stitch Speed 82 分貝以下 under 82 dB 噪音值 (5500rpm 測試數值 test value) Noise Level 縫距 4 / 5 / 6 mm Stitch Length 針棒行程 24.3 ±0.2 mm Stroke of the needle bar 押具揚程...

-

Page 11: Names Of Major Parts

Introduction NAMES OF MAJOR PARTS 各部件名稱 圖 5 / Fig. 5 (1) 押具扳手 ( 圖 5) (1)Lifting lever (Fig. 5) (2) 押具 (2)Presser foot (3) 控制箱 (3)Control box (4) 線架 (4)Thread stand (5) 油窗 (5)Oil gauge window (6) 手輪 (6)Pulley (Hand Wheel) -

Page 12: Installation

INSTALLATION 安裝 1. 縫紉機拆箱搬運過程中,不可扶持針座板① 1. While unpacking and moving the sewing 下方 ( 圖 6)。 machine, do not hold under the stitch seat 2. 依本機所附桌板裁製圖及零件組合圖所列之 plate1 .(Fig.6) 配件,依序安裝防震機座鋁板 ② ( 圖 6)。 2. Based on the accessories attached with 3. 裝置導布屑及線架。( 圖 7) the table cut-out drawing and components drawings, install the shockproof machine bed aluminum plate1. (Fig.6) 3. Install the waste fabric guide and the thread stand. (Fig.7) ① ② 圖 6 / Fig. 6 圖 7 / Fig. 7... - Page 13 Introduction 4. 馬達啟動踏板①裝於左邊,押具腳踏板②則 4.Install the motor activating plate ① to the 裝於右邊。( 圖 8) left, and the presser pedal ② to the right. (Fig.8) 本體與車板不得干涉 圖 8 / Fig. 8 5. 注意馬達之轉向為順時鐘方向,皮帶①之鬆 5.Pay attention to the motor rotation which 緊度以用手指向內壓下縮 10mm 之緊度為 should be clockwise.

-

Page 14: How To Operate The New Machine

HOW TO OPERATE 新機器啟用規定 THE NEW MACHINE 1. 新機器在最初啟用磨合期的四個星期內,請 1. Please operate this machine in 80% of the 用低於最高速度 20%的速度運轉,之後換上 maximum speed in the first four weeks for engagement. After four weeks, please do 新潤滑油,才可運轉至最高速度。 2. 定期之清潔保養,確保延長機器之使用壽 not operate under the maximum speed until replacing the new lubrication oil. 命。 2. Periodically maintain and clean the machine to ensure and extend the usage term of the machine. LUBRICATION AND DRAINAGE 潤滑油之注入與更換 1. 潤滑油之注入 ( 圖 10) 1.Fill the lubrication oil (Fig.10) (1) 油鏡①旋開,以包裝箱內所附之超高速潤滑 (1)Remove the oil level inspection leng ①, 油或選用... - Page 15 Introduction (3) 為延長此機器之壽命,特別裝有濾油器之機 (3)To extend the usage term, this machine has equipped an oil filter. Please disassemble 構,請在每使用一個月後卸下清洗乾淨,必 and clean it every month, as well as change 要時得更換新品。 3. 針之冷卻油使用油 : 矽油 ( 圖 11) it if needed. 3.Needle cooling lubrication oil: SILICON OIL. (Fig.

- Page 16 THREADING 穿線方法 Follow the procedures for threading. Wrong 請確實按照圖示穿線,錯誤之穿線將引起斷 threading may cause thread breaking, stitch 線、跳針及車縫不平坦 … 等現象。 1.737 用穿線圖 ( 圖 12) skipping, puckering or unexpected sewing. 1.For three thread only 737(Fig. 12) 圖 12 / Fig. 12 2.747 用穿線圖 ( 圖 13) 2.For three thread only 747(Fig. 13) 圖 13 / Fig. 13...

-

Page 17: Adjust Thread Tension

Introduction ADJUST THREAD TENSION 控線調整 The thread tension should be adjusted properly 線張力必須根據縫合布料種類,布料厚薄,線 according to the kinds and the thickness of 及包邊寬度等之差異而做不同的調整。順時針 the materials, stitch length, and seam width, 旋轉張力控制螺帽,縫線張力加大,反之減弱。 1. 調整鈕之控線關係 ( 圖 14) etc. In addition, adjust the nuts case by case (1) 第一調整鈕①控制雙環針線或左邊拷克線... - Page 18 2. 針線控線關係 ( 圖 15) 2.Relation of needle thread tension (Fig.15) (1) 縫合方式 504、505、514 時,將過線組件 (1)While doing the stitches, 504,505,514, move the eyelet ① to the bottom. ①移至最下端。 (2) + 表示增加針線放線量。 (2) + indicates to increase the thread amount. (3) - 表示減少針線放線量。 (3) -...

-

Page 19: Replace The Needle

Introduction REPLACE THE NEEDLE 換針方法 1. 使用 DCX27 或同規格之針。 1.Please use the needle DCX27 or the 2. 旋開螺絲①並取下針。 equivalents. 3. 將新針插至針孔最底端,並使針之長溝面向 2.Loosen the screw ① and take off the needle. 自己,固定螺絲①。( 圖 17) 3.Insert the new needle till reaching the end, as well as the long groove faces your side. -

Page 20: Adjust The Differential Feed Ratio

皮帶輪刻度 Pulley scale 最大差動比 機種 Maxi Diff ratio Machine type 1:1.3 包邊 Serging 接縫 Seaming 1.13 1.66 2.19 2.72 3.25 摺縫 Shirring 1.03 1.46 1.89 2.32 2.71 特規 Special 1.02 1.44 1.66 2.88 表 2 / Table2 ① 圖 18 / Fig. 18 ADJUST THE DIFFERENTIAL 差動比調整... - Page 21 Introduction 刻度 Scale 1:1.3 1:0.7 1:0.9 1:1.1 1:1.3 1:0.7 1:1.14 1:1.17 差動傳送比 Differential feed ratio 1:1.5 1:2.5 1:1.1 1:1.6 1:2.3 1:2.3 1:3.3 表 3 / Table3 圖 19 / Fig. 19 2. 調整方法二 : 2.Adjusting manner2: (1) 鬆開蓋板①。 (1)Loosen the cover board ①. (2) 鬆開螺絲②,上下移動連桿③欲增加行程,...

-

Page 22: Replace The Trimmers

REPLACE THE TRIMMERS 更換切刀 1. 更換上切刀 ( 圖 21) 1.Replace the upper knife (Fig.21) (1) 取下螺絲①將上刀座②移出,鬆開螺絲③, (1)Take down the screw ① and move out the upper knife bracket ②. Loosen the screw ③ 更換刀片④。 (2) 轉動皮帶輪使上刀移至下死點,調整上刀 and replace the knife ④. 高低使上刀與下刀相交約... -

Page 23: Adjust The Needle Height

Introduction ADJUST THE NEEDLE HEIGHT 針高度之調整 1. 轉動皮帶輪使針上昇至最高點時,針尖至針 1.Turn the pulley to raise the needle to the top 板面之距離為 (a)。( 圖 22) point. The distance between the tip of the 2. 調整 : needle to the needle plate is (a). (Fig.22) (1) 打開上蓋①。... - Page 24 Strong Weak 圖 23 / Fig. 23 2. Adjust the arising amount of the presser 2. 押具提升量調整 (1)Turn the pulley to lower feed dog down (1) 轉動皮帶輪使送具降至針板下,押具底平貼 under the needle plate. The bottom side of 針板。 the presser touches the needle plate flatly. (2) 放鬆螺帽①,壓下拉桿②使押具⑦...

-

Page 25: Adjust The Feed Dog

Introduction ADJUST THE FEED DOG 送具調整 1. 送具高度調整 ( 圖 25) 1.Adjust the feed dog height(Fig.25) (1) 轉動皮帶輪使送具上升至針板上最高點。 (1)Rotate the pulley to rise the feed dog the (2) 放鬆螺絲①,上下移動主送具②,使其齒面 highest point of the needle plate. 高出針板面約 0.8 ~ 1.0mm ,鎖緊螺絲①。 (2)Loosen the screw ①... - Page 26 圖 26 / Fig. 26 3. 輔助送布齒高度 3. The height of the auxiliary feed teeth The auxiliary feed dog 1, the side of teeth 輔助送具①,其齒面比送布齒齒面低 0.1~0.3mm,可放鬆螺絲②來調整。 is lower 0.1~0.3mm than the teeth side of ( 圖 27) the feeder. Loosen the screw 2 to adjust. (Fig.27) 圖...

-

Page 27: The Relationship Between Needle And Looper

Introduction 圖 28 / Fig. 28 THE RELATIONSHIP BETWEEN 針與勾針之關係 NEEDLE AND LOOPER 1. 針與上勾針之關係 1.The relationship between the needle and the upper looper 當上勾針移至最左時,勾針尖端與針中心距 約 4.4 ~ 4.7mm ,雙針時其左針中心與勾 When the upper looper moves to the leftest 針尖端距約 5.4 ~ 5.7mm 。( 圖 29) point, the distance from the looper tip to the middle line of the needle is 4.4 ~ 4.7mm. - Page 28 2. 針與下勾針之關係 2. Relation between the needle and the looper (1) 當下勾針移至最左時,勾針尖端與針中心 (1)The distance between the tip of the looper 距約 2.8~3.0mm( 雙針時以左針為主 )。 and the center of the needle should be ( 圖 30) 2.8~3.0mm when the lower looper moves the extreme left.

- Page 29 Introduction 3. 上勾針與下勾針之關係 3. Relation between the upper looper and the lower looper 當上下勾針相交時,兩勾針盡量接近,但不 可磨擦或碰撞,其間隙 A 點為 0.5mm B 點 When the upper and the lower loopers 為 0.2mm。( 圖 32) meet, they reach each other as close as possible, but should not rub or hit each other.

- Page 30 圖 33 / Fig. 33 ADJUSTMENT OF THE HIGH-LOW STROKE OF THE UPPER FEED 上送具高低行程調整 Loosen the screw ①, and take down the upper 放鬆螺絲①,取下上蓋②,放鬆螺絲③, 利用④滑動來調整高低行程。( 圖 34) cover②. Loosen the screw ③, and adjust the stroke by sliding ④. (Fig.34) 圖...

- Page 31 Introduction RELATION BETWEEN THE UPPER FEED DOG AND THE 上送具與差動齒之關係 DIFFERENTIAL FEEDER When the upper feeder ① moves to the lowest 當上送具①走至行程最下方時,與差動齒②之 距離為 0.5mm。( 圖 35) stroke, the distance from the differential feeder is 0.5mm. (Fig.35) 圖 35 / Fig. 35 ADJUST THE FRONT-REAR 上送具前後行程調整...

- Page 32 2. 放鬆螺絲 ①,取下上蓋 ②,放鬆螺絲③來 2. Loosen the screw ①, and take down the 調整上送齒④前後距離。( 圖 37) upper cover ②. Loosen the screw ③ to adjust the front-rear of the upper feeder ④. (Fig.37) 圖 37 / Fig. 37...

- Page 33 Introduction POSITION THE LOOPER AND 定位勾針線挑線凸輪 TAKE-UP THREAD CAM 圖 38 / Fig. 38 針型式 Needle Type 504 505 514 504 514 勾針能力 Looper 21.5 21.5 21.5 21.5 14.5 14.5 17.5 17.5 Left Left Left Right Left Left Left Right 表...

- Page 34 LIGHTENING OF THE 操 作 環 境 照 明 OPERATION ENVIRONMENT 提 供 一 個 警 示 標 誌 , 告 知 使 用 者 : 工 業 Provide a warning that an industrial sewing 用 縫 紉 品 或 是 縫 紉 系 統 必 須 在 該 縫 紉 區 unit or sewing system must always be 域...

-

Page 35: Maintenance

Introduction MAINTENANCE 保 養 啓 ( 表 5) Periodical Maintenance Items 定 期 保 養 項 目 (Table5) 保 養 循 環 保 養 項 目 Maintenance Cycle Maintenance Items 1. 清 潔 送 料 具 上 之 棉 絮 1. - Page 36 DEMOLITION PROCEDURE 報廢流程 1. 當機器需要被淘汰與報廢時,有一些基本規 1.When the machine needs to be eliminated and demolished, certain basic rules must 則必須採納、遵守以保護環境及公眾健康。 2. 所有的機器零組件必須依照下列分類來區分 be observed to protect the environment and public health. 開: (1) 所有護套、可伸縮軟管及塑膠或非金屬零 2.All machine componenets must be divided according to categories as the followings: 件。...

- Page 62 由於對產品的改良及更新 , 本產品使用說明書中與零件圖之產品及外觀的修改恕不事先通知 ! The specification and/or appearances of the equipment described in this instruction book & parts list are subject to change because of modification which will without previous notice. KZ508.APR.2017...

Need help?

Do you have a question about the 700KST and is the answer not in the manual?

Questions and answers