Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Siruba 700LX

- Page 1 使用說明書 ORIGINAL INSTRUCTIONS BOOK 700LD...

- Page 2 如果忽視此標記而運行了錯誤的機械操作,保養時肯定會引起當事者 或第三者人員重傷或死亡。 如果忽視此標記而運行了錯誤的機械操作,保養時有可能會引起當事 者或第三者人員受傷及造成設備損壞。 運動 部位 , 謹防 工 傷 事故 Moving part, beware of industrial accident 高壓 部 位, 謹防 觸 電 事故 High voltage, beware of electric shock 高溫 部 位, 謹防燙 傷事 故 High temperature, beware of burns 禁止...

- Page 3 Introduction 頁 /PAGE INDEX 索引 GENERAL SAFETY INSTRUCTIONS 一般安全事項說明 IMPORTANT SAFETY INSTRUCTIONS 重要安全事項說明 WARNING 特別事項 WARNING TAG 警告標籤 SAFETY ILLUSTRATION OF THE NEEDLE GUARD 護針安全圖說 MOVING THE SEWING MACHINE 搬運縫紉機 THE INSTALLATION POSITION OF THE SEWING MACHINE 縫紉機的安裝位置 SPECIFICATIONS 規格 NAMES OF MAJOR PARTS 各部件名稱...

- Page 4 頁 /PAGE INDEX 索引 ELECTRIC 電眼 TAPE / THREAD CUTTER BUTTON SWITCH 切刀開關 SAFETY DEVICE 安全開關 ILLUSTRATION TO OPEN THE LOOPER COVER 勾針蓋開關方向示意圖 WIRING DIAGRAM 接管圖位置圖 DEMOLITION PROCEDURE 報廢流程 LIGHTENING OF THE OPERATION ENVIRONMENT 操作環境照明 CONDITIONS OF ALL OPERATORS 操作者條件 MAINTENANCE 保養...

-

Page 5: General Safety Instructions

Introduction GENERAL SAFETY 一般安全事項說明 INSTRUCTIONS Warning! 警告! When using this machine, basic safety 當使用這台機器,基本安全預防應恆被遵守 Precautions should always be followed to ,以減輕火災、電擊、或是個人傷害的風險 reduce the risk of fire, electric shock and 。包含以下注意事項。 personal injury, including the followings. 在操作這台機器之前,請閱讀所有說明並且 Read all these instructions before 緊記於心。... - Page 6 8. 中斷機器電源 8. Disconnect machine When not in use, before servicing and 當不使用機器時、維修前、以及更換配件 when changing accessories. 時。 9. 避免誤啟動 9. Avoid unintentional starting Do not carry a plug-in tool with a finger on 不要以手指置於啟動開關上之後,搬運一個 the switch. Ensure the power switch is off 已插入電源的工具。確定在插電之前,電源...

-

Page 7: Important Safety Instruction

Introduction IMPORTANT SAFETY 重要安全事項說明 INSTRUCTION For operating safely and getting the 恭喜您購買本機器,為了使這台機器能獲 best functions of this machine, you must 得最佳功能以及安全的操作,務必請正確 operate it correctly. Please read and 的使用這台機器,使用前請仔細閱讀使用 follow the instructions of this manual, 說明書,希望您能長期使用它。請記得將 and keep it at hand for future references. 此說明書放在容易取得的地方。... - Page 8 8. 假如不慎讓機器及配件使用之油或油 8. If grease, oil, or any fluid contacts your skin or eyes by any chance, please 脂,接觸到眼睛、皮膚或誤食時,請立 wash the contacted area completely 刻以水清洗接觸部位及就診。 with clean water and consult a doctor. Or, swallow any fluid mistakenly,consult a doctor immediately. 9.

- Page 9 Introduction 15. 為使機器能正常操作以及減少噪音, 15. In order to operate properly and to reduce the noise, please place the 機台務必平放地上,機器避免在強烈 machine flat and level on the ground. 噪音的環境下操作。 Avoid operating the sewing machine at a noisy surrounding. 16. 選用適當的電源插頭,並由電子技師 16. Select a proper power plug and install it by an electrician.

- Page 10 c. 當您打開電源開關後或機器已 在運轉 c. Please never put your fingers under the needle(s) or in the thread take-up cover 中,絕不可將您的手放在針的下方或針 to prevent physical injuries when you 線控線桿外蓋中,以免導致人員受傷。 turn on the power switch or operate the machine. d. 當機器運轉中,梭頭高速轉動,為了避 d. While the machine is in operation, the 免對手可能引起之...

- Page 11 Introduction WARNING 特別事項 Please confirm the followings to avoid 為了避免機器故障及損壞,請先確定以下 malfunction or damage to this machine. 事項: 1. 當您安裝好機器後,做第一次機器操作 1. After installing the machine, and before the first operation, please clean it 前,請徹底清潔機器。 completely. 2. 清除運送途中累積之灰塵及溢出之油 2. Clean all dust and overflowed oil during transportation.

-

Page 12: Warning Tag

WARNING TAG 警告標籤 1. 縫紉機上有警告標籤 ( 圖 1)。 1. The following warning tags will be attached 2. 當使用縫紉機時,請遵守標籤上的說明。 on the sewing machine.(Fig. 1) 2. When using the sewing machine,please 如果標籤脫落或模糊不清,請和購買商店聯 follow the instructions of the tags. please 繫。 contact the dealer if any of the tags is fallen off or fuzzy. -

Page 13: Safety Illustration Of The Needle Guard

Introduction SAFETY ILLUSTRATION OF 護針安全圖說 THE NEEDLE GUARD • 本縫紉機之押具防護裝置如圖所示,為保護 • The presser foot protection device is as shown as the fugure 3. 操作者之操作安全,嚴禁將此裝置拆卸。 ( 圖 3) For safety of all operators,this device is restriced to disassemble.(Fig.3) 圖 3 / Fig. 3 MOVING THE SEWING MACHINE 搬運縫紉機... -

Page 14: The Installation Position Of The Sewing Machine

THE INSTALLATION POSITION 縫紉機的安裝位置 OF THE SEWING MACHINE 1. 勿將該縫紉機置於設備附近,如電視機、收 1. Please do not install the sewing machine near the equipments,such as Television, 音機或無線電話等,否則這些設備可能會對 縫紉機的電子干擾所影響。( 圖 5) Radio,or Wireless Telephone.Or these equipments will experience electronic interference.(Fig.5) 2. 應將縫紉機直接插入 AC 電源插座,如果使 2. -

Page 15: Specifications

Introduction SPECIFICATIONS 規格 1. 型號分類表示 : 1.Description: 514 M 2 2 4 (6) (7) (1) 表示線數分 737、747、757、767 (1)Thread numbers / Four types: (2) 機種別 737、747、757、767 (3) 縫合方式 ( 圖表 1) (2)Machine type (3)Sewing type(Chart1) 型式 Type 514+401 圖形 Pattern 圖表 1 / Chart1 (4) 車縫布料... - Page 16 2. 規格說明 ( 表 1) 2. Specification(Tab.1) 機型 Model 700LD 最高縫速 Max Stitch Speed 7500rpm / 7500rpm 82 分貝以下 under 82 dB 噪音值 Noise Level (6500 rpm 測試數值 test value) 縫距 Stitch Length 4 / 5 / 6 mm 針棒行程 Stroke of the needle bar 24.3 ±0.2 mm 押具揚程...

-

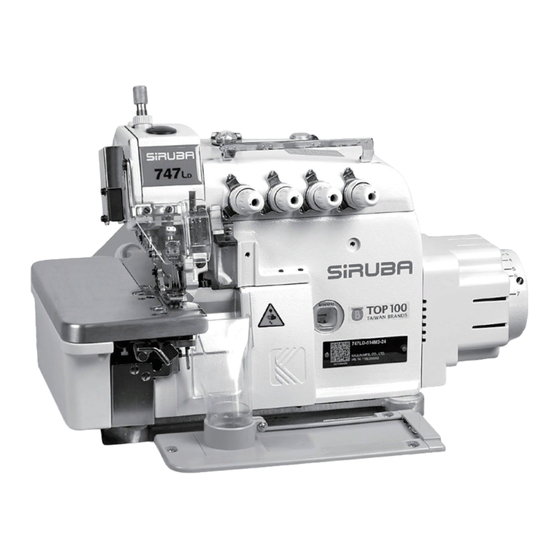

Page 17: Names Of Major Parts

Introduction NAMES OF MAJOR PARTS 各部件名稱 圖 6 / Fig. 6 (1) 押具扳手 ( 圖 6) (1)Lifting lever (Fig. 6) (2) 押具 (2)Presser foot (3) 線架 (3)Thread stand (4) 油窗 (4)Oil gauge window (5) 手輪 (5)Pulley (Hand Wheel) -

Page 18: Installation

INSTALLATION 安裝 1. 縫紉機拆箱搬運過程中,不可扶持布板蓋 1. While moving the sewing machine, please do not hold the below side of the cloth ①。( 圖 7) cover ① .(Fig. 7) 圖 7 / Fig. 7... - Page 19 Introduction 2. 依本機所附桌板裁製圖及零件組合圖所列之 2. Please refer to the attached table cut- 配件,依序安裝防震基座 ②。 ( 圖 8) out diagram and the parts list to orderly assemble the cushion Foundation ② . (Fig.8) 圖 8 / Fig. 8 3. 裝置導布屑及線架。( 圖 9) 3.

-

Page 20: Lightening Equipment

4. 馬達啟動踏板 ① 裝於左邊。( 圖 10) 4. Assemble the motor starting pedal ① to the left side. ( Fig.10) 本體與桌板不得干涉 The machine cannot touch the table. 圖 10 / Fig. 10 LIGHTENING EQUIPMENT 照明設備 Thoughtful lightening equipment is deigned for 貼心使用者設計的照明機構,其採用不發熱、... -

Page 21: How To Operate The New Machine

Introduction HOW TO OPERATE THE 新機器使用規定 NEW MACHINE 1. Please operate this machine in 80% of the 1. 新機器在最初啟用磨合期的四個星期內,請 用低於最高速度 20% 的速度運轉,之後換上 maximum speed in the first four weeks for engagement. After four weeks, please do 新潤滑油,才運轉至最高速度。 2. 定 期 之 清 潔 保 養, 確 保 延 長 機 器 之 使 用 壽 not operate under the maximum speed until replacing the new lubrication oil. - Page 22 2. 潤滑油之更換 ( 圖 13) 2.Drainage and refill the oil :(Fig. 13 ) (1) 將螺絲②放鬆旋開,使油槽內的油完全排出 (1)Loosen the screw ② and drain all the oil inside the oil tank. Then, tighten the screw 後再將螺絲②鎖緊。 ② again. (2) 為延長本機器之壽命,請於開始使用後四個 (2)In order to extend the term of usage, please replace the oil after the first four week, and 星期更換新油,爾後約每四個月更換一次。...

-

Page 23: Threading The Machine

Introduction THREADING THE MACHINE 穿線方式 • 請確實按照圖示穿線,錯誤之穿線將引起斷 • Follow the procedures for threading. Wrong threading may cause thread breaking, stitch 線、跳針或車縫不平…‥等現象。 skipping, puckering or unexpected sewing. 1.737 用穿線圖 ( 圖 15) 1. For three thread only 737(Fig. 15) 圖 15 / Fig. 15 2.747 用穿線圖... -

Page 24: Adjust Thread Tension

3.767 用穿線圖 ( 圖 18) 3. For five thread only 767(Fig. 18) 圖 18 / Fig. 18 ADJUST THREAD TENSION 控線調整 The thread tension should be adjusted 線張力必須根據縫合布料種類,布料厚薄,線 properly according to the kinds and the 及包邊寬度等之差異而做不同的調整。順時針 thickness of the materials, stitch length, 旋轉張力控制螺帽,縫線張力加大,反之減弱。... - Page 25 Introduction 弱 Weak 強 Sreong 圖 19 / Fig. 19 2. 針線控線關係 ( 圖 20 ) 2.Needle thread control. (Fig. 20) (1) 縫合方式 504、512、514 時,將過線組件 (1)When the sewing type is set to 504, 512 ⑥ 移至最下端,縫合方式 516 時,則將過 or 514 , move the threading part ⑥ to the lowest part.

- Page 26 3. 勾針控線關係 ( 圖 21) 3.Looper thread control.( Fig. 21) (1) 若縫合方式 504,上勾針移至最低時,將 (1) When the sewing type is 504 and the upper ⑨ 及 ⑩ 調至 + 位置。 looper is on the lowest point, adjust ⑨ and (2) 固定線導板 如下...

-

Page 27: Replace The Needle

Introduction REPLACE THE NEEDLE 換針方式 1. 使用 DCX27 或同規格之針。 1.Please use the needle DCX27 or the equivalents. 2. 旋開螺絲 ① 並取下針。 3. 將新針插至針孔最底端,並使針之溝面向自 2.Loosen the screw ① and take off the needle. 己,固定螺絲 ①。( 圖 23) 3.Insert the new needle till reaching the end, as well as the long groove faces your side. -

Page 28: Adjust The Differential Feed Ratio

ADJUST THE DIFFERENTIAL 差動比調整 FEED RATIO If the stroke of the main feed dog is larger 若主送具之運動行程大於差動送具運動行程 than the stroke of the differential feed dog, 時,布料車縫時會伸張,反之則會收縮。 1. 調整方法一: the fabric will be extended while sewing. Otherwise, it will be shrunk. 為放鬆調整鈕... -

Page 29: Replace The Trimmers

Introduction REPLACE THE TRIMMERS 更換切刀 1. 更換上切刀 1.Replace the upper trimmer: (1) 放鬆螺絲①將下刀座②向左邊推,輕鎖螺絲 (1)Loosen the screw ① and move the lower trimmer holder ② to the left. Then, tighten ① 。 (2) 取下螺絲③換上新刀片後,輕輕鎖緊螺絲③ the screw ① a little. (2)Remove the screw ③ and put the new 。... -

Page 30: Adjust The Hem Width

ADJUST THE HEM WIDTH 包邊寬度調整 1. Turn the pulley to move the upper trimmer to 1. 轉動手輪,將上刀移至下死點。( 圖 28) the lower dead point. (Fig.28) 2. 放鬆螺絲①,向左移動下刀座疊②後,暫時 2. Loosen the screw ①and move the lower 輕鎖螺絲①。 trimmer holder ② to the left, and then 3. -

Page 31: Adjust The Needle Height

Introduction ADJUST THE NEEDLE HEIGHT 針高度之調整 1. 轉動手輪使針上昇至最高點時,針尖至針板 1.The (a) is the distance from the needle tip 面之距離為 (a)。( 圖 29) to the surface of the needle plate when the 2. 調整 : needle is rised to the highest point after (1) 打開上蓋①。... - Page 32 強 Sreong 弱 Weak 圖 30 / Fig. 30 2. 押具提升量調整 2. Adjust the lift amount of the presser foot. (1) 轉動手輪使送具降至針板下,押具底平貼針 (1)Rotate the pulley to move the feed dog downward until the feed dog is under the 板。 (2) 放鬆螺帽④,壓下拉桿⑥使押具上昇至適當 needle plate, as well as the bottom of the 位置約...

-

Page 33: Adjust The Feed Dog

Introduction ADJUST THE FEED DOG 送具調整 1. 送具高度調整 1.Adjust the feed dog height. (1) 轉動手輪使送具上升至針板上最高點。 (1)Rotate the pulley to rise the feed dog the (2) 放鬆螺絲①,上下移動主送具②,使其齒面 highest point of the needle plate. 高出針板面約 0.9~1.1mm,鎖緊螺絲①。 (2)Loosen the screw ① , and move the main (3) 放鬆螺絲③,上下移動差動送具④,使其齒... - Page 34 2. 送具水平調整 2. Adjust the feed dog horizontally. (1) 送具齒的齒面在運轉的循環中,必須保持針 (1)During operation, the teeth side of the feed dog should keep parallel with the surface of 板面成水平。 (2) 調整時放鬆螺絲⑤,旋轉後支軸 ⑥,齒面 the needle plate. 呈水平後固定螺絲⑤。( 圖 33) (2)For adjustment, loosen the screw ⑤ , and rotate the rear support shaft ⑥.

-

Page 35: The Relationship Between Needle And Looper

Introduction THE RELATIONSHIP BETWEEN 針與勾針之關係 NEEDLE AND LOOPER 1. 針與上勾針之關係 1.The relationship between the needle and the When the upper looper moves to the leftest 當上勾針移至最左時,勾針尖端與針中心距 約 4.4 ~ 4.7mm ,雙針時其左針中心與勾 point, the distance from the looper tip to the 針尖端距約... - Page 36 (2) 當下勾針向右移至針中心時 ( 雙針以左針 (2)The relationship between the needle and 為主 ) 針與勾針之間隙為 0~0.05mm。 the middle line of the needle (use the left ( 圖 37) needle as standard when it's double needle model), the clearance between them should be 0 ~ 0.05mm.( Fig.37) 0~0.05mm 圖...

-

Page 37: Adjust The Chainstitch Looper Movement Amount

Introduction 5. 針與檔針片之關係 5.The relationship between the needle and the (1) 當下勾針由左向右至針中心時 ( 雙針以左針 needle guard. 為主 ) 針與後檔針片之間隙為 0~0.05mm。 (1)When the lower looper moves from left to (2) 當針在下死點時針與前檔針片之間隙為 right to the central line of the needle (when 0.1~0.2mm。( 圖 40) it's double needle model, it means the left needle), the clearance from the needle to the rear needle guard is 0 ~ 0.05 mm. - Page 38 ELECTRIC 電眼 新型電眼共分為三段式感應電眼: ( 圖 42) The new electric sensors:( Fig.42) 1. 前電眼 - 自動車縫感應電眼 1.Front electric sensor – Automatic seaming electric eye sensors 功能: (1) 無布料時不運轉,保護操作者安全。 Function: (2) 自動起壓腳動作。 (1)The machine will deactivate without the (3) VTE/CTE 吸風啟動。 fabrics to ensure effective and safe (4) 組件入料,線上組裝方便,節省組裝工...

- Page 39 Introduction 3. 後電眼 3.Rear electric sensor Function: 功能: (1) 保護布料不會被切刀誤切。 (1)Rear cutter trigger by the programmed (2) 後切針數計數。 needle numbers. (2)Avoid wrong cutting of the fabrics. ※ 電眼透明外殼不可以尖銳工具刮傷,可能產 ※Don't damage the clear case of electric 生電眼辨識不正確問題。 sensor by tools with sharp tips. Damaged case may result in incorrect detection for electric sensor.

-

Page 40: Safety Device

TAPE / THREAD CUTTER 切刀開關 BUTTON SWITCH ECA/ECB 手動切刀按鈕: ECA/ECB button switch – manual mode Push the button to activate the cutter manually 當馬達停止時,按壓一下開關,切刀動作一次。 ( 圖 43) when the motor stop working. ( Fig.43) 圖 43 / Fig. 43 SAFETY DEVICE 安全開關... - Page 41 Introduction 2. 壓腳安全開關 2.Presser foot lifter Safety device To ensure the safety operation during 穿線或調整機台時,將壓腳移出即進入保護 模式,無法運轉,確保作業人員安全。 ( 圖 threading and machine adjustment.( Fig.45) 圖 45 / Fig. 45 ILLUSTRATION TO OPEN THE 勾針蓋開關方向示意圖 LOOPER COVER Put the thumb on the entrance of the fabric 在開勾針蓋時,會將布屑吸入口向右滑,將拇...

-

Page 42: Wiring Diagram

WIRING DIAGRAM 接管圖位置圖 FOR ECA / VTA FOR VTE/CTE FOR BKT ECA / BKT Wring Diagram FOR VTA... - Page 43 Introduction DEMOLITION PROCEDURE 報廢流程 1. 當機器需要被淘汰與報廢時,有一些基本規 1.When the machine needs to be eliminated and demolished, certain basic rules must 則必須採納、遵守以保護環境及公眾健康。 2. 所有的機器零組件必須依照下列分類來區分 be observed to protect the environment and public health. 開: 2.All machine componenets must be divided (1) 所有護套、可伸縮軟管及塑膠或非金屬零 according to categories as the followings: 件。...

- Page 44 LIGHTENING OF THE 操作環境照明 OPERATION ENVIRONMENT CONDITIONS OF ALL 操作者條件 OPERATORS...

-

Page 45: Maintenance

Introduction MAINTENANCE 保養... -

Page 46: Troubleshooting

TROUBLESHOOTING 故障檢修... - Page 47 Introduction...

- Page 49 Introduction...

- Page 51 Introduction...

- Page 54 由於對產品的改良及更新 , 本產品使用說明書中與零件圖之產品及外觀的修改恕不事先通知 ! The specification and/or appearances of the equipment described in this instruction book & parts list are subject to change because of modification which will without previous notice. KZ08LD-1.JUL.2017...

Need help?

Do you have a question about the 700LX and is the answer not in the manual?

Questions and answers

Error 20 solution?