Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kemppi Flexlite GX Series

- Page 1 Flexlite GX Operating manual - EN Flexlite GX © Kemppi 2/49 1921390 / 2002...

-

Page 2: Table Of Contents

6.4 Technical data: Flexlite GX 400A (gas-cooled) 6.5 Technical data: Flexlite GX 300A/400A/420A (water-cooled) 6.6 Technical data: Flexlite GX 500A/520A (water-cooled) 6.7 Technical data: Flexlite GX 600A (water-cooled) 6.8 Component selection 7. Ordering codes © Kemppi 3/49 1921390 / 2002... -

Page 3: General

Operating manual - EN 1. GENERAL These instructions describe the use of Kemppi's Flexlite GX MIG welding guns. Flexlite GX welding guns are designed for professional manual welding. Flexlite GX range covers both water-cooled and gas-cooled models for MIG welding. Flexlite GX welding guns are available in three different levels – K3, K5 and K8 – each designed to serve specific welding needs. - Page 4 * K3 level welding gun models are compatible with the majority of welding equipment. ** K5 level welding gun models are designed for Kemppi Fastmig equipment with limited support to other models. *** K8 level welding gun models are compatible with Kemppi X8 MIG Welder.

-

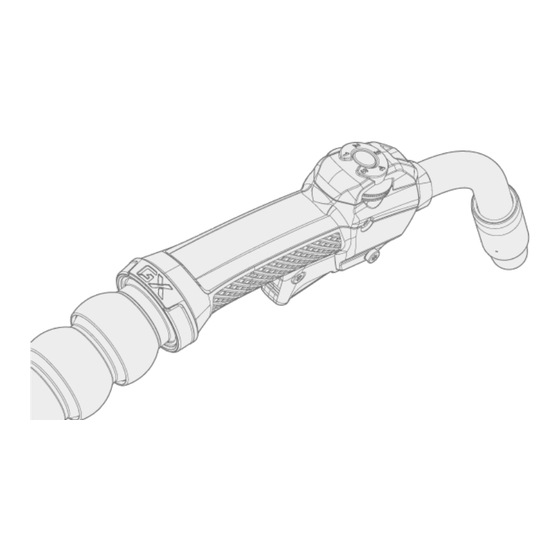

Page 5: About Equipment

"Installing gun remote" on page 10. >> Not available with Flexlite GX K3 level models. Gun connector Coolant inlet and outlet hose connectors >> With water-cooled welding guns only. 10. Neck tightening collar >> With multi-neck welding guns only. © Kemppi 6/49 1921390 / 2002... - Page 6 The serial number and other device-related identification information may also be saved in the form of a QR code (or a barcode) on the device. Such code can be read by a smartphone camera or with a dedicated code reader device providing fast access to the device-specific information. © Kemppi 7/49 1921390 / 2002...

-

Page 7: Installation

Before installation and use Ensure compliance with your local and national safety requirements regarding the installation and use of high voltage units. Check the contents of the packages and make sure the parts are not damaged. © Kemppi 8/49 1921390 / 2002... -

Page 8: Assembling Gun

With multi-neck gun models only: Attach the assembled neck to the gun body. Secure with the neck tightening collar. Hand-tighten the neck tightening collar only. Over-tightening and/or using a tool can damage the gun components. © Kemppi 9/49 1921390 / 2002... -

Page 9: Installing Gun Remote

The Flexlite GX K5 level welding gun remote can be used with Kemppi Fastmig equipment only. The Flexlite GX K8 level welding gun and digital gun remote can be used with Kemppi X8 MIG Welder only. Ensure that the welding equipment is not connected to the mains or that the welding gun is not connected at this stage. - Page 10 Set the new gun remote control cover against the gun body slightly off to the front and slide it backward so that the connectors (*) align and connect. Secure the remote control cover in place with the screws from the sides. © Kemppi 11/49 1921390 / 2002...

-

Page 11: Connecting Gun

Water-cooled models only: Connect the coolant inlet and outlet hoses to your welding equipment. Note that the connectors are color-coded. Make sure to connect the coolant hoses to the correct hose connectors. If the connections cross, the welding gun may overheat. © Kemppi 12/49 1921390 / 2002... -

Page 12: Installing And Replacing Wire Liner

The filler wire must be removed before the wire liner replacement. Tools needed: Straighten the welding gun cable pack. At the wire feeder end of the cable, remove the wire liner's short guide tip, sleeve and cone. © Kemppi 13/49 1921390 / 2002... - Page 13 Tip: The wire liner needs to be cut exactly at the edge of the liner sleeve. To get the best possible result, mark and cut the wire liner already before securing the liner sleeve. © Kemppi 14/49 1921390 / 2002...

- Page 14 Insert the short guide tip to the end of the liner sleeve and secure it in place. All K8 level Flexlite GX models include a longer wire liner sleeve and the K8 level gas-cooled models also an additional sealing ring (*): © Kemppi 15/49 1921390 / 2002...

-

Page 15: Installing And Replacing Wire Liner For Multi-Neck

With Flexlite GX multi-neck welding guns the wire liner needs to be replaced separately for the neck. For more information on wire liner replacement in general, refer to "Installing and replacing wire liner" on page 13. Remove the neck. Release the neck liner fastener and remove the old neck wire liner. © Kemppi 16/49 1921390 / 2002... - Page 16 Insert the new neck wire liner into the neck and secure with the fastener. Attach the assembled neck to the gun body. Secure with the neck tightening collar. Hand-tighten only. Over-tightening and/or using a tool can damage the gun components. © Kemppi 17/49 1921390 / 2002...

-

Page 17: Trigger Switch Replacement

In normal use, the trigger switch replacement is not a frequent task. However, removing the trigger switch tem- porarily may be necessary, for example, when using a K5 level Flexlite GX welding gun with other than Kemppi Fast- mig equipment. - Page 18 To reinstate the trigger switch or to install a replacement trigger switch, repeat the previous steps in reverse. Use caution when connecting the wiring connector. Wrong alignment and/or too much force may damage the con- nector pins. © Kemppi 19/49 1921390 / 2002...

-

Page 19: Trigger Switch Setting (K5 Level)

3.7 Trigger switch setting (K5 level) K5 level Flexlite GX welding guns are designed and set up for Kemppi Fastmig equipment. The trigger switch setting described here, provides only limited support for other than Kemppi Fastmig welding equipment. Use this option with caution. -

Page 20: Installing And Removing Grip Handle (Optional)

Keeping the bottom of the grip handle pointing forward, fit the inside grooves of the grip handle over the screws on the gun. Pull the handle backward to lock it in position. To remove the grip handle, press the unlock button in the grip handle rear: © Kemppi 21/49 1921390 / 2002... -

Page 21: Adjusting And Tightening Neck (Gas-Cooled Models)

Tighten or loosen the neck retaining nut with a spanner so that it is either possible to adjust the neck position by hand or tighten the nut so that it secures the neck into the desired welding position. © Kemppi 22/49... -

Page 22: Operation

"Using gun remote (K5 level)" on the next page "Using gun remote (K8 level)" on page 25 For more information on component selection and availability, refer to "Component selection" on page 47 and "Ordering codes" on page 49. © Kemppi 23/49 1921390 / 2002... -

Page 23: Using Gun Remote (K5 Level)

4.1 Using gun remote (K5 level) The Flexlite GX K5 level welding gun remote can be used with Kemppi Fastmig equipment only. Adjust the wire feed speed or change the memory channel by turning the roller switch on the gun handle. -

Page 24: Using Gun Remote (K8 Level)

4.2 Using gun remote (K8 level) The K8 level Flexlite GX welding gun and digital gun remote can be used with Kemppi X8 MIG Welder only. With the K8 level Flexlite GX remote control, you can select memory channels and WPSs (Welding Procedure Spe- cifications), and adjust wire feed speed, fine tuning and dynamics. - Page 25 Flexlite GX Operating manual - EN System error. Welding is disabled. © Kemppi 26/49 1921390 / 2002...

-

Page 26: Maintenance

• Check regularly that all the components are tightly fastened. • Check that the current transfer surface on the Kemppi gun adapter is clean and unscratched, and the connector pins are straight and undamaged. • Check the protective hose on the cable for damage. - Page 27 Flexlite GX Operating manual - EN • Maintenance test • Test and calibration of operation and performance values when needed. Find your closest service workshop at Kemppi website. © Kemppi 28/49 1921390 / 2002...

-

Page 28: Troubleshooting

5.1 Troubleshooting The problems and the possible causes listed are not definitive, but suggest some typical situations that may turn up during normal use of the welding system. For further information and assistance, contact your nearest Kemppi service workshop. General: The welding system does not power up •... - Page 29 Flexlite GX Operating manual - EN • Make sure you are using original Kemppi consumable and spare parts. Incorrect spare part materials may cause the overheating of the neck. The welding gun connector overheats • Make sure the connector is properly connected to the wire feeder.

-

Page 30: Disposal Of Machine

The owner of the equipment is obliged to deliver a decommissioned unit to a regional collection center, as per the instructions of local authorities or a Kemppi representative. By applying these European Directives you improve the environment and human health. -

Page 31: Technical Data

"Technical data: Flexlite GX 500A/520A (water-cooled)" on page 43 "Technical data: Flexlite GX 600A (water-cooled)" on page 45 For component selection, refer to "Component selection" on page 47. For ordering codes, refer to "Ordering codes" on page 49. © Kemppi 32/49 1921390 / 2002... -

Page 32: Technical Data: Flexlite Gx 200A/250A (Gas-Cooled)

-20°C…+40°C -20°C…+40°C -20°C…+40°C Storage temperature range -40°C…+60°C -40°C…+60°C -40°C…+60°C Pistol grip handle Rotating neck Changeable neck Neck dimensions: Length x (mm) ( see figure below ) Height y (mm) ( see figure below ) © Kemppi 33/49 1921390 / 2002... - Page 33 IEC 60974-7 IEC 60974-7 IEC 60974-7 Gun length (m) 3.5 / 5 3.5 / 5 3.5 / 5 * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 34/49 1921390 / 2002...

-

Page 34: Technical Data: Flexlite Gx 300A/350A (Gas-Cooled)

0.9...1.2 0.8...1.2 0.8...1.2 0.8...1.2 Ss-MC/FC 0.9...1.2 0.9...1.2 0.9...1.2 0.8...1.2 0.8...1.2 0.8...1.2 Operating temperature range 20°C…+40°C 20°C…+40°C 20°C…+40°C 20°C…+40°C Storage temperature range 40°C…+60°C 40°C…+60°C 40°C…+60°C 40°C…+60°C Pistol grip handle Rotating neck Changeable neck Neck dimensions: © Kemppi 35/49 1921390 / 2002... - Page 35 IEC 60974-7 IEC 60974-7 Gun length (m) 3.5 / 5 3.5 / 5 6 / 8 3.5 / 5 * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 36/49 1921390 / 2002...

-

Page 36: Technical Data: Flexlite Gx 250A/300A (Water-Cooled)

Operating temperature range -20°C…+40°C -20°C…+40°C Storage temperature range -40°C…+60°C -40°C…+60°C Pistol grip handle Rotating neck Changeable neck Neck dimensions: Length x (mm) ( see figure below ) Height y (mm) ( see figure below ) © Kemppi 37/49 1921390 / 2002... - Page 37 Neck angle ɑ (°) ( see figure below ) Standards IEC 60974-7 IEC 60974-7 Gun length (m) 3.5 / 5 * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 38/49 1921390 / 2002...

-

Page 38: Technical Data: Flexlite Gx 400A (Gas-Cooled)

Operating temperature range -20°C…+40°C -20°C…+40°C Storage temperature range -40°C…+60°C -40°C…+60°C Pistol grip handle Rotating neck Changeable neck Neck dimensions: Length x (mm) ( see figure below ) Height y (mm) ( see figure below ) © Kemppi 39/49 1921390 / 2002... - Page 39 Neck angle ɑ (°) ( see figure below ) Standards IEC 60974-7 IEC 60974-7 Gun length (m) 3.5 / 5 3.5 / 5 * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 40/49 1921390 / 2002...

-

Page 40: Technical Data: Flexlite Gx 300A/400A/420A (Water-Cooled)

0.9...1.6 0.9...1.6 0.8...1.6 1.0...1.2 0.8...1.6 1.2...1.6 Ss-MC/FC 0.9...1.6 0.9...1.6 0.8...1.6 1.2...1.6 0.8...1.6 1.2...1.6 Operating temperature range 20°C…+40°C 20°C…+40°C 20°C…+40°C 20°C…+40°C Storage temperature range 40°C…+60°C 40°C…+60°C 40°C…+60°C 40°C…+60°C Pistol grip handle Rotating neck Changeable neck © Kemppi 41/49 1921390 / 2002... - Page 41 IEC 60974-7 IEC 60974-7 IEC 60974-7 Gun length (m) 3.5 / 5 6 / 8 3.5 / 5 * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 42/49 1921390 / 2002...

-

Page 42: Technical Data: Flexlite Gx 500A/520A (Water-Cooled)

-20°C…+40°C Storage temperature range -40°C…+60°C -40°C…+60°C Pistol grip handle Rotating neck Changeable neck Neck dimensions: Length x (mm) ( see figure below ) 145 / 245 Height y (mm) ( see figure below ) © Kemppi 43/49 1921390 / 2002... - Page 43 Neck angle ɑ (°) ( see figure below ) Standards IEC 60974-7 IEC 60974-7 Gun length (m) 3.5 / 5 3.5 / 5 * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 44/49 1921390 / 2002...

-

Page 44: Technical Data: Flexlite Gx 600A (Water-Cooled)

Operating temperature range -20°C…+40°C -20°C…+40°C Storage temperature range -40°C…+60°C -40°C…+60°C Pistol grip handle Rotating neck Changeable neck Neck dimensions: Length x (mm) ( see figure below ) Height y (mm) ( see figure below ) © Kemppi 45/49 1921390 / 2002... - Page 45 Operating manual - EN Neck angle ɑ (°) ( see figure below ) Standards IEC 60974-7 IEC 60974-7 Gun length (m) * Measured using the longest gun length available. Neck dimensions, G-models: Neck dimensions, W-models: Neck dimensions, MN-models: © Kemppi 46/49 1921390 / 2002...

-

Page 46: Component Selection

GX 405WS L57 / OD25 / D15 / threaded GX 428W L61 / OD25 / D16 / threaded 1.0C1 M10 GX 428W N250 GX 208GMN L57 / OD25 / D15 / threaded GX 308GMN © Kemppi 47/49 1921390 / 2002... - Page 47 L60 / OD28 / D15 / threaded The letters in the gas nozzle specification stand for: L = length, OD = outer diameter (at the widest point), D = diameter (inner diameter of the gas nozzle tip). © Kemppi 48/49 1921390 / 2002...

-

Page 48: Ordering Codes

Flexlite GX 428W GX428W35 GX428W5 Flexlite GX 428WS GX428WS8 Flexlite GX 528W GX528W35 GX528W5 Flexlite GX 608W GX608W5 Flexlite GX 428W (250 mm neck) GX428W35N250 GX428W5N250 Flexlite GX 528W (250 mm neck) GX528W35N250 GX528W5N250 © Kemppi 49/49 1921390 / 2002... - Page 49 Flexlite GX Operating manual - EN Flexlite GX remotes (optional) Product Ordering code GXR10 gun remote, K5 level GXR10 GXR80 gun remote, K8 level GXR80 © Kemppi 50/49 1921390 / 2002...

Need help?

Do you have a question about the Flexlite GX Series and is the answer not in the manual?

Questions and answers