Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Kemppi MagTrac F 61

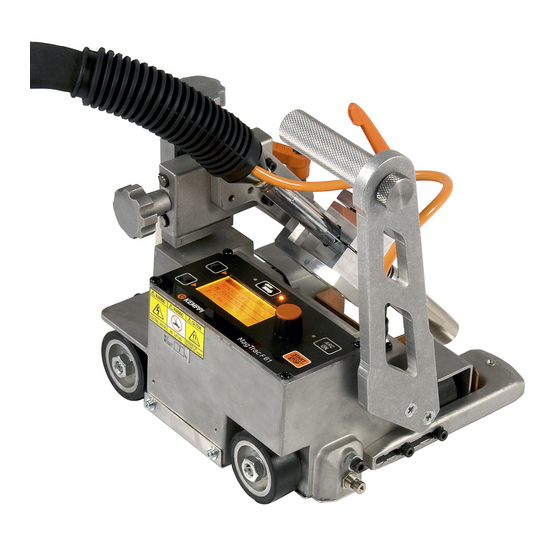

- Page 1 MagTrac F 61...

- Page 3 OPERATING MANUAL English...

-

Page 4: Table Of Contents

3.3.1 MagTrac F 61 main menu .................... -

Page 5: Introduction

MagTrac F 61 is a welding carriage for mechanisation of longitudinal MIG/MAG welding applications. Used in combination with the high quality process control system of Kemppi FastMig welding equipment, the MagTrac F 61 is an easy and efficient way of improving the welding productivity and quality. -

Page 6: Product Parts

PREPARING THE CARRIAGE FOR USE Welding machine connections To use the MagTrac F 61, you need a FastMig power source, wire feeder, and a shielding gas cylinder or other source of shielding gas appropriate for your welding task. MagTrac F 61... -

Page 7: Magtrac F 61 Connections

MagTrac F 61 connections Attach the welding power cable to the Euro connector and the control cable to the data connector either in the wire feeder unit or in Kemppi SuperSnake subfeeder. See the pictures below. To connect the welding gun to MagTrac device: The MagTrac F 61 is equipped with Kemppi's unique welding gun quick-fixing mechanism. - Page 8 To fine adjust the gun position, change the distance and height of the welding gun with the adjustment knobs (see the picture). You can use the fine adjustment knobs also when the carriage is moving. NOTE! MagTrac F 61...

-

Page 9: Working Environment

Working environment Kemppi MagTrac F 61 welding carriage is equipped with a strong magnet that keeps it steadily in it's track also if you drive the device uphill or downhill. You can also use the MagTrac F 61 on curved surfaces. - Page 10 Wide range of adjustments MagTrac F 61 offers a wide range of adjustments. For example, you can turn the guide roller arms 180° to point outwards if you need to improve visibility to the welding arc, or you can swing the welding gun over the side (see the picture).

-

Page 11: Using The Control Panel

• Press this button to turn the welding arc on and off. With the welding arc off, you can test the carriage operation When making selections in the MagTrac F 61 menu, you can use a quick shortcut: Turn and NOTE! press the multi-function knob 1 instead of pressing soft keys 2 and 3. -

Page 12: Control Panel Menus

• The selected active menu items are marked with a solid box. • The Selected inactive menu items are marked with a dotted box. You cannot changed the values of these menu items. 3.3.1 MagTrac F 61 main menu Menu item Description MEMORY CH Load and save memory channels. -

Page 13: Memory Channel Selections (Memory Ch)

To change welding current, do the following Press the multi-function knob on the CURRENT menu item. Turn the multi-function knob to change the current value. Press the multi-function knob to accept the new current. © Kemppi Oy / R01... -

Page 14: Welding Voltage Selections (Voltage)

STOP. 3.3.10 Wire inch selections (WIRE INCH) Select this menu item to run the filler wire into the welding gun. In MagTrac F 61, the wire inch speed is always the same as the selected wire feed speed. If the wire inch function is activated on the wire feeder's panel, the wire inch function on NOTE! MagTrac is not available. -

Page 15: Weld Data Selections (Weld Data)

Heat input in the latest welding session in kJ/mm. RESET WELD DATA This resets all weld data settings. 3.3.12 Setup selections (SETTINGS) Select this menu to check or change the MagTrac F 61 settings. The settings are stored in the carriage memory. Menu item Values Description Change the contrast of the carriage display. -

Page 16: Disposal Of The Machine

The owner of the equipment is obliged to deliver a decommissioned unit to a regional collection centre, per the instructions of local authorities or a Kemppi representative. By applying this European Directive you will improve the environment and human health. - Page 17 SuperSnake GT 02SC 15 m 61531501 FastMig KMS 300 power source 6053000 FastMig MXF 63 wire feeder 6152300 MMT 42 C welding gun 4.5 m 6254207 Control extension cable W005871 MT51MWC welding gun 4,5 m 6255162 © Kemppi Oy / R01...

-

Page 18: Technical Data

TECHNICAL DATA MagTrac F 61 Input power 50 VDC / 1 A Data bus type KempBus Travel speed 150–1800 mm/min Towing power 30 kg Driving method Rail-less drive with permanent magnetic suction Wheels 4 rubber wheels Tracing method Guide rollers Guide roller height range 10–38 mm, 3 positions... - Page 20 www.kemppi.com...

Need help?

Do you have a question about the MagTrac F 61 and is the answer not in the manual?

Questions and answers