Broaster 1600 Service Manual

Solid state pressure fryer

Hide thumbs

Also See for 1600:

- Service manual (131 pages) ,

- Operation manual (57 pages) ,

- Installation manual (56 pages)

Table of Contents

Advertisement

Quick Links

"An American Tradition Since 1954!"

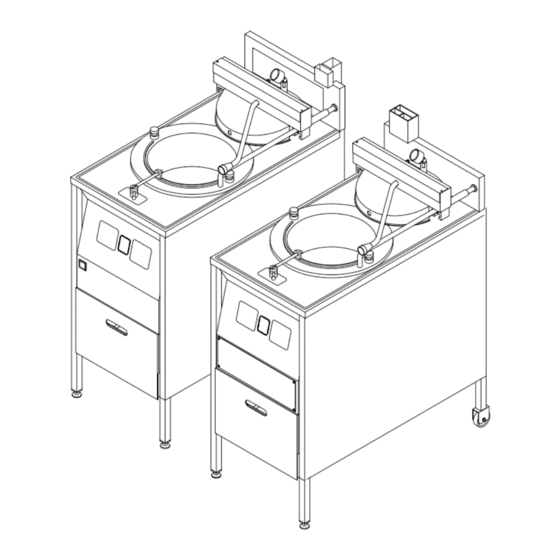

MODEL 1600 AND 1800 SOLID STATE

®

BROASTER

PRESSURE FRYER

SERVICE MANUAL

1988 THRU 1998

Be sure ALL installers read, understand, and have access to this manual at all times.

Broaster®, Broasted®, Broasted Chicken®, Broaster Foods®. and Broasterie® are registered trademarks.

Usage is available only to licensed opertors with written authorization from The Broaster Comany.

The Broaster Company

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193 www.broaster.com

Design Certified By:

1600: CSA, NSF and UL 1800: CSA (AGA & CGA), NSF and UL

Copyright 2000 The Broaster Company

Printed in U.S.A.

13898 2/00 Rev 11/11

Advertisement

Table of Contents

Summary of Contents for Broaster 1600

- Page 1 Be sure ALL installers read, understand, and have access to this manual at all times. Broaster®, Broasted®, Broasted Chicken®, Broaster Foods®. and Broasterie® are registered trademarks. Usage is available only to licensed opertors with written authorization from The Broaster Comany. The Broaster Company 2855 Cranston Road, Beloit, WI 53511-3991 608/365-0193 www.broaster.com...

- Page 3 All adjustments and repairs shall be made WARNING: Rags or papers containing by an authorized Broaster Company repre- cooking oil can catch fire if exposed to sentative. heat. Laundering will not remove the oil. Dis-...

-

Page 5: Table Of Contents

TABLE OF CONTENTS 1 - WARNING SIGNS 1600.......................... 1 - 1 1800.......................... 1 - 4 2 - ELECTRIC POWER SUPPLY WIRING DIAGRAMS ....................2 - 1 3 - MECHANICAL CONTROL PANEL FAMILIARIZATION ....................3 - 1 ACCESS FOR SERVICE ..................3 - 2 INDICATOR LIGHTS .................... - Page 6 POWER ON INDICATOR LIGHT ..............4 - 16 SOLID STATE CONTROLLER................4 - 16 TEMPERATURE SENSOR PROBE ..............4 - 17 5 - 1600/1800E POWER INPUT BOX 5 - 1 CONTACTORS (1600/1800E) .................. 5 - 2 FUSE (1600/1800E) ....................5 - 3 HEATING ELEMENTS (1600/1800E)...............

- Page 7 11 - DRAIN VALVE AND FILTER SYSTEM DRAIN VALVE ......................11 - 1 FILTER PAN ......................11 - 2 CHECK VALVE....................... 11 - 3 MOTOR ........................11 - 4 PUMP ........................11 - 5 12 - TROUBLESHOOTING ELECTRICAL TIPS ....................12 - 1 CONTROLLER TIPS (SOLID STATE)..............

- Page 9 Broaster be sure all safety devices and warning signs Company representative or The Broaster are in place and legible. If not, The Broaster Company Service Department at 608/365- Company should be notified in writing of the 0193.

- Page 10 Item 1 - Part #10773 Item 2 - Part #11027 1 - 2 Manual #13898 2/00...

- Page 11 Item 3 - Part #10900 Item 6 - Part #06375 Item 7 - Part #12750 Item 4 - Part #11073 Item 8 - Part #16368 Item 5 - Part #11028 1 - 3 Manual #13898 2/00 Rev 3/06...

- Page 12 1800: 1 - 4 Manual #13898 2/00 Rev 3/06...

- Page 13 Item 1 - Part #10886 Item 2 - Part #11027 Item 3 - Part #11058 (1800GH Only) 1 - 5 Manual #13898 2/00...

- Page 14 Item 4 - Part #11746 (1800GH Only) Item 8 - Part #06375 Item 5 - Part #10900 Item 9 - Part #14463 Item 6 - Part #11073 (1800E Only) Item 10 - Part #16368 Item 7 - Part #11028 1 - 6 Manual #13898 2/00 Rev 3/06...

-

Page 15: Electric Power Supply

2 - ELECTRIC POWER SUPPLY DANGER: Many sections in this man- Perform the following if unit will not turn on: ual pertain to checking and repairing electrical components. High voltage will be 1. Disconnect main power supply. encountered in several instances. Only per- sons trained and equipped for checking high 2. - Page 16 1600/1800E MECH 208/240V: 2 - 2 Manual #13898 2/00 Rev 11/11...

- Page 17 1600/1800E 208/240V: 1600/1800E 480V: 2 - 3 Manual #13898 2/00 Rev 9/11...

- Page 18 1600/1800E Export: 2 - 4 Manual #13898 2/00 Rev 9/11...

- Page 19 1800G: 1800G & 1800GH: Effective: SG8H392750 2 - 5 Manual #13898 2/00 Rev 9/11...

- Page 20 1800G: Export 1800G & 1800GH Export: Effective: SG8H392750 2 - 6 Manual #13898 2/00 Rev 9/11...

-

Page 21: Mechanical Control Panel

3 - 1600 MECHANICAL CONTROL PANEL FAMILIARIZATION 1. Timer: Shows desired cooking time 6. Hi-Limit Control: Prevents oil tempera- ° and time countdown during a cook ture from exceeding 475 cycle. 7. Temperature Control: Regulates oil 2. Power Switch: Upper position allows temperature. -

Page 22: Access For Service

ACCESS FOR SERVICE 3. Remove two screws holding control panel (9) to the power input box. Tilt panel down so back is visible. 1. Disconnect main power supply. 2. Remove condensate pan and one screw from bottom of front panel. 3 - 2 Manual #13898 2/00 Rev 9/11... -

Page 23: Indicator Lights

INDICATOR LIGHTS COOK/FILTER SWITCH AND POWER ON SWITCH There are three indicator lights on the con- trol panel. Indicator lights will illuminate 1. See ACCESS FOR SERVICE. respectively when the POWER ON switch is on, COOK/FILTER switch is in COOK posi- 2. -

Page 24: Timer

2. With needle nose pliers, remove all 3. Turn timer knob to any number greater wires from switch (2 or 4). than zero. 3. Loosen hex nut (11) on rear of control 4. With needle nose pliers, disconnect panel. Remove small knurled nut (12) common (COM) wire terminal from from front of switch. -

Page 25: Hi-Limit Control

HI-LIMIT CONTROL 4. Remove capillary guard (13) from inside the cooking well. When the control opens, all controls are dis- abled. • Check cooking oil temperature one inch below oil surface in center of cooking well. If oil temperature is close to the desired cooking temperature, check for a faulty control. -

Page 26: Thermostat

10. Reconnect wires then mount new con- Replacement: trol. 1. See ACCESS FOR SERVICE. 11. Replace capillary guard. 2. OPEN cover. Drain cooking oil from 12. Return cooking oil into cooking well. cooking well. 13. Cook a load of product and check for leaks. - Page 27 5. Remove capillary guard (13) from 7. Pull control bulb (16) out of cooking inside the cooking well. well then remove control. 8. Insert new control bulb in same posi- tion as the original. Pull excess capil- lary (17) out of cooking well. Bend in the capillary must be large and smooth as possible.

-

Page 29: Solid State Pushbutton Control Panel

OFF and DO NOT attempt to operate adjusts time down rate to compensate until it has been serviced by an autho- for temperature fluctuations. rized Broaster Company representa- tive. 7. Valve Closed Indicator Light: Illumi- nates when pressure regulating valve Note: It is possible for this control to trip is CLOSED. -

Page 30: Access For Service

ACCESS FOR SERVICE 3. Remove screws holding controller (12) to the power input box. Tilt panel down so back is visible. 1. Disconnect main power supply. 2. Remove condensate pan and screw(s) from bottom of front panel. Pull out and down on bottom to remove. 3A - 2 Manual #13898 2/00 Rev 9/11... -

Page 31: Pushbutton Controller Programming

PUSH BUTTON CONTROLLER Response: Display alternates between number values for COOK TEMP, COOK PROGRAMMING TIME and LO. LO will disappear when cooking oil temperature has reached COOK CAUTION: Check oil level before TEMP value. turning cook/filter switch to COOK. Action: Turn cook/filter switch to COOK. Response: Display alternates between number values for COOK TEMP, COOK TIME and LO. -

Page 32: Warning Displays

CALIBRATION Cause: Gas valve (1800GH Only), contactor (1600/1800E Only) or faulty Calibration will be necessary when tempera- controller. ture sensor probe or controller is replaced. Calibrate using an accurate non-mercury PROB - Display will flash PROB if there is a test thermometer. -

Page 33: Solid State Control Panel Rotary Dial Familiarization

OFF and DO NOT attempt to operate until it has been serviced by an autho- Cook Temperature Button rized Broaster Company representa- tive. Cook Time Button Note: It is possible for this control to trip AUTO COMP (Automatic Time Com- during shipment. -

Page 34: Controller Programming

CONTROLLER PROGRAMMING Time: Action: Press cook time button twice CAUTION: Check oil level before turning within one second. cook/filter switch to COOK. Response: Programming mode has Action: Turn cook/filter switch to been entered. Flashing display reads COOK. “##:##.” (##:## = time value ie: 08:00) Response: Display alternates Action: If desired, turn rotary knob to between number values for cook tem-... -

Page 35: Access For Service

ACCESS FOR SERVICE 3. Remove screws holding controller (12) to the power input box. Tilt panel down so back is visible. 1. Disconnect main power supply. 2. Remove condensate pan and screw(s) from bottom of front panel. Pull out and down on bottom to remove. 4 - 3 Manual #13898 2/00 Rev 9/11... -

Page 36: Cook/Filter Switch

1. See ACCESS FOR SERVICE. Control effects each model differently when it opens: 2. Check all terminals and connections. 1600/1800E 1800G prior to SG8H392750: Refer to wiring diagram. All controls are disabled except the filter motor. 3. With needle nose pliers, disconnect center terminal from switch. - Page 37 Replacement: 10. Reconnect wires then mount new con- trol. 11. Replace capillary guard. 12. Return cooking oil to cooking well. 13. Cook a load and check for leaks. 14. Tighten smaller nut (6) if necessary. 1. See ACCESS FOR SERVICE. 2.

-

Page 38: Power On Indicator Light

POWER ON INDICATOR LIGHT SPEAKER Illuminates when cook/filter switch is turned Sounds an audible alert at the end of a to COOK. cooking cycle. Replacement: Replacement: 1. See ACCESS FOR SERVICE. 2. Disconnect wires. 1. See ACCESS FOR SERVICE. 3. Push down on light fixture (10) located behind control panel. -

Page 39: Solid State Controller

This probe is a thermocouple. It sends fluc- tuating millivolts to the controller which is 3. Remove POWER ON indicator light. translated into degrees of temperature. Replacement (1600/1800E): 1. See ACCESS FOR SERVICE. 2. Disconnect probe (14) wires. 3. OPEN cover. Drain cooking oil from cooking well. - Page 40 4. Remove capillary guard (15) inside of cooking well. 5. Remove basket guides (16) inside of cooking well. 6. With a dull tool such as a crescent wrench handle, pry top heating ele- ment inward far enough to slide bracket (17) away from temperature sensor probe (14).

- Page 41 Replacement (1800G and 1800GH): 10. Replace capillary guard. 1. Follow steps 1 through 4 under Replacement (1600/1800E). 11. Return cooking oil to cooking well. 2. Remove smaller nut (18). 12. See CALIBRATION. 3. Remove reducer fitting (19) from out- 13.

-

Page 42: Dual Display Control Familiarization

OFF and DO NOT attempt to operate until it has been serviced by an autho- 13. Numerical Keypad: Enters and adjusts rized Broaster Company representa- set point values. tive. 14. AUTO COMP (Automatic Time Com- Note: It is possible for this control to trip pensation) Set Button and Light: Indi- during shipment. -

Page 43: Controller Programming

CONTROLLER PROGRAMMING Action: If desired, press key pad num- bers to change displayed value in min- utes and seconds. Press Cook Time CAUTION: Check oil level before turn- Button to enter new value into memory. ing cook/filter switch to COOK. Response: Controller returns to idle Action: Turn cook/filter switch to mode. -

Page 44: Warning Displays

Action: Press cook temperature but- Cause: Faulty controller, gas valve ton again to return to idle mode. (1800GH Only) or contactor (1600/ 1800E Only). CALIBRATION PROB - Display will flash PROB if there is a problem with temperature sensor probe. -

Page 45: Access For Service

ACCESS FOR SERVICE 3. Remove screws holding controller (12) to the power input box. Tilt panel down 1. Disconnect main power supply. so back is visible. 2. Remove condensate pan and screw(s) from bottom of front panel. Pull out and down on bottom to remove. 4 - 13 Manual #13898 2/00 Rev 9/11... -

Page 46: Cook/Filter Switch

COOK/FILTER SWITCH HI-LIMIT CONTROL 1. See ACCESS FOR SERVICE. When controller opens, all controls are dis- abled except the filter motor. 2. Check all terminals and connections. Refer to wiring diagram. There are two ways to determine if the con- trol is faulty: 3. - Page 47 Replacement: 10. Reconnect wires then mount new con- trol. 11. Replace capillary guard. 12. Return cooking oil to cooking well. 13. Cook a load and check for leaks. 14. Tighten smaller nut (14) if necessary. 1. See ACCESS FOR SERVICE. 2.

-

Page 48: Power On Indicator Light

POWER ON INDICATOR LIGHT SOLID STATE CONTROLLER Illuminates when cook/filter switch is turned The controller regulates time and tempera- to COOK. ture. Replacement: Miscellaneous: Remove F/C jumper to dis- play temperature in Celsius. Replacement: Note: Within warranty, controller should be replaced as a whole: circuit board, trans- former, speaker and control panel. -

Page 49: Temperature Sensor Probe

6. With a dull tool such as a crescent translated into degrees of temperature. wrench handle, pry top heating ele- ment inward far enough to slide Replacement 1600/1800E: bracket (21) away from temperature sensor probe (19). Note where probe 1. See ACCESS FOR SERVICE. - Page 50 19. Cook a load and check for leaks. 20. Tighten smaller nut (14) if necessary. Replacement (1800GH): 1. Follow steps 1 through 4 under Replacement (1600/1800E). 2. Loosen compression nut (14). 3. Remove fitting (23) from outside of the cooking well. Leave reducer fitting (15) in place.

- Page 51 13. See CALIBRATION. 14. Cook a load and check for leaks. 15. Tighten smaller nut (14) if necessary. 4 - 19 Manual #13898 2/00 Rev 9/11...

-

Page 53: 1600/1800E Power Input Box

5 - 1600/1800E POWER INPUT BOX 1600 Pressure Fryer: 1800E Pressure Fryer: 5 - 1 Manual #13898 2/00... -

Page 54: Contactors (1600/1800E)

CONTACTORS (1600/1800E) 7. Disconnect main power supply. Primary contactor (1) is controlled by the cook/filter switch. This contactor opens if hi- limit opens. Secondary contactor (2) is con- trolled by the solid state controller. 1. See ACCESS FOR SERVICE. CAUTION: Check oil level before turning cook/filter switch to COOK. -

Page 55: Fuse (1600/1800E)

FUSE (1600/1800E) HEATING ELEMENTS (1600/1800E) Two 15 amp fuses protect the control and fil- ter circuits. All elements heat the oil when solid state controller calls for heat. If HEAT ON light is 1. See ACCESS FOR SERVICE. illumminated for long periods of time, this may indicate a faulty element or wire con- nection. - Page 56 2. Drain cooking oil from the cooking well. 7. Position element to allow removal of probe bracket (13). Lightly pry inward 1600: on top element if necessary. Slide probe bracket off the temperature sen- sor probe (14).

-

Page 57: Limit Switch

9. Install new element (8) in reverse mounting bracket is out of adjustment order. Use new element seals (15) or or switch is faulty. new O-rings (16) (effective: 1600- SE6D890763 or 1800E-SE8D891133) Adjustment: located between element and inside of the cooking well. -

Page 59: Cover And Yoke

6 - COVER AND YOKE PROPER COVER OPERATION Note: Always fully rotate cover handle (2) OPEN or CLOSED. • Never use force to OPEN the cover. OPEN only when no pressure is present in the cooking well. If cover will not open easily: •... - Page 60 sure in cooking well pushes up on the cover. 6 - 2 Manual #13898 2/00...

-

Page 61: Familiarization

FAMILIARIZATION Centering Cover: ADJUSTMENTS This is important for prevention of steam leaks and keeping O-ring wear to a mini- Height Adjustment: mum. Proper alignment of the left side yoke latch Note: It is important warning sign (8) be (6) and latch column (7) is essential. placed back into its original position and Remove black cover and turn set screw in or screw replaced after making this adjust-... -

Page 62: Removal

2. Remove front panel (11). Remove bolt right. (12) from bottom of slide rod, remove bolt from back of slide rod (1600) and 3. Remove two cover bolts (9) in top of remove rod (13). Complete assembly splash shield (10). -

Page 63: Assembly

4. Place yoke bar over spacer block and cover. Line holes up and install cover bolts but do not tighten. 5. Install slide rod through bearings on right hand side of yoke bar. 6. Place assembly onto counter top. Place slide rod (13) into rear support and install bolt into front of slide rod. -

Page 64: Pressure Gauge

PRESSURE GAUGE SAFETY RELIEF VALVE Gauge indicates pressure within the cooking The safety relief valve opens in the event well. Operating pressure is 12-14 PSI. pressure in the cooking well meets relief pressure rating of the valve. DO NOT alter Replacement: or attempt to repair this valve. - Page 65 Note: DO NOT install valve discharge opening in the direction of foot traffic areas. 3. Apply teflon tape to threads. Screw new valve into the cover with valve dis- charge opening facing rear away from foot traffic as shown below. 6 - 7 Manual #13898 2/00...

-

Page 67: 1600 Pressure System

7 - 1600 PRESSURE SYSTEM DANGER: DO NOT attempt to • Overloading basket with product: Oil tighten, repair, or replace any fitting, level will raise too high. line or component unless main electric power is disconnected, pressure regulating • Breading then dropping: Excess coating valve is OPEN and cooking oil has cooled. -

Page 68: Exhaust Drain Tube

EXHAUST DRAIN TUBE Cleaning: Tube (1) drains condensation from exhaust tank into the condensate pan. EXHAUST TANK 1. Remove two screws, cover (4) and seal (5) from tank.. Steam and vapors are exhausted through this tank. 2. Scrape inside of tank clean. 3. -

Page 69: 1800 Pressure System

8 - 1800 PRESSURE SYSTEM DANGER: DO NOT attempt to • Overloading basket with product: Oil tighten, repair, or replace any fitting, level will raise too high. line or component unless main electric power is disconnected, pressure regulating • Breading then dropping: Excess coating valve (1) is OPEN and cooking oil has can collect in pressure regulating valve cooled. -

Page 70: Exhaust Drain Tube

EXHAUST DRAIN TUBE Cleaning: Tube (2) drains condensation from exhaust tank into the condensate pan. EXHAUST TANK 1. Remove exhaust drain tube (2) from bottom of the tank (3). Steam and vapors are exhausted through this tank. 2. Remove two screws from the stack (4) which mount tank to the unit. -

Page 71: Exhaust Tube

EXHAUST TUBE Tube (5) directs steam and vapors from cooking well into the exhaust tank. 8 - 3 Manual #13898 2/00... -

Page 73: Pressure Regulating Valve

9 - PRESSURE REGULATING VALVE 1600: REPLACEMENT 1. Disconnect main electric power supply. 2. Slide right hand squeeze clamp (2), on valve outlet, to the left. 3. Pull silicone sleeve and exhaust tube (3) free of valve outlet. 4. Remove two allen screws mounting valve to the cooking well and remove valve. - Page 74 Earlier Version: Later Version: Effective: SE8D891133 SE6D890763 SG8D891340 Note: Be sure flat end of spacer (4) is against piston (5). 9 - 2 Manual #13898 2/00...

-

Page 75: Repair And Cleaning

REPAIR AND CLEANING 8. Reassemble in reverse order. Lubri- cate all O-rings and contacting sur- faces with olive oil. 1. Remove silicone sleeve holding exhaust tube (3) to exhaust valve (1). 9. Mount valve assembly back on cooking well with the allen screws. 2. -

Page 77: 1800Gh Main Burner System

Propane: #41 HIGH ALTITUDE Standard gas units operate up to 2000 feet above sea level. Installations above this require a special main burner orifice. Con- tact The Broaster Company for orifice siz- ing. 10 - 1 Manual #13898 2/00... -

Page 78: Ventilation

VENTILATION Replacement: 1. Turn cook/filter switch, gas valve knob (1) and manual gas shut off valve (2) OFF. 2. Turn main gas supply OFF. 3. Disconnect main electric supply. • Never modify exhaust flue! Back pres- 4. Remove condensate pan and front sures from added extensions can cause panel. -

Page 79: Flame Adjustments

9. Loosen pipe union (10). 10. Remove piping from valve. 11. Effective SG8H392750, remove brass adapter (11) from faulty valve and install on new gas valve. WARNING: Be sure pilot burner gas supply line is fully installed into gas valve fitting during installation. If not, a gas leak may be the result. - Page 80 11. Turn gas valve knob to PILOT. Main Burner Flame: 12. Light pilot burner and turn gas valve Flame must be blue and sit on burner sur- knob ON. face. See AIR SHUTTER. During normal operation, a slight “ whoosing” sound may be 13.

-

Page 81: Air Shutter

Adjustment: 6. Loose venturi (15) or bad gasket can affect combustion. Tighten or replace gasket. AIR SHUTTER Maintains air/gas mixture for good combus- 1. Loosen locknut (16) which locks air tion. Start with a 1/4” gap after installing a shutter. new gas valve. -

Page 82: Combustion Chamber

COMBUSTION CHAMBER 8. Remove cooking well. 9. Remove the screws (19) connecting 1. Disconnect power and turn off gas sup- the combustion chamber to the flue ply. (20). 2. Remove side panels. 10. Remove nuts and bolts (21) attaching the four uprights (22) of the combus- 3. -

Page 83: Combustion Chamber Effective Sg8A490010

COMBUSTION CHAMBER 3. Disconnect main electric supply. EFFECTIVE: SG8A490010 4. Remove condensate pan. Combustion chamber directs heat from 5. Remove left and right hand side pan- main burner flame across fins on cooking els. well and out exhaust flue (20). If main burner flame is not adjusted correctly, soot 6. -

Page 84: Main Burner Orifice

MAIN BURNER ORIFICE Replacement: 1. Turn cook/filter switch, gas valve knob and manual gas shut off valve OFF. 2. Turn main gas supply OFF. 3. Disconnect main electric supply. 4. Remove condensate pan. 5. Facing the front of unit, remove left hand side panel if possible. -

Page 85: Pilot Burner Orifice

PILOT BURNER ORIFICE THERMOCOUPLE Correct operating millivolts at the safety pilot will be 12 to 30mV. Replacement: Be sure gas valve end of thermocouple is clean of grease and oils before installing. 1. Turn cook/filter switch, gas valve knob and manual gas shut off valve OFF. Orifice (30) is located above brass fitting (28). -

Page 87: Drain Valve And Filter System

11 - DRAIN VALVE AND FILTER SYSTEM DRAIN VALVE Used to drain oil from cooking well into filter pan or container made for handling hot oil. DANGER: Never drain oil unless cook/filter switch is OFF and pressure regulating valve is OPEN. Hot oil could spray out under pressure causing serious burns. -

Page 88: Filter Pan

1600: Be sure filter components are assembled correctly. Correct order is filter screen (7) on bottom of filter pan, filter paper (8), filter hold-down (9), one cup (1600) or two cups ® (1800) of Broaster filtering compound on top of filter paper and cover (10) on filter pan. -

Page 89: Check Valve

2. Be sure the O-ring (12) (1600: located 4. Loosen fitting (13), motor mounting in suction line) is in good condition, bolts, remove pipe (14 and 15) (1800: lubricated with cooking oil and installed slide motor back to remove pipe). -

Page 90: Motor

5. Unscrew valve (16). Replacement: 6. Remove any fittings from the valve. 1. Disconnect main electric power supply. 7. Install in reverse order using #15820 2. Disconnect conduit wires and conduit Primer & #15359 Sealant on pipe from the motor. threads. -

Page 91: Pump

4. Loosen three set screws (19) in neck of motor (17) which hold pump in place. Note: Remove pump. 1600 - Rotates clockwise 1800 - Rotates counterclockwise 5. Assemble in reverse order using teflon tape on pipe threads. Installation Hints: 1. - Page 92 Pump Cleaning: Reassembly Hints: Cleaning will be necessary if pump is seized 1. Pour olive oil or cooking oil on gears and tripping thermal overload on the motor. and inside front cover bearing where gear shaft is installed. Turn gears by 1.

-

Page 93: Troubleshooting

2. Replace 1. Controller in program mode 1. Exit program mode Heating element(s) won’t heat 2. Faulty element(s) 2. Replace (1600/1800E) 3. Faulty contactor 3. Replace 1. Controller in program mode 2. Controller needs calibrating Cooking oil temperature too hot 3. -

Page 94: Controller Tips (Solid State)

6. Faulty heating element(s) 6. Replace (1600/1800E) 7. Faulty temperature sensor 7. Replace probe 8. Open or faulty wall fuse 8. Check wall fuse or circuit (1600/1800E only) breaker 9. Faulty controller 9. Replace 12 - 2 Manual #13898 2/00... -

Page 95: Gas Tips (1800Gh)

GAS TIPS (1800GH) COMPLAINT CAUSE REMEDY 1. Gas valve OFF 1. Turn ON 2. Air in gas line 2. Tighten 3. Manual gas shut-off valve 3. Open Pilot burner won’t light closed 4. Pilot burner flame too small 4. Adjust flame 5. -

Page 96: Cover And Yoke Tips

COVER AND YOKE TIPS COMPLAINT CAUSE REMEDY 1. O-ring groove and O-ring 1. Clean and lubricate dry or dirty 2. Hard O-ring 2. Replace Cover hard to CLOSE 3. Teflon bearing out of adjust- 3. Adjust or replace ment or worn 4. -

Page 97: Pressure System Tips

PRESSURE SYSTEM TIPS DANGER: DO NOT attempt to tighten, repair or replace any fitting, line or component when there is pressure in the cooking well. Hot oil could spray out under pressure caus- ing serious burns. COMPLAINT CAUSE REMEDY 1. No product in cooking well 1. -

Page 98: Product Tips

PRODUCT TIPS COMPLAINT CAUSE REMEDY 1. Low cooking oil 1. Check cook temperature temperature 2. Wrong coating 2. Check procedures Product too light 3. No coating 3. Check procedures 4. Not done 4. Increase cook time 5. Food basket overloaded 5. - Page 99 Frozen IQF Chicken: COMPLAINT CAUSE REMEDY 1. Low cooking oil tempera- 1. Check cook temperature ture Product too light 2. Not done 2. Increase cook time 3. Food basket overloaded 3. Decrease load 1. High cooking oil tempera- 1. Check cook temperature ture 2.

-

Page 100: Filtering Tips

2. Not using enough 2. Next filtering cycle, make Motor starts but will not ® sure proper amount of pump or stops at any level Broaster filtering com- ® pound Broaster filtering com- pound is used Motor starts but stops 1.

Need help?

Do you have a question about the 1600 and is the answer not in the manual?

Questions and answers