Broaster 1600 Installation Manual

Pressure fryer

Hide thumbs

Also See for 1600:

- Service manual (131 pages) ,

- Operation manual (57 pages) ,

- Installation manual (54 pages)

Table of Contents

Advertisement

Quick Links

INSTALLATION MANUAL

®

BROASTER

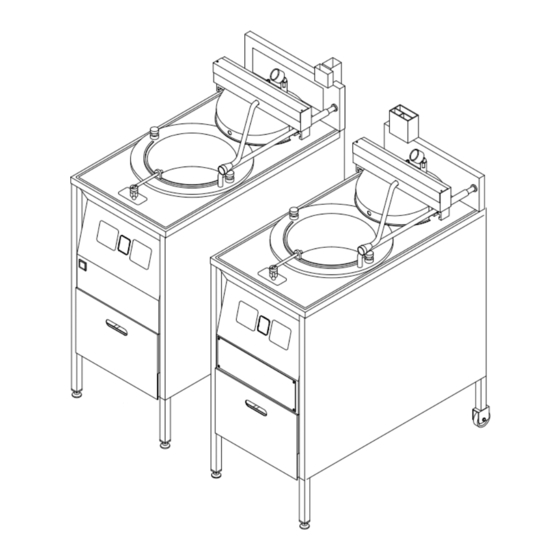

1600 AND 1800

PRESSURE FRYER

Be sure ALL installers read, understand, and have access to this manual at all times.

Genuine Broaster Chicken®, Broasted®, Broaster Chicken®, Broaster Foods®. and Broasterie® are registered

trademarks. Usage is available only to licensed operators with written authorization from the Broaster Company.

The Broaster Company

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193 broaster.com

Design Certified By:

© 1999 the Broaster Company

1600: CSA, NSF and UL

Printed In U.S.A.

1800: CSA (AGA & CGA), NSF and UL

#14678 1/99 Rev: 10/14

Advertisement

Table of Contents

Summary of Contents for Broaster 1600

- Page 1 Be sure ALL installers read, understand, and have access to this manual at all times. Genuine Broaster Chicken®, Broasted®, Broaster Chicken®, Broaster Foods®. and Broasterie® are registered trademarks. Usage is available only to licensed operators with written authorization from the Broaster Company. The Broaster Company 2855 Cranston Road, Beloit, WI 53511-3991 608/365-0193 broaster.com...

- Page 3 All adjustments and repairs shall be made If at any time the POWER by an authorized Broaster Company repre- ON light does not turn off sentative. when the cook/filter switch is moved to...

- Page 4 1600/1800E Solid State Controls: If at any time the POWER ON light does not turn off when the cook/filter switch is moved to the OFF position, contact your local Broaster Company representative for service immediately. broaster.com Manual #14678 1/99 Rev: 2/14...

-

Page 5: Table Of Contents

LEVELING ........................1 - 1 RECOMMENDED VENTILATION REQUIREMENTS............1 - 2 General Requirements ..................1 - 2 1600 Hood Dimensions In Inches ...............1 - 3 1800 Hood Dimensions In Inches ...............1 - 4 1600/1800 Hood Dimensions In Millimeters ............1 - 5 2 - FILTER PAN ASSEMBLY ....................2 - 1 HARDWARE LIST......................2 - 1... - Page 6 COVER ASSEMBLY ....................5 - 1 INITIAL STARTUP Electric ......................5 - 1 Gas ........................5 - 2 1800GH LIGHTING INSTRUCTIONS ................5 - 2 Start-Up ......................5 - 2 Shut Down ......................5 - 3 AIR SHUTTER ADJUSTMENT ...................5 - 3 broaster.com Manual #14678 1/99 Rev: 3/14...

-

Page 7: Pre-Installation

Adjust front feet to level entire unit. Add strain on electrical and gas connections. additional blocking if necessary on a slop- ing floor. • DO NOT install unit where traffic areas are on either side or in back of unit. broaster.com Manual #14678 1/99 Rev 2/14... -

Page 8: Recommended Ventilation Requirements

1800 cu. ft./minute. Canopy hood open on three sides or less: 1200 cu. ft./minute. 5. Exhaust Air Velocity: All exhaust ducts should be sized to provide an air velocity in the ducts of at least 1500 ft./minute. broaster.com Manual #14678 1/99 Rev 2/14... -

Page 9: 1600 Hood Dimensions In Inches

1600 Hood Dimensions In Inches: COVER CLOSED MODEL 1600 COV ER OPE N DO NOT OPEN COVER UNLESS PRESSURE IS AT ZERO P.S.I. MANUFACTURED BY THE BROASTER COMPANY CAUTION! CHECK OIL LEVEL BEFORE OPERATING SAFETY AND OPERATING INSTRUCTIONS DANGER MAXIMUM WORKING PRESSURE 15 PSI MADE IN U.S.A. -

Page 10: 1800 Hood Dimensions In Inches

1800 Hood Dimensions In Inches: broaster.com Manual #14678 1/99 Rev 2/14... -

Page 11: 1600/1800 Hood Dimensions In Millimeters

1600/1800 Hood Dimension In Millimeters: broaster.com Manual #14678 1/99 Rev 2/14... -

Page 13: Filter Pan Assembly

2 - Brass Ferrule #02537 3 - Riser Line #11308 6 - Keps Nut #00522 7 - O-ring #09883 1800: 1. From bag of hardware, install com- pression nut (1) then ferrule (2) onto riser line (3). broaster.com Manual #14678 1/99 Rev 2/14... - Page 14 5. .Lubricate O-ring (7) with cooking oil. 1600: Install O-ring (7) into inner groove in suction line (6). Screw nipple (9) into drain valve (10). 1800: Install O-ring (7) into groove on riser line (3).

-

Page 15: Additional Adjustments If Needed

1. Loosen nut and bolt (11). 2. Push pan under unit. By hand, move suction line (8) until riser line (3) is fully inserted into suction line. 3. Tighten all nuts and bolts. 1800: 1. Remove side panel. broaster.com Manual #14678 1/99 Rev 2/14... -

Page 17: 1600/1800E Installation

• When installing or servicing the unit, 240/415 always check the dataplate located on the front panel (1600) or toward the rear of the counter top (1800) to make cer- 1800E Suggested Wiring Capacity Table: tain proper parts are used and the cor- rect service rendered. -

Page 18: Electrical Hook-Up

C2. Install wire #3 with wires #1 2. Remove condensate pan and one and #5 and install wire #2 with wires #4 and screw (1600) or two screws (1800) #6. In this case, applied voltage must be from bottom of front panel. Pull out connected to L1 and L3 of contactor C1 and down on bottom to remove. -

Page 19: Unit Dimensions For Electrical Hook-Up

Unit Dimensions For Electrical Hook-Up: broaster.com Manual #14678 1/99 Rev 2/14... -

Page 20: Wiring Diagrams

WIRING DIAGRAMS Wiring diagrams are located inside front panel. See Access For Hook-up under ELECTRICAL HOOK-UP. 1600 Mechanical 208 or 240VAC: broaster.com Manual #14678 1/99 Rev 2/14... - Page 21 1600 Mechanical 208 or 240VAC: Effective E16E401073 E18C401133 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 22 1600 Mechanical 208 or 240VAC: Effective E16A700023 E18A700043 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 23 1600 Mechanical 208 or 240VAC: Effective E16L700000 E18K700000 broaster.com Manual #14678 1/99 Rev 2/14...

-

Page 24: 1600/1800E Solid State

1600/1800E Solid State 208 or 240VAC: broaster.com Manual #14678 1/99 Rev 2/14... - Page 25 1600/1800E Solid State 208 or 240VAC: Effective SE6E401073 SE8C400951 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 26 1600/1800E Solid State 208 or 240VAC: Effective SE6A700013 SE8A700011 3-10 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 27 1800E Solid State 208 or 240VAC: Effective - SE8I213193 3-11 broaster.com Manual #14678 1/99 Rev 2/14...

-

Page 28: 1600Xp/1800Exp Mechanical

EXPORT: 1600XP/1800EXP Mechanical: 3-12 broaster.com Manual #14678 1/99 Rev 2/14... - Page 29 EXPORT: 1600XP/1800EXP Mechanical: Effective E16E401073 E18D401133 3-13 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 30 EXPORT: 1600XP/1800EXP Mechanical: Effective E16A700023 E18A700043 3-14 broaster.com Manual #14678 1/99 Rev 2/14...

-

Page 31: 1600Xp/1800Exp Solid State

EXPORT: 1600XP/1800EXP Solid State: 3-15 broaster.com Manual #14678 1/99 Rev 2/14... - Page 32 EXPORT: 1600XP/1800EXP Solid State: Effective SE6A700013 SE8A700011 3-16 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 33 1800EXP Solid State 208 or 240VAC: Effective - SE8I213193 3-17 broaster.com Manual #14678 1/99 Rev 2/14...

-

Page 34: 1600Ce Mechanical

EU: 1600CE MECHANICAL: 3-18 broaster.com Manual #14678 1/99 Rev 2/14... -

Page 35: 1600Ce/1800Ece Solid State

EU: 1600CE/1800ECE SOLID STATE: 3-19 broaster.com Manual #14678 1/99 Rev 2/14... - Page 36 EU: 1600UK/1800EUK SOLID STATE: 3-20 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 37 1800E Solid State 480VAC: 3-21 broaster.com Manual #14678 1/99 Rev 6/14...

- Page 38 EXPORT: 1600XP Solid State 240/480VAC: Effective SE6E401231 3-22 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 39 EXPORT: 1600XP Solid State 240/480VAC: Effective SE6A700013 3-23 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 40 EXPORT: 1800EXP Solid State 480V: Effective January 04 (A40) 3-24 broaster.com Manual #14678 1/99 Rev 2/14...

- Page 41 EXPORT: 1800EXP Solid State 480V: Effective January 06 (K60) 3-25 broaster.com Manual #14678 1/99 Rev 2/14...

-

Page 43: 1800Gh Installation

1/2psi(3.45kPa). broaster.com Manual #14678 1/99 Rev 6/14b... -

Page 44: Electrical Characteristics

DO NOT cut or remove codes, or in the absence of local codes, grounding prong from this plug. with the National Electrical Code, ANSI/ NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable. 1800GH Wiring Diagram: broaster.com Manual #14678 1/99 Rev 10/14... -

Page 45: Export: 1800Gh

EXPORT: 1800GH Wiring Diagram: broaster.com Manual #14678 1/99 Rev 10/14... - Page 46 1800GHCE Wiring Diagram: broaster.com Manual #14678 1/99 Rev 2/14...

- Page 47 1800GHCE Wiring Diagram for the United Kingdom: broaster.com Manual #14678 1/99 Rev 2/14...

-

Page 48: Gas Characteristics

Gas Conversion: US & CANADA All gas units are tested using local gas sup- • Contact your local Broaster Company ply. Your unit may or may not operate cor- representative for converting from one rectly on your type of gas. Therefore, the type of gas to another. -

Page 49: Gas Piping

• Use only black steel pipe and malleable open flame to check for gas leaks. fittings for gas connections. • Pressure loss in the piping must not exceed 0.3” W.C. Unit Dimensions For Gas Hook-Up: broaster.com Manual #14678 1/99 Rev 2/14... -

Page 50: Example Of Piping System Design

4,100 8,300 1,270 2,000 3,600 7,400 1,150 1,850 3,250 6,800 1,050 1,700 3,000 6,200 1,600 2,800 5,800 1,500 2,600 5,400 1,400 2,500 5,100 1,250 2,200 4,500 1,130 2,000 4,100 1,050 1,850 3,800 1,700 3,500 broaster.com Manual #14678 1/99 Rev 2/14... -

Page 51: Operational Check-Out

OPEN. Handle should slide easily from side to side and locking pin should move in 9. If CHEC appears in display, turn unit and out over the cover. off and back to COOK. broaster.com Manual #14678 1/99 Rev 2/14... -

Page 52: Gas

10. Turn pressure regulating valve handle to CLOSED. The timer will start count- ing down. At the end of a cook cycle, an audible alarm will sound until pres- sure regulating valve handle is turned to OPEN. broaster.com Manual #14678 1/99 Rev 2/14... -

Page 53: Shut Down

If soot is present, DO NOT operate unit and call Ser- vice Technician. Soot is black and powdery to the touch. See COMBUSTION CHAM- BER. broaster.com Manual #14678 1/99 Rev 2/14... - Page 56 The Broaster Company 2855 Cranston Road, Beloit, WI 53511-3991 608/365-0193 broaster.com...

Need help?

Do you have a question about the 1600 and is the answer not in the manual?

Questions and answers