Summary of Contents for SCHUNK TANDEM KSF plus Series

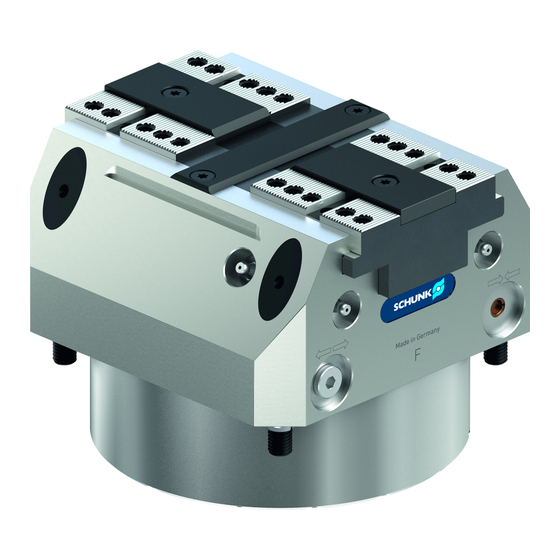

- Page 1 Translation of Original Operating Manual TANDEM Clamping Block KSF plus, KSF-LH plus, KSF-F plus Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 About this manual ....................4 1.1 Presentation of Warning Labels ................4 1.2 Applicable documents ....................4 2 Basic safety instructions ................... 5 2.1 Intended use ......................5 2.2 Not intended use ...................... 5 2.3 Notes on particular risks ................... -

Page 4: About This Manual

Information about avoiding material damage. Applicable documents • General terms of business * • Catalog data sheet of the purchased product * The documents marked with an asterisk (*) can be downloaded on our homepage www.schunk.com. 03.00|KSF plus, KSF-LH plus, KSF-F plus |en... -

Page 5: Basic Safety Instructions

Report any failures and damage immediately and repair without delay to keep the extent of the damage to a minimum and prevent compromising the safety of the product. Only original SCHUNK spare parts may be used. Intended use • This product is intended for clamping and holding workpieces on machine tools and other suitable technical devices. -

Page 6: Notes On Particular Risks

Basic safety instructions Notes on particular risks The TANDEM clamping block can cause injury for persons and material damage, for example: • it is used other than as intended; • it is not installed or maintained properly; • the safety and installation instructions, the safety and accident prevention regulations valid at the usage site or the EC Machinery Directive are not observed. - Page 7 Basic safety instructions WARNING Risk of injury from clamping block or chuck jaws falling during transport, installation or removal! • Make sure the clamping block and chuck jaws do not fall during transport, installation or removal. • Use a crane and/or a transport truck for transport. •...

-

Page 8: Notes On Safe Operation

• If the clamping block is involved in a collision, it must be tested to see if it is still functioning properly before using it again. Only use original SCHUNK spare parts when replacing damaged items. • Check the clamping block at least once per shift for externally visible damage and malfunctions. -

Page 9: Constructional Changes, Attachments Or Modifications

Constructional changes, attachments or modifications Modifications and rework (additional threads or bore holes) or attaching fittings that are not offered as accessories by SCHUNK may be performed only with permission of SCHUNK. This also applies to the installation of safety devices. -

Page 10: Personal Protective Equipment

Basic safety instructions Spare parts Only use original SCHUNK spare parts. Environmental regulations The applicable environmental regulations must be observed for all maintenance and repair work. The use of petroleum ether is prohibited. It is extremely flammable, can build up an electrostatic charge and can form an explosive gas air mixture. -

Page 11: Warranty

Scope of delivery Warranty If the product is used as intended, the warranty is valid for 24 months from the ex-works delivery date under the following conditions: • Observe the applicable documents, ( 1.2, Page 4) • Observe the ambient conditions and operating conditions •... -

Page 12: Technical Data

Technical data Technical data Pressure medium Compressed air, compressed air quality according to ISO 8573- 1:7 4 4 Operating pressure max. 6 bar Operating temperature 5 °C to 60 °C Installation position Noise emission [dB(A)] ≤ 70 NOTICE The TANDEM clamping blocks KSF plus and KSF-F plus may not be operated with the turbo function. - Page 13 Technical data 1 Optional Z variant ± 0.01 mm to 2 Clamping sleeve ± 0.04 mm to clamping clamping center center 3 Fitting screw ± 0.02 mm to clamping 4 Bottom lubrication connection center KSF plus, KSF-LH plus, KSF-F plus Dimension Ø...

- Page 14 Technical data KSF plus, KSF-LH plus, KSF-F plus Dimension 13.5 15.5 Ø Q 10f7 10f7 12f7 14f7 Ø R 37.3 44.2 Ø U 97.5 136.5 03.00|KSF plus, KSF-LH plus, KSF-F plus |en...

-

Page 15: Tightening Torques For Screws

Assembly Tightening torques for screws Tightening torques to mount the clamping system on the machine table (screw quality 10.9) Screw size M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 Admissible torque 120 160 200 290 400 500 (Nm) Tightening torques to mount top jaws on the TANDEM clamping block (screw quality 12.9) - Page 16 Assembly • Surface "X" is parallel to the guideway of the base jaws (item 2) so that the clamping block can be aligned on the machine table. Assembling the clamping block Assembly with clamping sleeves: the clamping block is mounted on the machine table together with clamping sleeves (item 27) and screws (item 19).

-

Page 17: Connections Of The Clamping Block

Assembly Connections of the clamping block Connections of the clamping block KSF plus and KSF-F plus: The clamping block has two air connections: »I« and »III« • Open against spring assembly, no turbo function. The clamping block is closed mechanically via the integrated spring assembly. - Page 18 Assembly Connection of the KSF plus and KSF-F plus versions: The clamping block has two air connections for OPEN: "I" and "III" (opening against spring assembly, no turbo function) and an air bleed screw (sound absorber). The application determines which of the two air connections (at the front or at the base) must be opened for actuation: •...

-

Page 19: Mounting Recommendations

Assembly NOTICE Always make sure that the connections are tight and use a suitable metal hose to protect the pneumatic hoses against hot chips, falling parts or other damage. WARNING Risk of injury due to immediate closing of the clamping block with a high spring pressure in case of failure of the pneumatic pressure. -

Page 20: Installation Recommendation For Partial Integration

Assembly 7.3.1 Installation recommendation for partial integration: • The cover (part 5) is built into the table top via a mounting- or through-hole. • Compressed air is supplied to the base-side air connection »III« on the clamping block by a hose line with a pneumatic plug-in connection that is built into the opening in the cover (item 5) below the table top. - Page 21 Assembly • Do not open the frontal connection »I« of the clamping block or seal it airtight with a locking screw (M5 or G1/8"). • The pneumatic pressure supply to connection »III« is sealed by an O-ring, which is laid into the O-ring seat in the flat surface of the mounting hole.

-

Page 22: Trouble Shooting

Disassemble clamping block and piston rod breakage replace damaged parts ( 9.1, Page 23) (e.g. due to overload) send to Schunk for repair Clamping block does not complete stroke Possible cause Remedial measures Chips or dirt between covering strip and... -

Page 23: Maintenance And Care

Reassemble everything and relubricate the two frontal or the two lateral lubricating nipples with LINOMAX 200 or an equivalent lubricant. (Product information about LINOMAX can be requested from SCHUNK). CAUTION Skin contact with lubricating grease can cause allergic reactions! Wear protective gloves. - Page 24 The base jaws (items 2, 31), the chuck piston (item 3) and the housing (item 1) are specially attuned to each other. To replace these parts, ship the entire clamping block to SCHUNK along with a repair order. When replacing wearing parts (e.g. seals), adhere to the following...

- Page 25 Maintenance and care removed after being heated by a hot-air blower. The sleeve should therefore remain built into the base body. 13 Remove the seals (items 20, 22). 14 Remove the seals (items 12, 15, 17). 15 Clean all the parts thoroughly and check for damage and wear. Damaged and worn parts must be replaced.

- Page 26 Maintenance and care diagonal sequence. It is absolutely necessary to install the original fastening screws (item 21) afterwards. 27 If using clamping sleeves (item 27) for centering, insert these into the housing (item 1) now. 28 Grease the sliding surfaces of the housing (item 1), base jaws (item 2) and chuck piston (item 3) with LINOMAX 200 or an equivalent lubricant.

-

Page 27: Control Of Thightness

Maintenance and care Control of thightness • The following components are required to check for leaks: pressure gauge, pneumatic fitting, supply line and quick coupler. • Check for leaks with the clamping block in the CLOSED position. Proceed as follows: 1 Connect the following sequence of parts to the connection in the OPEN (I) position: pressure gauge, pneumatic fitting, supply line with fast coupler. -

Page 28: Sealing Kits, Accessory Packs And Parts Lists

Sealing kits, accessory packs and parts lists Sealing kits, accessory packs and parts lists When ordering spare parts, the type , size and, if possible, the serial number of the clamping block must always be stated to avoid delivery mistakes. Seals, sealing elements, screw connections, springs, bearings, screws, wiper bars and parts that come into contact with the workpiece are not covered by the warranty. -

Page 29: Accessory Packs

Sealing kits, accessory packs and parts lists KSFplus 250, KSF-LH plus 250, KSF-F plus 250 (ID: 1370978) Item Designation Quantity Quad ring Combined sealing element O-ring O-ring O-ring O-ring O-ring Wear parts - replacement recommended during maintenance The sealing kit can only be ordered as a compete kit. 10.2 Accessory packs KSF plus 100, KSF-LH plus 100, KSF-F plus 100 (ID: 8508184) -

Page 30: Lists Of Spare Parts

Sealing kits, accessory packs and parts lists KSF plus 160, KSF-LH plus 160, KSF-F plus 160 (ID: 8508185) Item Designation Quantity Plug Fitting screw O-ring Screw Clamping sleeve Screw O-ring KSF plus 250, KSF-LH plus 250, KSF-F plus 250 (ID: 8508534) Item Designation Quantity... - Page 31 Sealing kits, accessory packs and parts lists Locking screw 12** Quad ring Sound absorber Screw 15** Combined sealing ring Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw 22** O-ring Set-screw Set-screw Countersunk screw 27*** Clamping sleeve Sound absorber Sleeve Compression spring 51*** Screw...

- Page 32 Sealing kits, accessory packs and parts lists Sound absorber Screw 15** Combined sealing ring Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw 22** O-ring Set-screw Set-screw Countersunk screw 27*** Clamping sleeve Sleeve Compression spring 51*** Screw 54*** O-ring KSF-F plus 100 (ID: 0405270) Item Designation...

- Page 33 Sealing kits, accessory packs and parts lists Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw 22** O-ring Set-screw Set-screw Countersunk screw 27*** Clamping sleeve Spherical washer Socket pin Screw Base jaw Screw Sound absorber Sleeve Compression spring 51*** Screw 54*** O-ring KSF plus 140 (ID: 1330220)

- Page 34 Sealing kits, accessory packs and parts lists Sound absorber Screw 15** Combined sealing ring Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw Set-screw Countersunk screw 27*** Clamping sleeve Sound absorber Sleeve Compression spring 51*** Screw 54*** O-ring KSF-LH plus 140 (ID: 1330222) Item Designation...

- Page 35 Sealing kits, accessory packs and parts lists 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw Set-screw Countersunk screw 27*** Clamping sleeve Sleeve Compression spring 51*** Screw 54*** O-ring KSF-F plus 140 (ID: 1330224) Item Designation Quantity Body Base jaws Chuck piston Cylinder piston Cover...

- Page 36 Sealing kits, accessory packs and parts lists Set-screw Countersunk screw 27*** Clamping sleeve Spherical washer Socket pin Screw Base jaws Screw Sound absorber Sleeve Compression spring 51*** Screw 54*** O-ring Guide strip KSF plus 160 (ID: 0405360) Item Designation Quantity Body Base jaws Chuck piston...

- Page 37 Sealing kits, accessory packs and parts lists 20** O-ring Countersunk screw 22** O-ring Set-screw Countersunk screw Set-screw 27*** Clamping sleeve Sound absorber Sleeve Screw O-ring Compression spring 51*** Screw 54*** O-ring KSF-LH plus 160 (ID: 0405380) Item Designation Quantity Body Base jaws Chuck piston Cylinder piston...

- Page 38 Sealing kits, accessory packs and parts lists 20** O-ring Countersunk screw 22** O-ring Set-screw Countersunk screw Set-screw 27*** Clamping sleeve Sleeve Screw O-ring Compression spring 51*** Screw 54*** O-ring KSF-F plus 160 (ID: 0405370) Item Designation Quantity Body Base jaws Chuck piston Cylinder piston Cover...

- Page 39 Sealing kits, accessory packs and parts lists Countersunk screw 22** O-ring Set-screw Countersunk screw Set-screw 27*** Clamping sleeve Spherical washer Socket pin Screw Base jaws Screw Sound absorber Sleeve Screw O-ring Compression spring 51*** Screw 54*** O-ring KSF plus 250 (ID: 0405560) Item Designation Quantity...

- Page 40 Sealing kits, accessory packs and parts lists Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw 22** O-ring Set-screw Set-screw Countersunk screw Set-screw 27*** Clamping sleeve Sound absorber Sleeve Screw 45** O-ring Compression spring 51*** Screw 52*** T-handle 53*** Set-screw 54*** O-ring KSF-LH plus 250 (ID: 0405580)

- Page 41 Sealing kits, accessory packs and parts lists Sound absorber Screw 15** Combined sealing ring Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw 22** O-ring Set-screw Set-screw Countersunk screw Set-screw 27*** Clamping sleeve Sleeve Screw 45** O-ring Compression spring 51*** Screw 52*** T-handle 53*** Set-screw...

- Page 42 Sealing kits, accessory packs and parts lists Locking screw 12** Quad ring Sound absorber Screw 15** Combined sealing ring Screw 17** O-ring 18*** O-ring 19*** Screw 20** O-ring Countersunk screw 22** O-ring Set-screw Set-screw Countersunk screw Set-screw 27*** Clamping sleeve Spherical washer Socket pin Screw...

-

Page 43: Drawings

Drawings Drawings KSF plus, KSF-LH plus For size 100 For sizes 140/160 Centering with clamping sleeves Centering with fitting screws For size 250 03.00|KSF plus, KSF-LH plus, KSF-F plus |en... - Page 44 Drawings KSF-F plus For size 100 For sizes 140/160 Centering with clamping sleeves Centering with fitting screws For size 250 03.00|KSF plus, KSF-LH plus, KSF-F plus |en...

-

Page 45: Translation Of Original Declaration Of Incorporation

Translation of original declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG Distributor Lothringer Str. 23 D-88512 Mengen... -

Page 46: Appendix On Declaration Of Incorporation, As Per 2006/42/Ec, Annex Ii, No. 1 B

Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1. Description of the basic safety and health protection requirements, as per 2006/42/EC, Annex I, that apply to and are fulfilled for the scope of the partly completed machinery: Product designation $Company name$ Type designation... - Page 47 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1.3.4 Risks due to surfaces, edges or angles 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 1.3.7 Risks related to moving parts 1.3.8 Choice of protection against risks arising from moving parts 1.3.8.1 Moving transmission parts...

- Page 48 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1.7.2 Warning of residual risks 1.7.3 Marking of machinery 1.7.4 Instructions 1.7.4.1 General principles for the drafting of instructions 1.7.4.2 Contents of the instructions 1.7.4.3 Sales literature The classification from Annex 1 is to be supplemented from here forward.

Need help?

Do you have a question about the TANDEM KSF plus Series and is the answer not in the manual?

Questions and answers