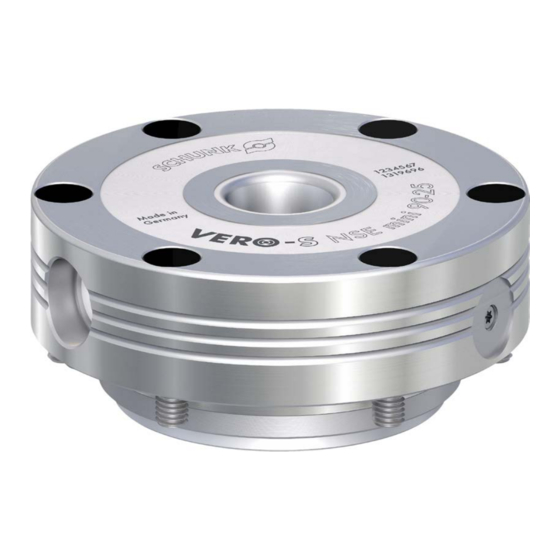

SCHUNK VERO-S NSE mini 90-25 Assembly And Operating Manual

Quick-change pallet system

Hide thumbs

Also See for VERO-S NSE mini 90-25:

- Assembly and operating manual (44 pages) ,

- Assembly and operating manual (37 pages) ,

- Assembly and operating manual (36 pages)

Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK VERO-S NSE mini 90-25

- Page 1 Translation of Original Operating Manual VERO-S quick-change pallet system NSE mini 90-25, NSE mini 90-25-V10 Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 General ........................5 1.1 About this manual ....................5 1.1.1 Presentation of Warning Labels ..............5 1.1.2 Applicable documents ................... 6 1.1.3 Sizes ....................... 6 1.2 Warranty ........................6 1.3 Scope of delivery ...................... 7 1.4 Accessories ....................... - Page 4 Table of contents 5 Operation ........................ 28 6 Maintenance and care ..................... 29 7 Troubleshooting ...................... 30 7.1 The clamping area does not unlock ............... 30 7.2 The clamping area does not unlock properly ............30 7.3 The quick-change pallet system no longer opens quietly ........30 8 Seal kit and part lists ....................

-

Page 5: General

General General About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and under- stood this operating manual. -

Page 6: Applicable Documents

Applicable documents • General terms of business* • Catalog data sheet of the purchased product * The documents marked with an asterisk (*) can be downloaded on our homepage schunk.com 1.1.3 Sizes This operating manual applies to the following sizes: Quick-Change Pallet System •... -

Page 7: Scope Of Delivery

General Scope of delivery The scope of delivery includes • Quick-change pallet system in the version ordered • NSE mini 90-25 accessory pack: 3 O-rings Ø 8 x 1 6 cover caps 6 fastening screws M6 • NSE mini 90-25-V10 accessory pack: 3 O-rings Ø... -

Page 8: Basic Safety Notes

• It is used as a pressing tool, a chuck, a load-handling device or as lifting equipment. • It is used for turning applications without consulting SCHUNK. • It is used in working environments that are not permissible. • People work on machines or technical equipment that do not comply with the EC Machinery Directive 2006/42/EC, disregarding the applicable safety regulations. -

Page 9: Spare Parts

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. Environmental and operating conditions Required ambient conditions and operating conditions... -

Page 10: Personal Protective Equipment

Basic safety notes The following personal qualifications are necessary for the various activities related to the product: Trained electrician Due to their technical training, knowledge and experience, trained electricians are able to work on electrical systems, recognize and avoid possible dangers and know the relevant standards and regulations. -

Page 11: Notes On Safe Operation

Basic safety notes Notes on safe operation Incorrect handling of the personnel Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. • Avoid any manner of working that may interfere with the function and operational safety of the product. -

Page 12: Disposal

Basic safety notes • Test the product after a malfunction to establish whether it still functions properly and no increased risks have arisen. 2.11 Disposal Handling of disposal The incorrect handling of disposal may impair the product's safety and cause serious injuries as well as considerable material and environmental harm. -

Page 13: Protection During Commissioning And Operation

Basic safety notes • Stand clear of suspended loads and do not step into their swiveling range. • Never move loads without supervision. • Do not leave suspended loads unattended. 2.12.2 Protection during commissioning and operation Falling or violently ejected components Falling and violently ejected components can cause serious injuries and even death. -

Page 14: Notes On Particular Risks

Basic safety notes machine if this protective equipment does not function correctly. 2.12.4 Notes on particular risks DANGER Risk of fatal injury from suspended loads! Falling loads can cause serious injuries and even death. • Stand clear of suspended loads and do not step within their swiveling range. - Page 15 Basic safety notes WARNING The system clamps using spring force. Risk of injury due to parts automatically moving to their end positions following actuation of an "emergency stop" or after switching off the power supply. • Wait for the system to shut down completely. •...

- Page 16 Basic safety notes CAUTION There is a risk of limbs being crushed by moving parts during manual loading and unloading and the clamping procedure. • Do not reach into the clamping pin holder. • Use loading devices. • Wear protective gloves. CAUTION Risk of slipping or falling if the quick-change pallet system's operational environment is not clean (e.g.

-

Page 17: Technical Data

Technical data Technical data Type ID no. Holding force* Pull-in force Pull-in force designation (M6 / M8) without with turbo turbo NSE mini 90-25 1319696 15 kN / 25 kN 1.5 kN 6 kN NSE mini 90-25-V10 1313269 15 kN / 25 kN 1.5 kN 6 kN * Holding force when fastening the clamping pin with cylindrical... -

Page 18: Assembly

Assembly Assembly Pre-assembly Request our installation drawings if installing the module in the customer's clamping stations yourself. The installation position must be observed when performing the installation yourself. Partial installation Do not use Full installation NOTICE With installation location 2, the clamping slide can be blocked by chips and dirt. -

Page 19: Fastening And Connection

Assembly 1 Check the flatness of the mounting surface, ( 4.3, Page 19) 2 Screw the module with the clamping station, Observe permissible tightening torques for the mounting screws and the strength class, ( 4.7, Page 27). 3 Connect module (... - Page 20 Assembly Turbo connection When using the turbo connection (if supply is connected), the spring actuated locking procedure is actively supported with air pressure and in so doing strengthens the achievable pull-in force of the quick-change clamping system. For force amplification, a pressure pulse is sufficient, the pressure line can be decoupled, the pull-in force remains intact.

-

Page 21: Nse Mini 90-25

Assembly 4.3.1 NSE mini 90-25 Fastening in the installation space with 6 M6 screws. The assembly module is positioned using the centering diameter of the installation space: Ø 66 H6. The air connection is normally made via the coupling holes in the floor of the unit. Alternative connection option: two M5 connections on the side. -

Page 22: Nse Mini 90-25-V10

Assembly 4.3.2 NSE mini 90-25-V10 Fastening in the installation space with 6 M6 screws. The assembly module is positioned using the centering diameter of the installation space: Ø 66 H6. The exact position orientation is done with a fitting screw with a diameter of Ø... -

Page 23: Spa 20 Mini, Spb 20 Mini, Spc 20 Mini Clamping Bolts

This is why only screws of strength class 12.9 may be used. Only original SCHUNK clamping pins may be used. If the clamping pins are to be used in customer-owned devices, the customer must provide sufficiently dimensioned threaded holes or a sufficiently thick mounting material. - Page 24 Assembly Tolerances and installation conditions Type ID no. SPA mini 20 0435610 > 8 mm > 13 mm M8 > 9 mm > 11 mm M6 11 mm > 8 mm SPB mini 20 0435620 > 8 mm > 13 mm M8 > 9 mm > 11 mm M6 11 mm > 8 mm SPC mini 20 0435630 >...

-

Page 25: Options

Assembly Options It is possible to monitor the dynamic pressure of the clamping slide position. Pressure build-up in "OPENED" status. Control of the clamping slide monitor requires a reduced pressure supply limited to 2 bar (see chapter "Pneumatic circuit diagram" (... -

Page 26: Pneumatic Circuit Diagram Nse Mini 90-25, Nse Mini 90-25-V10

Assembly Pneumatic circuit diagram NSE mini 90-25, NSE mini 90-25-V10 Pneumatic circuit diagram When controlling the NSE mini quick-change pallet system, the following must be observed: Turbo function: • The actuating pressure for the turbo function must not exceed 6 bar. Slide monitoring: •... -

Page 27: Screw Tightening Torques

Assembly • If the feeder query of several standard NSE mini modules is connected in series, only the evaluation of the OPEN position works (dynamic pressure = all modules open). Screw tightening torques Tightening torques for mounting clamping pins (Screw quality 12.9) Screw size Tightening torque (Nm) 01.00|NSE mini 90-25, NSE mini 90-25-V10 |en... -

Page 28: Operation

In this case, the system must be inspected and damaged parts must be replaced immediately. Only original SCHUNK spare parts may be used! WARNING Risk of injury due to losing pallets or workpieces in the case of incorrect actuation caused by incorrect operation. -

Page 29: Maintenance And Care

Risk of injury and risk of damage to the clamping module when opening the housing cover. If the clamping module has to be disassembled, send the module to SCHUNK for repair. The covers of the clamping modules are spring preloaded and may only be removed by trained specialist personnel. The... -

Page 30: Troubleshooting

Check air supply Pressure below minimum Check operating pressure (min. 5 bar) A component is broken (e.g. due to over- Replace the module or send it to SCHUNK for loading) repair Excess tensile load on clamping pins Reduce support weight... -

Page 31: Seal Kit And Part Lists

Seal kit and part lists Seal kit and part lists Seal kit lists NSE mini 90-25, NSE mini 90-25-V10 Item Designation Quantity O-ring Ø 55 x 1.5 O-ring Ø 32 x 1.5 O-ring Ø 35 x 1.5 O-ring Ø 11 x 1 Cover caps Wearing parts - we recommend replacing when maintenance is performed... - Page 32 Seal kit and part lists NSE mini 90-25-V10 (I.D. no. 1313269) Item Designation Quantity Body Clamping slide Piston Cover Fitting screw Countersunk screw O-ring O-ring O-ring O-ring Cylindrical pin Set-screw Compression spring O-ring Set-screw Screw VERO-S ADK 01.00|NSE mini 90-25, NSE mini 90-25-V10 |en...

-

Page 33: Assembly Drawings

Assembly Drawings Assembly Drawings NSE mini 90-25 01.00|NSE mini 90-25, NSE mini 90-25-V10 |en... -

Page 34: Nse Mini 90-25-V10

Assembly Drawings NSE mini 90-25-V10 01.00|NSE mini 90-25, NSE mini 90-25-V10 |en... -

Page 35: Translation Of Original Declaration Of Incorporation

Translation of original declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG Distributor Lothringer Str. 23 D-88512 Mengen... -

Page 36: Appendix On Declaration Of Incorporation, As Per 2006/42/Ec, Annex Ii, No. 1 B

Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1. Description of the basic safety and health protection requirements, as per 2006/42/EC, Annex I, that apply to and are fulfilled for the scope of the partly completed machine: Product designation VERO-S quick-change pallet system Type designation... - Page 37 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1.4.2.1 Fixed guards 1.4.2.2 Interlocking movable guards 1.4.2.3 Adjustable guards restricting access 1.4.3 Special requirements for protective devices Risks due to other hazards 1.5.1 Electricity supply 1.5.2 Static electricity 1.5.3 Energy supply other than electricity...

Need help?

Do you have a question about the VERO-S NSE mini 90-25 and is the answer not in the manual?

Questions and answers