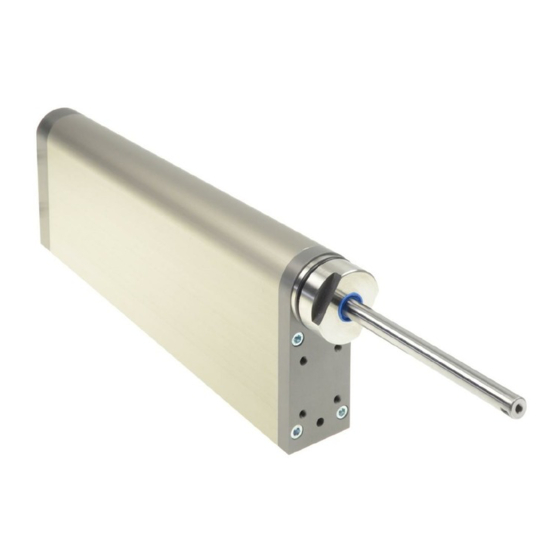

Summary of Contents for LinMot PR02-52x60-R_37x120F-HP-R-100_MS00_TS00

- Page 1 Installation Guide Linear Rotary Motors PR02-52 NTI AG / LinMot Dok-Nr. 0185-0021-E_1V2_IG_Linear_Rotary_Motors_PR02...

-

Page 2: Table Of Contents

Dimensions and technical data ....................19 7.4.2 Mounting ............................19 Maintenance and test instructions ....................... 20 Stator checking ..........................20 8.1.1 Linear Motor PS01-37x120F-HP-R....................20 8.1.2 Rotary Motor Stator RS01-52x60-R .................... 20 Maintenance ............................ 20 Page 2 / 24 PR02-52 NTI AG / LinMot... - Page 3 Preventive inspection every 6'000h ..................... 21 8.2.2 Inspection after each 12'000h ...................... 21 Calibration of torque measuring shaft ....................21 Storage, transport, installation altitude ....................21 Dimensions............................22 Declaration of Conformity and CE-marking ..................23 NTI AG / LinMot PR02-52 Page 3 / 24...

-

Page 4: General Information

1.4 Liability NTI AG (as manufacturer of LinMot linear motors and MagSpring products) excludes all liability for damages and expenses caused by incorrect use of the products. This also applies to false applications, which are caused by NTI AG's own data and notes, for example in the course of sales, support or application activities. -

Page 5: Safety Instructions

For non-anti-magnetic watches, keep the double minimum distance. Burn hazard The shaft of LinMot linear rotary motors can reach temperatures of 80 °C, which may cause burns upon contact. Grounding All metal parts that are exposed to contact during any user operation or servicing and likely to become energized shall be reliably connected to the means for grounding. - Page 6 For your own safety, avoid constant contact with magnets. Store large magnets at least one meter away from your body. Temperature resistance Keep motors away from unshielded flame or heat. Temperature above 120°C will cause demagnetization. Page 6 / 24 PR02-52 NTI AG / LinMot...

-

Page 7: Installation Instructions

(see explanation above). In addition, the front of the motor should be fixed using the 4 tapped holes. The positions of the tapped holes can be found in the "Dimensions" section. NTI AG / LinMot PR02-52 Page 7 / 24... -

Page 8: Mounting The Load On The Shaft

The shaft-hub clamping is a non-positive connection which is produced by means of two conical rings. The use of drivers or the production of grooves is completely eliminated. The suitable shaft-hub clamping type can be ordered from LinMot. Mounting instructions and ordering information can be found in the "Accessories" chapter. -

Page 9: Electrical Connection

Only connect or disconnect the motor connector and sensor cable if no voltage is applied to the servo drive! Only original LinMot cables may be used for wiring the motor and sensor! Even assembled cables may only be manufactured from the original LinMot accessories and must be... -

Page 10: Wiring Linear Rotary Motor

Installation Guide Linear Rotary Motors 4.2 Wiring Linear Rotary Motor The following schema shows the connection of the linear actuator and the torque measuring shaft with the LinMot Drive. Page 10 / 24 PR02-52 NTI AG / LinMot... -

Page 11: Connector Wiring Linear Rotary Motor

(not at the transducer) if required. External EMC circuitry A ceramic capacitor 100nF / 50V can be soldered between pins 4 - 5 on the evaluation to avoid wirebound interference. NTI AG / LinMot PR02-52 Page 11 / 24... -

Page 12: Start-Up

No.: 0150-2503) must be ordered. Without this software package it is not possible to control to a certain torque or the operation commands of the force control cannot be used. If the signal of the torque measuring shaft is only evaluated (PLC or LinMot Drive), the software package is not necessary. -

Page 13: Setting The Parameters

Installation Guide Linear Rotary Motors 5.2.3 Setting the parameters Logged into the drive, you will find all parameters to be set in the LinMot-Talk software under the path "Parameters -> Motion Control SW -> Protected Technology Functions -> Analog Force Feedback Control". -

Page 14: Accessories

Trailing Chain Cable Y/R, 4 m 0150-2433 KS05-Y/R-6 Trailing Chain Cable Y/R, 6 m 0150-2434 KS05-Y/R-8 Trailing Chain Cable Y/R, 8 m 0150-2435 KS05-Y-Fe/R- Trailing Chain Cable KS05-Y-Fe/R, Custom 0150-3507 length Page 14 / 24 PR02-52 NTI AG / LinMot... -

Page 15: Sensor Cable

The brake acts on the shaft and is released by compressed air. The brake has only a holding function and is not designed to slow or stop dynamic movements. No use for safety devices! Not approved as safety element! NTI AG / LinMot PR02-52 Page 15 / 24... -

Page 16: Dimensions

Filtered compressed air (40 µm), unoiled or oiled Operating pressure: 4 - 6 bar 10 °C…80 °C Ambient temperature: 7.3.4 Mounting Please attend to the safety instructions in chapter 2 during the assembling! Page 16 / 24 PR02-52 NTI AG / LinMot... - Page 17 4. Fasten the brake flange. 360° The brake flange with the applied brake can be rotated 360° and positioned as required. Then fasten with 4 hexagonal screws. Tightening torque: 10 Nm NTI AG / LinMot PR02-52 Page 17 / 24...

-

Page 18: Shaft-Hub Clamping

When pressure is applied, the brake is released and the shaft can be moved again. The air pressure for the brake can be controlled using the LinMot servo drives and a valve. Attention! Before the motor is moved, make sure that the brake is completely vented! -

Page 19: Dimensions And Technical Data

Slightly oil the shaft-hub clamping before mounting, do not use molybdenum disulphide or fat. Tighten screws opposite each other 180 degrees offset in several steps to tightening torque T (see above for details). NTI AG / LinMot PR02-52 Page 19 / 24... -

Page 20: Maintenance And Test Instructions

Increased operating temperature Other special environmental conditions Maintenance or disassembly of the linear rotary motors may only be carried out by trained companies: LinMot Companies qualified by LinMot Page 20 / 24 PR02-52 NTI AG / LinMot... -

Page 21: Preventive Inspection Every 6'000H

Replacement and maintenance of ball bearings / plain bearings, if necessary e) Calibration of torque measuring shaft, if necessary (The calibration of built-in torque measuring shafts is carried out at the NTI AG / LinMot factory.) 8.2.2 Inspection after each 12'000h Maintenance is recommended every 12,000 hours of operation or every two years. -

Page 22: Dimensions

Installation Guide Linear Rotary Motors 10 Dimensions Page 22 / 24 PR02-52 NTI AG / LinMot... -

Page 23: Declaration Of Conformity And Ce-Marking

EN61000-6-2:2005 EN61000-6-4:2007 Jahr der CE-Kennzeichnung: Year of CE marking: Annee du marquage CE: 2018 Spreitenbach, 07.06.2018 Dr.-Ing. Ronald Rohner CEO NTI AG NTI AG / LinMot PR02-52 Page 23 / 24... - Page 24 +41-(0)56-544 71 00 Tech. Support: 262-743-1284 support@linmot.com Tech. Support (Skype): skype:support.linmot Fax: 262-723-6688 Fax: +41-(0)56-419 91 92 E-Mail: usasales@linmot.com Web: http://www.linmot.com/ Web: http://www.linmot-usa.com/ Visit http://www.linmot.com/ to find a distributor next to you. © 2019 NTI AG / LinMot Subject to alterations...

Need help?

Do you have a question about the PR02-52x60-R_37x120F-HP-R-100_MS00_TS00 and is the answer not in the manual?

Questions and answers