Festo CPX Series Manual

Hide thumbs

Also See for CPX Series:

- Manual (446 pages) ,

- Electronic manual (232 pages) ,

- Description (156 pages)

Chapters

Table of Contents

Summary of Contents for Festo CPX Series

- Page 1 CPX Terminal Manual electronics Multi-Axis Interface CPX-CMXX Manual 564 222 en 1102b [757 652]...

- Page 3 ....... . . 564 222 © (Festo AG & Co. KG, D -73726 Esslingen, 2011) Internet: http://www.festo.com E-mail: service_international@festo.com...

- Page 4 Contents and general instructions ® ® ® ® ® ® ® TORX , PROFIBUS , PROFIBUS-DP , PROFINET IO , DeviceNet , EtherNet/IP , CC-Link ® and Interbus are registered trademarks of the respective owners in certain countries. Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 5: Table Of Contents

Connection and display components ....... 1-13 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 6 ......... . . 2-10 2.5.2 Connection with Festo CAN bus plug ......2-11 2.5.3...

- Page 7 ............Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 8 Contents and general instructions Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 9: Intended Use

Contents and general instructions Intended use The CPX-CMXX multi-axis interface documented in this manual is intended exclusively for use in Festo CPX terminals for installation in a machine or an automation control system. The multi-axis interface CPX-CMXX permits coordination of axis portals and positioning axes in conjunction with a PLC. -

Page 10: Target Group

This manual is intended exclusively for technicians trained in control and automation technology, who have experience in installing, commissioning, programming and diagnosing positioning systems. Service Please consult your local Festo Service agent if you have any technical problems. VIII Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 11: Important User Instructions

This means that failure to observe this instruction may result in damage to property. The following pictogram marks passages in the text which describe activities with electrostatically sensitive compo- nents. Electrostatically sensitive components may be damaged if they are not handled correctly. Festo P.BE-CPX-CMXX-EN en 1102b... - Page 12 Accessories: Information on necessary or sensible accessories for the Festo product. Environment: Information on environment-friendly use of Festo products. Text markings The bullet indicates activities which may be carried out in • any order. 1. Figures denote activities which must be carried out in the numerical order specified.

- Page 13 Contents and general instructions Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 14: Safety Regulations

Make sure that no persons are in the operating range of • the drive or any other connected actuators. Do not switch on the compressed air supply until the • system is correctly installed and parametrised. Festo P.BE-CPX-CMXX-EN en 1102b... - Page 15 Do not connect, disconnect or open pressurised tubing. • The tubing must always be vented before removal • (release compressed air). Use suitable protective equipment (e.g. safety goggles, • safety shoes, etc.). XIII Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 16: Instructions On This Manual

Online help on the FCT plug-in Description of the configuration, CMXX parametrisation and commissioning of the multi-axis interface CPX-CMXX Manual for the Festo handling Description for the Festo data and positioning profile for profile FHPP-MAX, which is used multi-axis movements for communication between the (FHPP-MAX), controller and CPX-CMXX. - Page 17 General basic information on the mode of operation, mount- ing, installation and commissioning of CPX terminals can be found in the CPX system description, type P.BE-CPX-SYS-... Observe also the user documentation of the components used in the CPX terminal. Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 18: Glossary

(as a CPX module: CPX fieldbus node). Gantry axis Gantry axes are axes with the following characteristics: – Gantry axes run synchronously, see synchronous PtP movement. Handheld CPX-MMI Hand-operated device for service purposes Festo P.BE-CPX-CMXX-EN en 1102b... - Page 19 – The positioning times of the axes are adapted to the axis with the greatest positioning time. – All axes end their movement simultaneously. Tab. 0/2: Terms and abbreviations XVII Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 20 Contents and general instructions XVIII Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 21: System Summary

System summary Chapter 1 System summary Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 22: The Cpx-Cmxx Multi-Axis Interface

Connection and display components ....... 1-13 Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 23: System Summary

CPX fieldbus node or through the CPX-FEC/CPX-CEC controller integrated into the CPX terminal. Communication with the CPX-CMXX takes place over the Festo data profile FHPP-MAX. The Festo data profile is based on the Festo data profile FHPP, which was expanded for the multi-axis mode. -

Page 24: Functions And Characteristics

Configuration of two axis groups with up to four axes each is possible – 1,024 position sets available per axis group – Configuration with the Festo Configuration Tool (FCT) – Simple input or teaching of positions in a specified record structure –... -

Page 25: Mode Of Operation

CPX-CMXX via a CPX fieldbus node, or a CPX-FEC/CPX-CEC control the movement sequence via the Festo data profile FHPP-MAX. The controller can thereby either specify just the record numbers stored in the CPX-CMXX or separate values for position, velocity and acceleration for each axis. - Page 26 SFC-LAC 1.05 — SFC-LACI 1.00 — Tab. 1/1: Summary supported motor controllers (Status: February 2011) With higher software versions, a warning message is displayed, but this does not influence the functioning of the motor controller. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 27 – Control through CPX-FEC or CPX-CEC Communication with the controller takes place with 16-byte input and output data, 8 bytes per axis group. Communication takes place over the Festo data profile FHPP-MAX, see manual P.BE-CMXX-FHPP-MAX-SW-... Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 28 02 — Software status (SW) see type plate Tab. 1/2: Summary CPX modules (Status: February 2011) Note Please also observe the notes on the software status in the documentation of the respective CPX modules. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 29 4 positioning axis One motor controller per axis One drive per axis One translatory or rotatory axis each Tab. 1/3: Design of a multi-axis system The possible system configurations are explained in chapter 1.5. Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 30: Autonomous Automation Solution

In this configuration, the sequence control of the CPX ter- minal is taken over by the CPX-FEC/CPX-CEC. Programming takes place over the Festo data profile FHPP -MAX. The CPX-CMXX takes over multi-axis control in combination with the CPX-FEC/CPX-CEC. Communication between the CPX-CMMX and CPX-FEC/CPX-CEC is carried out over the CPX terminal. -

Page 31: Control Of The Cpx Terminal Through A Higher-Order Controller

In this configuration, the sequence control of the CPX ter- minal is taken over by a higher-order controller. Programming takes place over the Festo data profile FHPP -MAX. The CPX-CMXX takes over multi-axis control in combination with the higher-order controller. Communication between the CPX-CMMX and the higher-order controller is carried out over the CPX fieldbus node. -

Page 32: Autonomous Automation Solution With Communication

In this configuration, the sequence control of the CPX ter- minal is taken over by the CPX-FEC/CPX-CEC. Programming takes place over the Festo data profile FHPP -MAX. The CPX-CMXX takes over multi-axis control in combination with the CPX-FEC/CPX-CEC. Communication between the CPX-CMMX and CPX-FEC/CPX-CEC is carried out over the CPX terminal. -

Page 33: Connection And Display Components

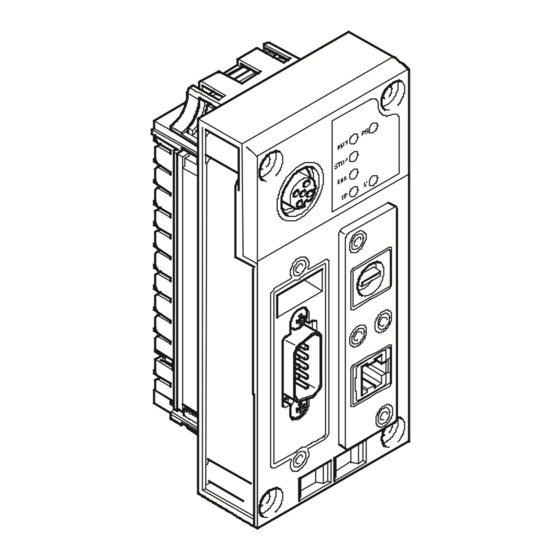

(Selection of the operating mode) RUN/STOP rotary switch DIL switch 2 Ethernet interface (CAN bus termination) (10/100BaseT, RJ45) Interface, reserved Control interface (CAN bus, 9-pin sub-D plug) Fig. 1/4: Connection and display elements on the CPX-CMXX 1-13 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 34 (yellow) ERROR Error (red) Ethernet connection (green) Control hierarchy is with FCT (yellow) Power system (green) The LEDs RUN 1 and STOP 2 show the status of the RUN/STOP rotary switch. Fig. 1/5: Status LEDs 1-14 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 35 Fitting and installation Chapter 2 Fitting and installation Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 36 ......... . . 2-10 2.5.2 Connection with Festo CAN bus plug ......2-11 2.5.3...

-

Page 37: Fitting And Installation

Information about fitting the CPX terminal can be found in the CPX system manual (P.BE-CPX-SYS-...). Information on mounting the components of the multi-axis system can be found in the related documentation of the components. Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 38: Dismantling And Mounting

2.2.1 Dismantling Dismantle the CPX-CMMX as follows: 1. Loosen the four screws of the CPX-CMXX with a size-T10 TORX screwdriver. 2. Pull the CPX-CMXX carefully and without tilting away from the contact rails of the manifold sub-base. Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 39: Mounting

4. Place the screws so that the self-cutting threads can be used. Tighten the screws by hand. 5. Tighten the screws with a size-T10 Torx screwdriver with 0.9 ... 1.1 Nm of torque. Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 40: Setting The Switches

CPX-CMXX stopped The STOP LED lights up yellow. 1 ... F CPX-CMXX started. The switch positions 1 ... F have no further function. The RUN LED lights up green. Tab. 2/1: Setting the RUN/STOP rotary switch Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 41: Dil Switches

Setting the operating mode Note Check that the setting of the DIL switch is correct before commissioning the CPX-CMXX. Modification to the switch setting is not recognized until the power supply is switched off, then on again. Festo P.BE-CPX-CMXX-EN en 1102b... - Page 42 CAN bus termination switched on. DIL 2.1: ON DIL 2.2: OFF All further switch settings are reserved. Tab. 2/3: Setting the CAN bus termination Changes to DIL switch 2 have a direct effect on the CAN bus termination. Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 43: Control Interface

If a motor controller with external voltage supply is connected, CAN Ground (optional), pin 6, on the CPX-CMXX must not be used. FE: Functional earthing Tab. 2/4: Pin assignment of the control interface The CPX-CMXX does not provide any voltage for the connected CAN bus slaves via the control interface. Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 44: Connecting The Can Bus

Use a twisted, screened 4-core cable as CAN bus line. The CPX-CMXX communicates with the motor controllers via the CAN bus line. If the Festo CAN bus plug is used, a cable diameter of 5-8 mm or 7-10 mm is permitted. Note... -

Page 45: Connection With Festo Can Bus Plug

(T-TAP function). Note The clamp strap in the Festo CAN bus plug is connected only capacitively internally with the metal housing of the sub-D plug. This prevents equalizing currents from flowing via the screening of the CAN bus cable (Fig. - Page 46 Bus in Clamp strap for Bus out screening connection Protective cap if connection is not used CAN bus outgoing (OUT) CAN bus incoming (IN) Sub-D plug connected capacitively Fig. 2/2: CAN bus plug from Festo, FBS-SUB-9-BU-2x5POL-B 2-12 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 47: Further Connection Possibilities For The Can Bus With Adapters

Make sure of the correct polarity when you connect the • CAN bus interface. Connect the screen. • There are further possibilities of connecting the CAN bus with adapters, which can be ordered separately from Festo under: www.festo.com/catalogue – M12 adapter 5-pin (protection class IP65) FBA-2-M12-5POL –... - Page 48 Protective cap or plug with bus termination resistor if connection is not used. Fig. 2/3: Pin assignment of the CAN bus interface (adapter for M12 connection 5-pin) With the two M12 connections, you can implement a T-adapter. 2-14 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 49 Fig. 2/4: Pin assignment of the CAN bus interface (screw terminal adapter 5-pin) If you connect the CAN bus over the terminal strip FBSD-KL-2x5POL from Festo, you can realize a T-adapter function. Note If you use the screw terminal adapter in conjunction with the terminal strip, you achieve protection class IP20.

-

Page 50: Ethernet Interface

Screened covering Tab. 2/5: Pin allocation for the Ethernet interface Seal an unused Ethernet interface with the suitable cover • (see chapter 2.7). Use the suitable plug for the Ethernet interface • (see chapter 2.7). 2-16 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 51 AK-RJ45 Reserved – Protective cap interface, M12 ISK-M12 Rotary switch – Cover AK-RJ45 DIL switches – if connection is not used included in scope of delivery Tab. 2/6: Connections and covers for protection class IP65/IP67 2-17 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 52 2. Fitting and installation 2-18 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 53 Commissioning Chapter 3 Commissioning Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 54 ..........3-14 3.4.3 Configuring and parametrising CPX-CMXX ....3-16 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 55: Commissioning

Information about commissioning the CPX terminal can be found in the CPX system manual (P.BE-CPX-SYS-...). Information on commissioning the components of the multi-axis system can be found in the related components documentation. Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 56: Preparing Configuration And Parametrisation

3. Commissioning Preparing configuration and parametrisation To configure and parametrise the CPX-CMXX and motor controller, you need a PC on which the Festo Configuration Tool (FCT) and the respective FCT plug-ins are installed. 3.2.1 Installing FCT and FCT plug-ins Note Installation of the FCT plug-ins of the motor controller is described in the respective online help. - Page 57 When installation is completed, you will find the FCT entry in the start menu under “Festo Software”. The CMXX plug-in is available for setting up new projects as Festo components and is activated automatically when an existing CMXX project is selected. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 58 3. Commissioning Deinstallation The CMXX plug-in and the FCT program are disconnected in each case with help of the “Software” function in Windows System Control. Follow the instructions in your Windows manual. • Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 59: Parametrisation Of The Connected Motor Controllers

If the CAN bus malfunctions (DIL2.1 termination OFF or separation of the connection), drives can continue to move and cause collisions with severe injuries. Make sure that no persons are in the operating range of • the drive or any other connected actuators. Festo P.BE-CPX-CMXX-EN en 1102b... - Page 60 3.3.2 Communication between CPX-CMXX and the motor controllers Communication between CPX-CMXX and the motor controllers takes place over the following interface: Parameters Setting Interface CANopen Data profile DS 402 Transmission rate 1 mbps CAN address see Tab. 3/2 Tab. 3/1: Parameters for communication Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 61 3. Commissioning The CAN address of the axes is established as follows: Axis group Axis CAN address Tab. 3/2: CAN addresses of the axes Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 62: Specific Settings For Cmmx-Xx Motor Controller

With this setting, when parametrising the CPX-CMXX for all CMMx-xx motor controllers, the transmission factor must be set at 1000 increments/mm or 1000 increments/° see Online Help for FCT plug-in CPX-CMXX. Tab. 3/3: Specific settings for CMMx-xx motor controller 3-10 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 63 Menu/Tab Parameters Value [Configuration] Controller type SFC-DC-...-CO [Controller] [Interface] CAN address CAN address of the axis, see Tab. 3/2 Bit rate 1 mbps Data profile DS 402 Tab. 3/5: Specific settings for SFC-DC motor controller 3-11 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 64: Specific Settings For Sfc-Lac/Sfc-Laci Motor Controller

“external” option: An external power supply must be attached to the CAN bus plug; see chapter 2.4, Tab. 2/4 and P.BE-SFC-LAC-CO-... or P.BE-SFC-LACI-CO-... Tab. 3/6: Specific settings for SFC-LAC / SFC-LACI motor controller 3-12 Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 65: Configuration Of The Cpx-Cmxx

PC directly to the CPX-CMXX, use alternatively – a crossover cable with RJ45 plug – a patch cable with RJ45 plug. The Ethernet interface of the CPX-CMXX recognises which cable is connected and automatically switches over internally. 3-13 Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 66: Prepare Pc

Windows start menu. The “Network connections” window opens. 2. Double click in the “Network connections” window on the network connection intended for connection of the CPX-CMXX. The dialog “Status of <Your Connection>” opens. 3-14 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 67 Fig. 3/1: Setting the IP address and subnetwork mask Note Write down the network settings of your PC before you • change them. 5. Set the network properties of your PC in the dialogue “Properties of Internet Protocol (TCP/IP)” and confirm with OK. 3-15 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 68: Configuring And Parametrising Cpx-Cmxx

1. Change the network settings of your PC to the original values. 2. Disconnect the Ethernet connection to the CPX-CMXX. 3. Place a suitable protective cap (see chapter A.2) on the Ethernet interface to reestablish the protection class IP65/67. 3-16 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 69 Diagnosis and error treatment Chapter 4 Diagnosis and error treatment Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 70 4-19 4.4.4 Other diagnostic information ......4-21 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 71: Diagnosis And Error Treatment

(CPX-FEC/CPX-CEC or I/O diagnostic CPX fieldbus node) interface or on the CPX-MMI handheld LED display The LEDs directly indicate error Fast “on-the-spot” Chapter 4.3 states. recognition of errors Tab. 4/1: Diagnostics options Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 72: Errors And Warnings

The motor controllers of the axis group are not switched off. – No new positioning task will be accepted. – With disturbances of type 2 – All motor controllers of the axis group are switched off. – No new positioning task will be accepted. Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 73: Acknowledging Errors

(Positioning task is sent to axis when reset has been ended. while reset is active) • Warning Axis stopped Send a positioning task only (Positioning task is sent to axis when the stop process has been while axis stops) ended. Festo P.BE-CPX-CMXX-EN en 1102b... - Page 74 A direction of rotation is blocked, since the limit switch has been actuated) Warning Warning: Recognised device is not The warning serves as information completely supported that possibly not all functions of the device are supported; operation is still possible. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 75 Invalid product code recognised Check or change the configuration. • Close the device configured in the FCT plug-in. • Invalid firmware recognised Check or change the configuration. • Close the device configured in the FCT plug-in. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 76 Check the motor controller and execution the axis. (Axis command could not be ended in the specified time) • Command for inactive axis Check the triggering or configuration. • Command for inactive group Check the triggering or configuration. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 77 (Number of the selected positioning record outside the range 1 ... 1024) System error A (CPX error category 104, System_A) • Positioning record memory not Please consult your local Festo initialised service or (Positioning records could not be service_international@festo.com written from file {permanent...

- Page 78 Error when resetting a node Check the CAN bus and the configuration of the node involved. • Internal error at node start Please consult your local Festo service or service_international@festo.com • Serious internal error Please consult your local Festo service or service_international@festo.com...

- Page 79 Check the motor controller. “Interpolated position mode” Licence error (CPX error category 144, Licence Error) • – – CoDeSys licence error Please consult your local Festo service or service_international@festo.com Tab. 4/2: Error messages of the CMXX 4-11 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 80: Diagnostics Via Leds

(RUN/STOP switch is in position 0). LED lights up • CPX-CMXX not stopped – Set the RUN/STOP (RUN/STOP switch is in switch to 0. LED is off position 1 ... F. Tab. 4/4: LED STOP 4-12 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 81 Data transfer active – None (LED flashes irregularly) LED flashes • Ethernet connection to the – Check: parametrisation PC not OK – the connection – the IP address LED is off Tab. 4/6: LED TP 4-13 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 82 Power supply longer than – Eliminate the low 10 ms below the threshold voltage of 17 V. LED flashes • Power supply is not on – Check the operating voltage connection. LED is off Tab. 4/8: LED PS 4-14 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 83: Diagnosis At The Cpx Terminal

Tab. 4/9. The following sections contain the special features of the presentation for the CPX-specific diagnostics options. – Status bits (see section 4.4.1) – Diagnosis memory with CPX error categories (I/O diagnosis interface, see section 4.4.2) 4-15 Festo P.BE-CPX-CMXX-EN en 1102b... -

Page 84: Status Bits In The System Status Of The Cpx Terminal

I/O diagnostic interface and the diagnostic memory of the CPX terminal. Diagnostic memory data (I/O diagnostic interface) The specific representation of diagnostic messages of the CPX-CMXX in the diagnostic memory of the CPX terminal occurs as shown in Tab. 4/9. 4-16 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 85 (diagnostic event) [NB] = 0 ... 39 ; most current diagnostic event = 0 Tab. 4/9: Diagnostic memory data of the CPX-CMXX Instructions on diagnosis with the I/O diagnostic interface can be found in the CPX system manual. 4-17 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 86 = module number (0 ... 47) Description CPX error category Bits 0 ... 7 Range of values: 0 ... 255 Remark The CPX error categories of the CPX-CMXX are described in chapter 4.2. Tab. 4/11: Module error number 4-18 Festo P.BE-CPX-CMXX-EN en 1102b...

-

Page 87: Definition Of Diagnosis Channels

The following tables show the definition of the diagnosis channels Channel number Axis group Axis Input channel – – – – – – – – – – – – – – Tab. 4/12: Definition of diagnostic channels, part 1 4-19 Festo P.BE-CPX-CMXX-EN en 1102b... - Page 88 4. Diagnosis and error treatment Channel number Axis group Axis Output channel Tab. 4/13: Definition of diagnostic channels, part 2 4-20 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 89 In byte 1 ... 3, each nibble contains one digit of the serial number (BCD encoded) Function no: 784 + m*4 + 0 784 + m*4 + 1 784 + m*4 + 2 784 + m*4 + 3 4-21 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 90 4. Diagnosis and error treatment 4-22 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 91 Technical appendix Appendix A Technical appendix Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 92 ........... . Device-specific information on the handheld unit CPX-MMI ... . . Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 93 Error in the program execution Status Ethernet connection LED display (product-specific) Modify, parameterisation Electronic supply, sensor supply Protocol FHPP-MAX (Festo Handling and Positioning Profile for Multi-Axis Movements) Control interface CAN bus – Data profile DS 402 – Baud rate 1 Mbps –...

- Page 94 18 ... 30 VDC Intrinsic current consumption – at nominal operating voltage typ. 85 mA Power failure buffering 10 ms Product weight approx. 155 g Dimensions W x L x H 50 mm x 107 mm x 55 mm Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 95 A. Technical appendix Accessories Please select the appropriate accessories from our catalogue www.festo.com/catalogue/cpx-cmxx. Information on accessories for the CPX terminal can be found in the CPX system manual or in the description for the CPX modules used. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 96 Force mode in the Monitoring/Forcing (M) menu – Fail Safe (F) Warning Incorrect entries in the Force Mode or with the Fail safe function can cause undesired movements and severe personal injury and property damage! The Parameters (P) function is not supported. Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 97 1: CMXX: D _____ CPX-CMXX are displayed with the Diagnostics function. Channel fault CH1: Output The diagnosis channel gives the error location, Controller error see section 4.4.3 _____________________________________________________ The CPX error categories are described in section 4.2.3. Back Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 98 IP address gateway: 0.0. – Revision: 1 Startup: via saved IP par _____________________________________________________ Back – Series number 0x5001FFD1 – IP address: 192.168.2.10 – IP net mask: 255.255.0.0 – IP address gateway: 0.0.0.0 – Startup: via saved IP parameters Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 99 First faulty module 1: CMXX Multi-axis interf Fault number: 107 – Module position and designation Controller error – Number of the CPX error category _____________________________________________________ Back – Designation of the CPX error category Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 100 Module position Seconds: 57 Milliseconds: 13 – Module designation _____________________________________________________ Back – Time stamp in the format Days:Hours:Minutes: Seconds: Milliseconds since switch-on Note Further information on the MMI can be found in the documentation P.BE-CPX-MMI-1-... A-10 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 101 Index Appendix B Index Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 102 ............Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 103 ....... 2-16 Handheld CPX-MMI ......Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 104 ........Protection class IP65/IP67 ..... . . 2-17 Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 105 ........Use for intended purpose ......Festo P.BE-CPX-CMXX-EN en 1102b...

- Page 106 B. Index Festo P.BE-CPX-CMXX-EN en 1102b...

Need help?

Do you have a question about the CPX Series and is the answer not in the manual?

Questions and answers