Siemens SIVACON 8PS Configuration Manual

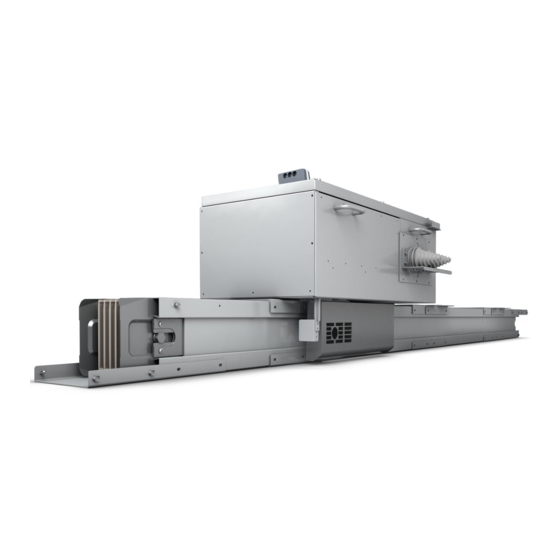

Busbar trunking system.

configuring with lx system.

low-voltage power distribution and

electrical installation technology

Hide thumbs

Also See for SIVACON 8PS:

- Installation instructions (3 pages) ,

- Installation instructions (4 pages) ,

- Installation instructions (2 pages)

Summary of Contents for Siemens SIVACON 8PS

- Page 1 Busbar trunking system SIVACON 8PS - Configuring with LX system Configuration Manual 10/2011 • Low-Voltage Power Distribution and Electrical Installation Technology Answers for infrastructure.

- Page 3 ___________________ SIVACON 8PS - Configuring with LX About this documentation system Standards, certifications and ___________________ approvals ___________________ Product description Low-voltage power distribution and ___________________ electrical installation technology Product selection Busbar trunking system ___________________ SIVACON 8PS - Configuring with Installation and mounting...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Standards.............................11 Certifications ..........................11 Approvals .............................12 Product description ..........................13 Overview of Siemens busbar trunking systems................13 Performance capability of the individual SIVACON 8PS systems..........17 Application areas of the individual SIVACON 8PS systems............19 System description........................20 System sizes and structure......................21 Conductor configuration.......................23 Cross-sections ..........................24 Product selection ............................. - Page 6 6.1.3.3 Cable feeder units ........................91 6.1.3.4 Connection to non-Siemens distribution boards ................. 93 6.1.3.5 Connection to Siemens power distribution systems ..............94 6.1.4 Tap-off units ..........................98 Configuring the busbar run layout..................... 101 6.2.1 Configuring horizontal busbar runs ................... 101 6.2.1.1...

- Page 7 Universal busbar connection unit AS2 with T tap-off unit ............169 8.3.1.7 Connection tags .........................170 8.3.2 Incoming cable connection units....................173 8.3.3 Non-Siemens distribution board connection units ..............175 8.3.4 Distribution board connection units....................182 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 8 Size 2 or 3 (400 A and 630 A)....................190 Additional equipment......................... 191 Circuit diagrams............................. 197 Tap-off unit with circuit breaker, 3-pole..................197 Tap-off unit with circuit breaker, 4-pole..................200 Glossary ..............................201 Index..............................205 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 9: About This Documentation

What information will you find in this documentation? This documentation contains all essential information you need to configure SIVACON 8PS LXA/LXC. In this documentation you will find overview depictions and detailed and reference information. The individual chapters of this documentation offer you detailed information about: ●... -

Page 10: Structure Of The Documentation

Valid standards, certifications and approvals for busbar trunking systems approvals and their use. Chapter 3 Product description Overview of SIVACON 8PS busbar trunking systems Application areas for high-current systems Detailed technical information on the design of LXA/LXC ... -

Page 11: Target Group Of This Documentation

Siemens AG branch office. Catalogues Catalogue LV 70 - SIVACON 8PS busbar trunking systems CD, BD01, BD2 (up to 1250 A) Brochure For safe power flows. Busbar trunking system SIVACON 8PS... - Page 12 About this documentation 1.4 Supplementary documentation SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 13: Standards, Certifications And Approvals

Standards, certifications and approvals Standards Standards The standards listed below are applicable to the Siemens SIVACON 8PS busbar trunking system: Standards Standard reference IEC / EN 60439-1 and 2 Busbar trunking systems in general DIN VDE 0100-600 Determining loop impedance... -

Page 14: Approvals

Catalogue LV 1. You can find an overview of the certification available for low-voltage energy distribution products updated daily on the Internet at the low-voltage power distribution address (http://www.siemens.com/lowvoltage/support). SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 15: Product Description

⑤ CD-K system LX system ② ⑥ BD01 system LR system ③ ⑦ BD2 system Communication-enabled busbar trunking systems ④ LD system Figure 3-1 Overview of busbar trunking systems SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 16 ● Storage-friendly system ● High degree of protection (IP54) for side-mounted and downwards tap-off points under extreme ambient conditions, IP55 with additional equipment. For further information: see also Catalogue LV 70 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 17 ● High degree of protection IP54 or IP55 for use in harsh industrial environments ● Innovative design: Omission of compensation elements to compensate for expansion For further information: see also Catalogue LV 70 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 18 ● IP34 degree of protection with air cooling (IP54 with sealed enclosure) ● Type-tested connection to distribution boards and transformers For further information: See also the planning manual Planning with SIVACON 8PS. Busbar trunking systems up to 6300 A (order number: A5E01541101)

-

Page 19: Performance Capability Of The Individual Sivacon 8Ps Systems

Product description 3.2 Performance capability of the individual SIVACON 8PS systems Performance capability of the individual SIVACON 8PS systems Performance overview for the CD-K, BD01 and BD2 systems The following tables present an overview of the performance capabilities of the individual... - Page 20 Product description 3.2 Performance capability of the individual SIVACON 8PS systems Performance overview for the LD, LX, LR systems The following tables present an overview of the performance capabilities of the individual SIVACON 8PS systems: Table 3- 2 Performance data...

-

Page 21: Application Areas Of The Individual Sivacon 8Ps Systems

Application areas of the individual SIVACON 8PS systems Application areas of the individual SIVACON 8PS systems The individual systems of SIVACON 8PS are designed for the building and industry application areas. They enable flexible power distribution in building construction and a safe power supply to electronic loads. -

Page 22: System Description

The high degree of protection IP54 (IP55 on request) and tap-off units up to 1250 A also ensure reliable power supply in industrial applications with high power requirements. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 23: System Sizes And Structure

LXC03, LXA(C)04 LXA(C)05 LXA(C)06, LXA(C)07 Width is always 145 mm Sizes (H x W ), double system Height H [mm] System LXA(C)08 LXA(C)09, LXA10 Width is always 145 mm SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 24 Deviations for the horizontal flat mounting position are listed in the technical data of the relevant system sizes. Horizontal busbar run, Horizontal busbar run, flat Vertical busbar run edgewise busbars busbars SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 25: Conductor Configuration

PE conductor LX...53 Electrical connection between enclosure and PE LX...61 Clean is the PE conductor earth LX...54 Electrical connection between enclosure and PE LX...62 Clean is the PE conductor earth SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 26: Cross-Sections

Even the fault currents in the enclosure generated by magnetic fields do not affect the clean earth. This means the clean earth is optimally suited to PE connection of sensitive electronic loads. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 27 L1, L2, L3, N, clean earth: 100 % PE (enclosure): 280 % in Cu equivalent 2. LXC0554 L1, L2, L3: 100 % N: 200 % PE (enclosure + busbar): 219 % in Cu equivalent SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 28 Product description 3.7 Cross-sections SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 29: Product Selection

Meaning Distance between tap-off point centre and joint block centre Length of expansion compensation unit [m] Standard length Optional length Length X dimension Length Y dimension Length Z dimension SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 30: Basic Type Code

The resulting type codes enable the required system to be precisely defined. Please refer to the selection tables for the type codes you must use for each system. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 31 +LX..-S120 and mounted on the trunking unit in the factory is available on request. Others only on request You can find details in the type code under Universal busbar connection units (Page 46) . Only available as a copper system (LXC). SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 32 For conductor configurations 54, 61 and 62, the fire barrier in accordance with type suffix +LX ..-S120 and mounted on the trunking unit in the factory is available on request. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 33: Selection Tables

+LX..-S120-X* 2.01...2.99 LX..-3W* +LX..-S120-X* See type code 1 See type code 2 Fire barrier possible from optional length W = 1.04 m Complete type with relevant dimensions (e.g. LX..-1W0.76) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 34 Phase change unit Length L/W/D Type On request 1.25 LX..-P See type code 2 Expansion compensation All types in copper version Length D Type LX..-D See type code 2 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 35: Straight Trunking Units With Tap-Off Points

Standard length with up to 5 tap-off points selectable, on one side Length L Position of the Type Type suffix tap- tap-off point off point ADO-U 0.67 LX..-3-AD +LX-F 1.17 +LX-G 1.67 +LX-H 2.17 +LX-I 2.67 +LX-K SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 36 Examples of trunking units with 3 tap-off points top and bottom: LXA0141-3-ADO-U+LX-A+LX-C+LX-E Note Dimensions of the tap-off units When configuring the tap-off points, please note the dimensions of the tap-off units, see Configuration (Page 79). SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 37: Straight Trunking Units With Tap-Off Points And Configurable Fire Barrier

See type code 1 See type code 2 Complete type with relevant dimensions (e.g. LX..-1W1.70-1AD0.8) Example types LXA0141-3-1AD LXA0141-3W2.80-1AD1.3 Note Positioning of the fire barrier, see Configuration (Page 79) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 38: Junction Units

See type code 1 See type code 2 Fire barrier possible on X dimension Fire barrier possible on Y dimension Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LR-YB0.80) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 39 See type code 1 See type code 2 Fire barrier possible on X dimension Fire barrier possible on Y dimension Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LV-YB0.80) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 40 See type code 1 See type code 2 Fire barrier possible on X dimension Fire barrier possible on Y dimension Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LH-YB0.80) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 41 …0.85 0.35 …0.70 0.52 …0.85 LX.08 to LX.10 0.80 …1.15 0.35 …0.70 0.84 …1.15 See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LLH-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 42 …0.85 0.35 …0.70 0.52 …0.85 LX.08 to LX.10 0.80 …1.15 0.35 …0.70 0.84 …1.15 See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LRH-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 43 …0.70 0.50 …0.85 0.52 …0.85 LX.08 to LX.10 0.35 …0.70 0.80 …1.15 0.84 …1.15 See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LHR-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 44 …0.70 0.50 …0.85 0.52 …0.85 LX.08 to LX.10 0.35 …0.70 0.80 …1.15 0.84 …1.15 See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-LVR-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 45 …0.85 0.50 …0.85 0.70 …1.00 LX.08 to LX.10 0.80 …1.15 0.80 …1.15 1.33 …1.60 See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-ZH-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 46 0.40 …0.70 LX…..-ZR-Z* LX.01 to LX.10 0.35 …0.70 0.35 …0.70 0.40 …0.70 LX…..-ZR- X*/Y*/Z* See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-ZR-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 47 …0.85 0.50 …0.85 0.50 …0.85 LX.08 to LX.10 0.80 …1.15 0.80 …1.15 0.80 …1.15 See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-TH-X0.40/Y0.56/Z0.60) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 48: Feeder Units

Product selection 4.3 Selection tables 4.3.3 Feeder units 4.3.3.1 Universal busbar connection units Type code 3 for universal connection units SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 49 Phase sequence transformer Installation position of Type Type suffix Type suffix and LX connection trunking units Phase Phase distance sequence/ LX connection LX..-AS. +LX-1A +LX-P*(/N*) LX..-AS. +LX-2A +LX-P*(/N*) LX..-AS. +LX-1B +LX-P*(/N*) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 50 LX connection LX..-AS. +LX-2B +LX-P*(/N*) LX..-AS. +LX-1C +LX-P*(/N*) LX..-AS. +LX-2C +LX-P*(/N*) LX..-AS. +LX-1D +LX-P*(/N*) LX..-AS. +LX-2D +LX-P*(/N*) See type code 3 Complete type with relevant dimensions (e.g. +LX-P0.20) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 51 Type suffix Type suffix and LX connection trunking units Phase Phase distance sequence/ LX connection LX..-AS2 +LX-1E +LX-P*(/N*) LX..-AS2 +LX-2E +LX-P*(/N*) LX..-AS2 +LX-1F +LX-P*(/N*) LX..-AS2 +LX-2F +LX-P*(/N*) LX..-AS2 +LX-1G +LX-P*(/N*) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 52 LX connection trunking units Phase Phase distance sequence/ LX connection LX..-AS2 +LX-2G +LX-P*(/N*) LX..-AS2 +LX-1H +LX-P*(/N*) LX..-AS2 +LX-2H +LX-P*(/N*) See type code 3 Complete type with relevant dimensions (e.g. +LX-P0.20) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 53 Values in brackets and dotted lines apply to the 5-core system. Phase sequence transformer and LX Type Type suffix Type suffix connection Phase sequence/ Phase distance LX connection LX..-AS.-T +LX-1A +LX-P*(/N*) LX..-AS.-T +LX-2A +LX-P*(/N*) LX..-AS.-T +LX-1B +LX-P*(/N*) PEN(N) (PE) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 54 Phase distance LX connection LX..-AS.-T +LX-2B +LX-P*(/N*) LX..-AS.-T +LX-1C +LX-P*(/N*) LX..-AS.-T +LX-2C +LX-P*(/N*) LX..-AS.-T +LX-1D +LX-P*(/N*) LX..-AS.-T +LX-2D +LX-P*(/N*) See type code 3 Complete type with relevant dimensions (e.g. +LX-P0.20) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 55 Phase sequence transformer and LX Type Type suffix Type suffix connection Phase sequence/ Phase distance LX connection LX..-AS2-T +LX-1E +LX-P*(/N*) LX..-AS2-T +LX-2E +LX-P*(/N*) LX..-AS2-T +LX-1F +LX-P*(/N*) LX..-AS2-T +LX-2F +LX-P*(/N*) LX..-AS2-T +LX-1G +LX-P*(/N*) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 56 Type suffix connection Phase sequence/ Phase distance LX connection LX..-AS2-T +LX-2G +LX-P*(/N*) LX..-AS2-T +LX-1H +LX-P*(/N*) LX..-AS2-T +LX-2H +LX-P*(/N*) See type code 3 Complete type with relevant dimensions (e.g. +LX-P0.20) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 57: Incoming Cable Connection Units

Incoming cable connection units are only available on request for the following systems: ● Double systems LX.08.. to LX.10.. ● Systems with conductor configurations of the key digits 30, 52, 53, 54, 61 and 62. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 58: Non-Siemens Distribution Board Connection Units

Note Use in distribution systems When using busbar connection units for non-Siemens distribution boards, you must ensure that the permissible limit temperature of 135 °C for the busbars is not exceeded at an ambient temperature of 35 °C averaged over 24 hours. - Page 59 Product selection 4.3 Selection tables Non-Siemens distribution board connection units, connection elbow right System Length X Length Y Type LX.01 to LX.10 0.35 ...0.70 0.22...0.55 LX..-FLR-X*/Y* See type code 1 Shorter lengths on request Complete type with relevant dimensions (e.g. LX..-FLR-X0.70/Y0.53)

- Page 60 Product selection 4.3 Selection tables Non-Siemens distribution board connection units, connection knee front System Length X Length Y Type LX.01 to LX.04 0.35 ...0.70 0.35 ...0.70 LX..-FLV-X*/Y* LX.05 to LX.07 0.50 ...0.85 0.50 ...0.85 LX.08 to LX.10 0.80 ...1.15 0.80 ...1.15...

-

Page 61: Tap-Off Units

250 A on request. Identifier for the overload release in the type of the tap-off unit can differ from the installed circuit breaker due to new MLFBs for designating the overload release SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 62 315 to 630 A with manual operating mechanism mechanism Note Degree of protection IP55 You must order additional IP55 seals to use tap-off units with IP55 requirements (see Additional equipment (Page 65)) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 63 (Page 125) Identifier for the overload release in the type of the tap-off unit can differ from the installed circuit breaker due to new MLFBs for designating the overload release SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 64 208 V to 277 V AC releases Note Degree of protection IP55 You must order additional IP55 seals to use tap-off units with IP55 requirements (see Additional equipment (Page 65)) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 65: Tap-Off Units With Fuse Switch Disconnector Up To 630 A

Please observe national regulations. Connection under load may not be permissible. Aluminium plate undrilled, cable glands provided by the customer, see Technical data (Page 125) For 125 A to 250 A on request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 66 250 A 315 to 630 A Note Degree of protection IP55 You must order additional IP55 seals to use tap-off units with IP55 requirements (see Additional equipment (Page 65)) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 67: Additional Equipment

For system Type LX..-KB See type code 2 End cap Length Type [mm] L = 140 LX..-EF x = 25 x = Centre of joint block See type code 2 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 68 See type code 2 Tap-off units (additional seals for tap-off unit cover) Up to 250 A LX-AK1-IP55 315 A to 630 A LX-AK2-IP55 800 A to 1250 A LX-AK3-IP55 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 69 LX-BHF Flat busbars Type code Design Type Flexible LX..-BF with fixed point LX..-BFF See type code above Fixing hook Design Type for flexible support LX-K for fixed-point support LX-KF SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 70 Vertical installation on ceilings/floors (only in combination with fixing bracket for vertical installation) Type +LX-BVD Fixing brackets with fixed point for vertical installation Can be used for Type LX.01 to LX.07 LX-BV1FP1 LX.08 to LX.10 LX-BV1FP2 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 71: Installation And Mounting

Tap-off unit at bottom (by rotating the trunking unit) ⑥ Tap-off unit ⑦ Minimum dimension dependent on the dimensions of the tap-off unit used. Figure 5-1 Installation of horizontal runs SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 72 This enables safe room for maneouver of the busbar run during operation. The fixing brackets can be attached to the customer's fixing material. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 73: Distances From Structures

● Ventilation of the system. The minimum distance for guaranteeing sufficient heat dissipation is 0.10 m. You can find recommendations for distance dimensions in the planning manual "Planning with SIVACON 8PS". Busbar trunking systems up to 6300 A (order number: A5E01541101) Note Shorter distance in special cases If a fire barrier or expansion compensation is used, the wall/ceiling distance is lower at this point since the system is overlapped by the fire barrier, for example. - Page 74 The fixing brackets can be secured directly on the wall if the wall is completely smooth and vertical. You can find recommendations for distance dimensions in the planning manual "Planning with SIVACON 8PS". Busbar trunking systems up to 6300 A (order number: A5E01541101) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 75: Fire Barrier

Case 2: Fire barrier finishes flush with the fire wall/fire ceiling ≤ 820 ≤ 820 Case 3: Fire barrier in front of the fire wall/fire ceiling ≤ 820 ≤ 820 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 76 Case 4: Fire barrier in the centre of the fire ceiling Case 5: Fire barrier in front of the fire ceiling Case 6: Not permissible! Fire barrier not fully in the fire wall/fire ceiling SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 77 The mortar or concrete must comply with the applicable regulations to maintain the fire resistance class of the wall or ceiling, e.g. DIN 1045 and DIN 1053 Part 1 and EN 206-1 and EN 998-2. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 78 Recommended dimensions of the ceiling or wall opening Position of the fire barrier In the wall (ceiling) In front of the wall (ceiling) LX.1 LX.2 LX.3 LX.4 LX.5 LX.6 LX.7 LX.8 LX.9 LX.10 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 79: Fixing A Horizontal Busbar Run

LX.05 to LX.10 Solution suggestions You can find practice-oriented solution suggestions for implementing fixed points with supplied accessories in the installation manual "Installation with LX System" (order number: A5E01120816). SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 80: Fixing A Vertical Busbar Run

Size Type LX.01 to LX.07 (single systems) LX-BV1FP1 LX.08 to LX.10 (double systems) LX-BV1FP2 Fixing brackets for vertical installation Fixing brackets with fixed point for vertical installation SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 81: Configuration

Indicate the open busbar end (without joint block) with a short line and position the busbar edgewise. The view is always of the end of the trunking unit without joint block. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 82 ● Position of the bold full line on the right ● Busbar runs away from viewer. Tap-off points at top Tap-off points at bottom ① Joint block ② Joint block can be modified SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 83 The usefulness of the tap-off point therefore depends on the position of the tap-off point and on the dimensions of the selected tap-off unit. All selectable dimensions specified in m. The changed position of the tap-off points must be noted when rotating. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 84: Junction Units

Intermediate limb (if available) Examples Single junction units In the case of single junction units, the direction of the Y dimension determines the type. Figure 6-1 Elbow right Offset junction units SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 85 ● The point of offset. Figure 6-2 Offset junction unit Z units In the case of Z units, the direction of the Z dimension determines the type. Figure 6-3 Z unit (front) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 86 6.1 Basic knowledge for configuring T units In the case of T units, the direction of the add-on unit (T tap-off unit) determines the type. Figure 6-4 T unit (add-on unit top) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 87: Feeder Units

● Define the phase sequence of the remaining busbar run layout, that is, position the PEN or N conductor on the right or left side depending on the conductor configuration (see bold marking). +LX-1. +LX-2. ① Direction of view SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 88 ● The PEN(N) phase is always on the outside Phase sequence +LX-.A PEN(N) +LX-.B PEN(N) +LX-.C PEN(N) +LX-.D PEN(N) Tag distance (in mm) Example for complete order type with tag distance 350 mm: LXA0541-AS1+LX-1C+LX-P350 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 89 +LX-.C PEN(N) +LX-.D PEN(N) Tag distance +LX-P*/N* ● For P* (external conductor - external conductor) 450 to 750 mm ● For N* (external conductor PEN(N)) 150 to 400 mm SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 90 Centre of 1st connection tag ② Centre of joint block The transformer connection tags and the LX connection units are linked using flexible bands. The bands must be provided by the customer. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 91: Universal Busbar Connection Units With T Tap-Off Unit

● In addition, the same assignments apply for phase sequence and tag distances as for the connection unit without T tap-off unit. +LX-1. +LX-2. ① Direction of view ② T tap-off plug ③ PEN(N) position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 92 The configuring dimensions a, b and c are decisive for configuring the remaining run. You can find type-related dimension specifications for a under Dimension drawings (Page 159) . ① Centre of joint block SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 93: Cable Feeder Units

● 3 system-independent enclosure sizes Enclosure size Type of cable connection Enclosure size 1 LX.01...-KE. to LX.02...-KE. Enclosure size 2 LX.03...-KE. to LX.05...-KE. Enclosure size 3 LX.06...-KE. to LX.07...-KE. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 94 Cable clamps for supporting the cable to be inserted by the customer. No standard types are available for the following systems: LX...30 LX...52 LX...53 LX...54 LX...61 LX...62 Please contact Product Support if required. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 95: Connection To Non-Siemens Distribution Boards

Connection to non-Siemens distribution boards Versions The connection units for non-Siemens distribution boards are available in aluminium or copper depending on the version. They are delivered without a joint block. For type selection: See selection and ordering data (Page 56). -

Page 96: Connection To Siemens Power Distribution Systems

When connecting from above, phase L1 is to the front (corresponding to the actuation side of the joint block). When connecting from below, phase L1 is at the rear. Exception: When connecting to SIVACON S4 from below, phase L1 is at the front. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 97 ① LX... ② LX...-KB ③ LX..-FA3(4)A (example) ④ Front view ① LX... (L1 position at rear when connecting S4/S8 from above) ② LX...-KB ③ LX..-FA3(4)A (example) ④ Front view SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 98 Connection systems for LX systems with conductor configurations with the key digits 30, 52, 53, 54, 61 and 62 are only available on request ② Dimensions of the connection systems are only available on request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 99 Connection systems for LX systems with conductor configurations with the key digits 30, 52, 53, 54, 61 and 62 are only available on request. ② Dimensions of the connection systems are only available on request. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 100: Tap-Off Units

● Freedom from load thanks to a mandatory sequence of operations when installing and uninstalling ● Cable insertion safety thanks to partitioning of the current tap-off space from the cable space. Please observe national regulations. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 101 200...400 3VL4740 300...630 3VL5763 400...800 3VL7710 1000 500...1250 3VL7712 1250 500...1250 3VL7712 Reduced current value specifications caused by built-in units and mounting position are described in the technical data. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 102 NH00 BS88 BS88 BS88 BS88 BS88 IEC International Electrotechnical Commission British Standard Reduced current value specifications caused by built-in units and mounting position are described in the technical data. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 103: Configuring The Busbar Run Layout

End of trunking unit with joint block ③ Tap-off point ④ Configuring dimension centre of tap-off point ⑤ Configuring dimension, length of the straight trunking unit Figure 6-8 Plan view SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 104 Dimension a is measured between the metal edges at the assembly site. The configuring dimension W of the trunking unit is calculated as follows: W [m] = a [m] – 0.23 [m] SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 105: Load Tap-Offs For Straight Trunking Units

Tap-off units of size 1 can be connected. Sizes 2 and 3 only on request. ④ Straight length with 3 tap-off points: LX..-3ADO-U+LX-A+LX-C+LX-E ⑤ Fixing side for joint block at front. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 106 Straight length without tap-off points Minimum length W = 2000 mm ③ Tap-off joint block is used instead of the joint block on the trunking unit. ④ Fixing for joint block at front. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 107: Configuring Tap-Off Units

The end of the trunking unit without mounted joint block is underneath. Cable entry is always from below or from the side. ① Cable entry on front ② Cable entry from the side SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 108: Fire Barrier

611370) must also be ordered and supplied along with the fire barrier. The fire barrier meets the requirements of IEC/EN 60439-2 and fire resistance class S120 in accordance with DIN 4102 Part 9, ISO 834. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 109 Fire barrier length on the trunking unit Ceiling fire barrier for the systems LXC08 and LXC09 on request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 110 Size of tap-off unit 3 and 4 Space requirements for 0.47 0.87 0.87 the tap-off unit Note The tap-off units cannot be mounted over the fire barrier and the connection flange. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 111: Planning Expansion Compensation And Fixed Point

Attachment of a fixed point is necessary on the following busbar components: ● Universal connection units (AS and AS-T) ● Cable feeder units (KE) ● Busbar connection units for non-Siemens distribution boards (FA). ● Straight busbar elements and junction units depending on the length and course of the busbar run. -

Page 112: Planning Horizontal Busbar Runs

L1 = max. 15 m L2 = max. 30 m L3 = max. 40 m Run length L Number of fixed points Number of expansion compensation units ≤ 40 ≤ 55 ≤ 85 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 113 Configuration between junction unit and universal busbar connection unit ① Junction unit ② Fixed point (here: LX-BHF) ③ Universal busbar connection unit (AS) ④ Last trunking unit before the universal busbar connection unit L ≤ 15 m SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 114 Configuration 6.2 Configuring the busbar run layout Feeder unit of non-Siemens distribution boards via non-Siemens distribution board connection units (FA) ① Junction unit ② Busbar connection units for non-Siemens distribution boards (FA) ③ Non-Siemens distribution boards ④ Last trunking unit before the non-Siemens distribution board connection unit ⑤...

- Page 115 Additional fixed points must be configured before or after changes in height and directly at T units. L ≤ 6 m ① Fixed point With a maximum height difference of 6 m, expansion compensation is not necessary. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 116: Planning In The Case Of Vertical Busbar Runs

● between two fixed points with expansion compensation ● between fixed point and end cap without expansion compensation. For sub-lengths between infeed and fixed point with expansion compensation, sub-length L1 is halved. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 117 Run length L Number of fixed points (FP) Number of expansion compensation units (D) ≤ 6 (≤ 6) ≤ 50 (≤ 60) ≤ 100 (≤ 120) ≤ 150 (≤ 180) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 118 Run length L Number of fixed points (FP) Number of expansion compensation units (D) ≤ 50 (≤ 60) ≤ 100 (≤ 120) ≤ 150 (≤ 180) ≤ 200 (≤ 240) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 119 Run length L Number of fixed points (FP) Number of expansion compensation units (D) ≤ 6 (≤ 6) ≤ 25 (≤ 30) ≤ 75 (≤ 90) ≤ 125 (≤ 150) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 120 Run length L Number of fixed points (FP) Number of expansion compensation units (D) ≤ 6 (≤ 6) ≤ 25 (≤ 30) ≤ 75 (≤ 90) ≤ 125 (≤ 150) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 121: Configuring Vertical Busbar Runs

The end of trunking unit without joint block always points downwards. Tightening of the joint block always on the side with phase L1. Depending on the conductor configuration, the PEN, L3, N or PE conductor is always on the right. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 122: Configuring Example

6.2 Configuring the busbar run layout 6.2.4 Configuring example This configuring example refers to the planning example from the SIVACON 8PS Planning Manual, Chap. 7. Please refer to this planning manual for details of the planning procedure. System selection The system size LXA0551 results from the planning example in the planning manual. - Page 123 Fire barrier (positioning see hotspot text; here: fire barrier in the centre of the fire ceiling) ⑤ Tap-off unit ⑥ End cap ⑦ Fixed point ⑧ 1. floor ⑨ 2. floor ⑩ 11. floor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 124 Vertical fixing bracket for power distribution LX-AK5/FSH250-IEC-3S Tap-off unit with fuse switch disconnector, IEC 3- pole See also Planning expansion compensation and fixed point (Page 109) Fire barrier (Page 106) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 125: Special Cases

6.2 Configuring the busbar run layout 6.2.5 Special cases 6.2.5.1 Functional endurance Please refer to the SIVACON 8PS Planning Manual for details of standards, application areas and planning. Overview of implementing the functional endurance channel and reduction factors System Functional... -

Page 126: Phase Change Units

Phase change units are used in the following cases: ● When the symmetric voltage drop during power transmission has to be kept low ● In the case of power transmission with high capacity over long distances. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 127: Technical Data

V AC for power distribution V AC Rated frequency Adaptation of the rated current depending on the ambient temperature Figure 7-1 Rated current and ambient temperature SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 128: Trunking Units Lxa

Conductor material Aluminium No. of busbars Conductor cross section L1, L2, L3 1192 Equivalent copper cross PE = enclosure 1018 1135 1348 section Weights kg/m 10.6 13.3 17.8 21.8 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 129 Reduction in rated current to 2400 A with horizontal flat mounting position Reduction in rated current to 3800 A with horizontal flat mounting position Reduction in rated current to 4300 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 130: Trunking Units Lxa

Conductor material Aluminium No. of busbars Conductor cross L1, L2, L3 1192 section Equivalent copper 1109 1161 1341 1657 2006 cross section Weights kg/m 10.6 12.0 15.2 20.8 25.6 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 131 Reduction in rated current to 2400 A with horizontal flat mounting position Reduction in rated current to 3800 A with horizontal flat mounting position Reduction in rated current to 4300 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 132: Trunking Units Lxa

Aluminium No. of busbars Conductor cross section L1, L2, L3 1192 1192 Equivalent copper cross PE = enclosure 1018 1135 1348 section Weights kg/m 10.6 12.0 15.2 20.8 25.6 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 133 Reduction in rated current to 2400 A with horizontal flat mounting position Reduction in rated current to 3800 A with horizontal flat mounting position Reduction in rated current to 4300 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 134: Trunking Units Lxa

No. of busbars Conductor cross section L1, L2, L3 1192 1172 1892 2384 Equivalent copper cross PE = enclosure 1018 1135 1348 section Weights kg/m 11.6 13.3 17.0 23.8 29.3 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 135 Reduction in rated current to 2400 A with horizontal flat mounting position Reduction in rated current to 3800 A with horizontal flat mounting position Reduction in rated current to 4300 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 136: Trunking Units Lxa

Conductor cross section L1, L2, L3, (PE) 1192 1192 Equivalent copper cross PE = enclosure 1018 1135 1348 section Weights kg/m 11.6 13.3 17.0 23.8 29.3 Insulated PE conductor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 137 Reduction in rated current to 2400 A with horizontal flat mounting position Reduction in rated current to 3800 A with horizontal flat mounting position Reduction in rated current to 4300 A with horizontal flat mounting position Insulated PE conductor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 138: Trunking Units Lxa

Conductor cross section L1, L2, L3, (PE) 1192 1172 1892 2384 Equivalent copper cross PE = enclosure 1018 1135 1348 section Weights kg/m 12.6 14.7 18.9 26.8 33.1 Insulated PE conductor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 139 Reduction in rated current to 2400 A with horizontal flat mounting position Reduction in rated current to 3800 A with horizontal flat mounting position Reduction in rated current to 4300 A with horizontal flat mounting position Insulated PE conductor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 140: Trunking Units Lxc

Conductor material Copper No. of busbars Conductor cross section L1, L2, L3 Equivalent copper cross PE = enclosure 1018 1018 1135 section Weights kg/m 17.8 19.9 24.2 28.6 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 141 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 142: Trunking Units Lxc

Conductor material Copper No. of busbars Conductor cross section L1, L2, L3 Equivalent copper cross 1240 1334 1460 1604 1847 section Weights kg/m 17.9 21.6 24.1 29.7 35.3 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 143 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 144: Trunking Units Lxc

Conductor material Copper No. of busbars Conductor cross section L1, L2, L3 Equivalent copper cross PE = enclosure 1018 1018 1135 section Weights kg/m 17.9 21.6 24.1 29.7 35.3 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 145 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 146: Trunking Units Lxc

Copper No. of busbars Conductor cross section L1, L2, L3 1172 1424 Equivalent copper cross PE = enclosure 1018 1018 1135 section Weights kg/m 20.7 25.3 28.2 35.2 41.9 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 147 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 148: Trunking Units Lxc

Copper No. of busbars Conductor cross section L1, L2, L3 Equivalent copper cross PE = enclosure 1018 1018 1135 section + busbar Weights kg/m 20.7 25.3 28.2 35.2 41.9 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 149 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 150: Trunking Units Lxc

No. of busbars Conductor cross section L1, L2, L3 1172 1424 Equivalent copper cross PE = enclosure 1018 1018 1135 section + busbar Weights kg/m 23.5 32.4 40.8 48.6 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 151 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 152: Trunking Units Lxc

Conductor material Copper No. of busbars Conductor cross section L1, L2, L3, (PE) Equivalent copper cross PE = enclosure 1018 1018 1135 section Weights kg/m 20.7 25.3 28.2 35.2 41.9 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 153 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position Insulated PE conductor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 154: Trunking Units Lxc

Copper No. of busbars Conductor cross section L1, L2, L3, (PE) 1172 1424 Equivalent copper cross PE = enclosure 1018 1018 1135 section Weights kg/m 23.5 32.4 40.8 48.6 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 155 Reduction in rated current to 1570 A with horizontal flat mounting position Reduction in rated current to 1900 A with horizontal flat mounting position Reduction in rated current to 3100 A with horizontal flat mounting position Insulated PE conductor SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 156: Fire Load For Trunking Units Without Tap-Off Points

For trunking units with tap-off points, regardless of system size, a fire load of 2.9 kWh must be taken into account for each tap-off point. Fire load values for LX...30, LX...52, LX...53, LX...54, LX...61, LX...62 are only available on request. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 157: Fixing Distances

160 x 10 120 x 10 LXA10.. Connection to LXA systems In accordance with DIN 43671, Table 1, the maximum continuous current for this copper cross section is 3980 A. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 158: Tap-Off Units

1 x 50...150 1 x 70...240 — 1 x 70...240 2 x 25...70 2 x 70...120 4 x 70...240 Bolted connection 315 A: M8 — 400 A: M10 630 A: M12 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 159 For "suspended, below" installation of the tap-off units, no reduction is necessary Values in brackets apply when using fuses in accordance with BS standard Cable glands with strain relief are required (not included in the scope of delivery). SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 160 Technical data 7.19 Tap-off units SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 161: Dimension Drawings

8.1.1 Straight trunking units with tap-off points Figure 8-1 LXA(C)01 to 07 Figure 8-2 LXA(C)08 to 10 System LXA(C)01, LXA(C)02 350...3000 LXC03, LXA(C)04 LXA(C)05 LXA(C)06, LXA(C)07 LXA(C)08 LXA(C)09, LXA10 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 162: Straight Trunking Units Without Tap-Off Points

8.1.2 Straight trunking units without tap-off points Figure 8-3 LXA(C)01 to 07 Figure 8-4 LXA(C)08 to 10 System LXA(C)01, LXA(C)02 350...3000 LXC03, LXA(C)04 LXA(C)05 LXA(C)06, LXA(C)07 LXA(C)08 LXA(C)09, LXA10 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 163: Straight Trunking Units With Expansion Compensation

Straight trunking units with expansion compensation LXA(C)01 to 07 Figure 8-6 Straight trunking units with expansion compensation LXA(C)08 to 10 System LXA(C)01, LXA(C)02 LXC03, LXA(C)04 LXA(C)05 LXA(C)06, LXA(C)07 LXA(C)08 LXA(C)09, LXA10 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 164: Junction Units

Junction units Elbow (here LX...-LR) Figure 8-7 LXA(C)01 to 07 Figure 8-8 LXA(C)08 to 10 System LXA(C)01, LXA(C)02 350...700 (1100) 350...700 (1100) LXC03, LXA(C)04 LXA(C)05 LXA(C)06, LXA(C)07 LXA(C)08 LXA(C)09, LXA10 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 165 LXA(C)01 to 07 Figure 8-10 LXA(C)08 to 10 System LXA(C)01, LXA(C)02 350...700 (1100) 350...700 (1100) LXC03, LXA(C)04 LXA(C)05 500...850 (1200) 500...850 (1200) LXA(C)06, LXA(C)07 LXA(C)08 800...1150 (1500) 800...1150 (1500) LXA(C)09, LXA10 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 166: Feeder Units

LX ..- AS1(+LX -.B)/(+LX-.D) System p min. p max. LXA(C)01 96.5 LXA(C)02 96.5 LXA(C)03 96.5 LXA(C)04 96.5 LXA(C)05 96.5 LXA(C)06 96.5 LXA(C)07 96.5 LXA(C)08 96.5 LXA(C)09 96.5 LXA(C)10 96.5 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 167: Universal Busbar Connection Unit As3

System p min. p max. n min. n max. LXA(C)01 96.5 LXA(C)02 96.5 LXA(C)03 96.5 LXA(C)04 96.5 LXA(C)05 96.5 LXA(C)06 96.5 LXA(C)07 96.5 LXA(C)08 96.5 LXA(C)09 96.5 LXA(C)10 96.5 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 168: Universal Busbar Connection Unit As2

System p min. p max. n min. n max. LXA(C)01 96.5 LXA(C)02 96.5 LXA(C)03 96.5 LXA(C)04 96.5 LXA(C)05 96.5 LXA(C)06 96.5 LXA(C)07 96.5 LXA(C)08 96.5 LXA(C)09 96.5 LXA(C)10 96.5 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 169: Universal Busbar Connection Unit As1 With T Tap-Off Unit

LX..-AS1-T(+LX-.B)/(+LX-.D) System p min. p max. LXA(C)01 1.5 x p 96.5 LXA(C)02 96.5 LXA(C)03 96.5 LXA(C)04 96.5 LXA(C)05 96.5 LXA(C)06 96.5 LXA(C)07 96.5 LXA(C)08 96.5 LXA(C)09 96.5 LXA(C)10 96.5 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 170: Universal Busbar Connection Unit As3 With T Tap-Off Unit

LXA(C)01 (2p + n)/2 96.5 LXA(C)02 96.5 LXA(C)03 96.5 LXA(C)04 96.5 LXA(C)05 96.5 LXA(C)06 96.5 LXA(C)07 96.5 LXA(C)08 96.5 LXA(C)09 96.5 LXA(C)10 96.5 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 171: Universal Busbar Connection Unit As2 With T Tap-Off Unit

= p max. b1 n min. n max. min. LXA(C)01 96.5 LXA(C)02 96.5 LXA(C)03 96.5 LXA(C)04 96.5 LXA(C)05 96.5 LXA(C)06 96.5 LXA(C)07 96.5 LXA(C)08 96.5 LXA(C)09 96.5 LXA(C)10 96.5 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 172: Connection Tags

Material thickness 15 mm Material thickness 15 mm LXA01.. LXC03.. LXC06.. LXC01.. LXC04.. LXA07.. LXA02.. LXA05.. LXC07.. LXC02.. LXC05.. LXA04.. LXA06.. Material thickness 15 mm LXA08.. LXC08.. LXA09.. LXC09.. LXA10.. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 173 8.3 Feeder units Connection tags PE LXA(C)01.. to 10, material thickness 15 mm Front view LX..-AS(-T) View from below LX..-AS(-T)+LX-1(2)A(B) Graphical representation is not to scale. PE connection see page … SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 174 Dimensioning between front edge of connection tag and outer edge of enclosure on the L1 side (L1=phase L1). The dimensions apply for all phase sequences, that is, also for the types +LX-.D, +LX-.E, LX-.F, +LX-.G and LX-.H SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 175: Incoming Cable Connection Units

Dimension drawings 8.3 Feeder units 8.3.2 Incoming cable connection units Incoming cable connection units KE1(2) Front view Side view View Z Cable entry plate BPAL for single-core cable (+LX) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 176 LXA(C)04.. - KE. 5 x 90 LXA05.. - KE. 5 x 90 LXC05.. - KE. 5 x 90 LXA(C)06.. - KE. 7 x 90 LXA(C)07.. - KE. 7 x 90 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 177: Non-Siemens Distribution Board Connection Units

Dimensioning of the connections for copper-plating see Distribution board connection units (Page 182) The PE connection (broken line in the figure) has a thickness of 6 mm Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 178 Dimensioning of the connections for copper-plating see Distribution board connection units (Page 182) The PE connection (broken line in the figure) has a thickness of 6 mm Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 179 Dimensioning of the connections for copper-plating see Distribution board connection units (Page 182) The PE connection (broken line in the figure) has a cross-section of 6 mm Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 180 LXC0153-FA(FL.) LXC0253-FA(FL.) LXC0353-FA(FL.) LXC0453-FA(FL.) LXC0553-FA(FL.) LXC0653-FA(FL.) LXC0753-FA(FL.) LXC0853-FA(FL.) LXC0953-FA(FL.) LXC1053-FA(FL.) Dimensioning of the connections for copper-plating see Distribution board connection units (Page 182) Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 181 LXC0754-FA(FL.) 124.5 95.5 LXC0854-FA(FL.) 124.5 95.5 LXC0954-FA(FL.) 123.5 96.5 LXC1054-FA(FL.) Dimensioning of the connections for copper-plating see Distribution board connection units (Page 182) Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 182 The PE connection for the enclosure (broken line in the figure) has a cross-section of 6 mm PE connection for the PE busbar isolated from the enclosure (clean earth; (PE)) Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 183 The PE connection for the enclosure (broken line in the figure) has a cross-section of 6 mm PE connection for the PE busbar isolated from the enclosure (clean earth; (PE)) Termination surface, not isolated On request SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 184: Distribution Board Connection Units

Dimension drawings 8.3 Feeder units 8.3.4 Distribution board connection units Preparing the device for making the cutout for LX…30, LX…41, LX…51, LX…52 LX.01 to 07..-FA LX.08..-FA SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 185 LXC08..-FA LXC09..-FA LXA10..-FA Cutout in the ceiling/floor plate of the distribution board = a x 330 Dimension d on the side without PE tag, dimension e with PE tag SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 186 Dimension drawings 8.3 Feeder units Preparing the device for making the cutout for LX…53, LX…54, LX…61, LX…62 LX.01..-FA to LX.07..-FA LX.08..-FA SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 187 LXC08..-FA LXC09..-FA LXA10..-FA Cutout in the ceiling/floor plate of the distribution board = a x 460 Dimension d on the side without PE tag, dimension e with PE tag SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 188 Dimension drawings 8.3 Feeder units Connections for copper-plating Side view LXC01..-FA LXC03..-FA LXA05..-FA LXC02..-FA LXC04..-FA LXC05..-FA LXC06..-FA LXC08..-FA LXC07..-FA ① Terminal plate on the customer side SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 189 Terminal plate on the customer side PE connection for LX..30 (51, 52, 53, 54, 61, 62) Drill holes of the PE tag for 5- LX.01 to LX.07 LX.08 to LX.10 conductor version SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 190: Tap-Off Units

Tap-off units with circuit breaker 3VL 8.4.1.1 Size 1 (50 A to 250 A) With circuit breaker 3VL 8.4.1.2 Size 2 (315 A to 630 A) With circuit breaker 3VL SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 191: Size 4 (800 A To 1250 A)

Dimension drawings 8.4 Tap-off units 8.4.1.3 Size 4 (800 A to 1250 A) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 192: Tap-Off Units With Fuse Switch Disconnector

8.4 Tap-off units 8.4.2 Tap-off units with fuse switch disconnector 8.4.2.1 Size 1 (125 A and 250 A) 8.4.2.2 Size 2 or 3 (400 A and 630 A) Type LX-AK5(6)/FSH-400IEC(BS)-3(4)S LX-AK5(6)FSH-630IEC(BS)-3(4)S SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 193: Additional Equipment

Dimension drawings 8.5 Additional equipment Additional equipment Joint block Figure 8-23 LX.01 to LX.05 Figure 8-24 LX.06 to LX.07 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 194 LX.01..-KB LX.02..-KB LX.03..-KB LX.04..-KB LX.05..-KB LX.06..-KB LX.07..-KB LX.08..-KB LX.09..-KB LX.10..-KB Note You can obtain the dimensions of the joint blocks for tap-off units (800 to 1250 A) on request. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 195 The LX-K fixing hooks are included in the scope of supply of the fixing brackets. LX-BH(F) LX..-BF(F) Type LX-BH(F) LX01..-BH(F) LX02..-BH(F) LX03..-BH(F) LX04..-BH(F) LX05..-BH(F) LX06..-BH(F) LX07..-BH(F) LX08..-BH(F) LX09..-BH(F) LX10..-BH(F) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 196 Dimension drawings 8.5 Additional equipment Fixing hook LX-K LX-KF Fixed point for vertical installation LX-BV1FP1(2) SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 197 Dimension drawings 8.5 Additional equipment Fixing bracket Figure 8-26 LX...-BV1(AK)/+LX-BVD End cap Figure 8-27 LX..-EF SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 198 Dimension drawings 8.5 Additional equipment SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 199: Circuit Diagrams

Circuit diagrams Tap-off unit with circuit breaker, 3-pole Figure 9-1 LX...30 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 200 Circuit diagrams 9.1 Tap-off unit with circuit breaker, 3-pole Figure 9-2 LX..41 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 201 Circuit diagrams 9.1 Tap-off unit with circuit breaker, 3-pole Figure 9-3 LX...5. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 202: Tap-Off Unit With Circuit Breaker, 4-Pole

Circuit diagrams 9.2 Tap-off unit with circuit breaker, 4-pole Tap-off unit with circuit breaker, 4-pole Figure 9-4 LX...5. SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... -

Page 203: Glossary

) (of a circuit-breaker) DIN EN 60947-2; 4.3.2.3 The current that is identical, for the circuit-breaker, to the rated continuous current and the conventional thermal current. ➜ Rated uninterrupted current SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 204 ➜ Rated operating voltage Rated uninterrupted current (I ) DIN EN 60947-1; 4.3.2.4 The current that a switching device can carry during continuous operation (for weeks, months or years). SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 205 Contrary to the other characteristic data, it is specified as a peak value. ➜ Rated operating voltage Conditional short-circuit current, rated DIN EN 60947-1; 2.5.29 ➜ Rated conditional short-circuit current (I SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 206 Glossary SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

-

Page 207: Index

Supplementary information material, 9 SIVACON 8PS Application areas, 19 Sizes, 21 Space requirements, 108 Expansion compensation, 109 Standards Busbar trunking systems, 11 Fire load, 154 Fixed point, 109 Fixing distances, max., 155 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02... - Page 208 Index Tap-off points for loads up to 1250 A, 16 Type code, 28 Type-tested connection to distribution boards and transformers, 16 SIVACON 8PS - Configuring with LX system Configuration Manual, 10/2011, A5E02194899-02...

- Page 210 Contact for all technical information: Technical Support www.siemens.com/lowvoltage/technical-support Siemens AG Subject to change without prior notice Infrastructure & Cities Sector Order No.: A5E02194899-02 Low and Medium Voltage Division © Siemens AG 2011 Low Voltage Distribution Postfach 10 09 53 93009 Regensburg GERMANY www.siemens.com/lowvoltage...

Need help?

Do you have a question about the SIVACON 8PS and is the answer not in the manual?

Questions and answers